Abstract

At present, the technical research and construction of underground gas storage for reservoir reconstruction are carried out. It is necessary to deeply study the mechanism of storage capacity expansion and the efficiency of gas injection and oil drive for reservoir reconstruction, and to understand the law of capacity expansion, so as to facilitate the scientific design of storage capacity parameters for reservoir type gas storage. Guided by the theory of percolation mechanics and molecular dynamics of oil and gas reservoirs, this paper expounds 10 mechanisms of oil and gas flooding and oil expansion in reservoir gas storage, and defines that the injection pressure difference driving is the main mechanism of oil flooding and oil expansion, accounting for more than 70% of the total expansion capacity. Through innovative experimental research on gas injection and production of full simulation gas storage, it is concluded that gas displacement efficiency of conventional reservoir is positively correlated with injection and production cycles, but when injection and production are 8–10 cycles, the gas displacement efficiency of single cycle approaches 0, and the total gas displacement efficiency reaches the maximum value. The total gas displacement efficiency of high, medium and low permeability reservoirs is about 45%, 40% and 30%. The corresponding storage capacity is about 45%-30% of the volume of crude oil according to the storage height, medium and low permeability conditions. This result has a guiding significance for the design of reservoir storage parameters.

Copyright 2023, IFEDC Organizing Committee.

This paper was prepared for presentation at the 2023 International Field Exploration and Development Conference in Wuhan, China, 20–22 September 2023.

This paper was selected for presentation by the IFEDC Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the IFEDC Technical Team and are subject to correction by the author(s). The material does not necessarily reflect any position of the IFEDC Technical Committee its members. Papers presented at the Conference are subject to publication review by Professional Team of IFEDC Technical Committee. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of IFEDC Organizing Committee is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of IFEDC. Contact email: paper@ifedc.org.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Reservoir gas storage is a type of gas storage that is built by injecting and producing natural gas into a reservoir and implementing peak regulation to replenish the energy supply to the market. According to the latest statistics of the International Gas Union (IGU), reservoir type gas storage accounts for 6% of the world's gas storage [1]. In recent years, Chinese oil fields such as Daqing and Jidong have also carried out reservoir reconstruction project research, and domestic units such as Chongqing University of Science and Technology, China National Petroleum Corporation Limited Exploration and development Research Institute have carried out gas displacement efficiency experiment of reservoir reconstruction gas storage, and made some progress. In this context, on the basis of theoretical research and experimental results, this paper expounds the capacity expansion mechanism of reservoir reconstruction gas storage, evaluates the efficiency of gas injection oil displacement, and strives to provide help for the technology of reservoir reconstruction gas storage that has been established in China.

1 Reservoir Type Gas Storage Capacity Expansion Mechanism

Reservoir-type gas storage is achieved by injecting gas into the reservoir to replace the space occupied by crude oil. The process of injecting gas to replace the volume of crude oil in order to increase the volume of gas in storage is known as the expansion process. Due to different reservoir characteristics and different operating modes of gas injection and production from different reservoir gas storage, there are some differences in the expansion mechanism of the crude oil replaced by gas injection from different storage, but the overall expansion mechanism includes the following 10 aspects.

1.1 Differential Pressure Driven Capacity Expansion Mechanism

The injected gas in the gas injection well creates a high-pressure zone at the bottom of the well, while the crude zone is a relatively low-pressure zone. Under the action of the displacement pressure difference, the gas drives the flow of crude oil into the low pressure region, leaving space occupied by the crude oil to form a gas storage volume that gradually increases with the injected gas. This is the most important reservoir gas storage expansion mechanism, accounting for more than 70 percent of the total expansion capacity.

1.2 Oil Production Capacity Expansion Mechanism

Since the injected gas and the formation crude oil form a mixed distribution of oil and gas, a portion of the crude oil will necessarily be produced in the gas production process, thereby vacating the formation pore space occupied by the crude oil and enabling gas storage expansion. This is a secondary mechanism of reservoir gas storage expansion and accounts for about 10–20% of the expansion capacity.

In addition, to accelerate reservoir expansion, oil production expansion is sometimes achieved by setting up production wells.

1.3 Dissolved Gas Driven Capacity Expansion Mechanism

In the process of depressurizing gas production in storage, the formation pressure will drop below the saturation pressure, and the dissolved gas in the oil will separate and aggregate to form bubbles that will expand and drive the crude oil.

1.4 Expansion Mechanism of Rock Elastic Drive

Gas storage operations are characterized by multi-cycle injection and production and high and low pressure reciprocity. As a result, the elastic expansion energy of the reservoir rock can drive the flow and expansion of crude oil during gas production and depressurization.

