Abstract

The uniformity coefficient (Cu) of sand and the cyclic loading frequency (f) is unclear in affecting soil's cyclic undrained behavior. This note presents experimental research on the combined effect of f and Cu on the liquefaction resistance of the sand. A series of constant-volume, stress-controlled, cyclic direct simple shear tests (CDSS) were performed on silica sands mixed with different particle proportions to make both poorly (SP) and well-graded (SW) samples. SP and SW samples are deposited in a medium-density dry state, consolidated to vertical stress of 100 kPa, and cyclically loaded under a cyclic stress ratio of 0.1 with various loading frequency (f = 0.03, 0.05, 0.1, 0.2, and 0.5 Hz). In SP sand, the number of cycles to cause liquefaction (Ncyc) remains unchanged when the load frequency rises from 0.03 Hz to 0.1 Hz, and increases when the load frequency rises from 0.1 Hz to 0.5 Hz. It can be stated that SP sand's liquefaction resistance is affected by the high loading frequency. On the contrary, the effect of loading frequency on the Ncyc of SW sand is negligible. Furthermore, SP sand is more resistant to liquefaction than SW sand. According to this study, Cu and f should be included in the sand's liquefaction resistance analysis.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The frequency (f) of the actual earthquake motions is random and varies from a few seconds to a few hertz. On the other hand, due to the limitation of the devices, laboratory tests were performed at lower frequencies (usually 0.1 Hz). Hence, f plays an important effect in laboratory testing results.

The effects of cyclic loading frequency on the liquefaction resistance of sand are summarized in Table 1. Some early studies found that increasing f had little impact on sand liquefaction resistance, but some more recent studies found that liquefaction resistance increased as f increased. Interestingly, some findings indicated that liquefaction resistance decreased with increased f or remained unchanged with a small f and increased with f. Therefore, the f effect on sand's liquefaction resistance is an interesting topic that needs further investigation.

A literature review of the effect on liquefaction resistance of the uniformity coefficient (Cu) also is shown in Table 2, which cannot be drawn to a consistent conclusion.

This study used two types of Silica sand with the same mean diameter (D50 = 0.64) but varying Cu and Cc, classified into SP sand and SW sand, to investigate the coupling effect of Cu and f on the liquefaction resistance of the sand.

2 Material and Testing Method

2.1 Materials

Silica sand with a specific gravity of 2.6 was used as a base sand, and several grain sizes of this sand were separated using the dry sieving technique. Two gradation curves for the poorly-graded sand (SP) and the well-graded sand (SW) were established by mixing various grain size groups with different proportions. The material properties of sand and particle-size distribution curves are shown in Table 3 and Fig. 1.

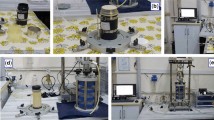

2.2 CDSS System and Sample Preparation

The testing program was conducted based on the CDSS system manufactured by Geocomp Corporation [1]. SP and SW silica sands in a dry state are poured into a cylinder-shaped steel-reinforced membrane by the dry deposition method to prepare a cylindrical sample with an initial relative density (Dr) of 60% (medium state). The typical samples have an initial height of 25 mm and an initial diameter of 63.5 mm.

All samples are consolidated to confining stress of 100 kPa (i.e.,σ’ = 100 kPa). Then the samples were loaded under harmonic form loading under constant volume conditions at cyclic stress ratios, CSR of 0.1 with a wide range of loading frequency, f (0.03, 0.05, 0.1, 0.2, and 0.5 Hz). The CDSS tests can be terminated when the double amplitude shear strain (DA) has reached 7.5%.

3 Result and Discussion

3.1 CDSS Testing Result

Table 4 summarizes the CDSS test results and the typical cyclic response of SP sand at the medium state with CSR of 0.1 and f of 0.03 Hz is illustrated in Fig. 2. While the test was performed until liquefying, the shear strain oscillated almost symmetrical at zero. The excess pore pressure rapidly increased in the first few cycles, then developed uniformly, leading to the effective vertical stress decreasing to zero at liquefy state.

