Abstract

Whey has been the most significant part of dairy waste till date and accounts for immense attention from researchers, academicians and scientists for its meaningful utilization. Whey obtained from cheese and paneer industry can be used in different manner to bring healthier and wonderful tasting products on the shelves of upcoming modern supermarkets. Nutritionally dense with vital minerals, whey can be utilized as a major base material to add economy. Prudent choice of operations, technical throughput required and expanding market size to this entity would trigger the use of whey towards value-added products including a range of cheeses like Ricotta, Manouri, Mato etc. and whey powders, which are in increasing weights in the modern times. Not only this, considering enormous availability of lactose content and other benefits such as presence of minerals and organic acids, whey can also be successfully used to prepare thirst quenching beverages to offer a great opportunity in harnessing its nutritional benefits. These products with special reference to the cheeses and powders highlighted, hold a promising future in the years to come at a global platform owing to its product portfolio, nutritional benefits, easy availability and low cost. This chapter confers various aspects of whey from its origin to utilization and production of products employing novel technologies.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

11.1 Introduction

Worldwide, milk production and processing have grown at a tremendous high rate, achieving a value of more than 10% every 4 years (FAOSTAT, 2017). Compared to 2018–2019, it has increased by 5.70% according to the survey done by GOI (Anonymous, 2021). A major chunk of total milk produced globally (more than 801 million tonnes), a hefty per cent is diverted (37%) to make cheese and other coagulated products, whereas a share of 30% is contributed by butter to meet the consumers’ demand. The figures also illustrates that only 10–20% of the milk fraction in terms of total solids is processed as the desired end-result during processing of various dairy-based commodities, while 80–90% of the liquid portion emerges is a liquid, referred as whey (Panghal et al., 2018), which is a yellow-green colored liquid by-product. Riboflavin, often known as vitamin B2, is responsible for conferring whey its characteristic yellowish hue (De Wit, 2001). In other words, whey, a greenish yellow coloured, salty liquid obtained from curd during the production of chhana, paneer, and cheese, is nutritional reservoir of many elements. It is a nourishing by-product including beneficial components counting lactose, proteins, minerals, and vitamins that are vital for human nutrition. In addition to making up 45–50% of the total milk solids, 70% of the milk sugar (lactose), 20% of milk proteins, and 70–90% of minerals, and most significantly, nearly all of the water-soluble vitamins that were previously present in milk, goes in the whey. Additionally, whey contains beneficial proteins such as α-lactalbumin, β-lactoglobulin serum albumin (SA), immunoglobulins (IG’s), lactose, milk salts, and so on (Bankar et al., 2021). Since the benefits of using whey for humankind were so great, it was first used in the 1970s for whey baths to nourish the skin. Owing to rich nutritional competency, whey could be used in production of various food products mentioning whey-based cheeses, whey-based unfermented and fermented beverages, protein concentrates and powders of various ranges. Valorisation of whey is a prudent manner not only will bring economic fringe benefits over main products but also helps in utilizing the enormous production of whey from the dairy industries, leading to create its own commercial worth in billion dollars. The whey utilization is not only challenging due to its high Biological oxygen demand (BOD) and chemical oxygen demand (COD), but also a herculean task, visualising its enormous production, which also included its restricted direct discharge into rivers and use as animal feed (Divya & Kumari, 2009; Papademas & Kotsaki, 2019). Literature states the production of 9–10 L of whey, against 1 kg of cheese, (Jelen, 2003) which not only poses an alarming situation for the environment but also look for sustainable solutions in this field.

Though the recent trend has identified many novel products to be placed in the shelves of supermarkets, many strategic interventions are still to be seen to check its viability model. Although owing to its health advantages, it targets to people of all ages, including children and teenagers. It also aids in the treatment of certain illnesses, such as digestive tract conditions and bears a long history of treating urinary tract scaling, intoxication, and other skin-related illnesses with the finest results. Furthermore, significant concentration of amino acids (a.a) in the beverage makes it extremely beneficial for athletes. Known primarily as branched chain amino acids (BCAAs) naming isoleucine, leucine, and valine, when performing resistance training, these are the first amino acids used that are metabolised right into muscle tissues. Among them are lactoferrin, GSH, and glycomacropeptide (GMP). These elements, especially the beverage, can be used to test the iron content’s absorption capacity and, possibly, improve the GIT’s capacity to absorb iron (more helpful in infants and neonates). In addition to being anti-inflammatory and antioxidant, absorption of various vital minerals benefits older people who suffer from osteoporosis. Envisaging the limitless opportunities, whey has become the vital entity for its exploration in valorisation wherein endless products like cheeses (Bhatti, 2021), beverages (Otte et al., 2007), lactose powders, infant foods (Bozanić et al., 2014), food supplements (Marshall, 2004; Morris & FitzGerald, 2008), soups and drinks (Marshall, 2004) hold a promising future to cater the needs of modern consumer. Though valorisation of whey has been taken up many researchers in the recent past emphasising sustainable biorefining (Goyal et al., 2023); industrial high-value added products (Arshad et al., 2023); non-ionic biosurfactants (Semproli et al., 2023), biomass to vitamins and many more to mention. However, to limit the length of the chapter, herein we precisely limit our discussion to food and related products.

11.2 Types of Whey: Origin and Nature

The whey can further be separated into two kinds depending upon nature and origin associated, process opted for the production of main product and acidulants added. Acid whey results from acidification of milk at pH levels lower than 5.0 (paneer whey) while sweet whey is the resultant product of chymosin-induced milk coagulation which occurs at pH 6–7 (cheese whey) (Papademas & Kotsaki, 2019). Characteristically, sweet whey is the waste product resulting from the production of cheeses including both hard and semi-hard cheeses, such as Cheddar cheese whereas acid-whey is produced as an end- product of various fermentation processes during fresh acid-coagulation processes, counting fresh cheeses such as Cottage cheese or direct acidification of milk which is undertaken during production of casein and caseinates. These type of products leads to a whey having a pH of about 4.6–5.0 (Tunick, 2008). Although both kinds of whey contains an equal amount of protein i.e. 11–13.5%. However, the former contains more amount of lactose content mentioning almost 63–75%. Therefore, presently cheese whey is most commonly used commodity in the food industry having a pH around 5.8–6.3 (Pouliot, 2008). The total composition of both kinds of whey has been compared and shown in Table 11.1. Whey contains beneficial proteins such as α-lactalbumin (LA), β-lactoglobulin (Lg) serum albumin (SA), immunoglobulins (Ig’s), lactose, milk salts, and so forth (Bankar et al., 2021). Apart from this, whey produced or released after the production of whey-based cheeses such as Ricotta cheese are termed as second cheese whey (SCW), having low fat and protein content compared to primary whey.

11.3 Therapeutic Value of Whey

As mentioned earlier, whey has also been successfully applied for diarrhoea, bile disease, skin problems, urinary tract scales and some intoxication treatments. Such beverages are also often regarded as an excellent source of energy and vital nutrients for athletes because of the high amount of quality proteins and a high nutritional value. Additionally, Whey proteins are rich source of branched chain amino acid (BCAA’s), such as isoleucine, leucine, and valine. Unlike other essential amino acids (EAA), BCAA’s are metabolized directly into the muscle tissue and are claimed to stimulate muscle protein synthesis in combination with resistance physical exercises (Santos & Nascimento, 2019) and many such claims have also been verified.

Whey being rich source of various vital minerals exerts its critical role in specific functions including transmission of nerve impulses and muscular contractions owing to presence of potassium, depolarization of nerve or muscle causing relaxation and consequently its role in lowering blood pressure due to magnesium. Apart from this, calcium present in whey helps in maintaining alkaline tissue pH, with maintaining bone density, integrity of the cell wall and nerve impulses, whereas lactoperoxidase prevents the growth of iron-dependent bacteria. Presence of lactoferrin inhibits bacterial growth (including pathogenic bacteria) and fungi. Many vital vitamins are included in whey, including vitamins D, B2, A, B3, C, B5, B1 E, and B6 (Anirudh et al., 2022). These have also a proven role against obesity and muscle-protection during dieting process by inducing increased rate of thermogenesis and helps in preserving lean mass (Pal & Radavelli-Bagatini, 2013). Therefore, whey proteins are conferred to bestow many therapeutic values (Fig. 11.1) (Gupta & Prakash, 2017; Ranganathan et al., 2020, Mehra et al., 2021).