1.5 Expansion Mechanism Driven by Gas Cap Pressure

Conventional reservoir gas storage generally uses a gas injection method in the high part of the structure and gradually expands to the low part. The gas cap will gradually form during the initial phase of construction. As can be seen from the molecular kinematics, the gas is composed of a large number of molecules in irregular motion, which continuously collide with the surface of the crude oil to generate shock forces. The result of successive collisions of a large number of gas molecules is reflected in the pressure of the gas at the surface of the crude. The more molecules there are, the more collisions there are, and the greater the pressure created. Therefore, the pressure of the gas cap can promote the flow and expansion of the crude oil to the low pressure region during the continuous increase of the injected gas and the gradual increase of the gas cap.

1.6 Expansion Mechanism of Liquid Column Driven by Gravity

Gas reservoirs reconstructed from anticlinal and syncline reservoirs typically have a column of oil at a certain height at the initial stage of reservoir construction, or even a column of oil-water mixed liquid in a flood reservoir. The columns of liquid drive the oil by their own gravity, expanding the capacity.

1.7 Mechanism of Dissolved Gas Viscosity Reduction and Capacity Expansion

Injected natural gas and crude oil are hydrocarbon mixtures with similar chemical structures, with dissolving properties in crude oil. Under the condition that the formation temperature is treated as a constant value, the higher the pressure and the higher the recombination fraction, the easier it is to dissolve in crude oil. After the gas dissolves in the crude oil, it has a certain expansion and viscosity reduction effect on the crude oil, which makes it easier for the crude oil to displace the flow and accelerate the capacity expansion.

1.8 Gas Molecular Displacement Dilatation Mechanism

The injected gas is dominated by methane, which has a tetrahedral stable structure and is a polar standing molecule. With a diameter of only 0.4 nm, methane can easily enter the tiny pore throat to replace the residual oil of the nonwetting phase. Under the continuous action of the injected pressure difference, the displacement space can be expanded in order to achieve inflation.

1.9 Oil and Gas Miscible Expansion Mechanism

The injected gas and crude oil are hydrocarbon mixtures with similar chemical structure and similar compatible properties. During the contact between injected gas and reservoir crude oil, component mass exchange is generated, and the heavy hydrocarbon C2 + component in natural gas is more easily miscible with the light hydrocarbon C2-C6component in crude oil, forming a more fluid hydrocarbon mixture, which improves oil displacement efficiency and accelerates capacity expansion.

In particular, because the injected gas is mainly methane, and the miscible heavy hydrocarbon C2 + component of oil is less, and the oil reservoir is often conventional black oil or even heavy oil, the light hydrocarbon C2-C6component of crude oil is less, so unless the light oil reservoir, the general black oil reservoir is difficult to miscible, the miscible pressure is about 40MPa.

1.10 Mechanism of Gravity Expansion of Gas Column

It is common for materials on Earth to have a gravitational pull due to the attraction of the Earth, and the pull is straight down. It can drive oil flows and expand in areas of low pressure. The gravity on the gas and the formed gas column can be calculated by formula (1):

In the formula:

G: Gravity of the air column, N(kg.m/s3);

ρ: The density of the air column, kg/m3;

g: Gravitational acceleration,9.8m/s2;

v: Column volume, m3.

Gas columns form under high-pressure, high-temperature conditions where the volume of gas is greatly compressed, typically 200 to 250 times smaller than the standard state of the ground, resulting in a greater increase in gas density than in the ground. Correspondingly, the gravitational pull of the gas column increases, so the mechanism of gravitational displacement of the gas column cannot be neglected.

In particular, it has been pointed out that when the gas column relies on gravity to drive the crude, the crude forms an upward buoyant force. The buoyancy principle states that the gravitational displacement of the volume of crude oil during the sinking of the gas column is only positively correlated with the density of the crude oil and the volume displaced. Formula (2) for calculating its buoyancy:

In the formula:

F: Buoyancy generated by crude oil, N(kg.m/s3);

ρ: The density of the crude oil,kg/m3.

g: Acceleration of gravity,9.8m/s2.

v: Displacement of crude volume, m3.

Since the density of the crude oil is greater than the density of the gas column, but the volume of the displaced crude oil is less than the volume of the gas column, the buoyancy of the liquid is greater than the gravity of the intrusive gas volume, causing the intrusive gas volume to float above the crude oil.

For crude oil itself, buoyancy does not cancel the gravitational effect of the gas column. Thus, the gravity of the air column is one of the driving forces for the displacement of the oil.

