Abstract

The Dalian Advanced Light Source (DALS), proposed by Dalian Institute of Chemical Physics (DICP), is a linear accelerator based on continuous wave superconducting radio frequency technology aiming to produce high-quality electron beam with repetition rate up to 1 MHz. Before the project is officially implemented, a DALS test facility (DATF) is under construction to qualify the performance of the key components, including the superconducting cavities and the cryomodules. A cryogenic system is designed to provide the cooling capacities for the DATF. The DATF is mainly composed of Horizontal Test Bench (HTB), Vertical Test Cryostat (VTC), Cryogenic Test Bench (CTB) and Injector Test Bench (ITB). The overall objective of cryogenic control system is basically a distributed system to guarantee the control and monitoring of the test facility. The system is mainly composed of Programmable Logic Controllers (PLCs) with local human machine interfaces (HMIs) and the Experimental Physics and Industrial Controls System (EPICS), it contains a total of seven control cabinets that can complete the functions of data acquisition and transmission, regulation/discrete/sequential control, monitoring layer operation, alarm display, data storage and login management of all important equipment. This paper reports on the architecture design and current progress of the control system of the DATF cryogenic system.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

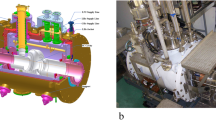

The cryogenic system will provide the necessary cryogenic environment to supply the 2 K superfluid helium required for operation of the superconducting cavities and cryomodules in the DALS Test Facility (DATF). The major components include Test Facility Cryoplant (TFCP), Process Vacuum Pump System (PVPS), Auxiliary System (e. g. helium recovery & purification system), and Cryogenic Distribution System (CDS). The DATF will be arranged mainly in the Cryomodule Test Bench Hall, Injector Test Bench Hall and Cryo-Hall. The Module Test Bench Hall will house the cold box, Test Facility Distribution Box (TFDB), HTB, VTC. The ITB will be located in the Injector Test Bench Hall. Meanwhile, the Cryo-Hall will contain the warm compressor system (WCS), PVPS, helium recovery & purification system [1]. The layout of the entire DATF is shown in Fig. 1.

In order to automatically monitor the operating mode and status of the DATF cryogenic system, it is necessary to design a cryogenic instrumentation and control system to control and monitor the devices. The number of sensors and actuators are shown in Table 1.

2 Control System Overview

With the increasing requirements for minimizing human intervention to address the complexity of the process, the control system of large scale of cryogenic equipment has gradually evolved towards fully automatic operation. The cryogenic control system is designed to integrate all major subsystems in the DATF cryogenic system, including Auxiliary System (e. g. helium recovery & purification system), PVPS, TFCP, TFDB, ITB, HTB, VTB, etc., and to implement the control of all devices. The control system of the DATF cryogenic system is mainly composed of the Siemens Process Control System SIMATIC PCS7 and EPICS. The TFCP had been purchased from LINDE, which mainly used Siemens PLCs (S7–1500) and WinCC software to control the refrigerator. The control of PVPS and helium purification system, supplied by domestic manufacturers, is also managed by Siemens PLCs. The control systems in the CDS adopt Siemens S7–1500/ET200M model PLCs. All subsystems of the DATF cryogenic system are integrated through the PROFINET network. EPICS is mainly used for information interaction with the main control system of the accelerator.

The control system will provide the appropriate control algorithms to support the complex operation of the cryogenic system, enabling fully automated or semi-automated modes of operation. The supervisory control can be achieved in this control system, such as visualization of the process hierarchy. All parameters essential for operation in the DATF cryogenic system can be monitored and controlled. The system will allow for equipment protection and personnel protection through a hierarchy of alarms, interlocks, troubleshooting and tripping. And it can also realize the information interaction with central systems in the accelerator.

3 The Architecture of Control System

In order to implement the necessary functions and integrate the subsystems, the control system of the DATF cryogenic system adopt the standard three layers distributed control architecture [2, 3]. It includes the supervision layer, control layer and device layer. The architecture of the control system for the DATF cryogenic system is shown in Fig. 2.

3.1 Supervision Layer

The supervision layer is an important tool for operator to monitor, develop and commission the system. In this project, the supervision layer is equipped with two data servers (including one redundant server), eight operator stations and one mobile workstation, and contains control software, human-machine interface, data management, and remote communication module. The entire DATF cryogenic system is supervised through Data Servers (DS) running the Siemens WinCC SCADA system. In this layer, the system can implement the data archiving and display, visualization of the process hierarchy, access to the interlocks between devices, automatic adjustment of the control loops, direct access to the device files, etc. The master computer communicates with the PLC controllers through PROFINET protocol, ensuring the real-time communication and enabling rapid diagnosis functions. It also provides the dedicated interfaces to other control systems in the accelerator.

3.2 Control Layer

The control layer is the core of remote device control, logic operation and signal acquisition and conversion. And it also provides safety interlock protection and hierarchical alarm for the system. The control layer continuously monitors the status of the cryogenic system and updates the control commands to maintain stable operation. In this project, the control layer is composed of Siemens S7–1500 PLCs and EPICS. The control duties are mainly executed within PLCs. Almost all process variables and status information of actuators and sensors are monitored and controlled by PLCs. The signal conversion, control algorithms (e. g. PID algorithms) and processing of variables are also implemented by PLCs.

