Abstract

The present research examines the potential of machine learning (ML) to improve sustainability and lessen harmful environmental effects across various industries. The paper discusses ML’s uses in sustainable manufacturing practices (SMP), such as supply chain management, waste management, energy efficiency, equipment maintenance, water quality management, and other fields. The investigations show how ML approaches may be used to forecast equipment failure, lower carbon footprints, optimize resource use, and improve water quality. The study highlights the benefits of utilizing ML to increase sustainability, including real-time data, simplified processes, lower costs, and a sustainable future while admitting the difficulties and limits of ML techniques. The article ends by recommending enterprises and the industrial sector explore the prospect of using ML to attain their goals for sustainability.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Machine learning

- Sustainability

- Supply chain management

- Waste management

- Energy efficiency

- Water quality management

- Carbon footprint

48.1 Introduction

Traditional manufacturing methods have been linked to harmful environmental effects such as resource depletion, pollution, and waste production. So, sustainable manufacturing techniques have been developed to minimize the negative environmental effects of manufacturing operations while fostering economic and social advancement [1].

Sustainable manufacturing refers to the process of producing goods in a manner that minimizes the environmental impact while balancing the economic and social dimensions of manufacturing. It is a process of creating products and services using resources and energy to reduce waste and pollution, conserve energy and natural resources, and improve the quality of life of the employees and the communities where the manufacturing occurs [2]. Implementing sustainable practices that strike a balance between the requirements of the present and the needs of the future aims to lessen this impact. Product design, material selection, manufacturing procedures, energy efficiency, waste reduction, and end-of-life disposal are some practices that go into sustainable manufacturing. It considers a product's whole lifespan, from the extraction of raw materials through disposal, and seeks to reduce the environmental effect at every turn [2].

Artificial intelligence’s branch of machine learning (ML) has demonstrated its ability to promote environmentally friendly manufacturing methods [3]. ML algorithms can analyze large data sets, find patterns, and forecast outcomes that may be used to streamline production, cut waste, and increase resource efficiency. The use of ML in sustainable manufacturing techniques has not received much attention, though [4].

ML can significantly advance environmentally friendly manufacturing techniques. Companies may lessen their impact on the environment, increase productivity, and save costs by utilizing ML algorithms to analyze and optimize production processes. Energy efficiency in industrial facilities is one way ML may support sustainable manufacturing [5]. Waste in industrial processes is decreased with the use of ML. By analyzing production data, ML algorithms can spot inefficiencies and provide strategies to reduce waste and maximize material consumption. Another area where ML might enhance industrial sustainability is predictive maintenance. ML algorithms can forecast when maintenance is necessary by examining equipment performance data and minimizing waste, downtime, and maintenance expenses. The supply chain activities may also be optimized using ML [6]. The development of sustainable products can also benefit from ML. ML may assist in developing more SMPs and lessen the manufacturing industry's impact on the environment by helping businesses to analyze and optimize production processes, cut waste, and increase productivity [7].

The demand in the industrial sector to increase sustainability and lessen its environmental effect is growing [2]. Traditional manufacturing procedures sometimes do not have the adaptability and effectiveness needed to accomplish these objectives. As a result, there is a demand for cutting-edge solutions that may assist manufacturers in streamlining their operations, cutting waste, increasing productivity, and reducing environmental impact. The potential uses of ML in sustainable manufacturing have many difficulties and constraints to put into practice and successful implementations. This paper provides an outline of SMPs and how ML contributes.

48.2 Application of Machine Learning in Sustainable Manufacturing

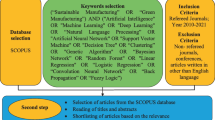

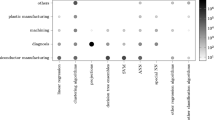

ML can be applied in several ways to promote SMPs. Figure 48.1 depicts various SMPs. The application of ML in various SMPs has been reviewed.