2 Efficiency of Reservoir Gas Storage Expansion

For the problem of gas flooding efficiency, there have been many laboratory experiments, and the conclusion shows that gas flooding efficiency can reach 50.61% [2,3,4]. There is also published literature on the efficiency of oil displacement in reservoir gas storage. However, from the existing literature, they mainly use full-diameter long core and short rock samples as a medium, and mainly perform high and low pressure experiments. There are some deviations from the simulation in terms of injection and production times, gas injection and production rates, and reservoir construction in terms of injection and production inter-flood patterns, which are mostly within the experimental results of the semi-simulations. To this end, in this paper, we conduct a fully simulated experimental study of gas storage injection and production gas displacement. The variational law of gas displacement efficiency is understood, which provides an experimental basis for storage capacity calculations and storage capacity variational laws.

2.1 Design of Full Simulation Experiment Scheme

① Experimental model: reservoir plane model; Approximate to reservoir formation.

② Physical properties parameters: low porosity and low permeability, medium porosity and medium permeability, high porosity and high permeability sandstone; approximate to reservoir.

③ Formation fluid: regular black oil; similar to conventional reservoir oil.

④ Displacement patterns: unidirectional, bidirectional, multidirectional, positive and negative displacement; similar to gas storage injection and production relations.

⑤ Injected gas: methane gas; Similar to injected gas.

⑥ Gas injection and production intensity: The range of variability in gas well production is first higher and then lower; Variations similar to gas storage injection and production well production.

⑦ Injection and production times: Gas injection times, gas production times and intermittency times are controlled in proportion to gas storage operation times; Similar to gas storage injection and production cycle.

⑧ Injection and production cycles: more than 5 cycles, producing regular data; Similar to the multi-cycle operation of gas storage.

⑨ Experimental pressure: 7–20 MPa (model pressure limit); Proportional to the operating upper and lower limit pressure of the gas storage.

⑩ Experimental temperature: 100 ℃; Similar to the gas storage formation temperature.

2.2 Full Simulation Experiment Test Method

Use “Test method for gas/water interdrive seepage characteristics of gas storage in multiple rounds” (Fig. 1).

2.3 Test Results of Full Simulation Experiment

For the reconstruction of the black oil reservoir, the experimental data for the gas displacement efficiency are shown in Table 1, the individual circular displacement efficiency is shown in Fig. 2, and the cumulative displacement efficiency is shown in Fig. 3.

Based on the experimental results, we summarize the variation of the gas-oil displacement efficiency as follows.

-

(1)

Variation of the gas-to-water efficiency law for a single round of gas storage.

① As the injection and production cycles increase, the gas displacement efficiency for a single cycle gradually decreases, reaching a very small value after five cycles, and it is estimated that the gas displacement efficiency tends to end after 8 - 10 cycles; the expansion rate of the gas reservoir first increases rapidly, then slows down and finally approaches a fixed value.

② The efficiency of the first round of gas displacement is the largest, up to more than 10 percent, and the extent of the expansion is the largest.

③ The range of gas displacement efficiencies is largest in high permeability reservoirs, with the highest efficiency in the first and second rounds, but slightly lower than in medium permeability reservoirs after the third round;

④ The range of gas displacement efficiencies in the intermediate permeability reservoir is intermediate, with higher gas displacement efficiencies in the first and second rounds followed by a slightly decreasing trend.

⑤ The range of variability in the gas displacement efficiency is smallest for low permeability reservoirs, where the gas displacement efficiency per cycle is lower than for high and medium permeability reservoirs.

-

(2)

Variation of gas displacement efficiency for multiple rounds of gas storage.

① As the number of gas storage injections and production rounds increases, the cumulative gas displacement efficiency gradually increases, with the growth rate slowing after five rounds and eventually stabilizing at a maximum;

② The maximum cumulative gas displacement efficiency for a high permeability reservoir can exceed 35%, and it is estimated that as subsequent injection and production rounds increase, the cumulative gas displacement efficiency can eventually reach 45%; the gas displacement efficiency of medium permeable reservoirs can reach over 31% and is estimated to reach 40% with subsequent injection and production rounds. The gas displacement efficiency of low permeability reservoirs can reach over 23% and is estimated to eventually reach 30% with the addition of subsequent injection and production rounds.

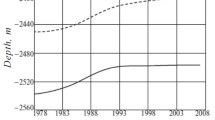

3 Result Verification

Currently, there is no successful example of gas storage in a reservoir in China to demonstrate the experimental results, but this can be confirmed by referring to the xxx gas storage in the xxx gas storage cluster [5,6,7,8]. The xxx gas storage is the first underground gas storage in China to be reconstructed from a depleted condensate reservoir with an oil ring. The gas storage has been in operation for 18 years since it was completed in 2003, and the gas displacement efficiency and capacity expansion process of the oil ring site reflect the capacity expansion characteristics of reservoir gas storage (Fig. 4).