WINCC and Siemens PLC are mainly used to monitor the cryogenic control system, while the EPICS is used in the entire accelerator control system. These are two relatively independent control systems. In order to reduce the interference between the two systems, EPICS in the cryogenic control system is used only to provide a set of operating interfaces in the center control of accelerator system, to alarm and archive, and to analyze real-time and historical data. Therefore, the PLCs in the cryogenic control are also used to send the signals from sensors and actuators to the EPICS Input/Output Controller (IOC).

In this project, each subsystem in the cryogenic control has its own control cabinet which is equipped with a switch to establish the Device-level Ring (DLR). The PLCs with HMI are connected to the switch based on the PROFINET protocol, while the switches communicate with each other through fiber optics. In addition, the TFCP control system is connected to the main control cabinet switch through PROFINET protocol, the recovery compressor control system is linked to the horizontal test bench switch through MODBUS protocol, the recovery & purification and PVPS control system are connected to the tank zone switch through PROFINET protocol. And the EPICS communicates with the main control cabinet by the optical fibers.

3.3 Device Layer

The device layer primarily consists of various types of instrumentation in the field, such as industrial sensors (pressure, temperature, flow rate, liquid level, etc.) and actuators, for data acquisition and information interaction with the PLC. The device I/O signal numbers are listed in Table 2.

Each field device is controlled remotely from the control room to minimize the workload of field personnel and to achieve a higher level of automation. Local manual control can be used when equipment requires maintenance or incident handling. Most devices communicate with PLCs through 4–20 mA signal lines. The temperature sensor and some valve positioners use PROFIBUS-DP protocol. The communication protocols used by each device is shown in Fig. 3.

Instrument Selection. At present, we have completed the selection and procurement of most of the instruments, as shown in Table 3.

Temperature Monitoring

A number of temperature sensors are installed in the DATF cryogenic system. In order to reduce the communication and calculation in the PLCs, we choose LAKESHORE 240-8P as temperature monitoring [4]. The CERNOX sensors are connected to the 240-8P modules in the corresponding control cabinet, and then the 240-8P modules communicate with the PLC controllers through the PROFIBUS -DP protocol.

Valve Positioner

The valve positioners used in radiation environment require special protection. We choose Siemens SIPART PS2 as the valve controller. Each module communicates through PROFIBUS-PA protocol, which needs to be converted to PROFIBUS-DP protocol through a DP/PA Coupler and then communicates with the PLC.

3.4 Interfaces

PLC to EPICS IOC

In this project, the s7nodave driver based on Asyn and libnodave is selected to implement the communication between Siemens PLCs and EPICS IOCs. The driver and the PLCs exchange data via the ISO-TCP protocol. In this process, the EPICS records specify the memory address in the PLCs and the driver uses the ISO-TCP protocol to read or write the channel data [5].

PLC to Other Accelerator Subsystems

The PLCs and the master computer are connected through the switch in the main control cabinet via an optical fiber. The PROFINET protocol is used to enable communication between the accelerator main control system and the cryogenic test facility control system. The local control of the cryogenic system realized by the PLCs is all done by the control system of the DATF cryogenic system. The cryogenic control system uploads the data to the EPICS network, and other subsystems of the accelerator can be extracted through the EPICS network if they need the data of the cryogenic system.

4 Conclusion

Up till now, the control system for the DATF cryogenic system is being designed and built. The hardware design has been completed, and the software design is in progress. The programming of the PLC side will be realized in the TIA Portal software, and the interface design and alarm display in the supervision layer will be implemented in the WINCC software. According to the project plan, the commissioning of the DATF Cryogenic system will be taken place in early 2023.

References

Sun, Z., Huang, L., Shi, X., Wang, X.L.: Conceptual design of DALS test facility cryogenic system. CEC.ICMC (2021)

Pezzetti, M.: Control of large helium cryogenic systems: a case study on CERN LHC. EPJ Tech. Instrum. 8.1 (2021)

Geyang, J., et al.: The cryogenic control system of SHINE. EPJ Tech. Instrum. 8.1 (2021)

Mattison, K., Boyes, M., Cyterski, M., Fairley, D., Lam, B.: LCLS-II cryomodule and cryogenic distribution control. In: International Conference on Accelerator and Large Experimental Physics Control Systems, Barcelona (2017)

s7nodave Device Support for EPICS website, https://oss.aquenos.com/epics/s7nodave/

Acknowledgments

The project is supported by the Dalian Municipal Government. The authors would like to express our gratitude to Prof. Guy Gistau Baguer and John Weisend II for their constructive comments and advices throughout process. We are also grateful that staff from IHEP, IASF and SHINE for their very valuable knowledge and experiences by hosting our visits or video meetings.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 Zhejiang University Press

About this paper

Cite this paper

Xu, L. et al. (2023). Architecture Design of Control System for the DALS Test Facility Cryogenic System. In: Qiu, L., Wang, K., Ma, Y. (eds) Proceedings of the 28th International Cryogenic Engineering Conference and International Cryogenic Materials Conference 2022. ICEC28-ICMC 2022. Advanced Topics in Science and Technology in China, vol 70. Springer, Singapore. https://doi.org/10.1007/978-981-99-6128-3_130

Download citation

DOI: https://doi.org/10.1007/978-981-99-6128-3_130

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-6127-6

Online ISBN: 978-981-99-6128-3

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)