Abstract

Natural single-sourced dye-sensitized solar cells (DSSC) was successfully fabricated from Theobroma cacao. The activated carbon from cacao pod husks and the natural sensitizer derived from cacao leaves were utilized as a sustainable substitute for expensive platinum counter electrodes and N719 sensitizer to fabricate a cheaper and more eco-friendly DSSC. Cacao pod husks activated carbon (CPHAC) was prepared using a chemical activation process while the natural dye was extracted using the maceration technique. The morphology and textural properties of the synthesized CPHAC was characterized by different physiochemical techniques while optical characterization of the natural dye extracted from cacao leaves and synthetic N719 dye was conducted using UV visible spectrophotometry (UV–Vis). Decent photovoltaic parameters were recorded for the activated carbon counter electrode due to its significantly large surface area and highly porous morphological structures. The highest recorded efficiency was about 87.57% of the conventional DSSC.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

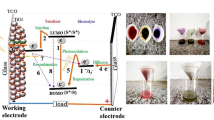

Dye-sensitized solar cells (DSSC) are 3rd-era photovoltaic intended to be a promising device that straightforwardly converts solar energy into power. Generally, it comprises a dye-sensitized photoanode, an electrolyte with redox couple, and a counter electrode (CE). The counter electrode is responsible for speeding up the regeneration of iodide from triiodide and the regeneration of dye sensitizer molecules while sensitizers are responsible for light absorption which assimilate photons of a wavelength that corresponds to the energy distinction between its highest occupied molecular orbital (HOMO) and lowest unoccupied molecular orbital (LUMO) [1]. Platinum and ruthenium complex dye was the most commonly used synthetic materials for counter electrodes and sensitizers for DSSC, respectively. However, these materials are expensive, scarce, and not sustainable. Thus, investigating functional, stable, and superior Pt-free DSSC is vitally important [2]. Past and ongoing research has shown that the DSSC with activated carbon cathode terminal displayed a decent power conversion efficiency (PCE). The preparation of activated carbon from the wood of Choerospondias axillaris seed-stones and Alnus nepalensis plant was successfully implemented as activated carbon for DSSC which yield to 0.94% and 1.12% efficiency, respectively [3]. Moreover, natural dyes are viewed as the fundamental subbed, the least expensive, and sustainable sensitizers employed in the production of DSSC. These dyes can be extracted directly from plants that may contain chlorophyll, anthocyanin, carotenoids, tannins, cyanins, and flavonoids used as photosensitizers for DSSC [4]. A comparison study was conducted regarding the efficiency of chlorophyll dye extracted from pandan leaves using various solvents through the maceration technique. Results showed that chlorophyll in ethanol exhibited better efficiency compared to chlorophyll dye in acetonitrile, chloroform, ethyl ether, and methanol [5].

Theobroma Cacao, otherwise called the “food of the gods,” cultivate bounteously in tropical nations like the Philippines. Cacao produces dried and aged greasy seeds, which are utilized to make chocolates [6]. More than half of the cacao's total weight was attributed to its pod and it was typically disposed of as waste or residue causing ecological problems like greenhouse gas emissions and foul scents. Nonetheless, cacao pod husks are wealthy in carbon sources proposing that they may be utilized as an energy source by ignition and changed over into valuable synthetic substances by pyrolysis [7]. Likewise, chlorophyll, being the most abundant pigmentation of plants can be extracted from its leaves. Thus, in this study theobroma cacao pod husk was used as a precursor for synthesizing activated carbon counter electrode while the natural dye extracted from theobroma cacao leaves was utilized as the photosensitizer for titania-based DSSC since there is no existing study regarding the utilization of Theobroma cacao for single-sourced DSSC. The implementation of this natural dye and activated carbon cathode is propitious due to its financial and environmental characteristics since it is single-sourced [8]. Furthermore, the photovoltaic characteristics of activated carbon-based DSSC, chlorophyll-based DSSC, and cacao-based DSSC were compared to the conventional DSSC.

