Abstract

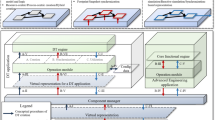

Currently, several facilities around the world, as part of government’s sustainable development strategies, are turning to the development of smart value chains that can leverage efficiently all of countries available and local resources. Smart factories vision embracing the fourth industrial revolution of manufacturing plants introduced a completely renewed industrial organization based on collaboration between human intelligence and capabilities and machines intelligence and computing capacities, manufacturing plants horizontal and vertical integration, and with particular interest for our paper end-to-end engineering. This collaborative endeavour has been translated in the field by a set of technologies for instance advanced simulation tools through digital twins. The use of these new resources and productivity enhancement has not been without consequences on natural ecosystems, which are increasingly subject to industrial competitiveness pressure. To counter the adverse environmental effects of industrial and technological growth, some manufacturers are developing simulation-based life cycle assessment approaches. Over the last few years, several research communities have explored the potential of simulation-based LCA method for the optimization of the environmental impact of production systems through the application of advanced artificial intelligence algorithms. However, only a limited number of these attempts have seen their practical implementation. Currently, digital twins’ technologies are rapidly expanding due to the advantages they offer for real-time simulation, multidimensional replication of industrial systems and end-to-end engineering. Through this work, we propose a generic solution based on digital twins’ technologies and ISO 20140 for real-time life cycle assessment and manufacturing systems sustainable optimization.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

W.S. Alaloul, M.S. Liew, N.A.W.A. Zawawi,I.B. Kennedy, Industrial revolution 4.0 in the construction industry: challenges and opportunities for stakeholders. Ain Shams Eng. J. S2090447919301157 (2019). https://doi.org/10.1016/j.asej.2019.08.010

W. El Hilali, A. El Manouar, Smart Companies: How to Reach Sustainability During a Digital Transformation. in Proceedings of the 3rd International Conference on Smart City Applications–SCA ‘18. (ACM Press, Tetouan, Morocco, 2018) pp. 1–6

E. Conrad, L.F. Cassar, Decoupling economic growth and environmental degradation: reviewing progress to date in the small island state of malta. Sustainability. 6, 6729–6750 (2014). https://doi.org/10.3390/su6106729

P. Tapio, Towards a theory of decoupling: degrees of decoupling in the EU and the case of road traffic in Finland between 1970 and 2001. Transp. Policy 12, 137–151 (2005). https://doi.org/10.1016/j.tranpol.2005.01.001

E. Sanyé-Mengual, M. Secchi, S. Corrado, A. Beylot, S. Sala, Assessing the decoupling of economic growth from environmental impacts in the European Union: A consumption-based approach. J. Cleaner Prod. 236, 117535 (2019). https://doi.org/10.1016/j.jclepro.2019.07.010

S. Stavropoulos, R. Wall, Y. Xu, Environmental regulations and industrial competitiveness: evidence from China. Appl. Econ. 50, 1378–1394 (2018). https://doi.org/10.1080/00036846.2017.1363858

D.C.A. Pigosso, A. Schmiegelow, M.M. Andersen, Measuring the readiness of SMEs for eco-innovation and industrial symbiosis: development of a screening tool. Sustainability. 10, 2861 (2018). https://doi.org/10.3390/su10082861

F.D. Pero, M. Delogu, M. Pierini, Life Cycle Assessment in the automotive sector: a comparative case study of Internal Combustion Engine (ICE) and electric car. Procedia Struct. Integrity. 12, 521–537 (2018). https://doi.org/10.1016/j.prostr.2018.11.066

I. Djekic, M. Pojić, A. Tonda, P. Putnik, D. Bursać Kovačević, A. Režek-Jambrak, I. Tomasevic, scientific challenges in performing life-cycle assessment in the food supply chain. Foods. 8 (2019). https://doi.org/10.3390/foods8080301