11.4 Present Status of Whey Production

Whey production is directly correlated with the production of cheese and paneer (Indian cottage cheese) in the global market and recently, the Indian cheese market had a worth around 71.3 billion in 2022 and is expected to rise by about 24.06% CAGR with a worth around 262.6 billion by 2028 (Anonymous, 2023). Between the 5 years of 2015–2020 only, it has grown nearly to 18% in the CAGR and it is anticipated to grow by 31% during the mentioned years. Globally almost 3000 cheese varieties are available in the commercial market, whilst only few i.e. around 40 to 45 cheese varieties are marketed in India (Anonymous, 2020). The cheese market in India developed at a CAGR of about 26% during the years 2014–2019 and this can be attributed to numbers of factors including addition of new variants like pepper, garlic, red chili flakes, and oregano to meet the different tastes and customer preferences in India (Anonymous, 2020). In the next 6 years, i.e., from 2017–2018 to 2022–2023, the overall cheese market in India is anticipated to reach a growth rate of around 20%. By the end of 2022–2023, it is predicted to attain over 100,000 metric tons of production registering CAGR of approximately 12%. The prevailing conditions of cheese market has demonstrated saturation in Europe and North America, forcing to explore new markets of developing countries such as Japan and Russia, including India.

Generally, cheese whey has a high nutritional value with 45–50% total milk solids (TMS), abundant amounts of lactose i.e. 70–80%, 9–20% proteins (particularly whey protein), 8–20% minerals, almost all of water–soluble vitamins which are found in milk, including minor components like hydrolyzed peptides of k-casein, lipids and bacteria on dry matter basis (Kinsella & Morr, 1984; Horton, 1995). Whey protein consists of four major protein fractions and six minor protein fractions. The major protein fractions including beta-lactoglobulin (about 65%), alpha-lactalbumin (about 25%), bovine serum albumin (about 8%) and immunoglobulin (about 2%), while the minor fractions include lactoferrin, lysozyme, lactoperoxidase and glycol macro peptides (Walzem et al., 2002; Marshall, 2004) and has a high Biological Oxygen Demand (BOD) value, ranging between 39,000 ppm and 48,000 ppm.

According to FAO (2020), there was 117 million tonnes of fresh whey produced worldwide in 2019 in which the European Union and the United States contributed a total of about 69% of this amount. The entire amount of whey produced increases by 1–2% annually. However, only less than 50% of this amount is consumed or utilized using various methods (Panghal et al., 2018). Currently, to valorize the whey, the commercial industrial scaling up the manufacturing process of products including production of lactose, dry whey, and whey paste (FAO, 2022). India produced over 1.3 million metric tonnes of whey in 2021, data validated by the Food Safety and Standards Authority of India’s (FSSAI). However, currently not a precise information could be fetched on whey production and wastage in India for 2022. Although the Indian government has started a number of programmes recently to encourage whey utilisation and decrease waste. For instance, the FSSAI introduced the “Eat Right Creativity Challenge” programme in 2020 to encourage the usage of whey in various food and beverage items. In addition, the government has given dairy producers and processors a financial aid to set up whey processing facilities and create infrastructure for its storage and transportation.

11.5 Impact on Environment and Economy

Since whey is regarded as a major pollutant and a by-product of dairy industry, carrying high BOD (40,000–60,000 mg/L) and COD (50,000 mg/L and 80,000 mg/L), the dairy industries are under pressure from the society to re-evaluate how this could be managed successfully without posing any serious threats to the environment. Also, a data illustrated that about 120 million tonnes of whey is produced each year all over the world, but only about half of that quantity is put to use in the manufacturing of products that are consumed by humans and animals alike (Nikodinovic-Runic et al., 2013). Lactose, the primary component of whey and accounting for 70–72% of the total solids, is the key factor contributing to the high BOD and COD values. According to estimates, 4000 L of whey might harm the environment in a similar way to 1900 people producing faeces (Papademas & Kotsaki, 2019). After an accident in 2008 where spilled acidic whey in water body in Ohio, caused the mortality of more than 5400 wild animals, most of which were fish. This established the fact of decline in the concentration of dissolved oxygen led to eutrophication, which ultimately led to the death of the animals. Dumping excess whey to the soil can also lead to a reduction in the redox potential of the soil and leads to the impaired soil nutrition, affecting decreased the productivity of the crops (Ghaly et al., 2007).

Whey is regarded as the dairy industry’s leading environmental contaminant in the absence of sustainable practises since it is frequently disposed of as wastewater and is connected to significant perils to the environmental. Henceforth, it is crucial to direct whey management towards a cost-effective and sustainable way of utilisation to direct its production into novel valuable products. This has two sides of the coin, firstly because the disposal of whey corresponds to a significant loss of prospective nutrients and energy, making it necessary to exploit and harness nutritional value of whey, while also mitigating the negative effects of disposal on the environment. Whey utilisation breakthroughs are contributing to the field of applied technology. The use of whey streams has been improved by membrane processes like ultrafiltration and nanofiltration, and fermentation techniques for turning whey into high-value added products, which have shown a promising route to the establishment of biorefineries. A great economical and sustainable alternative to employing whey for the production of more valuable goods is the simultaneous integration of many work units in one process, which lessens the environmental impact of whey (Zandona et al., 2021).

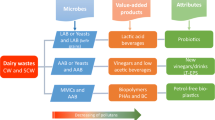

11.6 Way Towards Valorization: Green Era

It is noteworthy that over the course of the past several years, the dairy sector has introduced a range of technologies and procedures in order to process whey, and researchers and scientists are currently searching for a novel product portfolio that can be created utilising the by-product. Furthermore, it is possible to recover solid components from cheese whey employing a broad variety of separation processes, including hydrolysis, electrodialysis, ion exchange, nanofiltration (NF), microfiltration (MF), reverse osmosis (RO), and ultrafiltration (UF), amongst many others. However, when it comes to the processing of whey in dairy establishments, filtration is the foremost liked choice of manufactures (Pal & Nayak, 2016). Apart from this, simple physical and thermal treatments are not only cost effective but also acceptable for small-scale manufactures yielding acceptable results.

Data depicts that 45% of whey is used in its liquid form, whereas 30% as dried whey powder, 15% as lactose and various by-products and residual as whey protein concentrates (Kosseva et al., 2009; Panesar et al., 2007). Transformation of whey into valuable products derives its caption of “from gutter to gold” (Smithers, 2008). The extracted components are of high biological value and therefore carry a significant importance in healthcare supplements, confectionary and bakery and infant products (Minj & Anand, 2020).

Production of high protein products and recent innovation of these products for the synthesis of bioplastics have gained researchers attention. Many researchers have pointed out valorization of whey using microbial sources involving bacteria’s, yeasts and fungi (bioprocesses) for bioremediation processes, production of bioactive peptides, bacteriocins, including enzymes, bio-alcohol, and many more (Chourasia et al., 2022).

11.7 Value-Added Dairy Based Products

11.7.1 Whey-Based Beverages

Given its benefits, whey protein (WP) has gained popularity as a source of nourishment in number of products, including whey protein beverages. These can be divided into four categories (Chavan et al., 2015) namely—Mixtures of whey (processed or unprocessed, including permeates utilized from the ultrafiltration processes) with fruit or (rarely) juices derived from vegetables; thick or viscous beverages of dairy origin (fermented or unfermented); Thirst-quenching beverages with impinged carbonation; and alcoholic beverages or also termed as fermented beverages (Chavan et al., 2015).

However, for the convenience, these can be broadly classified as fermented or unfermented beverages and their nutritional comparison and sensory acceptability can be assessed.

11.7.1.1 Whey-Based Fermented Beverages

Presence of enormous amounts of lactose makes the prepared whey beverages perishable and vulnerable for microbial attack and proliferation, owing to which some fermented techniques could be opted to extend the life of such beverages. For this range of yeasts and lactic acid bacteria (LAB) could be harnessed to prepare innovative and shelf-stable drinks. Some strains are also reported to degrade β-lactoglobulin, which is otherwise present in whey-based products and is known for its allergenic behaviours in some people (Pescuma et al., 2011). Various reasearchers have explored the possibility of using L. acidophilus CRL 636, L. delbrueckii subsp. bulgaricus CRL 656, and S. thermophilus CRL 804, as single or mixed (SLaB) cultures in conjugation with WPC 35, to limit available lactose or protein using microbial fermentations in preparation of functional drinks (Pescuma et al., 2010). The fermentation not only exhibited decreasing β-Lg, but also demonstrated increased amounts of BCAA during storage.

Not only this, whey can also be successfully converted into low alcohol or acetic acid beverages, producing novel food commodity utilizing the bioconversion ways to tackle waste management. Since lactose is the fermentable sugar present in abundance quantities in whey, it can be used to prepare alcoholic beverages with varying alcohol content ranging with low (≤ 1.5%) alcohol content, to name—whey beer and whey wine. Production of beverages involves the technology of deproteinization of whey, concentration of whey, or fermentation of lactose employing various strains including some mentioned strains of yeast such as K. fragilis and S. lactis (Jelicic et al., 2008). Also, whey permeate from UF has been employed to prepare alcoholic beverage using Kluyveromyces fragilis (Parrondo et al., 2000).