2 Methodology

2.1 Synthesis of Cacao Pod Husk Activated Carbon (CPHAC)

The cacao pod husk wastes were collected from the Lembaga Koko Malaysia at Bagan Datuk, Perak, Malaysia. The pre-washed fresh cocoa pod husks were sun-dried for 24 h and crushed before further drying in the oven at 80 °C until a constant weight was obtained (Memmert, UN55). The dried cacao pod husks were grounded (Retsch, SM100 Rostfrei) and subsequently sieved to fractions with particle size 0.5 mm (Endecott’s Ltd, Minor-0646–03). The CPH powder was carbonized using a drop-type fixed-bed reactor at 500 ℃ in an inert nitrogen atmosphere and impregnated using potassium hydroxide (KOH) utilizing 0.5 g KOH/g CPH impregnation ratio at 30 °C for 1 h before drying in an oven at 110 °C for 24 h. Subsequently, the dried impregnated sample was further pyrolyzed at 800 ℃ using a tube furnace with the presence of nitrogen gas. Then, the KOH-treated sample was neutralized using 3 M hydrochloric acid (HCl) and deionized water. Finally, the resulting product was dried overnight in an oven at about 110 °C and stored in an air-tight container until further use [7] (Fig. 1).

2.2 Sensitizers Preparation

Fresh cacao leaves were obtained from Lembaga Koko Malaysia at Bagan Datuk, Perak. About 200 g of the pre-washed cacao leaves were combined with absolute ethanol utilizing 1:10 g/ml solid-to-liquid ratio. The samples were macerated for a week in a dark room before filtration (Whatman no. 1, 150 mm diameter). Solvent evaporation was done using a rotary evaporator at 70 °C until completely dried and then 200 ml of absolute ethanol was added to collect the extracted dye. Finally, the dye solution was properly stored in a vial and placed in the refrigerator to protect it from direct sunlight and atmospheric air. For the synthetic dye solution, about 0.755 g of N719 powder was dissolved in 2.5L of absolute ethanol to make 0.254 mM N719 dye solution (Fig. 2).

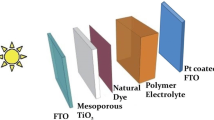

2.3 Fabrication of Dye-Sensitized Solar Cell

2.3.1 Preparation of Working Electrode

The pre-washed Fluorine-Tin-Oxide (FTO) glass was treated with 40 mM TiCl4 aqueous solution at 70 °C for 30 min and washed with deionized water and ethanol. The TiO2 with a thickness of 6 μm was applied twice on the FTO glass to make an active area of 1 cm2 using screen printing method (ATMA, AT-60PD). The TiO2 was dried before printing with another layer using 4 zones of conveyor furnace (HENGLI, HSH3003-0402, approx. 65” of belt working length) with a speed of 124 mm/min. The drying temperature was set at 75 °C, 85 °C, 95 °C and 85 °C for the first, second, third, and fourth zone, respectively. After applying the second layer, the working electrodes were cut into small cells and fired in a 6 zones conveyor furnace (HENGLI, HSH3003-0407, approx. 119.5” of belt working length) at temperatures of 300 °C, 510 °C, 505 °C, 350 °C, 270 °C and 180 °C for a consecutive zone with a conveyor speed of 140 mm/min. The working electrodes were treated again with TiCl4 aqueous solution and refired in a 6 zones conveyor furnace as described above. The TiO2-coated glass substrates were removed from the furnace belt and immersed in the staining solution of natural dye and synthetic dye, respectively. Finally, the electrodes were removed from the staining bath and carefully rinsed with ethanol.

2.3.2 Preparation of Counter Electrode

2.3.2.1 Platinum Counter Electrode

The platinum paste was screen printed onto the pre-washed and drilled FTO counter electrode. The Pt layer was dried with the same parameter as the working electrodes sides, then heat treated using a 4 zones conveyor furnace (HENGLI, HGL3005-4A, approx. 457” of belt working length) at speed of 148 mm/min and temperature of 350 °C, 410 °C, 240 °C and 190 °C for each zone, respectively.

2.3.2.2 Activated Carbon Counter Electrode (ACCE)

The synthesized CPHAC was dried in a vacuum oven at 70 °C overnight to minimize its moisture content. 10 mg of activated carbon, carbon black, and polyvinylidene fluoride were combined using an 80:10:10 ratio. The mixture was grounded for 20 min using agate mortar and pestle. To make the activated carbon slurry, 300 µl of 1-methyl-2-pyrrolidinone (NMP) was added to the mixture and grounded again for 10 min. The slurry was then deposited on pre-washed FTO glass using the D-blade technique. Finally, the counter electrode was sintered at 80 °C overnight using the oven.