48.2.1 Waste Management

ML can assist with waste management in manufacturing by reducing waste, improving recycling, and optimizing resource consumption. It can help decrease waste and boost efficiency by anticipating the ideal number of raw materials needed for production. In predictive maintenance, ML can be used to forecast equipment failure and determine the ideal time for maintenance [4].

Sami et al. [8] presented a waste classifying system and employed ML and Deep Learning (DL) algorithms to categorize waste into six categories: glass, paper, metal, plastic, cardboard, and rubbish. The performance of three ML algorithms, SVM, Random Forest (RF), and DT, and one DL algorithm CNN was compared, and it reported that CNN attained the highest classification accuracy of 90%. Anh Khoa et al. [1] described a waste management system that employed ML and graph theory to forecast the garbage levels in trash cans and optimize rubbish pickup by taking the shortest path. The solution was tested on a genuine university campus utilizing a low-cost IoT architecture. Zaman et al. [9] discussed the potential application of Industry 4.0 technology in waste management, which can help reduce costs, improve efficiency, and achieve circular economy goals. The 20,491 labeled images of waste items in six categories were collected, and the You Only Look Once version 4 ML algorithm was employed. Huang et al. [4] developed a framework for ML-driven predictive analytics for waste management operations, including material and energy recycling. A neural network was utilized to estimate the amount of trash, and an improved ML algorithm was used to improve waste collection. The results revealed that the proposed method reduced landfill analysis by 40%, transportation by 15%, and trash quantity analysis by 90%. Khan et al. [10] proposed an efficient solution for smart and effective waste management using ML and the IoT. The amount of waste in dustbins and disposal sites was detected by using an Arduino UNO microcontroller, an ultrasonic sensor, and a moisture sensor. The suggested approach aimed to produce clean, pollution-free towns while also reducing the overall time and cost.

The use of ML in SMP research has shown how it may be used to improve waste categorization, forecast waste levels, optimize resource usage, and cut waste through effective recycling. The suggested methods have shown increased accuracy, decreased waste, decreased costs of transportation and analysis, and fulfilled circular economy objectives.

48.2.2 Energy Optimization

Energy optimization is the practice of lowering energy use in production processes without sacrificing the quality of the final goods. Energy is a significant expense in manufacturing, and important to use energy as efficiently as possible to cut costs, increase sustainability [11], and adhere to laws. Manufacturing companies may benefit from ML by optimizing energy use and reducing energy waste, resulting in considerable cost savings and ecological benefits.

Mocanu et al. [12] explored methodology to optimize energy schedules for building smart grid energy management systems using deep reinforcement learning. The proposed technique was validated using the enormous Pecan Street Inc. database, which comprised information regarding photovoltaic power generation, electric vehicles, and building appliances. Pawanr et al. [7] developed soft computing models for a CNC lathe machine tool's carbon emissions, power factor, and energy efficiency using experimental data. These models assist in energy-efficient production and carbon footprint reduction. Narciso et al. [13] investigated the potential utility of industrial data and examined 42 published papers addressing various energy efficiency problems. It served as a reference manual for the manufacturing and process industries to select suitable energy-efficient ML tools. Mawson et al. [14] contrasted the use of two deep neural networks—feed-forward and recurrent to anticipate energy use in manufacturing facilities and workshop conditions. The data used to train the neural networks was obtained from a simulation of a medium-sized manufacturing plant in the UK. The feed- forward model predicted building energy, workshop air temperatures, and humidity with respective accuracies of 92.4, 99.5, and 64.8%, whereas the recurrent model anticipated these variables with respective accuracies of 96.82, 99.40, and 57.60%. Liao et al. [15] created a basic air conditioning model to forecast energy use in research and development buildings. The RF algorithm produced an R2 of 88% ahead of the first month and 81% ahead of the third month among the various ML approaches used.

The review depicts various ML techniques to optimize energy efficiency and reduce carbon footprint in different domains. The studies demonstrate the potential of ML techniques in enhancing energy efficiency and reducing carbon footprint in various domains.