C. Cimino, E. Negri, L. Fumagalli, Review of digital twin applications in manufacturing. Comput. Ind. 113, 103130 (2019). https://doi.org/10.1016/j.compind.2019.103130

M. Ghita, B. Siham, M. Hicham, Digital twins development architectures and deployment technologies: moroccan use case. Int. J. Adv. Comput. Sci. Appl. (IJACSA). 11 (2020). https://doi.org/10.14569/IJACSA.2020.0110260

B. Mota, A. Carvalho, M.I. Gomes, A. Barbosa-Póvoa, Design and Planning Supply Chains with Beneficial Societal Goals. in Computer Aided Chemical Engineering (Elsevier 2019), pp. 439–444

Sustainable Development Goals, https://www.undp.org/content/undp/en/home/sustainable-development-goals.html

A. Moldavska, T. Welo, The concept of sustainable manufacturing and its definitions: A content-analysis based literature review. J. Cleaner Prod. 166, 744–755 (2017). https://doi.org/10.1016/j.jclepro.2017.08.006

P. Rosa, S. Sassanelli, A. Urbinati, D. Chiaroni, S. Terzi, Assessing relations between Circular Economy and Industry 4.0: a systematic literature review. Int. J. Prod. Res. 58, 1662–1687 (2020). https://doi.org/10.1080/00207543.2019.1680896

Global Reporting Initiative, https://www.globalreporting.org/Pages/default.aspx

W.E. Rees, Ecological Footprints and Appropriated Carrying Capacity: What Urban Economics Leaves Out: Environment and Urbanization (2016). https://doi.org/10.1177/095624789200400212

J. Vogler, H.R. Stephan, The European Union in global environmental governance: Leadership in the making? Int. Environ. Agreements. 7, 389–413 (2007). https://doi.org/10.1007/s10784-007-9051-5

H. Ritchie, M. Roser, CO2 and Greenhouse Gas Emissions. Our World in Data (2017)

Worldometer—real time world statistics, https://www.worldometers.info/

Climate Change: Vital Signs of the Planet, https://climate.nasa.gov/

14:00–17:00: ISO 20140–3:2019, https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/06/46/64674.html

M.A. Pisching, M.A.O. Pessoa, F. Junqueira, D.J. dos Santos Filho, P.E. Miyagi, An architecture based on RAMI 4.0 to discover equipment to process operations required by products. Comput. Ind. Eng. 125, 574–591 (2018). https://doi.org/10.1016/j.cie.2017.12.029

M. Ghazivakili, C. Demartini, C. Zunino, Industrial Data-Collector by Enabling OPC-UA standard for Industry 4.0. in 2018 14th IEEE International Workshop on Factory Communication Systems (WFCS) (IEEE, Imperia, Italy, 2018), pp. 1–8

C. Toro, A. Seif, H. Akhtar, Modeling and connecting asset administrative shells for mini factories. Cybernet. Syst. 51, 232–245 (2020). https://doi.org/10.1080/01969722.2019.1705554

robert.lipman@nist.gov: Enabling the Digital Thread for Smart Manufacturing, https://www.nist.gov/el/systems-integration-division-73400/enabling-digital-thread-smart-manufacturing

A. Semmar, N. Machkour, R. Boutaleb, H. Bnouachir, H. Medromi, M. Chergui, L. Deshayes, M. Elouazguiti, F. Moutaouakkil, M. Zegrari, Modeling Input Data of Control System of a Mining Production Unit Based on ISA-95 Approach, in Smart Applications and Data Analysis. ed. by M. Hamlich, L. Bellatreche, A. Mondal, C. Ordonez (Springer International Publishing, Cham, 2020), pp. 47–55

Harbal, A.: La question environnementale au Maroc (2017)

SDD—GRI Database, https://database.globalreporting.org/organizations/7288/

Livre Blanc : La Transformation Digitale Au Maroc. AUSIM MAROC, https://www.ausimaroc.com/livre-blanc-la-transformation-digitale-au-maroc/

