Abstract

Agriculture intensification for production of more food to feed an increasing global population, as a consequence, generates a large volume of agricultural waste. The agro-waste, which is biochemically composed of cellulose, lignin, and hemicellulose, is frequently burned or buried in the soil. These disposal methods result in the release of noxious compounds into the environment that agitates the problem of pollution, human health issues, and global warming. To overcome such drawbacks, some agro-wastes are utilized for roof thatching, soil mulching, and making products like papers, matchsticks, and others. Nevertheless, these approaches cannot entirely solve the problem of agricultural residue generation. However, the conversion of plant biomass into biofuel could facilitate the reduction of residue comprehensively along with the generation of value-added products. The production of biofuel can be mediated by the action of certain microorganisms and enzymes. The efficient utilization of such microbes and/or enzymes could facilitate sustainable management of agro-waste with the generation of renewable bioenergy and economic benefits.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

8.1 Introduction

The continuously growing human population and escalating industrial development have increased the demand for food and energy. In the past 100 years, the global population has increased fourfold and the annual energy generation by 21 times (Pryshliak and Tokarchuk 2020). Thus, to ensure food and energy security, the burden on agricultural lands and fossil fuel has been intensified. As a consequence, it has led to the generation of tons of agro-waste and the depletion of reserves of traditional energy resources. The agro-waste produced is often disposed of unsustainably in landfills or by burning, which generates harmful gases, eventually causing air pollution (Yevich and Logan 2003; Afolalu et al. 2021). In India, in 2017, wheat residue alone accounted for 29% of the total crop residue generated and 26% of the total crop residue burned. A similar trend, if continued, the crop residue emission will increase by 45% by the year 2050 (Tiwari et al. 2021). Moreover, the excessive use of fossil fuel as a primary energy source to fulfill the global energy demand has diminished the fuel reserve size and increased greenhouse gas (GHGs) concentration in the atmosphere (Panpatte and Jhala 2019). Increased levels of GHGs have aggravated the issue of global warming and climate change (Chandra et al. 2012; Panpatte and Jhala 2019). To overcome the problem of agro-waste disposal, resolve the issue of energy crisis, and mitigate climate change in a sustainable manner, utilization of agricultural waste for biofuel generation is an effective and eco-friendly alternative (Milano et al. 2022).

Biofuels are fuels that are derived directly or indirectly from biomass. Biomass is a renewable resource that traps solar energy through photosynthesis and converts it into chemical energy. Thus, biomass shows extensive potential to generate biofuels. There are four generations of biofuel production depending upon the feedstock used for their production. The first generation of biofuel production is based on food crops and utilizes sugars, starch, and vegetable oils. However, the use of food crops for biofuel generation increases pressure on land as well as on water resources for the production of more edible crops, resulting in food shortage, monoculture cropping, and noneconomical production (Panpatte and Jhala 2019; Mehmood et al. 2021). The second generation of biofuel production depends upon the utilization of agro-based biomass, like nonedible crops, forest biomass, and grasses, and agro-waste, including plant residues, agro-industry waste, and wood chips, which are mainly composed of lignocellulosic (lignin (7–25% of dry matter), cellulose (30–60% of dry matter), and hemicellulose (14–40% of dry matter)) materials (Robak and Balcerek 2018; Tiwari et al. 2021). This method facilitates the utilization of huge amounts of agricultural waste sustainably, improves economic development, and does not induce pressure on agricultural lands. Third-generation biofuel is obtained from algae having more than 50% of oil content, whereas fourth-generation biofuel involves the use of genetically modified algae (Panpatte and Jhala 2019; Mehmood et al. 2021). The major limitation linked with algal-based third- and fourth-generation biofuel production is a high economic investment and environmental as well as a health risk, respectively (Panpatte and Jhala 2019; Abdullah et al. 2019).

The production of a second-generation biofuel is an effective approach for producing biofuel and utilizes locally available agro-waste. The agro-waste generated by a nation can be employed to derive biofuels such as biogas, bioethanol, and biodiesel (Sarangi and Nayak 2021), which not only reduces the volume of the agricultural solid waste but also alleviates environmental pollution, generates cheap and renewable energy, and facilitates economy development in rural areas (Anwar et al. 2018; Boro et al. 2022; Hoang et al. 2023). As per the estimate of the International Energy Agency and World Bioenergy Association, biomass-based energy accounted for 72.3% share of the total renewable energy utilized all over the world in 2016. Moreover, the generation of energy from biomass has been recorded to be elevated from 42.8 EJ in 2000 to 56.5 EJ in 2016 (Uthandi et al. 2022). Thus, the recent chapter aims to focus on the production of various biofuels from agricultural waste and provide information regarding benefits and new advances achieved in the field of biofuel production and application.

