Abstract

In the last 20 years, micro-fluidic technique has emerged as an important enabling tool for single-cell chemical analysis, owing to the miniaturization of the fluidic environment. These methodologies made various applications in single-cell analysis fields, and their superior performances such as rapid, simple, and high-efficient processing have been proved. Recently, the space is further downscaling to the 10–1000 nm scale (nano-space). The nano-space is located between conventional nanotechnology (10–1000 nm) and microtechnology (>1 mm), and the research tools are not well established. For these purposes, a new research field is now being created which are quite different from those in micro-space. In this chapter, we focus on the basic researches in nano-fluidic space and survey the fundamental technologies for nano-fluidic space. Then, recent developments of nano-fluidic technologies for single-cell analysis are reported. Finally, the potential of nano-fluidics-based single-cell analysis is discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

8.1 Introduction

Cell is one of the fundamental units of life. Individual cells are heterogeneous in terms of gene expression, metabolite levels, ion concentrations, or patterns of response to a specified stimulus [1,2,3,4,5,6]. Many investigations have demonstrated that individual cells, even for those identical in appearance, show cell-to-cell variability caused by genetic or microenvironment variations [7,8,9,10]. Recent investigations enumerate the cell heterogeneity as a characteristic of progress in cell biology and tissue engineering, highlighting the necessity to probe individual cells in a cell population [11, 12]. Single-cell analysis provides a new venue to capture the cellular heterogeneity in extracellular circumstances as well as intracellular conditions at the single-cell level [13].

Single-cell analysis requires the capacity to manipulate a small sample volume down to picoliter (pL) in order to interrogate individual cells. Generally, cell analysis is performed in microtubes or micro-wells with the sample volume on a microliter (μL) scale, which is much larger (six orders or magnitude) than the single-cell volume of pL. Table 8.1 presents the conventional methods for cell analysis (~106 cells) and the requirement for single-cell analysis. The reduced sample volume of single-cell analysis directly results in the improved detection limit. Assuming that a pM concentration of typical analytical targets is available, single-cell analysis tools could detect very few targeted molecules, while the number of detectable molecules is in the order of 106 by conventional cell analysis methods. Therefore, there is an urgent need to develop sophisticated tools for manipulation of single cells.

For these purposes, designing tools of micro-chemical processes and reliable fluidic devices will be important technologies. Micro-total analysis systems (μ-TAS) have shown great advantage for the analysis of single cells [15,16,17,18]. In addition, nanometer-scale chemical experiment is opening new horizon of single-cell study tool. Recently, the advances in nano-fabrication technologies enable the biochemical analysis within a “nano-space,” which is defined by the length scale between the 10 nm and 1000 nm [19, 20] as shown in Table 8.2. The major advantage of nano-space is the use of extremely small sample volumes: the femtoliter (fL) or attoliter (aL) scale [21, 22]. It is noted that the sample volume in nano-space is 104–103 times smaller than that of single cell, thus allowing for real-time analysis of a minute sample volume from living single cells [23, 24].

In this chapter, we focus on the methodologies and new application for single-cell analysis in nano-space. Firstly, nano-channel fabrication, the surface modification, and fluidic control methods as basic research tools for nano-space are reported. Secondly, nano-fluidic technology approaches for single-cell manipulation, single-cell treatment, and detection for samples from single-cell are reviewed. Thirdly, future perspectives and problems to be solved are briefly illustrated.

8.2 Nanofluidic Devices

Nanoscale devices can be used to manipulate single cells or deliver chemicals into cells in a controlled fashion. In the nano-fluidic chip, the nano-space can be used to characterize the behavior of individual molecules. There is much of the relevant literature cites the potential and especially the high-throughput operation for enveloping analytical methods to observe, manipulate, and explore single cell in the nano-space.

8.2.1 Fabrication Methods

There are many fabrication methods for nanoscale structures, and their methods can be divided into two categories. One is top-down processes in which the nano-structures are directly prepared on bulk substrates by cutting or milling the substrates. The other is a bottom-up process that manipulates and self-assembles atoms and molecules to prepare nano-structures on substrates. Microchips with nano-channels were fabricated using fused silica substrates via nano-channels fabrication (electron-beam lithography), micro-channel fabrication (UV lithography), dry etching, drilling holes, and substrate bonding.