The northern gas storage is an anticlinal structure with a buried depth of -2706m at the high point of the structure and a structural amplitude of 94m. The upper 60m is gas-bearing, the lower 30m is oil-bearing, and the lower part is water-bearing. The gas storage reservoir is a sandstone formation of the Lower Tertiary Shoshone Formation. The sand bodies have a large thickness, a broad distribution in the plane, and good connectivity. The porosity of the reservoir sandstone is 13.7 ~ 26.3%, and the permeability is 40.7 ~ 780.1 × 10−3μm, which is the medium porosity and high permeability reservoir. The original formation pressure of the gas reservoir is 30.5MPa, the formation temperature is 102℃, which is the normal temperature and pressure system. The oil ring has an oil-to-gas ratio of 0.84 and is light oil. The gas bearing area is 7.6km2, the geological reserves of condensate gas are 33.13 × 108m3, the oil ring oil bearing area is 4.2km2, and the geological reserves of crude oil are 170 × 104t.

In 2003, when the XXX gas reservoir was converted to gas storage, the oil ring and gas cap were used as a whole to implement gas injection and gas recovery operations.

At present, the overall storage capacity has increased by 13 × 108m3, of which 16.69 × 104m3is produced by oil and gas Wells, and the converted storage capacity has increased by 0.83 × 108m3, accounting for 6% of the total expansion capacity. In addition, the water production expansion capacity is about 4%, and the displacement expansion of oil and water driven by pressure difference of high-pressure gas injection accounts for about 90% of the total expansion capacity (Fig. 5).

4 Conclusions and Suggestions

(1) The reservoir gas storage capacity expansion mechanism is complex and comprises 10 aspects, where the differential pressure driven capacity expansion mechanism dominates, followed by the oil recovery capacity expansion mechanism, with other capacity expansion mechanisms playing minor roles.

(2) The gas displacement efficiency of reservoir gas storage reflects the capacity expansion efficiency. Simulations show that the gas-to-water efficiency depends on the injection and production cycles. The gas-to-water efficiency of the first cycle is about 10%, and the gas-to-water efficiency of a single cycle gradually decreases with the number of injection and production cycles, reaching zero after 8–10 cycles.

(3) The final gas displacement efficiency can be as high as 45 percent for high permeability reservoirs, 40 percent for medium permeability reservoirs, and 30 percent for high permeability reservoirs.

References

Liwei, W.: The International Gas Union releases the Global Gas Report (2019)

Xiaoming, M.A., Beibei, Y.U., Yabin, C., et al.: Regularities and influencing factors of the capacity of underground gas storage with water-flooding depletion. Nat. Gas Ind. 32(2), 87–90 (2012)

Bybee, K.: Minimizing risk of gas escape in gas storage. J. Pet. Technol. 60(11), 94–96 (2008). https://doi.org/10.2118/1108-0094-JPT

Xiong, Y., Hongguang, X., Hui, L., Jiandong, L., et al.: Laboratory experiment study on storage capacity variation mechanism of gas storage in abandoned oil reservoir. Sci. Technol. Eng. 15(06), 173–176 (2015)

Li Xiaoguang, H., Changhao, M.Z., et al.: Comprehensive evaluation of double 6 gas storage operation and research on expansion potential. Spec. Oil Gas Reservoirs 27(06), 114–119 (2020)

Tongwen, J., Jinfang, W., Zhengmao, W., et al.: Practice and understanding of collaborative construction of underground gas storage and natural gas displacement. Nat. Gas Ind. 41(09), 66–74 (2021)

International Energy Agency: Asia will lead the source of demands for global natural gas. Brief. Nat. Gas Technol. Econ. (75), 43 (2019)

Guosheng, D., Chun, L., Daming, W., et al.: Status and technical development direction of underground gas storage in China. Nat. Gas Ind. 35(11), 107–112 (2015)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Tang, Yn., Yang, Sh., Zhuang, Tl., Zhang, Zm., Yin, Sl. (2024). Study on Expansion Mechanism and Displacement Efficiency of Reservoir Gas Storage. In: Lin, J. (eds) Proceedings of the International Field Exploration and Development Conference 2023. IFEDC 2023. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-97-0268-8_70

Download citation

DOI: https://doi.org/10.1007/978-981-97-0268-8_70

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-97-0267-1

Online ISBN: 978-981-97-0268-8

eBook Packages: EngineeringEngineering (R0)