2.4 Dye-Sensitized Solar Cell Assembly

The working electrode and counter electrode were combined into a sealed sandwich-type cells using a thermoplastic gasket via a compression heat process. Two drops of redox iodide/triodide electrolyte (HPE, Dyesol) were inserted through sandblasted holes on the counter electrodes via vacuum backfilling. The holes are then closed by aluminum backed bynel. Finally, cerazoler active solder alloy was applied as a current collector using an ultrasonic soldering system.

2.5 Characterization of the Dye-Sensitized Solar Cells

Field Emission Scanning Electron Microscope and Energy-dispersive X-ray Spectroscopy (FESEM-EDx) was conducted to investigate the surface morphology and elemental composition of the synthesized CPHAC (Tescan, Clara and Oxford Instrument, Ultim Max). The pore properties and surface area of the CPHAC were analyzed using surface area and porosity analysis (Micromeritics, Tristar II 3020). The optical characterization of the dye was conducted using UV–Visible spectrophotometry (Cary 60) to analyze the light absorbance of N719 and natural dye from cacao leaves. The performance of the fabricated DSSC and silicon-based PV cell was evaluated using a Universal Photovoltaic Test System under 100 mWcm−2 intensity of an illuminant Xenon lamp at an AM 1.5 radiation angle connected to a voltmeter and ampere meter (Model 2420, Keithly).

3 Results and Discussions

3.1 Field Emission Scanning Electron Microscopy

Figure 3 shows FESEM micrographs of synthesized CPHAC. Images revealed the developed porous structure and the different morphologies of the synthesized activated carbon. Images a.1 and a.2 exhibit the spongy structure of the activated carbon. The development of macropores which are approximately 3–7 microns (measured using FESEM image software) are shown in images b.1 and b.2. It has been noticed that it consists of shallow pores that can be related to the carbonization of the CPHAC at 500 °C which resulted in the creation of initial porosity on the surface of the material [9, 10]. Images c.1 and c.2 manifest the formation of mesopores and micropores of CPHAC. The development of mesopores and micropores can be attributed to further heating of the CPH at 800 °C [11, 10, 12,13,14,15,16]. Images d.1 and d.2 show that the material consists of numerous deeper and tinier holes which are roughly 1 micron (measured using FESEM image software) which may be due to KOH treatment since chemical impregnation allows deep penetration into carbon structure [17, 18].

3.2 Energy-Dispersive X-ray Spectroscopy (EDX)

Figure 4 shows the EDX spectrum of the synthesized CPHAC that contains 94.3 wt% carbon, 5.5 wt% of oxygen, and 0.02 wt% of Aluminum. This indicates that approximately one in every 19 carbon atoms has oxygen features [19]. The presence of aluminum can be related to the sample holder used for the analysis and/or the equipment used in the pyrolysis process while the presence of oxygen is due to the partial decomposition of the oxygen content of the precursor during pyrolysis or oxygen-bonding occurs while activation process [20, 21]. Thus, EDX reveals that the synthesized CPHAC has high carbon content and the absence of impurities that may affect the performance of the material as a counter electrode for the DSSC such as potassium and chlorine used for impregnation pretreatment of the CPH and neutralizing the activated carbon, respectively.

