Abstract

High Thermal Substitution Rate (TSR) through co-processing of alternative fuels to a game changer to reduce Greenhouse Gas (GHG) emissions in cement industry. Cement plants in India are utilizing alternative fuels mainly in calciner. Firing of alternative fuels through main burner can help to achieve nationwide target of 25% TSR by 2025. This paper presents a case study of an Indian cement plant for achieving 25% TSR through Refused Derived Fuel (RDF) firing in kiln main burner of a suspension preheater cement plant. Conventional mono-channel burner, semi direct coal firing system, leakages at kiln outlet, low kiln inlet riser capacity, inefficient coal mill bag filter, coal dosing system, cooler with entire moving grate and high specific heat consumption are some of the identified challenges in achieving high TSR. Thus a comprehensive system design starting with RDF received in cement plant to the firing in kiln main burner for 3.64 tonnes per hour (tph). RDF handling and storage along with impact assessment and investment is worked out in the study. The major impact envisaged is the loss of clinker production to tune 25 tonnes per day (tpd) along with increase in the specific heat consumption of 5 kcal/kg clinker when achieving 25% TSR. At 25% of TSR through RDF, it is estimated that there shall be savings of approx. 0.135 t CO2/t clinker which corresponds to 30% of the existing CO2 emissions.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Global warming is a major threat in near future as temperature the world over are going to rise by 2.1–3.5 °C according to latest sixth IPCC report. It is well above the limit by 1.5–2.0 °C as laid down in Paris agreement. So the efforts to contain greenhouse gas emissions has been increased manifold globally. Cement industry is accountable for approx. 7% GHG emissions contributing significantly in this direction. One of the identified levers to achieve this target as per the low carbon technology roadmap devised by the industry is utilization of waste derived fuels replacing fossil fuels in cement plants [1, 2]. Cement plants have worldwide attained high TSR by utilization of alternative fuels with the world average TSR of approx. 18% in 2017. India is playing its part with an average TSR of 4% [3] and striving to achieve 25% TSR by 2025 [4, 5]. Refuse Derived Fuel (RDF) has been identified as one of the most promising alternative fuel. But RDF utilization in large volume in cement production is still not achieved thus far in India. Most of the cement plants in India are using RDF in calciner only due to the low heat value of RDF. Recently, RDF grading (SCF, grade I, grade II, grade III) carried out by Ministry of Housing and Urban Affairs in consultation with different stakeholders is based upon the quality to maximize RDF utilization [6]. This will support cement plants to achieve TSR through kiln main burner as well. In this regard, one cement plants in southern parts of India targeted to replace 25% of their fuel requirement by RDF available in the vicinity of the plant as alternative fuel. These efforts towards Municipal Solid Waste will support the cement plant in two ways: Substitute the main fuel i.e. a blend of coal & petcoke and secondly consume the waste generated, which otherwise would consume additional resources for its. The objective of the paper is to check the technical feasibility for achieving 25% TSR through kiln main burner in a cement plant.

2 Material and Methods

2.1 Methodology

A technical assessment was conducted to evaluate the feasibility of 25% TSR through RDF co-processing in kiln main burner of the cement plant. Raw materials and current fuel mix were analyzed and mass and energy balance was established by the process measurements during the site visit. Impact assessment for process, environment and clinker quality parameters are conducted using excel spreadsheets and plant data. System was designing done based upon the alternative fuel quantity and quality and outcomes of the impact assessment. Experiences shared by some European countries with RDF coprocessing in kiln main burner were also referred.

2.2 Fuel Availability and Specification

The system requirement to achieve 25% TSR through RDF is 87 tpd which will be made available to the plant by waste generators. The specification of RDF Grade I and Grade II is found most suitable to achieve high TSR through the main burner and is given in Table 1.

Presently, the plant is operating by using a mix of petcoke and coal. The analysis of fuel mix and proposed RDF Grade-I is given in Tables 2 and 3.

3 Feasibility for RDF Firing in Kiln Main Burner

3.1 Evaluation of Existing Plant Operation to Establish % TSR

The cement plant has a rated capacity of ~ 15 tpd clinker and producing approx. 1450 tpd. There were reducing conditions prevailing at kiln inlet. Specific heat consumption works out to 960 kcal/kg clinker based upon the heat balance, operating parameters and plant data for entire pyro processing section.

3.2 Process and System Design Limitations

It was observed that reducing conditions were prevailing in kiln system due to high CO peaks. The plant is having conventional mono-channel burner which is also contributing to high specific heat consumption. In the existing coal mill operation, the mill fan volume which is handled by coal mill bag filter fan is being split to bag filter and primary air fan due to insufficient bag filter capacity. Coal dosing system is old generation type (venturi type pneumatic conveying). Recuperation zone of grate cooler is not having static grate leading to low recuperation efficiency and high preheater fan volume. Kiln outlet seal was damaged leading to high false air ingress in the system. Figure 1 shown below is indicating the air/gas flow rate measured. The total cooling air is 2.37 Nm3/kg clinker, the cooler recuperated air is only 0.47 Nm3/kg clinker and primary air is 0.36 Nm3/kg clinker. The estimated air required for complete combustion with respect to the coal rate of 0.168 kg/kg clinker is 1.13 Nm3/kg clinker. During the visit it was observed that the kiln outlet seal was not present and a lot of atmospheric air estimated at around 0.3–0.35 Nm3/kg clinker was entering.