CHIMIE-PARACHIMIE | Ministère de l’Industrie, du Commerce et de l’Économie Verte et Numérique, https://www.mcinet.gov.ma/fr/content/chimie-parachimie

Goal 6: Clean Water and Sanitation–SDG Tracker, https://sdg-tracker.org/water-and-sanitation

SDG Indicators, https://unstats.un.org/sdgs/indicators/database/

E. Nieuwlaar, Life Cycle Assessment and Energy Systems, in Encyclopedia of Energy. ed. by C.J. Cleveland (Elsevier, New York, 2004), pp. 647–654

G. Mondello, R. Salomone, Chapter 10—Assessing Green Processes Through Life Cycle Assessment and Other LCA-Related Methods. in Studies in Surface Science and Catalysis, ed by A. Basile, G. Centi, M.D. Falco, G. Laquaniello A. Basile, G. Centi, M.D. Falco, G. Laquaniello (Elsevier 2019), pp. 159–185

14:00–17:00: ISO 14040:2006, https://www.iso.org/cms/render/live/fr/sites/isoorg/contents/data/standard/03/74/37456.html

R. Basosi, M. Cellura, S. Longo, M.L. Parisi, (eds.) Life Cycle Assessment of Energy Systems and Sustainable Energy Technologies: The Italian Experience (Springer International Publishing, 2019)

Y. Liu, A. Syberfeldt, M. Strand, Review of simulation-based life cycle assessment in manufacturing industry. Prod. Manuf. Res. 7, 490–502 (2019). https://doi.org/10.1080/21693277.2019.1669505

S. Suh, G. Huppes, Methods in the Life Cycle Inventory of a Product, in Handbook of Input-Output Economics in Industrial Ecology. ed. by S. Suh (Springer, Netherlands, Dordrecht, 2009), pp. 263–282

S. Asem-Hiablie, T. Battagliese, K.R. Stackhouse-Lawson, C. Alan Rotz, A life cycle assessment of the environmental impacts of a beef system in the USA. Int. J. Life Cycle Assess. 24, 441–455 (2019). https://doi.org/10.1007/s11367-018-1464-6

F. Torabi, P. Ahmadi, Battery Technologies. in Simulation of Battery Systems (Elsevier, 2020), pp. 1–54

M.L. Brusseau, Chapter 32 - Sustainable Development and Other Solutions to Pollution and Global Change. in Environmental and Pollution Science, ed. by M.L. Brusseau, I.L., Pepper, C.P. Gerba, Third Edition. (Academic Press, 2019), pp. 585–603

C.C. Wang, S.M.E. Sepasgozar, M. Wang, J. Sun, X. Ning, Green performance evaluation system for energy-efficiency-based planning for construction site layout. Energies. 12, 4620 (2019). https://doi.org/10.3390/en12244620

D. Husain, R. Prakash, Ecological footprint reduction of built envelope in India. J. Building Eng. 21, 278–286 (2019). https://doi.org/10.1016/j.jobe.2018.10.018

openLCA Nexus: The source for LCA data sets, https://nexus.openlca.org/

L. Hermann, F. Kraus, R. Hermann, Phosphorus Processing—potentials for higher efficiency. Sustainability. 10, 1482 (2018). https://doi.org/10.3390/su10051482

C.G. Machado, M.P. Winroth, E.H.D.R. Silva da, Sustainable manufacturing in Industry 4.0: an emerging research agenda. Int. J. Prod. Res. 58, 1462–1484 (2020). https://doi.org/10.1080/00207543.2019.1652777

F. Guarino, M. Cellura, M. Traverso, Costructal law, exergy analysis and life cycle energy sustainability assessment: an expanded framework applied to a boiler. Int. J. Life Cycle Assess. (2020). https://doi.org/10.1007/s11367-020-01779-9