Tofu whey has also been evaluated in this context, bringing 6–7% (V/V) ethanol in the final product utilizing yeasts for the same (Chua et al., 2017). In many researches natural juice along with source of fermentable whey were used together to bring out a novel product. For instance, apple juice with whey were used in combined format to prepare fermented beverage using kefir grains. Different ratios of kefir grains with varying temperature were studied and it’s on beverage properties was determined, demonstrating increasing high acidity, an increased kefiran concentration, lactic acid amount, viscosity, a higher lactobacilli and yeast population resulting from increasing concentration of kefir grains (Sabokbar et al., 2015). Herein new category i.e. carbonated whey drinks also emerged as a wonderful option to supplement taste with health wherein hydrolyzed lactose whey was utilized with herbs and sugar additives. Adding Fizz in the drinks not only attracts kids but also gives a tingling sensation, which is liked by one by all. In addition, carbonation is least expensive, safe apparently has no effects on dairy products (Paula, 2005). To add carbonation effect, Carbon dioxide was introduced and resulted in more acceptability. However, in few of the tested trials, whey beverages with incorporated lemon, green tea and peppermint extracts were found more acceptable (Mabrouk & Gemiel, 2020). Some other studies involving carbonation includes use of orange juice and whey (Pareek et al., 2014); guava whey beverage (Singh et al., 1999); probiotic functional carbonated beverage (Silva E Alves et al. 2018), carbonated feta cheese whey beverage (Jairath et al., 2012); carbonated flavoured Mozzarella-whey drink (Sameen et al., 2013). In some cases naturally developed carbonated drinks aided with the help of bacterial and yeast cultures (Kadyan et al., 2021) could be employed to prepare desirable carbonated drinks (Chilana et al., 2015; Kaur et al., 2018).

Another wonderful category in this classification stands apart with the remarkable feature of fermented though probiotic beverage based on acid-whey (Skryplonek et al., 2019). Probiotic strains of L. acidophilus LA-5 or B. animalis ssp. lactis BB-12 were tested in pasteurized acidic whey with UHT milk, unsweetened milk and SMP. Results proved the efficacy of beverage made with whey, condensed milk and L. acidophilus in sensory results over other tested combinations. Similarly, various functional fermented whey beverages were reported using different strains (Jitpakdee et al., 2022) and probiotic in combination with different fruit juices or milk (AbdulAlim et al., 2018; Bulatovic et al., 2014; Nursiwi et al., 2017; Rosa et al., 2023). Such beverages have been clinically proven to confer anti-obesity effect in animal model (Hong et al., 2015) and a source of biological active peptides (Rosa et al., 2023).

11.7.1.2 Whey-Based Unfermented Beverages

Various researchers have proven the fact that it is utmost necessary to optimize beverage formulation to get the best sensory profile of the drink (Djuric et al., 2004). Therefore, for the utilization of acid and sweet rennet whey-based fruit beverages, the side effect of precipitation of proteins during thermal treatment, which renders it unacceptable to the consumer, must be compromised or taken into attention (Ryan & Foegeding, 2015). However, in few cases, like Ricotta Cheese Whey (RCW), the secondary cheese whey, being low in protein content was demonstrated to be successfully used for the preparation of clear whey-based beverages (Rizzolo & Cortellino, 2018). Such RCW-based fruit beverages would have many health benefits such as muscle health, helps to burn fat, maintain blood sugar levels, energy production, strengthen immune system, and maintains a healthy heart (Anoymous, 2019).

The storage stability of such beverages stands at prime position for its wider acceptability wherein Cortellino and Rizzolo (2018) also conducted a study to analyze storage stability of novel functional beverages prepared from RCW with addition of fruit juices. The researchers concluded that storage days influenced the stability of total monomeric anthocyanins and a life of 150 days has been reported by the authors at −30 °C while pasteurized drink carries a life of 15 days at ambient temperature. Although whey can be added with variety of juices and purees at varying ratios, studies have demonstrated that it does not go well with much acidic options like oranges comparing with milder options such as pear, apple and peach (Djuric et al., 2004). Other references related to whey-based beverages could be cited at Singh et al., 1999; Rohit et al., 2020).

Whey-based beverages can also be a wonderful source of electrolytes and served as sports drink. According to Resolution no. 18 (09/27/2010), an electrolyte drink is a product designed to help hydration and must have minimal prescribed levels of sodium, potassium, and carbohydrates (Valadao et al., 2016). Various researchers have reviewed the importance of whey in formulation of sports drink carrying specific electrolyte balance, necessary to keep an optimal balance of salts (Anirudh et al., 2022). In addition, adding juice to prepare so, not only improves the sensory acceptability but also is a source of antioxidants.

Whey has also been used in conjugation with various herbs to prepare functional beverages carrying benefits of thirst-quenching properties and aiding health benefits of herbs side by side in one go. Various such reported studies signified the use of whey for the people who wish to manage their weight (Kanchana et al., 2020).

Maya and Ritu (2016) developed a herbal beverage based on guava juice, flavoured with various herbs including basil, mint, ginger, aloe vera, lemon grass, etc., using stevia as a natural sweetener. According to the study, the beverage with 74%, 20%, and 6% of whey, guava juice, and ginger, respectively had the highest sensory rating. Fruits including papaya leaf extract based therapeutic whey beverage was prepared using natural setvia (Singh et al., 2021). Similarly, whey-based banana herbal beverage was developed conferring 15 days shelf-life (Yadav et al., 2010). Different fruits such as apple with jaljeera extract (Sharma et al., 2019); mango with ginger extract (Alane et al., 2017); kokum-honey whey beverage (Terde et al., 2022) etc. In some studies, mixed herbal whey combining benefits of two entities was also taken into consideration, for instance, beverage containing pineapple and bottle gourd in whey (WPBH) had been formulated (Singh et al., 2013). A comprehensive list of few studies on varied areas has been made in Table 11.2, demonstrating that whey can be used in various modes and its implied usage could be harnessed at many places.

11.7.2 Whey-Based Fermented Dairy Products

Whey based fermented dairy products majorly includes cheeses of wide ranges including, Ricotta, Manouri, Mato, Urda, Anari and many more to mention including 28 total various types. According to the Codex Alimentarius (2010), whey cheeses are solid, semi-solid, or soft products which are principally obtained through either of the following processes: (1) the concentration of whey and the molding of the concentrated product or (2) the coagulation of whey by heat with or without the addition of acid’. Due to large amounts of lactose in the whey, the resultant cheese often exhibits yellowish to cookie colour accompanied by sweet or sometimes cooked or caramelized flavour (Bozanic et al., 2014). However, inclusion of milk, cream, or whey while heat precipitation or acidification lowers the overall lactose content and results in white to yellowish cheeses.

Depending upon the whey type, whey cheeses can be prepared wherein further membrane technology plays a pivotal role. The inclusion of membranes enables the fractionalization of whey components required to be retained in the resultant cheese. The general methodology includes heating to 88–92 °C while stirring, wherein rate of stirring and time of attaining the required temperature are critical factors mostly dependent upon the variety to be produced (fresh or dried whey cheese). In most of the fresh whey cheese production, generally lower temperature is employed whereas higher is often desirable for dried whey categories (Bintsis & Papademas, 2023).

Similarly, Ricotta cheese (RC) has also been utilized in production of functional product to combat various nutritional deficiencies as a source of fortification. Nzekoue et al. 2021 analysed the suitability of RC as a base to supplement vitamin D, exhibiting it a wonderful source of proteins (7.8 g/100 g) with good amount of BCAA’s (1.8 g/100 g). It indicated that 50 mg of supplemented vitamin D3 to a total cheese quantity of 95 kg resulted in a mean fortification level of 41.4 ± 4.0 μg/100 g of ricotta cheese, indicating an ideal alternative for vitamin D3 fortification.

Cheese whey or deproteinised cheese whey (DCW) has been identified as a substratum for production of acids or kefir-like beverages or traditional milk kefir. Changes in lactose amounts, consequent production of ethanol accompanied by various biochemical and physico-chemical changes, including production of volatile compounds have been noticed analyzing this potential dairy waste (Magalhaes et al., 2011).

Not only nutritionally superior whey cheeses can be prepared from this valuable entity, but also the whey cheeses have been recognized as source of Glycomacropeptide (GMP) in management of PKU (Ney et al., 2009). Authors reported low Phenyl alanine (2.5–5 mg/g protein) in cheese whey (CW) indicating it as an excellent palatable source of protein, improving necessary dietary compliance required for Phenylketonuria (PKU) patients. Another breakthrough involves fermentation of cheese whey in production of organic acids, single cells proteins and oils and bacteriocins (Mollea et al., 2013). Synthesis of galactooligosaccharides (GOS) using enzymes offers another wonderful opportunity of using whey as a substrate (Fisher & Kleinschmidt, 2015), which have critical role to mimic infant foods.

11.7.3 Whey-Based Protein Rich Products

Whey proteins are generally highly-valued commodity and available in a variety of forms, comprising whey powder containing 8–12% protein and more than 70% lactose; Whey Protein Concentrate (WPC), a product with between 30% and 89% protein, and Whey Protein Isolate (WPI), having over 90% protein and nearly no lactose (about 3%) (Boscaini et al., 2023).