3.3 Surface Area and Porosity Analysis

The nitrogen adsorption–desorption graph of the synthesized CPHAC as illustrated in Fig. 5a can be characterized as a combination of Type I and Type IV isotherms based on the International Union of Pure and Applied Chemistry (IUPAC) classification indicated by small H4 hysteresis loop at P/Po > 0.44. Type I isotherm referred to microporous material while Type IV isotherm corresponds to mesoporous materials [22, 23]. The large quantity of microporous feature of the sample can be confirmed by adsorption indicated by a significant increment in adsorption at very low relative pressure and the presence of mesopores was confirmed by the slope from 0.44–1.0 P/Po [24] shown in Fig. 5a. Detailed adsorption isotherm in micropore region was demonstrated in Fig. 5b. Brunauer–Emmett–Teller (BET) method by multipoint technique was used to estimate the specific surface area which was found to be 946.7420 m2/g through mesopore analysis and 960.4312 m2/g using micropore analysis are shown in Fig. 5c, d. Additionally, Barrett–Joyner–Halenda (BJH) method was used to determine the pore size distribution of the sample. Figure 5e shows the pore distribution plot in the mesoporous region. The total pore volume, average pore diameter, and pore of the sample were 0.502420 cm3/g, 4.0475 nm, and 2.12273 nm, respectively. Pore development that ranges from 0.64–1 nm with a peak at 0.68 nm was observed and analyzed from the pore distribution in the microporous region using Original Density Functional Theory (DFT) as shown in Fig. 5f [25]. Hence, SAP analysis confirms that the synthesized CPHAC has a large surface area and is highly porous. Such characteristics are beneficial properties in producing efficient carbon-based dye-sensitized solar cells such as high surface area, good electrocatalytic activity, and conductivity which may contribute to the efficient charge transfer, electron collection, and ion diffusion [26,27,28].

(a) Adsorption–Desorption Isoterms through mesopore analysis (b) Adsorption Isoterms through micropore analysis (c) BET surface plot through mesopore analysis (d) BET surface plot through micropore analysis (e) Mesopore distribution plot using BHJ method (f) Micropore distribution curve using DFT method

3.4 UV–Visible Spectroscopy

It is essential to study the absorption capability of the sensitizer for the general performance of the DSSC can be correlated to the light absorption capability of the dye for electron excitations and conversion of light to power. Based on UV visible spectrum of the two distinct dyes as shown in Fig. 6, four absorbance peaks were observed for the synthetic N719 dye, the first two peaks located in the ultraviolet region specifically at 235 nm and 265 nm corresponding to the π-π* charge transfer transition while the other two peaks in the visible region spotted at 388 nm and 531 nm were attributed to metal-to-ligand charge transfer (MLCT) origin [29–31]. Moreover, two peaks were recorded for cacao leaves dye. One in the near violet-blue visible region (352 nm) can be attributed to π-π* transition of the conjugated bonds and intermolecular charge transfer (ICT) transitions and another peak at the orange-red visible region (637 nm) which could be due to the n- π* electron transition. Furthermore, the absorption spectra of the extracted dye from cacao leaves indicate the presence of chlorophyll [32,33,34].

3.5 Photocurrent–voltage Measurement

The photovoltaic characteristics of the fabricated DSSC with a 1 cm2 active area were measured in 100mWcm−2 illumination. Parameters such as efficiency (Eff), fill factor (ff), open circuit voltage (Voc), short circuit current (Jsc), maximum voltage (Vmax), and maximum current (Jmax) were tabulated in Table 2. All photocurrent–voltage measurements were conducted right after the fabrication of the device (Fig. 7).

Activated carbon counter electrodes exhibited very promising photovoltaic performance as shown in Table 2. The efficiency of activated carbon-based DSSC (AC-based DSSC) was about 87.57% of the conventional DSSC. The high efficiency of AC-based DSSC is primarily due to the substantial surface area, highly porous morphology, and oxygen-containing surface functional group which can be confirmed by surface area and porosity analysis and EDX results, respectively. Moreover, the fill factor, open circuit voltage, and maximum voltage of the activated carbon-based DSSC were found to be larger compared to the conventional DSSC [24, 35]. Greater Voc values of activated carbon-based DSSC than Pt-based DSSC can be related to the lower electron recombination rate or to the higher number of electrons being inserted into the TiO2 conduction band since Voc relies normally on this occurrence [36,37,38]. However, the short circuit and maximum current of conventional DSSC were better than the activated carbon-based DSSC because metal-based electrodes such as platinum have better conductivity [24, 35]. Moreover, chlorophyll-based DSSC only produced 0.34% efficiency. The low efficiency of the device utilizing chlorophyll dye can be related to the weak bond between the carboxylic functional groups of chlorophyll dye molecule and the photoanode which is responsible for efficient charge injection. Such a strong bond between dye and photoanode prevents charge outflow in electrolytes [39,40,41]. Additionally, the device photovoltaic performance was comparable to a previous study conducted utilizing chlorophyll dye. Furthermore, cacao-based DSSC only produced 0.08% efficiency.