Life Cycle Assessment in the minerals industry, Current practice, harmonization efforts, and potential improvement through the integration with process simulation. J. Cleaner Prod. 232, 174–192 (2019). https://doi.org/10.1016/j.jclepro.2019.05.318

P. Stasinopoulos, N. Shiwakoti, M. Beining, Use-stage life cycle greenhouse gas emissions of the transition to an autonomous vehicle fleet: a system dynamics approach. J. Cleaner Prod. 123447 (2020). https://doi.org/10.1016/j.jclepro.2020.123447

L.F. Morales-Mendoza, C. Azzaro-Pantel, Bridging LCA data gaps by use of process simulation for energy generation. Clean Techn. Environ. Policy. 19, 1535–1546 (2017). https://doi.org/10.1007/s10098-017-1349-6

C. Brondi, E. Carpanzano, A modular framework for the LCA-based simulation of production systems. CIRP J. Manuf. Sci. Technol. 4, 305–312 (2011). https://doi.org/10.1016/j.cirpj.2011.06.006

G.M. Zanghelini, E. Cherubini, S.R. Soares, How Multi-criteria decision analysis (MCDA) is aiding life cycle assessment (LCA) in results interpretation. J. Cleaner Prod. 172, 609–622 (2018). https://doi.org/10.1016/j.jclepro.2017.10.230

M.J. Hermoso-Orzáez, J.A. Lozano-Miralles, R. Lopez-Garcia, P. Brito, Environmental criteria for assessing the competitiveness of public tenders with the replacement of large-scale LEDs in the outdoor lighting of cities as a key element for sustainable development: case study applied with Promethee methodology. Sustainability. 11, 5982 (2019). https://doi.org/10.3390/su11215982

M. Budzinski, M. Sisca, D. Thrän, Consequential LCA and LCC using linear programming: an illustrative example of biorefineries. Int. J. Life Cycle Assess. 24, 2191–2205 (2019). https://doi.org/10.1007/s11367-019-01650-6

K. Allacker, V. Castellani, G. Baldinelli, F. Bianchi, C. Baldassarri, S. Sala, Energy simulation and LCA for macro-scale analysis of eco-innovations in the housing stock. Int. J. Life Cycle Assess. 24, 989–1008 (2019). https://doi.org/10.1007/s11367-018-1548-3

S. Kim, G.-H. Kim, Y.-D. Lee, Sustainability life cycle cost analysis of roof waterproofing methods considering LCCO2. Sustainability. 6, 158–174 (2014). https://doi.org/10.3390/su6010158

B. Löfgren, A.-M. Tillman, Relating manufacturing system configuration to life-cycle environmental performance: discrete-event simulation supplemented with LCA. J. Cleaner Prod. 19, 2015–2024 (2011). https://doi.org/10.1016/j.jclepro.2011.07.014

R. Geyer, D.M. Stoms, J.P. Lindner, F.W. Davis, B. Wittstock, Coupling GIS and LCA for biodiversity assessments of land use. Int. J. Life Cycle Assess. 15, 454–467 (2010). https://doi.org/10.1007/s11367-010-0170-9

N. Perry, J. Garcia, Sustainable Design of Complex Systems, Products and Services with User Integration into Design, in Designing Sustainable Technologies, Products and Policies: From Science to Innovation. ed. by E. Benetto, K. Gericke, M. Guiton (Springer International Publishing, Cham, 2018), pp. 365–369

S. Payen, C. Basset-Mens, F. Colin, P. Roignant, Inventory of field water flows for agri-food LCA: critical review and recommendations of modelling options. Int. J. Life Cycle Assess. 23, 1331–1350 (2018). https://doi.org/10.1007/s11367-017-1353-4

C.-Y. Baek, K. Tahara, K.-H. Park, Parameter uncertainty analysis of the life cycle inventory database: application to greenhouse gas emissions from brown rice production in IDEA. Sustainability. 10, 922 (2018). https://doi.org/10.3390/su10040922