8.2 Agro-waste for Biofuel Production

Agricultural waste and agro-based industry by-products are low-cost feedstock commonly utilized for the production of biofuels (Fig. 8.1). It has been anticipated that nearly 4 billion tons of agro-residue is generated annually and 75% of which is contributed by cereal crops (Sarangi and Nayak 2021). Agro-waste includes the waste generated as a result of farming activities that include crop cultivation, horticulture, dairy farming, animal husbandry, market gardens, and forestry (El-Ramady et al. 2022). It has been estimated that globally nearly 30% of the agricultural material produced end up as waste (El-Ramady et al. 2022). Crop straw, stover and husk, seed hulls, shells, sawdust, bagasse, meat, dairy waste products, and wood chips are major agro-wastes that are generated in huge quantities and could be used to produce value-added products including biofuels, agro-composites, nanocellulose, compost, biochar, and others (Afolalu et al. 2021; El-Ramady et al. 2022). Generally, agricultural waste has been categorized into four categories, i.e., crop residue, agro-industrial waste, livestock waste, and fruit and vegetable wastes based on their production technologies (Demirbas et al. 2011; Pattanaik et al. 2019). Crop residues include the waste generated directly from crop cultivation such as wheat, corn, and rice straw (Afolalu et al. 2021). These are the cheapest and abundantly available forms of agro-waste that can be easily converted into biofuel. Agro-industrial waste includes by-products and/or waste generated from food processing industries such as poultry waste, bagasse, molasses, fruit and vegetable peel, meat, animal fat, de-oiled seed cakes, and starch residue (Afolalu et al. 2021). This type of waste is also utilized for biofuel generation. For instance, bagasse which is obtained in huge quantities from the sugar industries is used to produce bioethanol. The waste generated from livestock manure is utilized as a suitable substrate for biofuel production, particularly biogas (Seglah et al. 2022). Unprocessed waste of fruits and vegetables is also an agro-waste that could be used for biofuel generation. Like other agro-wastes, a huge quantity of fruit and vegetable waste is generated annually. In India, it has been reported that nearly 5.6 million tons of fruit and vegetable wastes is produced every year (Afolalu et al. 2021).

8.3 Types of Biofuels

The fuels which are derived from biomass such as plants, algae, and waste generated from agriculture, industrial, domestic, and commercial sectors are called biofuels (Panpatte and Jhala 2019). Biofuels can be in the form of solids, liquids, and gas. They have the potential to replace conventional fuel sources due to their renewable nature (Basumatary et al. 2018; Afolalu et al. 2021). Biofuels are synthesized from agro-waste by using approaches like fermentation, anaerobic digestion, pyrolysis, combustion, and gasification (Koupaie et al. 2019). Various types of biofuels can be produced using biomass, in particular biogas, biomethanol, bioethanol, and biodiesel.

8.3.1 Biodiesel

It is one of the most important biofuels. Biodiesel has gained attention all around the world owing to its characteristics of biodegradability, nontoxicity, carbon neutrality, and renewable nature (Basumatary et al. 2018; Milano et al. 2022). Production of biodiesel was initiated in the early 1990s, and since then, it is increasing steadily (Balat and Balat 2009). Biodiesel is an alternative solution to petroleum diesel, which is produced via the transesterification of oils and/or fats (Demirbas 2002, 2009a). Transesterification of agro-waste includes the conversion of branched triglycerides into simpler and smaller straight chain esters (Narnoliya et al. 2018). In the process of transesterification, methanol is used as a solvent to abridge the saponification reaction (Rajendran et al. 2022). Biodiesel has slightly low power and torque and higher fuel consumption than diesel #2 (Demirbas 2009a). However, biodiesel has better aromatic content, lubricity, flash point, and biodegradability than conventional diesel fuel (Demirbas 2009b). Biodiesel shows an improved combustion capacity due to the presence of oxygen (10–11%), which results in low emission of particulate matter, oxides of sulfur, carbon monoxides, and hydrocarbon but high emission of nitrogen oxide (Demirbas 2005, 2009a; Demirbas et al. 2011; Mehmood et al. 2018; Raman et al. 2019; Kanakdande and Khobragade 2020; Milano et al. 2022). Thus, biodiesel is blended with conventional diesel to reduce notorious emissions. The reduction in emissions increases with an increase in the amount of biodiesel in the blend (Demirbas et al. 2011). Moreover, the biodiesel-diesel fuel blend improves engine torque, brake power, thermal brake efficiency, and fuel efficiency (Dharma et al. 2017; Milano et al. 2022). Direct use of biodiesel in conventional diesel engines is avoided due to its high viscosity and low oxidative stability, which results in the corrosion of fuel tanks, pipes, and injectors, that is why it is blended with diesel (Mehmood et al. 2018; Milano et al. 2022). Biodiesel can be blended with fossil-based diesel in any amount and used in diesel engines without any modification (Demirbas et al. 2011; Kanakdande and Khobragade 2020). Biodiesel can be used as an additive in small amounts in low-sulfur-containing diesel, which improves its lost lubricity due to the elimination of sulfur content (Dorado et al. 2003; Demirbas 2009a). Production of biodiesel from nonedible oilseed crops and waste cooking oil has gained momentum in recent years to reduce dependency on oil-rich edible crops, land use for oil crop cultivation, and water used for irrigation, which otherwise incur environmental as well as economic burden and abridge availability of food grade materials (Kanakdande and Khobragade 2020; Azadbakht et al. 2021; Rajendran et al. 2022). The waste oil generated from post-processing industries and fast food restaurants could be utilized for manufacturing biodiesel (Milano et al. 2022). Biodiesel can also be synthesized by using microorganisms that have high lipid content, and for the growth of such microbes, agro-waste is used as a substrate and source of nutrition (Narnoliya et al. 2018).