4 Conclusion

In this study, activated carbon from Theobroma cacao pod husks and chlorophyll derived from Theobroma cacao leaves were utilized as a sustainable substitute for expensive platinum counter electrodes and N719 sensitizer to fabricate a cheaper and more eco-friendly DSSC. It was found that AC-based DSSC utilizing the synthesized activated carbon from Theobroma cacao pod husk recorded a decent light-to-power transformation efficiency which is very comparable to Pt-based DSSC. However, the natural dye from cacao leaves only produced 0.34% efficiency. Moreover, a very low efficiency was recorded for cacao-based DSSC. Thus, activated carbon can be a potential substitute for platinum but chlorophyll cannot be used to replace the synthetic N719 dye. Furthermore, the future study may focus on the effectivity of chlorophyll as a cosensitizer for N719 under lower light conditions and the effect of activated carbon counter electrode preparation on the DSSC photovoltaic performance.

References

N. Y. Amogne, D. W. Ayele and Y. A. Tsigie, Recent advances in anthocyanin dyes extracted from plants for dye sensitized solar cell, Mater. Renew. Sustain. Energy, p. 9:23, (2020)

Jingwen Li et al, Biomass-derived carbon boosted catalytic properties of tungsten-based nanohybrids for accelerating the triiodide reduction in dye-sensitized solar cells, J. Colloid Interface Sci. (2020)

P. Joshi, Novel counter electrodes of dye-sensitized solar cells based on activated carbon prepared from wood of Choerospondias axillaris seed-stones and Alnus nepalensis plant, International Journal of Engineering and Advanced Research Technology (IJEART), 3(3), pp. ISSN: 2454–9290, (March 2017)

Zhou, Wu, Gao and Ma, Dye-sensitized solar cells using 20 natural dyes as sensitizers., J. Photochem. Photobiol. A Chem. 219(2), p. 188–194, (2011)

M. A. M. Al-Alwani et. al, Natural dye extracted from Pandannus amaryllifolius leaves as sensitizer in fabrication of dye-sensitized solar cells, Int. J. Electrochem. Sci., pp. 747–761, (2017)

S. Palisoc et. al, Remediation of water using Theobroma Cacao pod-based activated carbon: A novel approach as determined by highly sensitive BiNP/MWCNT/Nafion-modified GCE, Mater. Res. Express, (2019)

W.-T. Tsai et. al, Porous and adsorption properties of activated carbon prepared from cocoa pod husk by chemical activation, Biomass Convers. Biorefinery, (2019)

K. Gasga, Dye and activated carbon from Canarium ovatum Engl. as photosensitizer and counter electrode for Titania-based dye sensitized solar cell, J. Phys.: Conf. Ser. 1882 012007, (2021)

A. W. S. M. Daud WMAW, The effects of carbonization temperature on pore development in palm-shell-based activated carbon. Carbon, 38, p. 1925–32, (2000)

M.-S. M. Rodriguez-Reinoso F, Activated carbons from lignocellulosic meterials by chemical and/or physical activation: an overview. Carbon, 30(7), p. 1111–8, (1992)

Z. A.-Q. C. Z. N. Mohd Adib Yahya, Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: A review, Renew. Sustain. Energy Rev. 46, p. 218–235, (2015)

K. A. Z. Z. H. M. K. D. A. F. e. a. Abdullah AH, Preparation and characterization of activated carbon from Gelam Wood Bark (Melaleuca cajuputi), Malays J. Anal. Sci. vol. 7(1), p. 65–8, (2001)

M.-S. M. R.-R. F. Caturla F, Preparation of activated carbon by chemical activation with ZnCl2. Carbon, 29(7), pp. 999–1007, (1991)

S. F. D. C. L. R. V. A. S. K. Solar C, Natural gas storage in microporous carbon obtained from waste of the olive oil production, Mater. Res. 11(4), pp. 409–14, (2008)

P. P. S. P. Baseri JR, Preparation and characterization of activated carbon from Thevetia peruviana for the removal of dyes from textile waste water, Adv. Appl. Sci. Res. 3(1), pp. 377–83, (2012)