48.2.3 Renewable Energy

ML optimizes the utilization of renewable energy sources like solar and wind energy. Manufacturers can maximize the usage of renewable energy sources and lessen their reliance on fossil fuels by studying weather patterns and energy demand data.

Ahmed et al. [16] demonstrated amalgamating renewable energy sources with smart grids to deal with the issue of managing energy demand. An effective Energy Management Model (EMM) was created using ML techniques. Sharmila et al. [17] developed a hybrid ML model with big data analytic techniques for the optimized distribution of available energy resources targeting smart energy management. Mostafa et al. [18] explored the use of big data analytics in renewable energy power plants and presented a framework for integrating it into smart grids. The research applied three distinct ML techniques to a decentralized smart grid data system with 60,000 instances and 12 variables to forecast the system's stability. The DT model's accuracy was 78%, the RF tree model's accuracy was 84%, and the penalized linear regression model's accuracy was 96%. The application of ML techniques for creating sustainable energy materials was discussed by Gu et al. [19]. Lai et al. [20] presented a survey and analysis of ML methods to forecast renewable energy.

In smart grids, ML approaches were used to manage energy consumption, lower carbon footprint, optimize energy scheduling, and look into the development of sustainable energy materials and the application of big data analytics in renewable energy power plants.

48.2.4 Supply Chain Optimization

ML has multiple roles in manufacturing supply chain optimization. It can estimate product demand by examining past data and market patterns. ML can also optimize delivery routes and analyze supplier performance data.

Carbonneau et al. [6] investigated the feasibility of applying non-linear ML algorithms for forecasting distorted demand signals in the extended supply chain. The basic approaches, including naive forecasting, trend, moving average, and linear regression, were compared with advanced ML techniques. Feizabadi et al. [21] developed a hybrid demand forecasting model by merging time-series data with advanced indicators based on ML techniques. The dataset was collected from a steel manufacturing company operating in four market categories. Bigliardi [22] discussed that supply chain digitization research could be divided into core, trendy, and emergent subjects. Nagar et al. [23] emphasized the importance of IT-enabled systems in allowing sectors to adapt to modern technology and remain competitive. Baryannis et al. [24] proposed a framework for predicting supply chain risks using AI techniques and expert collaboration. The dataset used contained information on around 500,000 product deliveries from tier 2 suppliers to the tier 1 supplier in the supply chain for six years from 2011 to 2016.

ML may greatly improve supply chain efficiency, and businesses must implement IT-enabled solutions to stay competitive in the rapidly evolving technological environment.

48.2.5 Predictive Maintenance

ML has transformed the way predictive maintenance is performed in the manufacturing sector. To find patterns and anomalies that indicate tackling equipment failure, manufacturers may utilize this technology to analyze vast amounts of data from numerous sources, including sensors and maintenance logs.

Arena et al. [25] proposed DTs to assist the industry in determining if predictive maintenance is a good fit for their systems. The procedure was tried in an actual industrial scenario, and the results demonstrated its effectiveness. Cınar et al. [26] presented an in-depth literature review on recent developments in ML methods for predictive maintenance for Industry 4.0 smart manufacturing. Dalzochio et al. [27] used an in-depth literature review to evaluate academic developments in failure prediction utilizing ML and reasoning for predictive maintenance in Industry 4.0. Several issues still need to be properly researched in the field of ML and predictive maintenance. Kavana et al. [28] developed an ML model for fault detection and classification of induction motor faults using real-time data from a 0.33 HP induction motor. The model accurately detected and classified faults in the motor, which could help prevent further damage and ensure the safety of electrical components. Paolanti et al. [29] described an ML architecture for the predictive maintenance of electric motors and other equipment used in the industry. The system was based on the RF approach and was tested on a real industry example.