8.3.2 Bioethanol

Bioethanol or ethyl alcohol (C2H5OH) is an excellent renewable liquid biofuel, which shows compatibility with modern internal combustion engines due to the high octane number. Bioethanol has an octane number of 108 that prevents engine knocking and early ignition and therefore has a high antiknock value (Aditiya et al. 2016). Bioethanol has 68% less energy content than petrol but high oxygen content that generates less toxic emissions (Aditiya et al. 2016). It alleviates carbon dioxide emission by 80% compared to petrol; thus, it is considered an eco-friendly fuel (Aditiya et al. 2016). Bioethanol used in vehicles to run engines is often blended with petrol as per the standard (Aditiya et al. 2016; Bušić et al. 2018). As per European Union (EU) quality standard EN 228, 5% bioethanol is blended with petrol and used in existing engines without any modification. However, modification in engines can allow the use of 85% of bioethanol (E85) (Demirbas 2009a).

Bioethanol is produced via fermentation of simple sugars, which is mediated by enzymatic digestion. Microorganisms are used in the process of bioethanol production, which facilitates digestion or fermentation (Kour et al. 2019). Plant residues, particularly rice, wheat, and corn straw, are suitable substrates for the production of bioethanol due to lignocellulosic content (Swain et al. 2019). The cellulose and hemicellulose portion of lignocellulose can easily be hydrolyzed into soluble sugars which can be fermented to produce bioethanol (Binod et al. 2010). The process of bioethanol production is affected by several factors such as high lignin content, degree of polymerization, crystalline structure of cellulose, moisture content, and available surface area (Swain et al. 2019). Therefore, before hydrolysis and fermentation, pre-treatment of agro-waste is performed (Swain et al. 2019).

The process of bioethanol production includes multiple steps (Fig. 8.2). Initially, agro-waste used as feedstock is pre-treated and then undergoes hydrolysis in the presence of microbial enzymes. The pre-treatment process involves various methods that are classified as physical (milling, grinding, irradiation), physicochemical (steam explosion, supercritical fluid pre-treatment), chemical (treatment with dilute acid or alkali), biological (microbial, enzymatic), and green solvent-based processes (Brodeur et al. 2011; Swain et al. 2019; Awogbemi and Von Kallon 2022). The second step of hydrolysis facilitates the conversion of complex carbohydrates into simpler forms such as glucose and pentose, using cellulolytic enzymes, which cleave polymers of cellulose and hemicellulose (Zhang and Lynd 2004; Swain et al. 2019). Further, the feedstock material is fermented in the presence of microorganisms, particularly yeast, which is subsequently followed by distillation and dehydration (Demirbas 2009a, 2009b; Kour et al. 2019). The method selected for the pre-treatment of raw material is crucial as it facilitates an increase in bioethanol production (Kour et al. 2019). For instance, rice straw pre-treated with different concentrations of NaOH (0.5%, 1.0%, 1.5%, and 2.0%) was reported to generate better sugar yield on treatment with 1.5% NaOH than other concentrations (Ashoor and Sukumaran 2020). Similarly, pre-treatment of rice straw with dilute sulfuric acid yielded 0.72 g/g of sugar during enzymatic hydrolysis, whereas steam-pre-treated and steam-nontreated straw resulted in 0.60 g/g and 0.46 g/g of sugar yield, respectively (Abedinifar et al. 2009).