M. Ziyadi, I.L. Al-Qadi, Model uncertainty analysis using data analytics for life-cycle assessment (LCA) applications. Int. J. Life Cycle Assess. 24, 945–959 (2019). https://doi.org/10.1007/s11367-018-1528-7

K. Tokimatsu, L. Tang, R. Yasuoka, R. Ii, N. Itsubo, M. Nishio, Toward more comprehensive environmental impact assessments: interlinked global models of LCIA and IAM applicable to this century. Int. J. Life Cycle Assess. (2020). https://doi.org/10.1007/s11367-020-01750-8

M.R. Giraldi-Díaz, L. De Medina-Salas, E. Castillo-González, R. León-Lira, Environmental impact associated with the supply chain and production of grounding and roasting coffee through life cycle analysis. Sustainability. 10, 4598 (2018). https://doi.org/10.3390/su10124598

P. Kerdlap, J.S.C. Low, S. Ramakrishna, Life cycle environmental and economic assessment of industrial symbiosis networks: a review of the past decade of models and computational methods through a multi-level analysis lens. Int. J. Life Cycle Assess. (2020). https://doi.org/10.1007/s11367-020-01792-y

T. Schaubroeck, Both completing system boundaries and realistic modeling of the economy are of interest for life cycle assessment—a reply to “Moving from completing system boundaries to more realistic modeling of the economy in life cycle assessment” by Yang and Heijungs (2018). Int. J. Life Cycle Assess. 24, 219–222 (2019). https://doi.org/10.1007/s11367-018-1546-5

Y. Leroy, D. Froelich, Qualitative and quantitative approaches dealing with uncertainty in life cycle assessment (LCA) of complex systems: towards a selective integration of uncertainty according to LCA objectives. Int. J. Design Eng. 3, 151–171 (2010). https://doi.org/10.1504/IJDE.2010.034862

V. Bellon-Maurel, M.D. Short, P. Roux, M. Schulz, G.M. Peters, Streamlining life cycle inventory data generation in agriculture using traceability data and information and communication technologies—part I: concepts and technical basis. J. Cleaner Prod. 69, 60–66 (2014). https://doi.org/10.1016/j.jclepro.2014.01.079

I.T. Herrmann, A. Jørgensen, S. Bruun, M.Z. Hauschild, Potential for optimized production and use of rapeseed biodiesel. Based on a comprehensive real-time LCA case study in Denmark with multiple pathways. Int. J. Life Cycle Assess. 18, 418–430 (2013). https://doi.org/10.1007/s11367-012-0486-8

V.E. de Oliveira Gomes, D.J. De Barba, J. de Oliveira Gomes, K.-H. Grote, C. Beyer, Sustainable Layout Planning Requirements by Integration of Discrete Event Simulation Analysis (DES) with Life Cycle Assessment (LCA). in Advances in Production Management Systems. Competitive Manufacturing for Innovative Products and Services, ed. by C. Emmanouilidis, M. Taisch, D. Kiritsis (Springer, Berlin, Heidelberg, 2013) pp. 232–239

T. Henriksen, J.W. Levis, M.A. Barlaz, A. Damgaard, Approaches to fill data gaps and evaluate process completeness in LCA—perspectives from solid waste management systems. Int. J. Life Cycle Assess. 24, 1587–1601 (2019). https://doi.org/10.1007/s11367-019-01592-z

S. Schwarzinger, D.N. Bird, T.M. Skjølsvold, Identifying consumer lifestyles through their energy impacts: transforming social science data into policy-relevant group-level knowledge. Sustainability. 11, 6162 (2019). https://doi.org/10.3390/su11216162

J. Pohl, L.M. Hilty, M. Finkbeiner, How LCA contributes to the environmental assessment of higher order effects of ICT application: A review of different approaches. J. Cleaner Prod. 219, 698–712 (2019). https://doi.org/10.1016/j.jclepro.2019.02.018