Y. K. P. J. Z. L. G. S. X. H. Li W, Effects of carbonization temperatures on characteristics of porosity in coconut shell chars and activated carbons derived from carbonized coconut shell chars, Ind. Crops Prod. 28, pp. 190–8, (2008)

M. H. D. M. H. G. J. I. A. M. S. Zoha Heidarinejad, Methods for preparation and activation of activated carbon: a review, Environ. Chem. Lett. pp. https://doi.org/10.1007/s10311-019-00955-0, (2019)

P. T. C. R.-A. e. a. Gratuito MKB, Production of activated carbon from coconut shell: optimization using response surface methodology, Bioresour Technol., 99, p. 4887–4895 https://doi.org/10.1016/j.biortech.2007.09.042, (2008)

G. K. R. R. D. L. K. T. K.D.M.S.P.K. Kumarasinghe, Activated coconut shell charcoal based counter electrode for dye-sensitized T solar cells, Org. Electron., 71, pp. 93–97, (2019)

A. Afrianda, Pembuatan dan Karakterisasi Elektroda Karbon Sel superkapasitor dari Bahan Ampas Sagu Menggunakan Aktivasi H2O Berdasarkan Variasi Waktu Aktivasi, Skripsi, Jurusan fisika fakultas matematika dan ilmu pengetahuan alam universitas riau, p. 201, (2018)

S. E. R. a. R. Y. Y Yuli, Biomass waste of cocoa skin for basic activated carbon as source of eco-friendly energy storage, J. Phys.: Conf. Ser., pp. doi:https://doi.org/10.1088/1742-6596/1788/1/012020, (2021)

A. V. I. L. P. G. L. D. L. A. P. T. R. C. J. Sabrina F. Lütke, Preparation of activated carbon from black wattle bark waste and its application for phenol adsorption, J. Environ. Chem. Eng., 7, p. https://doi.org/10.1016/j.jece.2019.103396, (2019)

G. Singh et al., Convenient design of porous and heteroatom self-doped carbons for CO2 capture. Microporous Mesoporous Mater. 287, 1–8 (2019)

G. N. S. C. S. L. K. B. J. S. Y. Sung Min Cha 1, Fallen leaves derived honeycomb-like porous carbon as a metal-free and low-cost counter electrode for dye-sensitized solar cells with excellent tri-iodide reduction, J. Colloid Interface Sci., 513, pp. 843–851, (2018)

N. S. N. M. A. A. Z. U. D. H. M. Z. F. N. A. Jibril Mohammed, Optimization of microwave irradiated—coconut shell activated carbon usingresponse surface methodology for adsorption of benzene and toluene, Desalination Water Treat., pp. 7881–7897, (2015)

H. A. Z. A. M. Jaafar, The use of carbon black-TiO2 composite prepared using solid state method as counter electrode and E. conferta as sensitizer for dye-sensitized solar cell (DSSC) applications, Opt. Mater. 79, pp. 366–371, (January 2018)

H. A. M. A. Z. Jaafar, Performance of dye-sensitized solar cell (DSSC) using carbon black-TiO2 composite as counter electrode subjected to different annealing temperatures, Opt. Quant. Electron., 52(4), (2020)

P. E. Y. W. S. H. N. C. M. L. Nurnajaa Narudin, Enhanced properties of low-cost carbon black-graphite counter electrode in DSSC by incorporating binders, Sol. Energy, 225, pp. 237–244, (2021)

M. K. Nazeeruddin, E. Baranoff and M. Gra ̈tzel, Dye-sensitized solar cells: A brief overview, Sol. Energy, pp. 1172–1178, (2011)

S. Agarwala, M. Kevin, A. Wong, C. Peh, V. Thavasi, G. Ho, Mesophase ordering of TiO2 film with high surface area and strong light harvesting for dye-sensitized solar cell. ACS Appl. Mater. & Interfaces 2, 1844–1850 (2010)

M. U. Shahid, S. N. Azella Zaine, N. Muti Mohamed, M. Khatani, A. E. Samsudin, Trap state and charge recombination in nanocrystalline passivized conductive and photoelectrode interface of dye-sensitized solar cell, Coatings, 10, p. 284, (2020)