While preparing WPC and WPI, whey proteins might get denaturized, which tends to impair their functionality. The most widely used methods for pre-concentrating whey in the manufacturing of WPC and WPI are UF and/or DF, along with a few other membrane processes including Nanofiltration (NF), Reverse Osmosis (RO), Electrodialysis (ED), and Microfiltration (MF). The concentrated whey using the UF/DF process, is then pasteurised, evaporated, and dehydrated to create WPC or WPI (Panghal et al., 2018). Currently, production of WPC and WPI has been considered best amongst available approaches to valorize whey into fruitful value-added product. The quality characteristics of the prepared products depend upon many variables, counting physic-chemical composition type of milk used, and the environment where cheese is manufactured. The functional qualities of these products are significantly influenced by processing conditions, such as thermal treatments, pH, and the type and amount of salts present (Pelegrine & Gasparetto, 2005). Methods like use of freeze concentration for enhanced recovery of protein and lactose has been advocated by Lamkaddam et al., 2023.

11.7.3.1 Whey Protein Concentrates (WPC)

Whey protein concentrates derived from the first generation had protein content as low as 30–40% with high quantities of lactose, fat, and undenatured proteins. It is the most concentrated type of protein supplement available, loaded with calories, containing every macro- and micronutrient obtained during production. It can, however, come in a variety of forms depending on the protein concentration, such as a WPC of 35, 50, 65, or 80% (w/w) protein (Minj & Anand, 2020). Nowadays concentrates include between 70% and 80% more protein and less lactose. Ultra-filtration processing is the method employed to accomplish the elimination of lactose to improve the final product’s protein and fat contents. Such equipment is expensive, and prevents small- and medium-sized dairy firms from adopting the technology (Carter & Drake, 2018). The final drying phase involved in the manufacture of WPC is carried out by employing freeze or spray drying (Carter et al., 2018). WPC incorporation improves the nutritional value of healthy drinks, meal bars, supplements, baby foods, processed cheese, meat or fish products, and feed rations (Arab et al., 2023). WPC can also be used in salad dressings as an emulsifier. Addition of WPC has demonstrated high firmness and stability in the salad dressings, along with bestowing good emulsifying capabilities (Kotoulas et al., 2019). Modernization in technology to produce instant powder enables this protein to have increased functional capabilities that offer certain performance qualities such as instantized WPC 80% may be quickly dissolved in liquids with hand stirring or shanking, unlike high protein powders that require an electric blender to dissolve (Guo & Wang, 2019).

11.7.3.2 Whey Protein Isolates (WPIs)

Whey protein isolate (WPI) is referred as when the majority of the components have been eliminated, or when the whey has undergone an additional purification step to eliminate or reduce the unnecessary carbohydrates and lipids to achieve a protein threshold of 90% (w/w). It is also the purest form of whey protein currently accessible and& contain over 90% protein, little to no milk sugar (lactose), and nearly no fat, making it a beneficial source of protein for those who cannot consume lactose due to any underlying reasons (Carter & Drake, 2018). Despite being a high-quality protein, whey protein isolate has the drawback of losing some essential micronutrients and protein fractions such as lactoferrins, lactoglobulins, and immune-globulins during the purifying process (Minj & Anand, 2020). Due to the product’s purity and higher protein content, WPI cost a little more than a WPC. Adsorption techniques like ion exchange chromatography, which offers an supplementary level of selectivity on the utilisation of membranes, can also be employed for WPI manufacturing. The final product prepared so carries more economic worth and it has better functional qualities than WPC (Foegeding et al., 2002).

Concentrates and isolates have a wide array of applications in many sectors especially predominate in food supplies, due to their extraordinary high protein content and can also function as water-binding, gelling, emulsifying and foaming agents. It is also believed to be more compatible with other associated ingredients keeping in mind its origin and perception of being natural (Solak & Akin, 2012). Due to its low lactose and fat content, WPI is appreciated by bodybuilders and athletes who follow a rigorous diet. WPC, on the other hand, is more affordable and frequently utilised in food products. WPI is easily digested and absorbed by the body, but WPC is a good source of BCAAs (Sharma et al., 2022).

11.7.4 Lactose Powder

The main source of calories in milk is lactose (O-β-d-galactopyranosyl-(1–4)-β-d-glucopyranose), which is also the primary sugar present in milk. While most mammals produce milk containing lactose, there are a few exceptions such as sea lions and walruses that produce lactose-free milk. Lactose is also the primary source of nutrition for new-borns (Dominici et al., 2022). The udder of cow synthesizes lactose by absorbing blood glucose through the basal membrane of mammary epithelial cells. During lactation, a dairy cow converts around 20% of its circulating blood glucose into lactose (Costa et al., 2019). Lactose is characteristically found in dairy products such as yoghurt, milk, butter, ice cream, and cheese. Some breads and baked foods, ready-to-eat breakfast cereals, instant soups, confectionery, biscuits, salad dressings, sausages, gravy, drink mixes, and margarine may also contain lactose, which is often referred to as ‘hidden lactose’ (Facioni et al., 2020). Additionally, over 90% of the lactose is found in the whey and it must be separated from whey. Filtration is the most widely used technology in the milk processing sector for removing lactose from whey due to its high quality-to-cost ratio. Lactose separation is carried out using several membranes with varying retention efficiencies: ultrafiltration (40%) and nanofiltration (>90% lactose retention) (Costa et al., 2019). In contrast to the permeate, which contains the bulk of the lactose and mineral salts, whey protein concentrate (WPC), the retentate following membrane filtering, contains the majority of the protein part (Illanes et al., 2016). Crystalline α-lactose monohydrate and β-crystalline anhydrous lactose, which is largely made of beta-lactose, are the two different forms of lactose. Other lactose forms include different polymorphic variations of the alphalactose molecule, as well as amorphous forms created by either quickly drying a lactose solution or grinding lactose. (Hebbink & Dickhoff, 2019).

11.7.4.1 Production of Lactose

11.7.4.1.1 Concentration

The permeate is generally pre-concentrated using reverse osmosis, and preconcentration combined with partial demineralization can be accomplished by the use of nanofiltration in some circumstances, leading to the development of a super saturated solution, this stage is typically carried out after evaporation (Cassano et al., 2019).

11.7.4.1.2 Crystallisation

Lactose crystallisation is an extremely complex procedure. Diffusion of lactose molecules to a crystal’s surface takes place during this process. When whey is supersaturated or nuclei are added with the intention of inducing crystallisation, the crystallisation process takes place spontaneously. The primary objective of crystallisation is to create a lot of crystals that are proportionately similar in size (average diameter of 0.2 mm), allowing for efficient separation (Sunkesula, 2020).

11.7.4.1.3 Recovery

Decantation or continuous centrifugation are two methods for recovering lactose crystals. Crystals are only separated while utilising continuous centrifuges; however, when employing decanters, crystals are additionally cleaned with new, clean water. Separation and rinsing are consequently carried out concurrently. Since lactose recovery from the mother liquor, which contains the majority of the minerals and around 20% of the lactose, is undesirable in the absence of preceding demineralization, it is discarded (Kravtsov et al., 2021).

11.7.4.1.4 Drying

Lactose crystals that initially contained 5–12% moisture are finally reduced to 0.1–0.5 g/100 g of water, and the dried powder is then referred to as “crude” lactose after being treated to drying in fluidized-bed, vibration or flash dryers at a temperature of 70 °C. It is undesirable to have a thin layer of amorphous lactose grow on top of the crystals of α-hydrate if the drying procedure is carried out too quickly (Portnoy & Barbano, 2021). The rest of the technological operations, involed in lactose powder such as milling, sieving and/or packaging resembles skim milk powder manufacturing.

11.7.4.1.5 Purification

Additional refinement may be required depending on its intended purpose. Pharmaceutical-grade lactose must be refined, whereas food-grade lactose doesn’t require polishing. It involves the re-dissolution of the lactose crystals, recrystallization of the lactose, and treatment of the solution with activated carbon to remove various solutes from the combination, including riboflavin. In addition, adding acids (such HCl) can occasionally be necessary to regulate the acidity, dissolve salts, or denature any leftover proteins. After obtaining a clear lactose solution, neutralisation, sedimentation, and filtration are performed (Durham, 2009).

11.7.4.2 Applications

There are numerous potential uses and applications of lactose. The inclusion of lactose in products for the diabetic population is one of these applications because lactose is a source of energy which is absorbed more quite slowly than sucrose (i.e., has a moderate glycemic index and lesser than the one of sucrose; 45 versus 65) and allows the concentration of blood sugar to rise gradually (Hebbink & Dickhoff, 2019). It is often utilised as a food ingredient in the food industry for dairy, bread, snacks, confectionery, and other foods and dietary products. In the field of food and beverages, lactose performs a number of functions, such as acting as a free-flowing agent, a non-hygroscopic transporter in dry blends, an absorbent and booster of flavours and colours, an ingredient that contributes to the development of colour and flavour through the maillard browning reaction, an alternative for other low calorie sweeteners as a source carrying low sweetness and a natural source of carbohydrate and energy in infant formulas (Rocha & Guerra, 2020).