8.3.3 Biomethanol

Biomethanol is a potential renewable biofuel, which can be generated from agro-waste. Biomethanol is considered superior to bioethanol because of the higher specific energy yield (Demirbas 2008). Liquid biomethanol exhibits several benefits over other fuels. It is easy to store and can easily be transported at room temperature (Gautam et al. 2020). Moreover, it has high a volumetric energy density and high octane number as compared to gasoline (Kumabe et al. 2008; Gautam et al. 2020). Biomethanol from biomass can be produced via two approaches: thermochemical conversion and biochemical method (Gautam et al. 2020). The thermochemical method operates in two steps. The first step involves the conversion of biomass into syngas (a mixture of hydrogen and carbon monoxide) on thermal decomposition (high temperature and pressure) under oxygen-deficient conditions (gasification) (Sarangi et al. 2020). The syngas in the next step is catalytically processed to generate biomethanol (Gautam et al. 2020). The biochemical process of methanol synthesis involves the production of biogas (methane) from biomass through anaerobic digestion. The methane is then converted into methanol by methanotrophs. These microorganisms perform the conversion of methane into methanol under ambient temperature and pressure conditions in the rate-limiting step of methane oxidation in the presence of an enzymatic catalyst, methane monooxygenase (MMO) (Gautam et al. 2020). In the biochemical process of methanol production, the enzyme methanol dehydrogenase (MDH), an inhibitor of MMO, is also used to prevent further oxidation (Gautam et al. 2020). The commercial bioconversion of agro-waste into biomethanol involves four steps, viz., pre-treatment, biogas production via anaerobic digestion, biogas purification, and methanol production. Pre-treatment is performed to break down the recalcitrant lignin and make it susceptible to biodegradation. Pre-treatment is followed by anaerobic digestion which takes place in a two-stage anaerobic digester to stabilize the process and increase biogas production. The biogas obtained is treated to remove gases like hydrogen sulfide generated as a side product, to eliminate their inhibitory, poisonous, and corrosive effect. The hydrogen sulfide is converted into elemental sulfur or sulfate by biological oxidation using biofilters containing bacteria like Thiobacillus and Sulfurimonas. Finally, the clean biogas is added to a bioreactor (trickle filter or fluidized bioreactor) as a substrate for methanotrophs to produce methanol (Gautam et al. 2020).

8.3.4 Biogas

Biogas is an attractive alternative biofuel that is generated from waste organic materials. It contains 65–70% of methane gas and 30–45% carbon dioxide along with traces of other gases like hydrogen, nitrogen, and hydrogen sulfide (Azadbakht et al. 2021). The composition of the gas depends on the substrate used as feedstock and the conditions of anaerobic digestion (Neshat et al. 2017). The calorific value of biogas is 21–24 MJ/m3 (Azadbakht et al. 2021). Biogas can be produced from biomass through anaerobic fermentation/digestion, also known as bio-methanation (Azadbakht et al. 2021; Tiwari et al. 2021; Devi et al. 2022). Anaerobic fermentation is a complex process, which involves the action of facultative and anaerobic microorganisms such as acidogens, methanogens, and hydrolytic organisms in the absence of oxygen (Neshat et al. 2017). Anaerobic fermentation facilitates the conversion of complex organic material into a simpler form by recruiting various stages, i.e., hydrolysis, acidogenesis (also known as fermentation), and methanogenesis (Hagos et al. 2017; Neshat et al. 2017) (Fig. 8.3). The first step of anaerobic fermentation, i.e., hydrolysis, involves the conversion of complex substances like protein, nucleic acids, polysaccharides, and fats into amino acids, purines, pyrimidines, fatty acid, and monosaccharides. Acidogenesis or fermentation stage is subsequently followed, resulting in the production of carbon dioxide, hydrogen, acetate, methanol, and others, eventually leading to the final stage of methane gas production (methanogenesis), catalyzed by the action of methanogens (Neshat et al. 2017).