K.H.M. Younas, Performance enhancement of dye-sensitized solar cells via co-sensitization of ruthenium (II) based N749 dye and organic sensitizer RK1. Sol. Energy 203, 260–266 (2020)

*. C. N. H. a. M. A. S. b. J. F. W. c. A. N. O. d. N. N. A. e. Sabastine C. Ezike a, S. C. Ezike, C. N. Hyelnasinyi, M. A. Salawu, A. N. Ossai, J. F. Wansah and N. N. Agu, Synergestic effect of chlorophyll and anthocyanin Co-sensitizers in TiO2-based dye-sensitized solar cells, Surfaces and Interfaces, (22), p. 100882, (2021)

R. Nakhaei, A. Razeghizadeh, P. Shabani, J. Ganji and S. S. Tabatabaee, Photoabsorption enhancement in synthetic-natural dye- sensitized solar cells using bilayer TiO2 deposition and separated sensitization, Hindawi: Int. J. Photoenergy, p. https://doi.org/10.1155/2022/5949837, (2022)

J. H. L. S. M. C. J. S. Y. Goli Nagaraju, Three-dimensional activated porous carbon with meso/macropore structures derived from fallen pine cone flowers: A low-cost counter electrode material in dye-sensitized solar cells, J. Alloy. Compd., 693, pp. 1297–1304, (2017)

V. S. a. P. B. Rahul Kumar, Fabrication of a counter electrode for dye- sensitized solar cells (DSSCs) using a carbon material produced with the organic ligand 2- methyl-8-hydroxyquinolinol (Mq), Nanoscale Adv., 1 pp. 3192, (2019)

M. T. Z. P. K. T. M.-M. u. R. H. B. J. Butt, Biomass-derived nitrogen-doped carbon aerogel counter electrodes for dye sensitized solar cells, Materials, 11, p. 1171, (2018)

A.M.K.S.N.C.V.S.S.N.B.Y.V.S.K.V.M.R.M. Gurulakshmi, A transparent and Pt-free all-carbon nanocomposite counter electrode T catalyst for efficient dye sensitized solar cells. Sol. Energy 193, 568–575 (2019)

G. M. Kay A, Artificial photosynthesis. 1. Photosensitization of titania solar cells with chlorophyll derivatives and related natural porphyrins, J. Phys. Chem., 97(23), p. 6272–7. https://doi.org/10.1021/j100125a029, (1993)

C. I. D. M. G. A. M. S. M. M. G. G. Calogero G, Brown seaweed pigment as a dye source for photoelectrochemical solar cells., Spectrochim Acta – Part A: Mol Biomol Spectrosc , 117, pp. 702–6, (2014)

S.M.M.M.B.S.A.H.G.A.H.M.F.G.T.D.S.M.R.M.R.A.A.A.A.M.A.M.M.A.F. Kabira, Instability of dye-sensitized solar cells using natural dyes and approaches to improving stability—An overview. Sustainable Energy Technol. Assess. 52, 102196 (2022)

Acknowledgements

This is to acknowledge the Department of Science and Technology-Engineering Research and Development for Technology (DOST-ERDT) for funding this research and Yayasan Universiti Teknologi PETRONAS through Fundamental Research Grant (015LC0-449) for supporting the submission of this study on 1st International Conference on New Energy (ICNE2022) under World Engineering, Science & Technology Congress (ESTCON 2022).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 Institute of Technology PETRONAS Sdn Bhd

About this paper

Cite this paper

Magbitang, R.D.S., Zaine, S.N.A.B., Osman, N.B., Ang, G. (2023). Natural Dye and Activated Carbon from Theobroma Cacao as Photosensitizer and Counter Electrode for Titania-Based Dye-Sensitized Solar Cell. In: Othman, M.B., Abdul Karim, S.A., Wilfred, C.D., Lee, K.C., Sokkalingam, R. (eds) Proceedings of the 1st International Conference of New Energy . Springer Proceedings in Energy. Springer, Singapore. https://doi.org/10.1007/978-981-99-0859-2_9

Download citation

DOI: https://doi.org/10.1007/978-981-99-0859-2_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-0858-5

Online ISBN: 978-981-99-0859-2

eBook Packages: EnergyEnergy (R0)