A.N. Azimi, S.M.R. Dente, S. Hashimoto, Social Life-cycle assessment of household waste management system in Kabul City. Sustainability. 12, 3217 (2020). https://doi.org/10.3390/su12083217

Z. Jin, J. Kim, C. Hyun, S. Han, Development of a model for predicting probabilistic life-cycle cost for the early stage of public-office construction. Sustainability. 11, 3828 (2019). https://doi.org/10.3390/su11143828

M. Zimek, A. Schober, C. Mair, R.J. Baumgartner, T. Stern, M. Füllsack, The third wave of LCA as the “decade of consolidation.” Sustainability. 11, 3283 (2019). https://doi.org/10.3390/su11123283

A.M. Herrera Almanza, B. Corona, Using social life cycle assessment to analyze the contribution of products to the sustainable development goals: a case study in the textile sector. Int. J. Life Cycle Assess. (2020). https://doi.org/10.1007/s11367-020-01789-7

S. O’Keeffe, D. Thrän, Energy crops in regional biogas systems: an integrative spatial LCA to assess the influence of crop mix and location on cultivation GHG emissions. Sustainability. 12, 237 (2020). https://doi.org/10.3390/su12010237

R. Kc, M. Aalto, O.-J. Korpinen, T. Ranta, S. Proskurina, Lifecycle assessment of biomass supply chain with the assistance of agent-based modelling. Sustainability. 12, 1964 (2020). https://doi.org/10.3390/su12051964

H.E. Otto, K.G. Mueller, F. Kimura, Efficient information visualization in LCA. Int. J. LCA. 8, 183 (2003). https://doi.org/10.1007/BF02978468

H.E. Otto, K.G. Mueller, F. Kimura, Efficient information visualization in LCA: Application and practice. Int. J. LCA. 9, 2 (2004). https://doi.org/10.1007/BF02978531

openLCA Nexus: The source for LCA data sets, https://nexus.openlca.org/databases

G. Sonnemann, B. Vigon, C. Broadbent, M.A. Curran, M. Finkbeiner, R. Frischknecht, A. Inaba, A. Schanssema, M. Stevenson, C.M.L. Ugaya, H. Wang, M.-A. Wolf, S. Valdivia, Process on “global guidance for LCA databases.” Int. J. Life Cycle Assess. 16, 95–97 (2011). https://doi.org/10.1007/s11367-010-0243-9

J. Liu, Z. Huang, X. Wang, Economic and environmental assessment of carbon emissions from demolition waste based on LCA and LCC. Sustainability. 12, 6683 (2020). https://doi.org/10.3390/su12166683

M.L. Kambanou, Life cycle costing: understanding how it is practised and its relationship to life cycle management—a case study. Sustainability. 12, 3252 (2020). https://doi.org/10.3390/su12083252

R. Baum, J. Bieńkowski, Eco-efficiency in measuring the sustainable production of agricultural crops. Sustainability. 12, 1418 (2020). https://doi.org/10.3390/su12041418

J. Sanfélix, F. Mathieux, C. de la Rúa, M.-A. Wolf, K. Chomkhamsri, The enhanced lca resources directory: a tool aimed at improving life cycle thinking practices. Int. J. Life Cycle Assess. 18, 273–277 (2013). https://doi.org/10.1007/s11367-012-0468-x

A. Siebert, A. Bezama, S. O’Keeffe, D. Thrän, Social life cycle assessment indices and indicators to monitor the social implications of wood-based products. J. Cleaner Prod. 172, 4074–4084 (2018). https://doi.org/10.1016/j.jclepro.2017.02.146

L. Jarosch, W. Zeug, A. Bezama, M. Finkbeiner, D. Thrän, A regional socio-economic life cycle assessment of a bioeconomy value chain. Sustainability. 12, 1259 (2020). https://doi.org/10.3390/su12031259