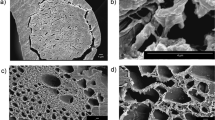

Biogas production through agro-waste has several ecological benefits (Neshat et al. 2017). Biogas is used for electricity and heat cogeneration, and the digestate produced is applied as a fertilizer (Bolzonella et al. 2020). Moreover, anaerobic digestion facilitates the reduction of volume, odor, and putrescible organic matter of waste that otherwise contributes to GHG levels in the atmosphere (Bolzonella et al. 2020). The production of biogas from agro-waste has one major drawback. Agro-wastes such as corn stover, straw, and others are comprised of lignocellulosic material, which biodegrades very slowly and thus reduces the biogas production capacity (Bolzonella et al. 2020; Azadbakht et al. 2021; Tamang et al. 2023). Only 40–50% of the substrate is utilized for biogas production; the rest remains in the digester in unused form and affects the efficiency of the process (Bolzonella et al. 2020). Besides, the digestate produced as an end product is stabilized partially which could result in odor and leakage on field application (Bolzonella et al. 2020). The challenge posed by the low biodegradability of feedstock is resolved through pre-treatment of the agro-waste. The pre-treatment improves the biodegradability of biorecalcitrant lignocellulosic waste by increasing its porosity and specific surface for microbes performing anaerobic digestion (Bolzonella et al. 2020). Moreover, pre-treatment of agro-waste optimizes biogas production and enhances the stabilization of organic substrate generated at the end of the digestion (Bolzonella et al. 2020). Biogas production from agro-waste such as lignocellulose co-digested with other biodegradable materials (livestock manure, sewage sludge) could enhance the capacity of the anaerobic digestion process (Hagos et al. 2017; Tiwari et al. 2021). Lignocellulosic waste has high carbon content but low nitrogen content, resulting in high C/N ratio i.e., it has >50 C/N ratio, which eventually slower down the biodegradation (Tiwari et al. 2021). This reduces the efficiency of the digester to generate methane/biogas. The addition of another organic substrate that is rich in nitrogen such as livestock manure to the lignocellulosic feedstock could maintain the optimum C/N ratio, thereby improving the anaerobic digestion process and increasing biogas yield (Tyagi et al. 2018; Tiwari et al. 2021). The anaerobic co-digestion method also reduces the cost of biogas production from agro-waste, which generally remains high when lignocellulosic waste is pre-treated to enhance biodegradation (Neshat et al. 2017).

8.4 Technological Advancement to Improve Biofuel Production

8.4.1 Direct Interspecies Electron Transfer (DIET)

This method has emerged as a solution for the challenges posed by the conventional anaerobic digestion process of biogas production (Gahlot et al. 2020; Tiwari et al. 2021). The application of DIET increases biogas production compared to microbe-amended anaerobic digestion and non-amended anaerobic digestion method (Zhang et al. 2020). DIET process includes the transfer of a free electron between syntrophic microbes (necessary to overcome the energy barrier and facilitate catabolism of complex organic materials), without requiring an electron carrier or redox mediator, i.e., indirect interspecies electron transfer (IIET), which are involved in conventional anaerobic digestion process (Gahlot et al. 2020; Tiwari et al. 2021). Thus, the application of the DIET technique in the anaerobic digestion process is an alternative to IIET (Baek et al. 2018). The process of DIET takes place via three basic mechanisms, i.e., abiotic conductive materials like carbon-based materials, conductive pili, and membrane-bound electron transport proteins (Baek et al. 2018; Gahlot et al. 2020). The process of DIET mediated by iron oxide minerals as conductive material for cell-to-cell electron transfer was demonstrated by Kato et al. (2012). Analogously, the amendment of granular activated carbon and granular biochar to the anaerobic fermentation process involving the digestion of lignocellulosic waste with sewage sludge under thermophilic conditions increased biogas production efficiency and process stability (Tiwari et al. 2021).

8.4.2 Synthetic Biology Aided Production of Biofuel from Agro-waste

To enhance the production of biofuel, there is a need to develop technology that improves the efficiency of the processes. For instance, the production of bio-ethanol through fermentation, where complex sugars are catabolized to simple sugars, could be increased by using genetically engineered microorganisms having better catabolic activity (Narnoliya et al. 2018). This can be achieved through the application of systemic biology. Systemic biology includes engineering and biology in a single stream. Systemic biology deals with the study of omics, i.e., genomic, proteomic, transcriptomic, and metabolomics, which facilitate to derive the valuable information on genes and enzymes that could be manipulated to engineer organisms or enzymes with desired characteristics (Narnoliya et al. 2018). In particular, for the production of biodiesel from yeast, recruitment of system biology can aid in identifying the pathways and enzymes that could enhance the oil content, and via the aid of genetic engineering, such pathways and enzymes could be altered (Narnoliya et al. 2018). The yeast Saccharomyces cerevisiae is well-known to mediate the production process of bioethanol from agro-waste. However, the efficiency of the yeast reduces with the production of compounds and altered conditions that could hamper their growth. However, these issues can be overcome by using systemic biology approaches (Madhavan et al. 2019).

8.5 Conclusion and Future Prospects

Agro-waste generation and its disposal are great challenges worldwide. Burning of crop residues to dispose of waste is unsustainable and causes environmental pollution. Conversion of agro-waste into biofuel serves multiple benefits along with the sustainable management of waste. Biomass can be converted into liquids, solids, as well as gaseous biofuels by using approaches like fermentation, anaerobic digestion, gasification, pyrolysis, and combustion. The biofuels such as biogas, bioethanol, and others synthesized from agro-waste have enormous potential to be used as an alternative fuel. However, the conversion of lignocellulosic wastes into biofuels presents challenges due to their recalcitrant nature. To overcome such problems, waste is pre-treated before biofuel production, which incurs high-cost inputs. Many technological advancements have been attained to improve the efficiency of process generating biofuels, but, still, more research is needed to reduce the cost and increase the rate of biofuel production. This achievement would facilitate the substitution of conventional fossil fuels with renewable and less polluting biofuels.