3.2 Effect of F on Ncyc

Figure 3 illustrates the relationship between Ncyc and f for CSR of 0.1. For SP sand, at CSR = 0.1, Ncyc remains unchanged (Ncyc = 70) when frequency increases from 0.03 Hz to 0.1 Hz and rises from 70 to 111 when f increases from 0.1 Hz to 0.5 Hz. In general, SP sand's liquefaction resistance is affected by high f. By contrast, for the SW sand, the effect of f on Ncyc can be neglected. Moreover, the Ncyc of SW sand is higher than that of SP at f less than 0.2 Hz, which leads to the fact that the liquefaction resistance of SW sand is higher than that of SP sand.

For practical use, the normalized number of cycles (NNcyc) is proposed by Eq. (1).

where \({N}_{cyc}^{f=iHz}\) is Ncyc at f of i Hz, and \({N}_{cyc}^{f=0.1Hz}\) is Ncyc at f of 0.1 Hz.

Figure 4 displays a function of NNcyc and f, and the relationship can be easily used in practice as the reference index.

4 Conclusion

The note presented a laboratory testing analysis on the effect of f on Ncyc of Silica sand with the same mean diameter and different particle size distribution (SP and SW). The CDSS test results showed that when f increased from 0.03 Hz to 0.1 Hz, Ncyc remained unchanged, while it increased when f increased from 0.1 Hz to 0.5 Hz. It can be stated that SP sand's liquefaction resistance is affected by the high f. In contrast, f had little effect on the liquefaction resistance of SW sand. Furthermore, SP sand was more resistant to liquefaction than SW sand. According to this study, Cu and f should be included in the sand's liquefaction resistance analysis.

References

Park S-S, Tran D-K-L, Nguyen T-N, Woo S-W, Sung H-Y (2023) Effect of loading frequency on the liquefaction resistance of poorly graded sand. In: Advances in geospatial technology in mining and earth sciences: selected papers of the 2nd international conference on geo-spatial technologies and earth resources. Springer, pp 95–104

Vaid YP, Fisher JM, Kuerbis RH, Negussey D (1990) Particle gradation and liquefaction. J Geotech Eng 116(4):698–703. https://doi.org/10.1061/(ASCE)0733-9410(1990)116:4(698)

Kokusho T, Hara T, Hiraoka R (2004) Undrained shear strength of granular soils with different particle gradations. J Geotech Geoenviron Eng 130(6):621–629. https://doi.org/10.1061/(asce)1090-0241(2004)130:6(621)

Yilmaz Y, Mollamahmutoglu M, Ozaydin V, Kayabali K (2008) Experimental investigation of the effect of grading characteristics on the liquefaction resistance of various graded sands. Eng Geol 100(3–4):91–100. https://doi.org/10.1016/j.enggeo.2007.12.002

Monkul MM, Kendir SB, Tütüncü YE (2021) Combined effect of fines content and uniformity coefficient on cyclic liquefaction resistance of silty sands. Soil Dyn Earthq Eng 151:106999. https://doi.org/10.1016/j.soildyn.2021.106999

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (NRF-2018R1A5A1025137 and NRF-2021R1I1A3059731).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Tran, DKL., Woo, SW., Lee, SD., Nguyen, NN., Park, SS. (2024). Couple Effect of Loading Frequency and Uniformity Coefficient on the Liquefaction Resistance of Sand. In: Reddy, J.N., Wang, C.M., Luong, V.H., Le, A.T. (eds) Proceedings of the Third International Conference on Sustainable Civil Engineering and Architecture. ICSCEA 2023. Lecture Notes in Civil Engineering, vol 442. Springer, Singapore. https://doi.org/10.1007/978-981-99-7434-4_114

Download citation

DOI: https://doi.org/10.1007/978-981-99-7434-4_114

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-7433-7

Online ISBN: 978-981-99-7434-4

eBook Packages: EngineeringEngineering (R0)