J. Veselka, M. Nehasilová, K. Dvořáková, P. Ryklová, M. Volf, J. Růžička, A. Lupíšek, Recommendations for developing a BIM for the purpose of LCA in green building certifications. Sustainability. 12, 6151 (2020). https://doi.org/10.3390/su12156151

J. Sherry, J. Koester, Life cycle assessment of aquaculture stewardship council certified atlantic Salmon (Salmo salar). Sustainability. 12, 6079 (2020). https://doi.org/10.3390/su12156079

L.F. Morales-Mendoza, C. Azzaro-Pantel, J.-P. Belaud, A. Ouattara, Coupling life cycle assessment with process simulation for ecodesign of chemical processes. Environ. Progress Sustainable Energy. 37, 777–796 (2018). https://doi.org/10.1002/ep.12723

R. Gaha, A. Benamara, B. Yannou, Proposition of Eco-Feature: A New CAD/PLM Data Model for an LCA Tool. in CMSM 2017: The Seventh International Congress Design and Modelling of Mechanical Systems (Hammamet, Tunisia, 2017)

M. Grieves, J. Vickers, Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems, in Transdisciplinary Perspectives on Complex Systems. ed. by F.-J. Kahlen, S. Flumerfelt, A. Alves (Springer International Publishing, Cham, 2017), pp. 85–113

Y. Liu, L. Zhang, Y. Yang, L. Zhou, L. Ren, F. Wang, R. Liu, Z. Pang, M.J. Deen, A novel cloud-based framework for the elderly healthcare services using digital twin. IEEE Access. 7, 49088–49101 (2019). https://doi.org/10.1109/ACCESS.2019.2909828

14:00–17:00: ISO/CD 23247–1, https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/07/50/75066.html

F. Coallier, ISO/IEC JTC 1/SC41 IoT and Related Technologies. 46

The Structure of the Administration Shell: Trilateral Perspectives from France, Italy and Germany. 64

E.J. Tuegel, P. Kobryn, J.V. Zweber, R.M. Kolonay, Digital Thread and Twin for Systems Engineering: Design to Retirement. in 55th AIAA Aerospace Sciences Meeting (American Institute of Aeronautics and Astronautics, Grapevine, Texas, 2017)

Digital twins • Eclipse Ditto • a digital twin framework, https://www.eclipse.org/ditto/intro-digitaltwins.html

B. He, K.-J. Bai, Digital twin-based sustainable intelligent manufacturing: a review. Adv. Manuf. (2020). https://doi.org/10.1007/s40436-020-00302-5

J. Jiao, (Roger), F. Zhou, N.Z. Gebraeel, V. Duffy, Towards augmenting cyber-physical-human collaborative cognition for human-automation interaction in complex manufacturing and operational environments. Int. J. Prod. Res. 0, 1–23 (2020). https://doi.org/10.1080/00207543.2020.1722324

M. Ghita, B. Siham, M. Hicham, A. Abdelhafid, D. Laurent, Digital twins: development and implementation challenges within Moroccan context. SN Appl. Sci. 2, 885 (2020). https://doi.org/10.1007/s42452-020-2691-6

M. Ghita, B. Siham, M. Hicham, A.E.M. Abdelhafid, D. Laurent, Geospatial Business Intelligence and Cloud Services for Context Aware Digital Twins Development. in 2020 IEEE International conference of Moroccan Geomatics (Morgeo) (2020), pp. 1–6

Acknowledgements

Work carried out within the framework of the cooperation agreement for technological and scientific development concluded between the UM6P and the FRDISI.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Ghita, M., Siham, B., Hicham, M., Griguer, H. (2021). Digital Twins Based LCA and ISO 20140 for Smart and Sustainable Manufacturing Systems. In: Joshi, A., Nagar, A.K., Marín-Raventós, G. (eds) Sustainable Intelligent Systems. Advances in Sustainability Science and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-33-4901-8_8

Download citation

DOI: https://doi.org/10.1007/978-981-33-4901-8_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-33-4900-1

Online ISBN: 978-981-33-4901-8

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)