Due to its physical and chemical characteristics, including chemical inertia, stability, and non-toxicity, as well as its reasonable pricing, lactose is one of the most widely used ingredient in the pharmaceutical business (Dominici et al., 2022). Given the lactose powder’s organoleptic properties—namely, that it is white, odourless, and pleasant tasting—its acceptability as a component in medicinal formulations is noteworthy. Lactose is a versatile excipient that can be used in a variety of pharmaceutical formulations. It is present in 6% of over-the-counter drugs and 20% of prescription medications. In tablets, lozenges, capsules, and powder for intravenous injections, for example, lactose can be employed as a diluent (Zdrojewicz et al., 2018).

11.7.5 Infant Foods

Mother’s milk is the best natural food available for nourishing infants. However, alternatives are occasionally required when the milk from the mother is inadequate or inaccessible. Infant foods are taken into consideration in such situations so as to fulfil the neonatal body care. They are segmented into five stages.

Infant formula (IF) is the name given to stage one meal, which is intended for new-borns between the age of birth and 6 months. Stage 2, or follow-on formula (FOF), is advised for infants between the ages of 6 months and 12 months. Due to the fact that newborns start eating other things (which include cereals, vegetables and fruits etc.), stage 2 formulae have a somewhat lower energy density than stage 1 formulae. Products which are for stages 3–5 are aimed at young children and babies between the ages of 1 and 3; 3–6; and older than 6 years old whereas Growing-Up Milk (GUM) is the principal product category for the higher phases (Happe & Gambelli, 2015). In this chapter, authors will be focussing on dairy-based infant formula.

The use of infant milk formula products is now considered indispensable towards ensuring adequate nourishment for young children today. Typically found in powdered form varieties, these formulas aim to recreate the nutritional profile which includes macro as well as micro-nutrients found in human breast-milk upon reconstitution (Masum et al., 2021). Infant formula refers specifically to a specially engineered food item that primarily uses milk as its main ingredient. Infants and young children under the age of one are its intended consumers. Key ingredients used during formulation include lactose, whey protein, casein powder, whole/non-fat milk powder supplements along with plant derived vegetable oils (Ackerman et al., 2017).

A key aspect of manufacturing ideal infant formula is achieving a balanced combination of approximately whey/casein ratio of 60:40. The preferred method involves incorporating demineralized whey alongside WPI or WPC with cow milk/milk powder blends. Finalizing this stage requires introducing carefully calculated amounts of both lactose and vegetable oils to address any variances in fat content. Sticking to this fundamental approach ensures that the resulting baby formula offers consistent quality, mimicking the composition of human breast milk (Guo & Wang, 2019). In infant feeding, lactose is also employed as a carbon source to help prevent the formation of pathogenic and dangerous bacteria while promoting the development of beneficial microbiota (Rocha & Guerra, 2020). Beyond their nutritional advantages, lactose-containing carbohydrates aid in the drying process, improve the physical and chemical characteristics, and enhance the handling attributes of dairy powders, which include fat and protein. Crystalline and amorphous lactose are both possible components of IF powders, with amorphous lactose being more common (Saxena et al., 2021). In some formulations, maltodextrin may occasionally be used to replace lactose (partially), and IF products may additionally contain galacto- or fructo-oligosaccharides (GOS) or fructose-oligosaccharides (FOS) (Masum et al., 2020). Differences may be seen depending on the amount of whey protein hydrolysis when working with IMF powders which include either partially or completely hydrolyzed whey protein. However, IMF powders usually have from 10% to 15% of their entire composition as protein (Kelly et al., 2016). In addition to this, presence of β-Lg could be a concern for infant foods wherein use of High pressure processing (HHP) could as a medium to enrich whey protein in α-La from bovine native whey concentrate (Romo et al., 2023). Authors documented the use of 600 Mega Pascal for 4 min at 23 °C for enrichment with α-La for this membrane- mediated separation.

11.8 Future Trends and Challenges

The unique nutraceutical properties of some whey components hold the key to the future of whey beverages and would bridge the gaps between circular economy. In addition, in the quest of sustainability whey valorisation is definitely necessary to bring novel products into the market and gearing with management issues. Although number of processes and approaches are in-line to valorization, many newer innovative and novel commercial processes are to be sought, visualizing ever-increasing production of this waste, alongside the economical and sustainability challenges. Integration of two or more flexible systems (physical, chemical, and/or biological processes) could be exploited to harness better recovery of desirable components and consequently fiscal benefits and to attain zero-waste approach within the milk industry (Asunis et al., 2020, Barba, 2021). Furthermore, the untapped potential of this waste in production of biofuels, organic acids, edible films and bioplastics as packaging materials is another area, which requires considerable attention to explore its hidden treasure. Although whey based beverages of various genre presents a considerable area of consumer acceptance, techniques like use of hydrolyzed whey (for calorie conscious segment), carbonation is adding more avenues for its further liking.

The new waste framework Directive (WFD, Directive/2008/98/EC), which is the basis for the current trend set forth by the European Commission, emphasises primarily on the prevention of waste creation, with a later focus on reuse, recycling, and recovery, and disposal given the least priority (Buchanan et al., 2023). It is essential that waste management approaches continue to be productive, profitable, and sustainable because the current processes present numerous problems with regard to waste management and the recovery of various profitable components (Roufou et al., 2021). Although much research has been done on the beverage made from whey, it has not yet been implemented or made widely available. Whey-based goods encounter a number of obstacles, including the availability of a variety of products in the market, consumer awareness, tiny industries, low levels of production at units, and competitiveness with other products (Panghal et al., 2018), which needs immediate scientific interventions.

11.9 Conclusions

The expected increase in dairy products by 2050 directly indicates the production of whey from the dairy industries, leading to a thought to valorize it prudently. Although such products have good expected acceptance in the market, still a careful research has to made for widely acceptable products. Also, modern value added whey-based products not only carries enhanced sensory properties but also impart nutrition compared to conventional sugary carbonated beverages, which further has a scope to expand the area employing advanced techniques such as carbonation, freeze concentration, deproteinization of whey etc. Production of such products not only adds variety to the table, but also helps in meeting the goals of sustainability and bridging the gaps of circular economy.

References

AbdulAlim, T. S., Zayan, A. F., Campelo, P. H., & Bakry, A. M. (2018). Development of new functional fermented product: Mulberry-whey beverage. Journal of Nutrition, Food Research and Technology, 1(3), 64–69.

Ackerman, D. L., Craft, K. M., & Townsend, S. D. (2017). Infant food applications of complex carbohydrates: Structure, synthesis, and function. Carbohydrate Research, 437, 16–27.

Alane, D., Raut, N., Kamble, D. B., & Bhotmange, M. (2017). Studies on preparation and storage stability of whey based mango herbal beverage. International Journal of Chemical Studies, 5(3), 237–241.

Alimentarius, C. (2010). Codex alimentarius commission. Toxicological evaluation of certain veterinary drug residues in food. Disponível em:<http://www.codexalimentarius.net/web/jecfa.jsp>. Acesso em, 28.

Anirudh, J., Dhineshkumar, V., & Sangeetha, T. (2022). Whey as crucial component in rejuvenating athlete health-a review. Journal of Postharvest Technology, 10(4), 135–155.

Anonymous. (2020). Global cheese market - statistics & facts|Statista, Accessed 1 May 2020

Anonymous. (2021). Economic Survey: Milk production rises by five percent to 198.4 million tonnes in 2019-20 - The Economic Times (indiatimes.com) Cited on 12.2.2023.

Anonymous. (2023). Indian Cheese Market Share, Size, Trends and Forecast 2023-2028 (imarcgroup.com). cited on 25.4.2023.

Anoymous. (2019). Ricotta cheese nutrition facts and health benefits. Ricotta Cheese Nutrition Facts and Health Benefits (verywellfit.com). Cited on 2.7.2019.

Arab, S. A., Kaemipoor, M., Alkhaleel, R., & Mahdian, A. (2023). Recent trends in developing whey products by advanced technologies. Scholars Academic Journal of Biosciences, 2, 74–79.

Arshad, U. E. T., Hassan, A., Ahmad, T., Naeem, M., Chaudhary, M. T., Abbas, S. Q., et al. (2023). A recent glance on the valorisation of cheese whey for industrial prerogative: High-value-added products development and integrated reutilising strategies. International Journal of Food Science & Technology, 58(4), 2001–2013.

Asunis, F., De Gioannis, G., Dessì, P., Isipato, M., Lens, P. N., Muntoni, A., et al. (2020). The dairy biorefinery: Integrating treatment processes for cheese whey valorisation. Journal of Environmental Management, 276, 111240.

Bankar, R., Desale, R. J., Bhosale, S., & Chougale, C. (2021). Storage study of bael & whey protein enriched nutritional whey beverage. The Pharma Innovation Journal, 10(8), 171–176.

Barba, F. J. (2021). An integrated approach for the valorization of cheese whey. Food, 10(3), 564–568.