References

Abdullah B, Muhammad SAFAS, Shokravi Z, Ismail S, Kassim KA, Mahmood AN, Aziz MMA (2019) Fourth generation biofuel: a review on risks and mitigation strategies. Renew Sust Energ Rev 107:37–50

Abedinifar S, Karimi K, Khanahmadi M, Taherzadeh MJ (2009) Ethanol production by Mucor indicus and Rhizopus oryzae from rice straw by separate hydrolysis and fermentation. Biomass Bioenergy 33(5):828–833

Aditiya HB, Mahlia TMI, Chong WT, Nur H, Sebayang AH (2016) Second generation bioethanol production: a critical review. Renew Sust Energ Rev 66:631–653

Afolalu SA, Salawu EY, Ogedengbe TS, Joseph OO, Okwilagwe O, Emetere ME, Yusuf OO, Noiki AA, Akinlabi SA (2021) Bio-agro waste valorization and its sustainability in the industry: a review. IOP Conf Ser Mater Sci Eng 1107:012140

Anwar M, Rasul MG, Ashwath N, Rahman MM (2018) Optimisation of second-generation biodiesel production from Australian native stone fruit oil using response surface method. Energies 11(10):2566

Ashoor S, Sukumaran RK (2020) Mild alkaline pretreatment can achieve high hydrolytic and fermentation efficiencies for rice straw conversion to bioethanol. Prep Biochem Biotechnol 50(8):814–819

Awogbemi O, Von Kallon DV (2022) Pretreatment techniques for agricultural waste. Case Stud Chem Environ Eng 6:100229

Azadbakht M, Safieddin Ardebili SM, Rahmani M (2021) Potential for the production of biofuels from agricultural waste, livestock, and slaughterhouse waste in Golestan Province, Iran. Biomass Convers Bioref 1:11

Baek G, Kim J, Kim J, Lee C (2018) Role and potential of direct interspecies electron transfer in anaerobic digestion. Energies 11(1):107

Balat M, Balat H (2009) Recent trends in global production and utilization of bio-ethanol fuel. Appl Energy 86(11):2273–2282

Basumatary S, Nath B, Kalita P (2018) Application of agro-waste derived materials as heterogeneous base catalysts for biodiesel synthesis. J Renew Sustain Energy 10(4):043105

Binod P, Sindhu R, Singhania RR, Vikram S, Devi L, Nagalakshmi S, Kurien N, Sukumaran RK, Pandey A (2010) Bioethanol production from rice straw: an overview. Bioresour Technol 101(13):4767–4774

Bolzonella D, Battista F, Mattioli A, Nicolato C, Frison N, Lampis S (2020) Biological thermophilic post hydrolysis of digestate enhances the biogas production in the anaerobic digestion of agro-waste. Renew Sust Energ Rev 134:110174

Boro M, Verma AK, Chettri D, Yata VK, Verma AK (2022) Strategies involved in biofuel production from agro-based lignocellulose biomass. Environ Technol Innov 28:102679

Brodeur G, Yau E, Badal K, Collier J, Ramachandran KB, Ramakrishnan S (2011) Chemical and physicochemical pretreatment of lignocellulosic biomass: a review. Enzyme Res 2011:787532

Bušić A, Marđetko N, Kundas S, Morzak G, Belskaya H, Ivančić Šantek M, Komes D, Novak S, Šantek B (2018) Bioethanol production from renewable raw materials and its separation and purification: a review. Food Technol Biotechnol 56(3):289–311

Chandra R, Takeuchi H, Hasegawa T (2012) Methane production from lignocellulosic agricultural crop wastes: a review in context to second generation of biofuel production. Renew Sust Energ Rev 16(3):1462–1476

Demirbas A (2002) Diesel fuel from vegetable oil via transesterification and soap pyrolysis. Energy Sources 24(9):835–841

Demirbas A (2005) Biodiesel production from vegetable oils via catalytic and non-catalytic supercritical methanol transesterification methods. Prog Energy Combust Sci 31(5–6):466–487

Demirbas A (2008) Biomethanol production from organic waste materials. Energy Sources A 30(6):565–572

Demirbas A (2009a) Biofuels from agricultural biomass. Energy Sources A 31(17):1573–1582

Demirbas A (2009b) Progress and recent trends in biodiesel fuels. Energy Convers Manag 50(1):14–34

Demirbas MF, Balat M, Balat H (2011) Biowastes-to-biofuels. Energy Convers Manag 52(4):1815–1828

