Abstract

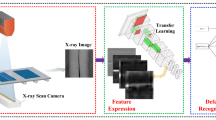

Aiming at the problems of low efficiency and strong subjectivity in the current detection of weld defects by radiographic imaging technology, an object detection method of weld defects based on multi-channel fusion convolutional neural network is proposed. In this method, the images of weld defects are encoded and input into multiple feature extraction channels formed by parallel fusion of CNN. After that, the extracted features are fused with full connection layer and the feature vectors are output. Finally, the final output is obtained by Softmax for classification. The proposed method is verified by weld defect images in actual production. The experimental results indicate that the mAP of the multi-channel fusion convolutional neural network reaches 76.37%, and the detection accuracy of weld defects is higher than that of other network such as ResNet-50 and VGG-16. The proposed method can be applied to X-ray intelligent detection of weld defects and other scenarios.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

GB/T 6417–86.: Classification and description of metal fusion weld defects

Wang, R., Hu, Y. L., Liu, W. P. L., Li, H. T.: Weld defect detection based on edge AI in X-ray image. Trans. China Weld. Inst. 43(01): 79–84+118 (2022)

Liu, H., Liu, X.J., Wang, Y.F., et al.: Research on weld defect classification technology based on compound convolution neural network structure. Acta Aeronaut. Astronaut. Sin. 43(S1), 726928 (2022). (In Chinese)

Chen, Y. F., Peng, H. S., Wang, J. T., et al.: Detection and recognition of weld defects based on lightweight convolutional neural network. Autom. & Instrum. 37(1), (2022)

Jiang, H.Q., He, S., Gao, J.M., et al.: An improved convolutional neural network for weld defect recognition. J. Mech. Eng. 56(08), 235–242 (2020)

Fan, D., Hu, A. D., Huang, J. K.: X-ray image defect recognition method for pipe weld based on improved convolutional neural network. Trans. China Weld. Inst. 41(01): 7–11+97 (2020)

Hi, Z.L., Jiang, H.Q., Yang, D.Y., et al.: A deep learning fusion model of wave and image data for weld defect recognition. J. Xi’an Jiaotong Univ. 55(05), 73–82 (2021)

He, K., Zhang, X., Ren, S., Sun, J.: Deep residual learning for image recognition.In: 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), pp. 770–778 (2016)

He, K., Zhang, X., Ren, S., Sun, J.: Identity mappings in deep residual networks, In: Leibe, B., Matas, J., Sebe, N, Welling, M. (eds.) Computer vision—ECCV 2016. ECCV 2016. Lecture notes in computer science, vol. 9908. Springer, Cham (2016)

Girshick, R., Donahue, J., Darrell, T., Malik, J.: Rich feature hierarchies for accurate object detection and semantic segmentation. In: 2014 IEEE conference on computer vision and pattern recognition, pp. 580–587 (2014)

Girshick, R.: Fast R-CNN. In: 2015 IEEE International Conference on Computer Vision (ICCV), pp. 1440–1448 (2015)

Ren, S., He, K., Girshick, R., Sun, J.: Faster R-CNN: Towards real-time object detection with region proposal networks. IEEE. Trans. Pattern. Anal. Mach Intell. 39(6), 1137–1149 (2017). https://doi.org/10.1109/TPAMI.2016.2577031. Epub 2016 Jun 6 PMID: 27295650

Acknowledgements

This research is supported by China Aerospace Science and Technology Corporation for study on high efficiency digital ray inspection and evaluation technology of welding seam of aluminum alloy tank of carrier rocket (Project No.GXGY-2020-08).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Geng, H., Li, Z., Zhou, Y. (2023). Research on Weld Defect Object Detection Based on Multi-channel Fusion Convolutional Neural Network. In: Patnaik, S., Kountchev, R., Tai, Y., Kountcheva, R. (eds) 3D Imaging—Multidimensional Signal Processing and Deep Learning. Smart Innovation, Systems and Technologies, vol 349. Springer, Singapore. https://doi.org/10.1007/978-981-99-1230-8_21

Download citation

DOI: https://doi.org/10.1007/978-981-99-1230-8_21

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-1229-2

Online ISBN: 978-981-99-1230-8

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)