Bhatti, G. S. (2021). In M. Krishikosh. (Ed.), Development of probiotic ricotta cheese with antimicrobial activity. Tech Thesis submitted to Guru Angad Dev Veterinary and Animal Sciences University.

Bintsis, T., & Papademas, P. (2023). Sustainable approaches in whey cheese production: A review. Dairy, 4(2), 249–270.

Boscaini, S., Skuse, P., Nilaweera, K. N., Cryan, J. F., & Cotter, P. D. (2023). The ‘Whey’to good health: Whey protein and its beneficial effect on metabolism, gut microbiota and mental health. Trends in Food Science & Technology, 133, 1–14.

Bozanić, R., Barukčić, I., & Lisak, K. (2014). Possibilities of whey utilisation. Austin Journal of Nutrition and Food Sciences, 2(7), 7.

Buchanan, D., Martindale, W., Romeih, E., & Hebishy, E. (2023). Recent advances in whey processing and valorisation: Technological and environmental perspectives. International Journal of Dairy Technology, 76(2), 291–312.

Bulatović, M. L., Krunić, T. Ž., Vukašinović-Sekulić, M. S., Zarić, D. B., & Rakin, M. B. (2014). Quality attributes of a fermented whey-based beverage enriched with milk and a probiotic strain. RSC Advances, 4(98), 55503–55510.

Carter, B., Patel, H., Barbano, D. M., & Drake, M. (2018). The effect of spray drying on the difference in flavor and functional properties of liquid and dried whey proteins, milk proteins, and micellar casein concentrates. Journal of Dairy Science, 101(5), 3900–3909.

Carter, B. G., & Drake, M. A. (2018). Invited review: The effects of processing parameters on the flavor of whey protein ingredients. Journal of Dairy Science, 101(8), 6691–6702.

Cassano, A., Conidi, C., & Castro-Muñoz, R. (2019). Current and future applications of nanofiltration in food processing. In Separation of functional molecules in food by membrane technology (pp. 305–348). Academic.

Chavan, R. S., Shraddha, R. C., Kumar, A., & Nalawade, T. (2015). Whey based beverage: Its functionality, formulations, health benefits and applications. Journal of Food Processing & Technology, 6(10), 1–8.

Chilana, H., Arora, S., Khajuria, R., & Kaur, L. (2015). Non-alcoholic, naturally-carbonated beverage from Vitis vinifera using saccharomyces cerevisae isolated from cheese whey. Online Journal of Biological Sciences, 15(3), 184.

Chourasia, R., Phukon, L. C., Abedin, M. M., Padhi, S., Singh, S. P., & Rai, A. K. (2022). Whey valorization by microbial and enzymatic bioprocesses for the production of nutraceuticals and value-added products. Bioresource Technology Reports, 19, 101144.

Chua, J. Y., Lu, Y., & Liu, S. Q. (2017). Biotransformation of soy whey into soy alcoholic beverage by four commercial strains of Saccharomyces cerevisiae. International Journal of Food Microbiology, 262, 14–22.

Cortellino, G., & Rizzolo, A. (2018). Storage stability of novel functional drinks based on ricotta cheese whey and fruit juices. Beverages, 4(3), 67.

Costa, A., Lopez-Villalobos, N., Sneddon, N. W., Shalloo, L., Franzoi, M., De Marchi, M., & Penasa, M. (2019). Invited review: Milk lactose—Current status and future challenges in dairy cattle. Journal of Dairy Science, 102(7), 5883–5898.

De Wit, J. N. (2001). Lecturer’s handbook on whey and whey products (p. 14). European Whey Products Association.

Dinkçi, N., Akdeniz, V., & Akalın, A. S. (2023). Probiotic whey-based beverages from cow, sheep and goat milk: Antioxidant activity, culture viability, amino acid contents. Foods, 12(3), 610.

Divya, & Kumari, A. (2009). Effect of different temperatures, timings and storage periods on the physico-chemical and nutritional characteristics of whey-guava beverage. World Journal of Dairy and Food Sciences, 4, 118–122.

Djurić, M., Carić, M., Milanović, S., Tekić, M., & Panić, M. (2004). Development of whey-based beverages. European Food Research and Technology, 219(4), 321–328.

Dominici, S., Marescotti, F., Sanmartin, C., Macaluso, M., Taglieri, I., Venturi, F., et al. (2022). Lactose: Characteristics, food and drug-related applications, and its possible substitutions in meeting the needs of people with lactose intolerance. Food, 11(10), 1486.

Durham, R. J. (2009). Modern approaches to lactose production. Dairy-Derived Ingredients, 103–144.

Facioni, M. S., Raspini, B., Pivari, F., Dogliotti, E., & Cena, H. (2020). Nutritional management of lactose intolerance: The importance of diet and food labelling. Journal of Translational Medicine, 18, 1–9.

FAO. (2020). Food and agriculture organization corporate statistical database. http://www.fao.org/faostat/en/#home.

FAO. (2022). Food and agriculture organization corporate statistical database. http://www.fao.org/faostat/en/#home

FAOSTAT. (2017). The future of food and agriculture trends and challenges., Www.Fao. Org/3/a-i6583e.Pdf (Accessed January 2018).

Fischer, C., & Kleinschmidt, T. (2015). Synthesis of galactooligosaccharides using sweet and acid whey as a substrate. International Dairy Journal, 48, 15–22.

Foegeding, E. A., Luck, P. J., Roginski, H., Fuquay, J. W., & Fox, P. F. (2002). Whey protein products. Encyclopedia of Dairy Sciences, 3, 1957–1960.

Ghaly, A. E., Mahmoud, N. S., Rushton, D. G., & Arab, F. (2007). Potential environmental and health impacts of highland application of cheese whey. American Journal of Agricultural and Biological Science, 2(2), 106–117.

Goyal, C., Dhyani, P., Rai, D. C., Tyagi, S., Dhull, S. B., Sadh, P. K., et al. (2023). Emerging trends and advancements in the processing of dairy whey for sustainable biorefining. Journal of Food Processing and Preservation, 2023, 6626513. https://doi.org/10.1155/2023/6626513

Guo, M., & Wang, G. (2019). Nutritional applications of whey protein. In Whey protein production, chemistry, functionality, and applications (pp. 141–156).

Gupta, C., & Prakash, D. (2017). Therapeutic potential of milk whey. Beverages, 3(3), 31.

Happe, R., & Gambelli, L. (2015). Infant formula. In Specialty oils and fats in food and nutrition (pp. 285–315).

Hebbink, G. A., & Dickhoff, B. H. (2019). Application of lactose in the pharmaceutical industry. In Lactose (pp. 175–229). Academic.

Hong, S. M., Chung, E. C., & Kim, C. H. (2015). Anti-obesity effect of fermented whey beverage using lactic acid bacteria in diet-induced obese rats. Korean Journal for Food Science of Animal Resources, 35(5), 653.

Horton, B. S. (1995). Commercial utilization of minor milk components in the health and food industries. Journal of Dairy Science, 78(11), 2584–2589.

Illanes, A., Guerrero, C., Wilson, L., Conejeros, R., & Scott, F. (2016). Lactose: Production and upgrading. In Lactose-Derived Prebiotics: A Process Perspective (pp. 1–33).

Iosca, G., Turetta, M., De Vero, L., Bang-Berthelsen, C. H., Gullo, M., & Pulvirenti, A. (2023). Valorization of wheat bread waste and cheese whey through cultivation of lactic acid bacteria for bio-preservation of bakery products. LWT, 176, 114524.

Jairath, S., Sahota, P., & Pandove, G. (2012). Preparation of non-alcoholic naturally carbonated beverage using yeast isolate from whey beverage. Czech Journal of Food Sciences, 30(2), 135–143.

Jelen, P. (2003). Whey processing. Utilization and products. In J. Fuquay, P. Fox, & P. McSweeney (Eds.), Encyclopedia of dairy sciences. Academic.

Jelicic, I., Bozanic, R., & Tratnik, L. (2008). Whey based beverages-new generation of dairy products. Mljekarstvo, 58, 257–274.

Jitpakdee, J., Kantachote, D., Kanzaki, H., & Nitoda, T. (2022). Potential of lactic acid bacteria to produce functional fermented whey beverage with putative health promoting attributes. LWT, 160, 113269.

Kadyan, S., Rashmi, H. M., Pradhan, D., Kumari, A., Chaudhari, A., & Deshwal, G. K. (2021). Effect of lactic acid bacteria and yeast fermentation on antimicrobial, antioxidative and metabolomic profile of naturally carbonated probiotic whey drink. LWT, 142, 111059.

Kanchana, N., Veeranan, A. G., & Vijayalakshmi, R. (2020). Development and evaluation of whey-based herbal beverages as health drink. The Madras Agricultural Journal, 108(1-3), 79–85.

Kaur, S., Bhise, S. R., Kaur, A., & Minhas, K. S. (2018). Development of naturally carbonated paneer whey fermented beverage blended with pineapple and strawberry juice. Nutrition & Food Science, 49(4), 528–547.