Devi MK, Manikandan S, Oviyapriya M, Selvaraj M, Assiri MA, Vickram S, Subbaiya R, Karmegam N, Ravindran B, Chang SW, Awasthi MK (2022) Recent advances in biogas production using agro-industrial waste: a comprehensive review outlook of techno-economic analysis. Bioresour Technol 363:127871

Dharma S, Hassan MH, Ong HC, Sebayang AH, Silitonga AS, Kusumo F, Milano J (2017) Experimental study and prediction of the performance and exhaust emissions of mixed Jatropha curcas-Ceiba pentandra biodiesel blends in diesel engine using artificial neural networks. J Clean Prod 164:618–633

Dorado MP, Ballesteros E, Arnal JM, Gomez J, Lopez FJ (2003) Exhaust emissions from a diesel engine fueled with transesterified waste olive oil. Fuel 82(11):1311–1315

El-Ramady H, Brevik EC, Bayoumi Y, Shalaby TA, El-Mahrouk ME, Taha N, Elbasiouny H, Elbehiry F, Amer M, Abdalla N, Prokisch J, Solberg SO, Ling W (2022) An overview of agro-waste management in light of the water-energy-waste nexus. Sustainability 14(23):15717

Gahlot P, Ahmed B, Tiwari SB, Aryal N, Khursheed A, Kazmi AA, Tyagi VK (2020) Conductive material engineered direct interspecies electron transfer (DIET) in anaerobic digestion: mechanism and application. Environ Technol Innov 20:101056

Gautam P, Upadhyay SN, Dubey SK (2020) Bio-methanol as a renewable fuel from waste biomass: current trends and future perspective. Fuel 273:117783

Hagos K, Zong J, Li D, Liu C, Lu X (2017) Anaerobic co-digestion process for biogas production: progress, challenges and perspectives. Renew Sust Energ Rev 76:1485–1496

Hoang AT, Pandey A, Huang Z, Nižetić S, Le AT, Nguyen XP (2023) Biofuels an option for agro-waste management. In: Hakeem KR, Bandh SA, Malla FA, Mehmood MA (eds) Environmental sustainability of biofuels. Elsevier, Amsterdam, pp 27–47

Kanakdande AP, Khobragade CN (2020) Biodiesel synthesis from non-edible oil using agro-waste and evaluation of its physicochemical properties. Int J Environ Sci Technol 17(8):3785–3800

Kato S, Hashimoto K, Watanabe K (2012) Methanogenesis facilitated by electric syntrophy via (semi) conductive iron-oxide minerals. Environ Microbiol 14(7):1646–1654

Koupaie EH, Dahadha S, Lakeh AB, Azizi A, Elbeshbishy E (2019) Enzymatic pretreatment of lignocellulosic biomass for enhanced biomethane production-a review. J Environ Manag 233:774–784

Kour D, Rana KL, Yadav N, Yadav AN, Rastegari AA, Singh C, Negi P, Singh K, Saxena AK (2019) Technologies for biofuel production: current development, challenges, and future prospects. In: Rastegari A, Yadav AN, Gupta A (eds) Prospects of renewable bioprocessing in future energy systems. Springer, Cham, pp 1–50

Kumabe K, Fujimoto S, Yanagida T, Ogata M, Fukuda T, Yabe A, Minowa T (2008) Environmental and economic analysis of methanol production process via biomass gasification. Fuel 87(7):1422–1427

Madhavan A, Sindhu R, Arun KB, Pandey A, Binod P, Gnansounou E (2019) Advances in biofuel production by strain development in yeast from lignocellulosic biomass. In: Molina G, Gupta V, Singh B, Gathergood N (eds) Bioprocessing for biomolecules production. Hoboken, Wiley, pp 289–302

Mehmood T, Fareed S, Iqbal M, Naseem A, Siddique F (2018) Utilization of agro-waste and nonconventional Eruca sativa seed oil for getting optimized process to acquire better yield of biodiesel by using response surface methodology (RSM). Chiang Mai J Sci 45(3):1507–1518

Mehmood MA, Shahid A, Malik S, Wang N, Javed MR, Haider MN, Verma P, Ashraf MUF, Habib N, Syafiuddin A, Boopathy R (2021) Advances in developing metabolically engineered microbial platforms to produce fourth-generation biofuels and high-value biochemicals. Bioresour Technol 337:125510

Milano J, Shamsuddin AH, Silitonga AS, Sebayang AH, Siregar MA, Masjuki HH, Pulungan MA, Chia SR, Zamri MFMA (2022) Tribological study on the biodiesel produced from waste cooking oil, waste cooking oil blend with Calophyllum inophyllum and its diesel blends on lubricant oil. Energy Rep 8:1578–1590

Narnoliya LK, Jadaun JS, Singh SP (2018) Management of agro-industrial wastes with the aid of synthetic biology. In: Varjani SJ, Parameswaram B, Kumar S, Khare SK (eds) Biosynthetic technology and environmental challenges. Springer, Singapore, pp 11–28