48.2.6 Carbon Footprint Reduction

By optimizing the consumption of energy, transportation, and production processes, ML plays a significant part in dropping carbon footprint [30]. Płoszaj-Mazurek [31] investigated strategies to optimize building design for a less carbon footprint using ML methods. Mardani et al. [32] proposed a multi-stage methodology to forecast carbon dioxide emissions based on energy consumption and economic growth in group 20 countries. Bhatt et al. [33] discussed carbon dioxide emissions and how they relate to climate change. The reduction and reversal rates necessary to return carbon emissions to safe levels were also calculated. Zhao et al. [34] developed a method for optimizing cutting parameters in CNC machining processes to reduce carbon emissions. The optimized cutting parameters reduced processing time and carbon emissions by 5.84% and 6.1%, respectively, improving the machining efficiency and reducing carbon emissions.

By streamlining production, transportation, and energy use, ML can help reduce carbon footprint. ML has demonstrated the potential to lower carbon emissions across various businesses and sectors.

48.2.7 Water Conservation

ML can conserve water in manufacturing by predicting equipment failure and identifying inefficient water usage through data from sensors and water quality monitors.

Hassan et al. [35] used ML algorithms, including RF, Neural Network, Multiple Linear Regression, SVM, and Boosted Tree Model, to estimate the water quality index in different regions of India. The proposed ML method achieved high accuracy in predicting water quality. Yan et al. [36] proposed a new framework for predicting long-term water quality using Bayesian-optimised ML methods. The proposed framework could efficiently predict future water quality and provide technical support for emergency pollution control. Adeleke et al. [37] aimed to construct, test, and evaluate the usefulness of ML and the IoT at water storage stations. The ANN models used had the highest accuracy and were most suitable for predicting water source and status. ML algorithms have the potential to accurately predict water quality, offering useful information for water management and pollution prevention.

48.2.8 Sustainable Product Design

By identifying prospects that reduce environmental impact, ML can help design sustainable products using data from the product lifecycle, consumer preferences, and production parameters [38]. Wang et al. [39] discussed the application of ML techniques in enhancing the sustainability of ships. ML has been useful in marine areas such as underwater vehicles, wave energy converters, condition monitoring, and maintenance. Pervez et al. [40] developed a sustainable resin-finishing procedure for cotton fabric. Bodendorf et al. [41] proposed using ML to support cost management in the early product development and design stages.

Manufacturers can employ ML to create goods that satisfy customer sustainability demand and enhance production procedures to minimize the negative environmental impact.

48.3 Future of Machine Learning in SMPs

By maximizing energy use, lowering waste, and enhancing production efficiency, ML has the potential to revolutionize sustainable manufacturing. ML algorithms may assist factories in making better-educated decisions regarding energy use and waste reduction by gathering data from numerous sources. High-quality data are necessary to utilize the capability of ML properly. The improvement of data collecting and organization may be the main emphasis of future advancements, especially in areas like energy use, trash creation, and emissions. Integrating sustainable practices into industrial processes will receive more attention as customers and authorities emphasize sustainability. Manufacturing may be optimized to reduce the negative effects on the environment, and problem areas can be found using ML. Manufacturers can forecast when machines will require repair or replacement by using ML to analyze data from sensors and other sources, minimizing waste and minimizing downtime. We should anticipate increasingly complex optimization algorithms that can balance conflicting demands like energy efficiency, manufacturing speed, and material utilization as ML techniques advance [42]. Cobots, or collaborative robots, are intended to do laborious or hazardous jobs alongside human operators. By allowing these robots to learn from their mistakes and develop better performance over time, ML can help them become more efficient. Manufacturers can enhance their environmental performance, lower their energy and waste consumption, and build a more sustainable future for everybody by using the potential of this technology.

48.4 Concluding Remarks

This paper reviewed the potential of machine learning in enhancing sustainability during sustainable manufacturing practices, including product design, waste management, energy efficiency, supply chain management, equipment maintenance, carbon emissions reduction, and water quality management. It allows manufacturers to make data-driven decisions that result in more environmentally friendly actions and improved overall performance. Also, it is essential to realize that ML is not a panacea for environmentally friendly production. Its efficacy relies on the data's accuracy, the selection of the right algorithms, and the availability of qualified individuals to deploy and maintain the systems. Therefore, a thorough strategy considering various sustainable manufacturing factors, such as material choice, circular economy principles, and renewable energy, is required to transition smoothly to a sustainable future. ML adoption in SMPs is a step in the right direction. Still, it must be part of a wider strategy that considers manufacturing operations’ social, economic, and environmental effects.