3.3 Firing Location

Kiln inlet and main kiln burner are two firing locations available for co-firing. Residence time of gas in kiln riser is less than 1 s which is not sufficient for combustion of pre-processed alternate fuel at this location. Moreover, varying CO was observed at kiln inlet with temperature lying in the range of 850–900 °C. For complete combustion and destruction of dioxins and furans generated due to the feeding of chlorinated waste, it requires residence time of gas in kiln riser should be at least 3–4 s at ~ 900 °C [7], which was not available. Hence, it is not recommended to feed alternative fuels like RDF at kiln inlet location. Therefore, the only option left to feed AF is in the kiln main burner.

3.4 Proposed System Design for RDF Firing in Kiln Main Burner

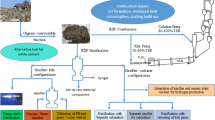

RDF is proposed to be received at plant through trucks in bales (2 m × 1 m)/in bags (50 kg cement empty bags)/in bulk (Self-tipping type trucks). A covered shed [20 m (Width) × 35 m (Length) × 19.2 m (Height)] is considered for complete pre-processing station where trucks will dump the received RDF. Material is proposed to be extracted by multipurpose fully automated grab crane from the over ground storage area and will be fed to fine shredder for material sizing. The input material will have maximum bale size 2 m × 1 m, hence fine shredder is proposed to get the required output size of < 10 mm. Shredded material shall be fed to underground pits (2 nos.) with the help of belt conveyor. Shredded material from the pit shall be extracted with the help of grab crane and will be fed to box feeder. Flexible conveyor shall lift the material vertically and discharge it on to the trough belt conveyor further to be transported which will be further transported to the material to the storage bin located at the cooler top level floor. Belt conveyor will enter into clinker cooler top floor and will discharge the material to hopper of screw weigh feeder; further into screw weigh feeder and after weighing, material shall be fed to new multichannel burner through IDMS blow through rotary valve. The flowsheet for the proposed system is shown in Fig. 2. It is proposed to replace the single channel burner with multi-channel multi fuel burner and Coal dosing system with highly accurate Pfister Pump/Rota Scale.

3.5 Impact Assessment

Chatterjee and Sui [8] reported the impacts of co-processing of alternative fuels in larger quantity on clinker production along with specific heat consumption. Parameters like clinker production, specific heat consumption, clinker quality along with environmental emissions were assessed at 25% TSR with the use of waste / alternative fuels. Impact assessment of RDF utilisation indicated the increase in specific heat consumption and reduction in clinker production. The introduction of moisture of ~ 15% in the process results in increase of specific heat consumption by ~ 5 kcal/kg clinker along with net reduction in flame temperature of ~ 30 °C. The reason for decrease in clinker production is mainly related to the high moisture of RDF. When the moisture in the system increases after introduction of RDF, part of the thermal energy input will be utilised to remove the fuel moisture. Thus, actual heat input for clinkerisation gets reduced. Hence more fuel needs to be fired in the system which requires more combustion air. But the existing preheater fan which extracts the flue gases will not be able to take the extra volume due to the design limitation. Therefore, fuel quantity cannot be increased, thereby reducing the kiln feed and clinker production to maintain the clinker quality. It is anticipated that there shall be 3.5% reduction in gas volume in preheater fan with the similar production levels. Increase in overall fuel moisture and decrease in overall ash content also results in net production loss of ~ 25 tpd of clinker after introduction of RDF.

High Cl content in RDF has several operational issues as reported in literature [9]. Cl content in hot meal and clinker is 0.04% and 0.007% which is within the normal limits of 0.8% and 0.1% respectively. As per the quality of RDF, chlorine content shall be < 0.7% which leads to rise in Cl content of total input to 0.043% which is higher than normal operating norms of 0.023%. This limits the TSR to 10% thus meeting the upper limit of %Cl. In the current scenario, SO3 input from the fuel is 0.95 kg/kg clinker. After utilization of RDF (1.5% S content) at 25% TSR, the SO3 input from the total fuel will decrease to 0.73 kg /kg clinker. Thus, SO3 will further decrease which will reduce the coating/build up formation. Ash content in RDF would be ~ 10%. Considering 25% TSR by RDF, overall ash content shall reduce to ~ 18% in the fuel mix as compared to the existing ash content of 23%. Accordingly, raw mix design needs to be optimized to meet the LSF (also SM and AM) target in the clinker.

3.6 CO2 Mitigation Potential

At 25% TSR through RDF, it is estimated that there shall be savings of ~ 0.135 t CO2/t clinker which corresponds to ~ 30% CO2 savings annually considering 62% carbon content in present fuel mix and 17% specific fuel consumption.

