Abstract

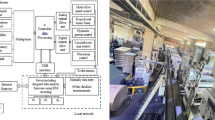

Predictive maintenance is the process of monitoring equipment continuously during its operation to monitor its performance to report its faults beforehand. Using machine learning and analytics, predicting the machine’s failure before it occurs is possible. Various anomaly detection algorithms and predictive learning algorithms can be used to check whether the machine performs normally during its operation. Using IoT, predictive maintenance can be performed remotely which saves costs and time for the company. This predictive maintenance project is aimed at oil rod pumps which are used to extract oil from the ground. The rod pump is machinery used to suck up the oil from the ground level. These machines are monitored by the sensors which are used to keep them in check. The data coming from the machines are called telemetry data. The telemetry data from these machines are collected. The collected data can be processed and used for prediction. The prediction can be used to prevent the failure of the machine beforehand. This can be used to reduce the sudden downtime caused by the machine. The data is collected from the IoT sensors and stored in the cloud storage for processing. Using deep learning, the data can be used to detect anomalies which cause the machine to fail in its operations. The components of the pump will be monitored and data coming out of them can be used to check their health. This keeps a continuous tab on the health of the machines. These companies will be able to remotely monitor and control the oil rod pumps and alert their repair teams only when needed. This work produces predictive systems that can detect anomalies in IoT machinery and alert the repair team automatically once set up.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Borghesi A, Bartolini A, Lombardi M, Milano M, Benini L (2019) Anomaly detection using autoencoders in high performance computing systems. In: AAAI conference on artificial intelligence, vol 30

Al-Subaiei W, Al-Herz E, Al-Marri W, Al-Otaibi R, Ashyan H, Jaber H (2021) Industry 4.0 smart predictive maintenance in the oil industry to enable near-zero downtime in operations. In: International conference on industrial engineering and operations management Singapore

Bousdekis A, Lepenioti K, Apostolou D, Mentzas G (2020) Decision making in predictive maintenance: literature review and research agenda for industry 4.0. IFAC-PapersOnLine, vol 53, Issue 13

Ran Y, Zhou X, Lin P, Wen Y, Deng R (2019) A survey of predictive maintenance: systems, purposes and approaches. IEEE Commun Surv Tutorials

Pech M, Vrchota J, Bedna J (2020) Predictive maintenance and intelligent sensors in smart factory: review

Lee GY, Kim M, Quan YJ (2018) Machine health management in a smart factory: a review of technology

Paidi V, Fleyeh H, Hakansson J, Nyberg RG (2018) Smart parking sensors, technologies and applications for open parking lots

Feng S, Farha F, Zhang T, Ning H (2019) Review on smart gas sensing technology

Carvalho TP, Soares, Vita R, Basto JP, Alcala SGS (2019) A systematic literature review of machine learning methods applied to predictive maintenance

Techniques for generating random numbers using C#: https://www.tutorialsteacher.com/articles/generate-random-numbers-in-csharp

Bousdekis A, Papageorgiou N, Magoutas B, Apostolou D, Mentzas G (2019) Enabling condition-based maintenance decisions with proactive event-driven computing, computers in industry

Bumblauskas D, Gemmill D, Igou A, Anzengruber J (2021) Smart maintenance decision support systems (SMDSS) based on corporate big data analytics. Exp Syst Appl

He Y, Gu C, Chen Z, Han X (2019) Integrated predictive maintenance strategy for manufacturing systems by combining quality control and mission reliability analysis. Int J Prod Res 55(19)

Nadj M, Jegadeesan H, Maedche A, Hoffmann D, Erdmann P (2021) A situation awareness driven design for predictive maintenance systems: the case of oil and gas pipeline operations. In ECIS

Zheng B, Gao X, Li X (2019) Fault detection for sucker rod pump based on motor power

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Kannammal, A., Guhanesvar, M., Venketesz, R.R. (2023). Predictive Maintenance for Remote Field IoT Devices—A Deep Learning and Cloud-Based Approach. In: Shakya, S., Papakostas, G., Kamel, K.A. (eds) Mobile Computing and Sustainable Informatics. Lecture Notes on Data Engineering and Communications Technologies, vol 166. Springer, Singapore. https://doi.org/10.1007/978-981-99-0835-6_40

Download citation

DOI: https://doi.org/10.1007/978-981-99-0835-6_40

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-0834-9

Online ISBN: 978-981-99-0835-6

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)