References

Anh Khoa, T., et al.: Waste management system using IoT-based machine learning in university. Wirel. Commun. Mob. Comput. 2020, 6138637 (2020). https://doi.org/10.1155/2020/6138637

Chandel, R.S., Kumar, R., Kapoor, J.: Sustainability aspects of machining operations: a summary of concepts. Mater. Today Proc. 50, 716–727 (2022). https://doi.org/10.1016/j.matpr.2021.04.624

Ranjan, N., Kumar, R., Kumar, R., Kaur, R., Singh, S.: Investigation of fused filament fabrication-based manufacturing of ABS-Al composite structures: prediction by machine learning and optimization. J. Mater. Eng. Performance 1–20 (2022)

Huang, J., Koroteev, D.D.: Artificial intelligence for planning of energy and waste management. Sustain. Energy Technol. Assess. 47, 101426 (2021). https://doi.org/10.1016/j.seta.2021.101426

Sidhu, A.S., Singh, S., Kumar, R., Pimenov, D.Y., Giasin, K.: Prioritizing energy-intensive machining operations and gauging the influence of electric parameters: an industrial case study. Energies 14(16), 4761 (2021). [Online]. Available: https://www.mdpi.com/1996-1073/14/16/4761

Carbonneau, R., Laframboise, K., Vahidov, R.: Application of machine learning techniques for supply chain demand forecasting. Eur. J. Oper. Res. 184(3), 1140–1154 (2008). https://doi.org/10.1016/j.ejor.2006.12.004

Pawanr, S., Garg, G.K., Routroy, S.: Prediction of energy efficiency, power factor and associated carbon emissions of machine tools using soft computing techniques. Int. J. Interact. Des. Manuf. (IJIDeM) (2022). https://doi.org/10.1007/s12008-022-01089-4

Sami, K.N., Amin, Z.M.A., Hassan, R.: Waste management using machine learning and deep learning algorithms. Int. J. Perceptive Cogn. Comput. 6(2), 97–106 (2020). https://doi.org/10.31436/ijpcc.v6i2.165

Zaman, A.: Waste management 4.0: an application of a machine learning model to identify and measure household waste contamination—a case study in Australia. Sustainability 14(5), 3061 (2022). [Online]. Available: https://www.mdpi.com/2071-1050/14/5/3061

Khan, R., et al.: Machine learning and IoT-based waste management model. Comput. Intell. Neurosci. 2021, 5942574 (2021). https://doi.org/10.1155/2021/5942574

Shu, X., et al.: Sustainability assessment of energy storage technologies based on commercialization viability: MCDM model. Sustainability 15(6), 4707 (2023). [Online]. Available: https://www.mdpi.com/2071-1050/15/6/4707

E Mocanu 2019 On-line building energy optimization using deep reinforcement learning IEEE Trans. Smart Grid 10 4 3698 3708 https://doi.org/10.1109/TSG.2018.2834219

Narciso, D.A.C., Martins, F.G.: Application of machine learning tools for energy efficiency in industry: a review. Energy Rep. 6, 1181–1199 (2020). https://doi.org/10.1016/j.egyr.2020.04.035

Mawson, V.J., Hughes, B.R.: Deep learning techniques for energy forecasting and condition monitoring in the manufacturing sector. Energy Build. 217, 109966 (2020). https://doi.org/10.1016/j.enbuild.2020.109966

Liao, J.-M., Chang, M.-J., Chang, L.-M.: Prediction of air-conditioning energy consumption in R&D building using multiple machine learning techniques. Energies 13(7), 1847 (2020). [Online]. Available: https://www.mdpi.com/1996-1073/13/7/1847