3.7 Project Cost and Payback Period

The total project cost for implementing 10% TSR through RDF is given in Table 4. The project cost includes new burner, cooler drive, RDF feeding system etc. The fuel cost considered is Rs 7000/tonne and RDF cost is Rs 3500/tonne. The payback period for 10% TSR through RDF with the above suggested modification in the plant will be ~ 4 years.

4 Results and Discussions

Plant must modify the existing kiln system to operate at high TSR using RDF as alternative fuel. The operation can be improved by arresting the false air entry from the kiln outlet and increasing the high temperature recuperated air from the cooler. This will further result in reduction of preheater exit fan volume. It is recommended to have lamella or pneumatic type kiln outlet seal which can further reduce the specific heat consumption to the level of ~ 10 kcal/kg clinker. If the plant implements multichannel low NOx burner, it can further reduce the specific heat consumption to ~ 20–25 kcal/kg clinker. During installation of the multi-channel burner, plant has to consider a new bag filter for handling the additional coal mill fan volume going to Primary Air (PA) fan. After installation of multi-channel burner with new PA fan and arresting kiln outlet leakages, the secondary air volume will increase. However, the secondary air temperature reduces due to conventional grate cooler with movable grate. It is recommended to install static grate from reputed technology suppliers in cooler along with up-gradation of cooler drive (for trouble free operation) which will reduce cooler losses leading to energy savings of 15–20 kcal/kg clinker and improve recuperation efficiency. Further, it will improve the kiln operation and facilitate higher TSR. Thus, a comprehensive study was conducted and a suitable system design catering to above aspects was proposed.

5 Conclusion

RDF utilization in kiln main burner necessitates stringent fuel quality parameters. Variation in fuel input parameters will affect kiln operation and clinker quality. Thus, pre-processing is the key to high TSR which has been considered in the proposed system design concept. Further, impact assessment has been done which concludes that there will be a loss of clinker production of the tune of 25 MT per day along with the increase in specific energy consumption of 5 kcal/kg clinker. Incapability of mono channel burner to handle AF, substantial moisture in the AF (RDF), low secondary air flow & temperature in kiln, present leakages through kiln outlet seal, high primary air requirement and incapability of coal mill bag filter demands certain modifications in the plant which are modification in cooler, replacement of kiln outlet seal, installation of multi-channel burner and accurate coal dosing system to achieve high TSR. Chloride content in RDF is major bottleneck to achieve high TSR of ~ 25%. With Grade I and Grade II RDF having maximum chloride content of 0.7%, the maximum achievable TSR is 10%. If plant wants to operate at high TSR with same chloride content in RDF, then plant must install kiln bypass system.

References

World Business Council for Sustainable Development: Low Carbon Technology Roadmap for the Indian Cement Sector: Status Review (2018)

International energy agency: Technology Roadmap Low-Carbon Transition in the cement industry. IEA (2018). pp. 5, 29. https://www.wbcsd.org/Sector-Projects/Cement-Sustainability-Initiative/Resources/Technology-Roadmap-Low-Carbon-Transition-in-the-Cement-Industry. Accessed 11 Jan 2022

Mohapatra B, Chaturvedi S, Saxena A, Sharma P, Bohra A, Naidu G (2019) Use of alternative fuels and raw materials in cement industry in India—prospects & challenges in conserve green & sustainable resources. New Delhi

Confederation of Indian Industry: Approach paper for achieving 25% thermal substitution rate in Indian cement industry by 2025 (2016), pp 1–8. http://www.ciiwasteexchange.org/doc/annexure_6.pdf. Accessed 20 April 2022

Confederation of Indian industry: Status paper on alternate fuel usage in Indian cement industry (2018), pp 1–2. http://www.ciiwasteexchange.org/doc/afr2018.pdf

Ministry of housing and urban affairs Government of India: Guidelines on usage of refuse derived fuel in various industries (2018). pp 13–14. http://cpheeo.gov.in/upload/5bda791e5afb3SBMRDFBook.pdf. Accessed 15 May 2022

Karstensen DKH (2017) Formation and control of dioxins in dry pre-heater/pre calciner kilns co-processing wastes. In: 13th NCB International seminar on cement, concrete and building materials, New Delhi

Chatterjee A, Sui T (2019) Alternative fuels—effects on clinker process and properties. Cem Concr Res 123:1–19

Mora N, Martinez J, Ayala C (2019) Clinker production with high chlorine alternative fuels. In: 15th International congress on the chemistry of cement, Prague, Czech Republic

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sharma, P., Kukreja, K., Reddy, K.P.K., Mittal, A., Panda, D.K., Mohapatra, B. (2023). Refuse Derived Fuel (RDF) Co-processing in Kiln Main Burner in a Cement Plant: A Case Study. In: Doolla, S., Rather, Z.H., Ramadesigan, V. (eds) Advances in Clean Energy and Sustainability. ICAER 2022. Green Energy and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-99-2279-6_28

Download citation

DOI: https://doi.org/10.1007/978-981-99-2279-6_28

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-2278-9

Online ISBN: 978-981-99-2279-6

eBook Packages: EnergyEnergy (R0)