Kelly, G. M., O’Mahony, J. A., Kelly, A. L., & O’Callaghan, D. J. (2016). Effect of hydrolyzed whey protein on surface morphology, water sorption, and glass transition temperature of a model infant formula. Journal of Dairy Science, 99(9), 6961–6972.

Kinsella, J. E., & Morr, C. V. (1984). Milk proteins: Physicochemical and functional properties. Critical Reviews in Food Science & Nutrition, 21(3), 197–262.

Kosseva, M. R., Panesar, P. S., Kaur, G., & Kennedy, J. F. (2009). Use of immobilised biocatalysts in the processing of cheese whey. International Journal of Biological Macromolecules, 45(5), 437–447.

Kotoulas, A., Agathou, D., Triantaphyllidou, I. E., Tatoulis, T. I., Akratos, C. S., Tekerlekopoulou, A. G., & Vayenas, D. V. (2019). Second cheese whey treatment using zeolite under continuous flow mode and its application on wheat growth. Water, 11(5), 928.

Kourkoutas, Y., Dimitropoulou, S., Kanellaki, M., Marchant, R., Nigam, P., Banat, I. M., & Koutinas, A. A. (2002). High-temperature alcoholic fermentation of whey using Kluyveromyces marxianus IMB3 yeast immobilized on delignified cellulosic material. Bioresource Technology, 82(2), 177–181.

Kravtsov, V. A., Kulikova, I. K., Anisimov, G. S., Evdokimov, I. A., & Khramtsov, A. G. (2021). Variety of dairy ultrafiltration permeates and their purification in lactose production. In IOP conference series: Earth and environmental science. (Vol. 677, No. 3, p. 032001. IOP Publishing.

Lamkaddam, I. U., Vega, E., Colón, J., Ponsá, S., Llenas, L., & Mora, M. (2023). Progressive freeze concentration of cheese whey for protein and lactose recovery. International Dairy Journal, 139, 105572.

Mabrouk, A., & Gemiel, D. (2020). Chemical characterizations of carbonated whey beverages fortified with fruit juice and some herbs extract. Egyptian Journal of Food Science, 48(2), 377–388.

Magalhães, K. T., Dragone, G., de Melo Pereira, G. V., Oliveira, J. M., Domingues, L., Teixeira, J. A., E Silva, J. B. A., & Schwan, R. F. (2011). Comparative study of the biochemical changes and volatile compound formations during the production of novel whey-based kefir beverages and traditional milk kefir. Food Chemistry, 126(1), 249–253. https://doi.org/10.1016/j.foodchem.2010.11.012

Marshall, K. N. D. (2004). Therapeutic applications of whey protein. Alternative Medicine Review, 9(2), 136–156.

Masum, A. K. M., Chandrapala, J., Huppertz, T., Adhikari, B., & Zisu, B. (2020). Effect of storage conditions on the physicochemical properties of infant milk formula powders containing different lactose-to-maltodextrin ratios. Food Chemistry, 319, 126591.

Masum, A. K. M., Chandrapala, J., Huppertz, T., Adhikari, B., & Zisu, B. (2021). Production and characterization of infant milk formula powders: A review. Drying Technology, 39(11), 1492–1512.

Maya, D., & Ritu, P. (2016). Formulation of fruit (orange juice) and whey based beverages flavoured with different herbs using natural sweetener as stevia. International Journal of Scientific Research and Education, 4(10), 5975–5979.

Mazzaglia, A., Legarová, V., Giaquinta, R., Lanza, C. M., & Restuccia, C. (2020). Theinfluence of almond flour, inulin and whey protein on the sensory and microbiological quality of goat milkyogurt. LWT, 124, 109138. https://doi.org/10.1016/j.lwt.2020.109138

Meena, M. K., Arora, S., Shendurse, A. M., Sharma, V., Wadhwa, B. K., & Singh, A. K. (2012). Formulation optimisation of a whey lemon beverage using a blend of the sweeteners aspartame and saccharin. International Journal of Dairy Technology, 65(1), 146–151. https://doi.org/10.1111/j.1471-0307.2011.00712.x

Mehra, R., Kumar, H., Kumar, N., Ranvir, S., Jana, A., Buttar, H. S., et al. (2021). Whey proteins processing and emergent derivatives: An insight perspective from constituents, bioactivities, functionalities to therapeutic applications. Journal of Functional Foods, 87, 104760.

Minj, S., & Anand, S. (2020). Whey proteins and its derivatives: Bioactivity, functionality, and current applications. Dairy, 1(3), 233–258.

Mollea, C., Marmo, L., & Bosco, F. (2013). Valorisation of cheese whey, a by-product from the dairy industry. In Food industry. ISBN: 9789535153450.

Morris, P. E., & FitzGerald, R. J. (2008). Whey proteins and peptides in human health (pp. 285–343). Ames.

Ney, D. M., Gleason, S. T., Calcar van, S. C., MacLeod, E. L., Nelson, K. L., Etzel, M. R., Rice, G. M., & Wolff, J. A. (2009). Nutritional management of PKU with glycomacropeptide from cheese whey. Journal of Inherited Metabolic Disease, 32, 32–39.

Nikodinovic-Runic, J., et al. (2013). Carbon-rich wastes as feedstocks for biodegradable polymer (polyhydroxyalkanoate) production using bacteria. Advances in Applied Microbiology, 84, 139–200.

Nursiwi, A., Nurhartadi, E., Utami, R., Sari, A. M., Laksono, P. W., & Aprilia, E. N. (2017). Characteristic of fermented whey beverage with addition of tomato juice (Lycopersicum esculentum). In IOP conference series: Materials science and engineering. (Vol. 193, No. 1, p. 012009. IOP Publishing.

Nzekoue, F. K., Alesi, A., Vittori, S., Sagratini, G., & Caprioli, G. (2021). Development of functional whey cheese enriched in vitamin D3: Nutritional composition, fortification, analysis, and stability study during cheese processing and storage. International Journal of Food Sciences and Nutrition, 72(6), 746–756.

Otte, J., Shalaby, S. M., Zakora, M., Pripp, A. H., & El-Shabrawy, S. A. (2007). Angiotensin-converting enzyme inhibitory activity of milk protein hydrolysates: Effect of substrate, enzyme and time of hydrolysis. International Dairy Journal, 17(5), 488–503.

Pal, P., & Nayak, J. (2016). Development and analysis of a sustainable technology in manufacturing acetic acid and whey protein from waste cheese whey. Journal of Cleaner Production, 112, 59–70.

Pal, S., & Radavelli-Bagatini, S. (2013). The effects of whey protein on cardio-metabolic risk factors. Obesity Reviews, 14(4), 324–343.

Panesar, P. S., Kennedy, J. F., Gandhi, D. N., & Bunko, K. (2007). Bioutilisation of whey for lactic acid production. Food Chemistry, 105(1), 1–14.

Panghal, A., Patidar, R., Jaglan, S., Chhikara, N., Khatkar, S. K., Gat, Y., & Sindhu, N. (2018). Whey valorization: Current options and future scenario–a critical review. Nutrition & Food Science, 48(3), 520–535.

Papademas, P., & Kotsaki, P. (2019). Technological utilization of whey towards sustainable exploitation. Advances in Dairy Research, 7(4), 231.

Pareek, N., Gupta, A., & Sengar, R. (2014). Preparation of healthy fruit based carbonated whey beverages using whey and orange juice. Asian Journal of Dairying & Foods Research, 33(1), 5–8.

Parrondo, J., Garcia, L. A., & Diaz, M. (2000). Production of an alcoholic beverage by fermentation of whey permeate with Kluyveromyces fragilis I: Primary metabolism. Journal of the Institute of Brewing, 106(6), 367–375.

Paula, J. C. J. D. (2005). Elaboração e estabilidade de bebida carbonatada aromatizada à base de soro de leite.

Pelegrine, D. H. G., & Gasparetto, C. A. (2005). Whey proteins solubility as function of temperature and pH. LWT, 38(1), 77–80.

Pescuma, M., Hébert, E. M., Mozzi, F., & De Valdez, G. F. (2010). Functional fermented whey-based beverage using lactic acid bacteria. International Journal of Food Microbiology, 141(1-2), 73–81.

Pescuma, M., Hébert, E. M., Rabesona, H., Drouet, M., Choiset, Y., Haertlé, T., Mozzi, F., Font de Valdez, G., & Chobert, J.-M. (2011). Proteolytic action of lactobacillus delbrueckii subsp. bulgaricus CRL 656 reduces antigenicresponse to bovine β-lactoglobulin. Food Chemistry, 127, 487–492.

Pintado, C. M. B. S., Ferreira, M. A. S. S., & Sousa, I. (2010). Control of pathogenic and spoilage microorganisms from cheese surface by whey protein films containing malic acid, nisin and natamycin. Food Control, 21(3), 240–246. https://doi.org/10.1016/j.foodcont.2009.05.017

Poonia, A., & Kumari, A. (2018). Development and shelf-life evaluation of functional Rabadi (a fermented pearl millet product) by incorporation of whey. The Indian Journal of Nutrition and Dietetics, 55(3), 318–333. https://doi.org/10.21048/ijnd.2018.55.3.17874

Portnoy, M., & Barbano, D. M. (2021). Lactose: Use, measurement, and expression of results. Journal of Dairy Science, 104(7), 8314–8325.