W Ahmed 2020 Machine learning based energy management model for smart grid and renewable energy districts IEEE Access 8 185059 185078 https://doi.org/10.1109/ACCESS.2020.3029943

Sharmila, P., Baskaran, J., Nayanatara, C., Maheswari, R.: A hybrid technique of machine learning and data analytics for optimized distribution of renewable energy resources targeting smart energy management. Procedia Comput. Sci. 165, 278–284 (2019). https://doi.org/10.1016/j.procs.2020.01.076

Mostafa, N., Ramadan, H.S.M., Elfarouk, O.: Renewable energy management in smart grids by using big data analytics and machine learning. Mach. Learn. Appl. 9, 100363 (2022). https://doi.org/10.1016/j.mlwa.2022.100363

Gu, G.H., Noh, J., Kim, I., Jung, Y.: Machine learning for renewable energy materials. J. Mater. Chem. A 7(29), 17096–17117 (2019). https://doi.org/10.1039/C9TA02356A

Lai, J.-P., Chang, Y.-M., Chen, C.-H., Pai, P.-F.: A survey of machine learning models in renewable energy predictions. Appl. Sci. 10(17), 5975 (2020). [Online]. Available: https://www.mdpi.com/2076-3417/10/17/5975

Feizabadi, J.: Machine learning demand forecasting and supply chain performance. Int. J. Logistics Res. Appl. 25(2), 119–142 (2022). https://doi.org/10.1080/13675567.2020.1803246

Bigliardi, B., Filippelli, S., Petroni, A., Tagliente, L.: The digitalization of supply chain: a review. Procedia Comput. Sci. 200, 1806–1815 (2022). https://doi.org/10.1016/j.procs.2022.01.381

Nagar, D., Raghav, S., Bhardwaj, A., Kumar, R., Lata Singh, P., Sindhwani, R.: Machine learning: best way to sustain the supply chain in the era of industry 4.0. Mater. Today Proc. 47, 3676–3682 (2021). https://doi.org/10.1016/j.matpr.2021.01.267

Baryannis, G., Dani, S., Antoniou, G.: Predicting supply chain risks using machine learning: the trade-off between performance and interpretability. Future Gener. Comput. Syst. 101, 993–1004 (2019). https://doi.org/10.1016/j.future.2019.07.059

Arena, S., Florian, E., Zennaro, I., Orrù, P.F., Sgarbossa, F.: A novel decision support system for managing predictive maintenance strategies based on machine learning approaches. Saf. Sci. 146, 105529 (2022). https://doi.org/10.1016/j.ssci.2021.105529

Çınar, Z.M., Abdussalam Nuhu, A., Zeeshan, Q., Korhan, O., Asmael, M., Safaei, B.: Machine learning in predictive maintenance towards sustainable smart manufacturing in industry 4.0. Sustainability 12(19), 8211 (2020). [Online]. Available: https://www.mdpi.com/2071-1050/12/19/8211

Dalzochio, J., et al.: Machine learning and reasoning for predictive maintenance in Industry 4.0: current status and challenges. Comput. Ind. 123, 103298 (2020). https://doi.org/10.1016/j.compind.2020.103298

Kavana, V., Neethi, M.: Fault analysis and predictive maintenance of induction motor using machine learning. In: 2018 International Conference on Electrical, Electronics, Communication, Computer, and Optimization Techniques (ICEECCOT), 14–15 Dec 2018, pp. 963–966. https://doi.org/10.1109/ICEECCOT43722.2018.9001543

Paolanti, M., Romeo, L., Felicetti, A., Mancini, A., Frontoni, E., Loncarski, J.: Machine learning approach for predictive maintenance in industry 4.0. In: 2018 14th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), 2–4 July 2018, pp. 1–6. https://doi.org/10.1109/MESA.2018.8449150

R Kumar S Singh AS Sidhu CI Pruncu 2021 Bibliometric analysis of specific energy consumption (SEC) in machining operations: a sustainable response Sustainability 13 10 5617