Neshat SA, Mohammadi M, Najafpour GD, Lahijani P (2017) Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renew Sust Energ Rev 79:308–322

Panpatte DG, Jhala YK (2019) Agricultural waste: a suitable source for biofuel production. In: Rastegari A, Yadav AN, Gupta A (eds) Prospects of renewable bioprocessing in future energy systems. Springer, Cham, pp 337–355

Pattanaik L, Pattnaik F, Saxena DK, Naik SN (2019) Biofuels from agricultural wastes. In: Basile A, Dalena F (eds) Second and third generation of feedstocks. Elsevier, Amsterdam, pp 103–142

Pryshliak N, Tokarchuk D (2020) Socio-economic and environmental benefits of biofuel production development from agricultural waste in Ukraine. Environ Socio-Econ Stud 8(1):18–27

Rajendran N, Kang D, Han J, Gurunathan B (2022) Process optimization, economic and environmental analysis of biodiesel production from food waste using a citrus fruit peel biochar catalyst. J Clean Prod 365:132712

Raman LA, Deepanraj B, Rajakumar S, Sivasubramanian V (2019) Experimental investigation on performance, combustion and emission analysis of a direct injection diesel engine fuelled with rapeseed oil biodiesel. Fuel 246:69–74

Robak K, Balcerek M (2018) Review of second generation bioethanol production from residual biomass. Food Technol Biotechnol 56(2):174

Sarangi PK, Nayak MM (2021) Agro-waste for second-generation biofuels. In: Shadangi KP (ed) Liquid biofuels: fundamentals, characterization, and applications. Hoboken, Wiley, pp 697–709

Sarangi PK, Nanda S, Vo DVN (2020) Technological advancements in the production and application of biomethanol. In: Nanda S, Vo DVN, Sarangi PK (eds) Biorefinery of alternative resources: targeting green fuels and platform chemicals. Springer, Singapore, pp 127–139

Seglah PA, Wang Y, Wang H, Gao C, Bi Y (2022) Sustainable biofuel production from animal manure and crop residues in Ghana. Energies 15(16):5800

Swain MR, Singh A, Sharma AK, Tuli DK (2019) Bioethanol production from rice-and wheat straw: an overview. In: Ray RC, Ramchandran S (eds) Bioethanol production from food crops. Elsevier, Amsterdam, pp 213–231

Tamang P, Tyagi VK, Gunjyal N, Rahmani AM, Singh R, Kumar P, Ahmed B, Tyagi P, Banu R, Varjani S, Kazmi AA (2023) Free nitrous acid (FNA) pretreatment enhances biomethanation of lignocellulosic agro-waste (wheat straw). Energy 264:126249

Tiwari SB, Dubey M, Ahmed B, Gahlot P, Khan AA, Rajpal A, Kazmi AA, Tyagi VK (2021) Carbon-based conductive materials facilitated anaerobic co-digestion of agro waste under thermophilic conditions. Waste Manag 124:17–25

Tyagi VK, Fdez-Güelfo LA, Zhou Y, Álvarez-Gallego CJ, Garcia LR, Ng WJ (2018) Anaerobic co-digestion of organic fraction of municipal solid waste (OFMSW): progress and challenges. Renew Sust Energ Rev 93:380–399

Uthandi S, Kaliyaperumal A, Srinivasan N, Thangavelu K, Muniraj IK, Zhan X, Gathergood N, Gupta VK (2022) Microbial biodiesel production from lignocellulosic biomass: new insights and future challenges. Crit Rev Environ Sci Technol 52(12):2197–2225

Yevich R, Logan JA (2003) An assessment of biofuel use and burning of agricultural waste in the developing world. Glob Biogeochem Cycles 17(4):1095. https://doi.org/10.1029/2002GB001952

Zhang YHP, Lynd LR (2004) Toward an aggregated understanding of enzymatic hydrolysis of cellulose: noncomplexed cellulase systems. Biotechnol Bioeng 88(7):797–824

Zhang J, Tian H, Wang X, Tong YW (2020) Effects of activated carbon on mesophilic and thermophilic anaerobic digestion of food waste: process performance and life cycle assessment. Chem Eng J 399:125757

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Sachdev, S. (2024). Biofuel Production from Agricultural Residue: An Effective and Sustainable Approach for Management of Agro-waste. In: Singh, P. (eds) Emerging Trends and Techniques in Biofuel Production from Agricultural Waste. Clean Energy Production Technologies. Springer, Singapore. https://doi.org/10.1007/978-981-99-8244-8_8

Download citation

DOI: https://doi.org/10.1007/978-981-99-8244-8_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-8243-1

Online ISBN: 978-981-99-8244-8

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)