Pouliot, Y. (2008). Membrane processes in dairy technology—From a simple idea to worldwide panacea. International Dairy Journal, 18(7), 735–740.

Ranganathan, S., Dutta, S., Moses, J. A., & Anandharamakrishnan, C. (2020). Utilization of food waste streams for the production of biopolymers. Heliyon, 6(9), e04891-4904.

Ribeiro, J. E. S., Martini, M., Andreucci, A., Altomonte, I., D’ascenzi, C., Marzoni, M., et al. (2017). Preliminary investigation of reuse of ricotta-cheese whey (scotta) as substrate for the growth of Rhodotorula glutinis intended for the production of carotenoids. ARPN Journal of Agricultural and Biological Science, 12(10), 302–306.

Rizzolo, A., & Cortellino, G. (2018). Beverages based on ricotta cheese whey and fruit juices. Italian Journal of Food Science, 30(2), 289–302.

Rocha, J. M., & Guerra, A. (2020). On the valorization of lactose and its derivatives from cheese whey as a dairy industry by-product: An overview. European Food Research and Technology, 246(11), 2161–2174.

Rohit, I., Chavan, K., More, R., & Dnyaneshwar, W. (2020). Studies on effect of using kiwi (Actinidia deliciosa) fruit extract on sensory properties of fruit based Chhana whey beverage. Journal of Pharmacognosy and Phytochemistry, 9(6), 522–526.

Romo, M., Castellari, M., Fartdinov, D., & Felipe, X. (2023). Separation of α-Lactalbumin enriched fraction from bovine native whey concentrate by combining membrane and high-pressure processing. Food, 12(3), 480.

Rosa, L. S., Santos, M. L., Abreu, J. P., Rocha, R. S., Esmerino, E. A., Freitas, M. Q., et al. (2023). Probiotic fermented whey-milk beverages: Effect of different probiotic strains on the physicochemical characteristics, biological activity, and bioactive peptides. Food Research International, 164, 112396.

Roufou, S., Griffin, S., Katsini, L., Polańska, M., Van Impe, J. F., & Valdramidis, V. P. (2021). The (potential) impact of seasonality and climate change on the physicochemical and microbial properties of dairy waste and its management. Trends in Food Science & Technology, 116, 1–10.

Ryan, K. N., & Foegeding, E. A. (2015). Formation of soluble whey protein aggregates and their stability in beverages. Food Hydrocolloids, 43, 265–274.

Sabokbar, N., Moosavi-Nasab, M., & Khodaiyan, F. (2015). Preparation and characterization of an apple juice and whey based novel beverage fermented using kefir grains. Food Science and Biotechnology, 24(6), 2095–2104. https://doi.org/10.1007/s10068-015-0278-6

Sameen, A., Tariq, M. R., Huma, N., & Khan, M. I. (2013). Effect of stabilizers on the quality of carbonated flavoured whey drink. African Journal of Agricultural Research, 8, 445–446.

Santos, C. D. S., & Nascimento, F. E. L. (2019). Isolated branched-chain amino acid intake and muscle protein synthesis in humans: A biochemical review. Einstein (Sao Paulo), 17, eRB4898.

Saxena, J., Adhikari, B., Brkljaca, R., Huppertz, T., Zisu, B., & Chandrapala, J. (2021). Influence of lactose on the physicochemical properties and stability of infant formula powders: A review. Food Reviews International, 39, 1–15.

Schlabitz, C., Gennari, A., De Mello Araújo, A. L., Bald, J. A., Volken De Souza, C. F., & Hoehne, L. (2015). Shelf life of a synbiotic fermented dairy beverage using ricotta cheese whey. American Journal of Food Technology, 10(6), 254–264.

Semproli, R., Simona Robescu, M., Sangiorgio, S., Pargoletti, E., Bavaro, T., Rabuffetti, M., et al. (2023). From lactose to alkyl galactoside fatty acid esters as non-ionic biosurfactants: A two-step enzymatic approach to cheese whey valorization. ChemPlusChem, 88(1), e202200331.

Sharma, K., Saini, R., & Patil, S. (2022). A systematic review on the emerging role of protein powder. International Journal of Research in Engineering and Science, 10(5), 88–90.

Sharma, R., Choudhary, R., Thakur, N. S., & Thakur, A. (2019). Development and quality of apple-whey based herbal functional ready-to-serve beverage. Journal of Applied and Natural Science, 11(2), 291–298.

Silva E Alves, A. T., Spadoti, L. M., Zacarchenco, P. B., & Trento, F. K. (2018). Probiotic functional carbonated whey beverages: Development and quality evaluation. Beverages, 4(3), 49.

Singh, H. K., Puranik, D. B., Patwadi, P. S., & Sain, M. (2021). Process optimisation for the production of papaya leaf extract based therapeutic whey beverage. Environment Conservation Journal, 22(1&2), 153–158.

Singh, M., Kumar, P., Patel, S. K., & Kalia, V. C. (2013). Production of polyhydroxyalkanoate co-polymer by bacillus thuringiensis. Indian Journal of Microbiology, 53(1), 77–83.

Singh, W., Kapoor, C. M., & Srivastava, D. N. (1999). Standardization of technology for the manufacture of guava whey beverage. Indian Journal of Dairy Science (India), 52, 268–2711.

Skryplonek, K., Dmytrów, I., & Mituniewicz-Małek, A. (2019). Probiotic fermented beverages based on acid whey. Journal of Dairy Science, 102(9), 7773–7780.

Smithers, G. W. (2008). Whey and whey proteins—From ‘gutter-to-gold’. International Dairy Journal, 18(7), 695–704. https://doi.org/10.1016/j.idairyj.2008.03.008

Solak, B. B., & Akin, N. (2012). Health benefits of whey protein: A review. International Journal of Nutrition, 3(1), 1–7.

Sunkesula, V. (2020). Development of methods to improve lactose recovery from permeate and drying characteristics of Greek acid whey. South Dakota State University.

Terde, S. H., Lande, S. R., Ramod, S. S., Suryawanshi, N. A., & Dandekar, V. S. (2022). Studies on effect of kokum syrup on physico-chemical properties of herbal kokum whey beverage. Asian Journal of Dairy and Food Research, 41(2), 242–246.

Tranjan, B. C., Cruz, A. G., Walter, E. H., Faria, J. A., Bolini, H. M., Moura, M. R., & Carvalho, L. M. (2009). Development of goat cheese whey-flavoured beverages. International Journal of Dairy Technology, 62(3), 438–443.

Tunick, M. H. (2008). Whey protein production and utilization: A brief history. In Whey processing, functionality and health benefits (Vol. 1, p. 13).

Ungureanu-Iuga, M., Dimian, M., & Mironeasa, S. (2020). Development andquality evaluation of gluten-free pasta with grape peels and whey powders. LWT, 130, 109714. https://doi.org/10.1016/j.lwt.2020.109714

Valadão, N. K., Andrade, I. M. G. D., Jory, J. C., Gallo, F. A., & Petrus, R. R. (2016). Development of a ricotta cheese whey-based sports drink. Advances in Dairy Research, 4(3), 156–162.

Walzem, R. L., Dillard, C. J., & German, J. B. (2002). Whey components: Millennia of evolution create functionalities for mammalian nutrition: What we know and what we may be overlooking. Critical Reviews in Food Science and Nutrition, 42(4), 353–375.

Wang, Y., Yang, C., Zhang, J., & Zhang, L. (2023). Interaction of preheated whey protein isolate with rose anthocyanin extracts in beverage model system: Influence on color stability, astringency and mechanism. Food Chemistry, 412, 135507.

Yadav, R. B., Yadav, B. S., & Kalia, N. (2010). Development and storage studies on whey-based banana herbal (Mentha arvensis) beverage. American Journal of Food Technology, 5(2), 121–129.

Zandona, E., Blažić, M., & Režek Jambrak, A. (2021). Whey utilization: Sustainable uses and environmental approach. Food Technology and Biotechnology, 59(2), 147–161.

Zdrojewicz, Z., Zyskowska, K., & Wasiuk, S. (2018). Lactose in drugs and lactose intolerance–realities and myths. Paediatrics and Family Medicine, 14(3), 261.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Chawla, R., Roy, S., Malik, B. (2023). Valorisation of Whey for Development of Different Types of Food Products Including Fermented Beverages. In: Poonia, A., Trajkovska Petkoska, A. (eds) Whey Valorization. Springer, Singapore. https://doi.org/10.1007/978-981-99-5459-9_11

Download citation

DOI: https://doi.org/10.1007/978-981-99-5459-9_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-5458-2

Online ISBN: 978-981-99-5459-9

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)