M Płoszaj-Mazurek 2020 Machine learning-aided architectural design for carbon footprint reduction Builder 24 7 35 39

Mardani, A., Liao, H., Nilashi, M., Alrasheedi, M., Cavallaro, F.: A multi-stage method to predict carbon dioxide emissions using dimensionality reduction, clustering, and machine learning techniques. J. Cleaner Prod. 275, 122942 (2020). https://doi.org/10.1016/j.jclepro.2020.122942

Bhatt, H., Davawala, M., Joshi, T., Shah, M., Unnarkat, A.: Forecasting and mitigation of global environmental carbon dioxide emission using machine learning techniques. Cleaner Chem. Eng. 5, 100095 (2023). https://doi.org/10.1016/j.clce.2023.100095

Zhao, L., Fang, Y., Lou, P., Yan, J., Xiao, A.: Cutting parameter optimization for reducing carbon emissions using digital twin. Int. J. Precis. Eng. Manuf. 22(5), 933–949 (2021). https://doi.org/10.1007/s12541-021-00486-1

MM Hassan 2021 Efficient prediction of water quality index (WQI) using machine learning algorithms Human-Centric Intell. Syst. 1 3–4 86 97

Yan, T., Zhou, A., Shen, S.-L.: Prediction of long-term water quality using machine learning enhanced by Bayesian optimization. Environ. Pollut. 318, 120870 (2023). https://doi.org/10.1016/j.envpol.2022.120870

Adeleke, I.A., Nwulu, N.I., Ogbolumani, O.A.: A hybrid machine learning and embedded IoT-based water quality monitoring system. Internet Things 22, 100774 (2023). https://doi.org/10.1016/j.iot.2023.100774

Thakur, V., Kumar, R., Kumar, R., Singh, R., Kumar, V.: Hybrid additive manufacturing of highly sustainable polylactic acid—carbon fiber-polylactic acid sandwiched composite structures: optimization and machine learning. J. Thermoplast. Compos. Materi. 0(0), 08927057231180186. https://doi.org/10.1177/08927057231180186

Wang, H.S.-H., Yao, Y.: Machine learning for sustainable development and applications of biomass and biomass-derived carbonaceous materials in water and agricultural systems: a review. Resour. Conserv. Recycl. 190, 106847 (2023). https://doi.org/10.1016/j.resconrec.2022.106847

Pervez, M.N., et al.: Sustainable fashion: design of the experiment assisted machine learning for the environmental-friendly resin finishing of cotton fabric. Heliyon 9(1), e12883 (2023). https://doi.org/10.1016/j.heliyon.2023.e12883

Bodendorf, F., Franke, J.: A machine learning approach to estimate product costs in the early product design phase: a use case from the automotive industry. Procedia CIRP 100, 643–648 (2021). https://doi.org/10.1016/j.procir.2021.05.137

R Kumar PS Bilga S Singh 2017 Multi objective optimization using different methods of assigning weights to energy consumption responses, surface roughness and material removal rate during rough turning operation J. Clean. Prod. 164 45 57

Acknowledgements

The authors express deep gratitude to the Department of Information Technology and Mechanical and Production Engineering, Guru Nanak Dev Engineering College, Ludhiana (Punjab), for allowing the research work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Kaur, R., Kumar, R., Aggarwal, H. (2024). Role of Machine Learning in Sustainable Manufacturing Practices: An Outline. In: Talpa Sai, P.H.V.S., Potnuru, S., Avcar, M., Ranjan Kar, V. (eds) Intelligent Manufacturing and Energy Sustainability. ICIMES 2023. Smart Innovation, Systems and Technologies, vol 372. Springer, Singapore. https://doi.org/10.1007/978-981-99-6774-2_48

Download citation

DOI: https://doi.org/10.1007/978-981-99-6774-2_48

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-6773-5

Online ISBN: 978-981-99-6774-2

eBook Packages: EngineeringEngineering (R0)