8.2.1.1 Nano-channel Fabrication (Electron-Beam Lithography and Dry Etching)

The substrates for fabrication of the nano-channel were 1-mm-thick fused silica rectangle plates. The substrates were mechanically polished and thermally annealed to obtain an optically flat surface and washed in acetone, ethanol, and pure water and cleaned in an O2 plasma reactor. First, the substrate was covered with electron-beam resist and conductive polymer layers by spin coater (Fig. 8.1a). Then, it was placed in the vacuum chamber of an electron-beam lithography system. A computer-controlled electron-beam scanner was used to draw a nanometer-sized channel pattern (Fig. 8.1b). After the exposure, the conductive polymer layer was removed in pure water, and the electron-beam resist layer was developed in xylene. After the drawn nano-patterns were etched due to inductively coupled plasma (ICP) etching with a mixture of SF6/CHF3 gases, plasma etching with CHF3/O2 gases, or a fast atom beam (FAB) etching with CHF3 gas, 2-D nano-space channels could be obtained onto the substrate. After FAB etching, the resist layer was removed in the O2 plasma chamber (Fig. 8.1c). The fabricated nano-spaces were connected with micro-channels that were fabricated by either plasma etching process. The inlet holes were pierced through the fabricated substrate using a diamond coated drill. The substrate was washed repeatedly in pure water and piranha solution, and the nano-in-micro structures on the substrate were sealed by thermal bonding or sodium silicate layer with pressing [25]. An example of the fabrication procedure for a glass chip with nano-in-micro structures is shown in Fig. 8.1d.

Fabrication scheme: a Spin coating of electron-beam resist and conductive polymer layers on fused silica substrate. b Electron-beam lithography of nanometer-sized channels. c Fast atom beam etching of nanometer-sized channels. d Photograph of a glass chip invoking nano-in-micro structures and SEM image of nano-channels

8.2.1.2 Micro-channel Fabrication

To introduce liquid samples into the nano-channels, we need fabricated micro-channels on the substrate to connect nano-channels. Micro-channels in fused silica rectangle plates were fabricated by laser-beam patterning and sand-blast processing. First, the positive photo-resist material was coated by spin onto the Au/Cr glass and UV (ultraviolet) light was irradiated by a photomask (polyimide sheet) for transferring the channel pattern onto the photo-resist material. The UV-exposed photo-resist material was etched by the pattern. Then, the micro-channel was etched into a patterned substrate by plasma etching technique and the remaining photo-resist material and metal layers were removed completely. After the try etching process, a 0.4-mm-diameter hole was drilled at the end of each channel.

8.2.1.3 Cover Plate Bonding

To cover the nano-channels and micro-channels, a fused silica plate (nano-channel) should bond to the substrate (micro-channel). In the traditional methods [26, 27], the fused silica plates were laminated by a thermally bonding method at the softening point of fused silica (1150 °C) for 24 h. However, too high a temperature cause glass to deform, we chose low-temperature bonding method by using hydrofluoric acid. Low-temperature (25–100 °C) bonding methods recently developed by Kitamori group [28, 29] avoid thermal destruction because the principle is based on chemical bonding between silanol groups without heat. Next, the substrates were laminated with the fused silica plate by low-temperature (25–100 °C) bonding methods. The substrate and fused silica plate were successively washed in acetone, ethanol, pure water, a mixed solution of sulfuric acid and hydrogen peroxide (2:1), 1 M NaOH solution, and pure water. Then, the clean silica substrate with channels was placed in the plasma chamber and treated with fluorine-containing oxygen plasma (60 Pa O2, 250 W power) for 40 s. The substrate was removed from the plasma chamber and brought into contact with each other. In order to increase the strength of substrate bonding, the plates were pressurized for 2 h at 5000 N and 100 °C using a bonding machine (Bondtech Co., Ltd., Japan). The bonded device was kept at room temperature (25 °C) for 24 h before use. Finally, completeness of the bonding was confirmed by sight and a leakage test observed under an optical microscope. If the bonding had failed, an optical interference ring pattern was observed.

8.2.2 Surface Modification Methods

On the surface modification methods, there were so many reports in micro-space utilizing light, electron beam, contact printing, ink-jet so on. However, a closed geometry of the nano-channel limits significantly the use of conventional methods for channel modification. Therefore, for closed nano-space, local surface modification with light will be one candidate. So far, there were only a few reports on the local surface modification in nano-space utilizing light.

Here, an example of local immunoassays in nano-space using a photolithographic technique with vacuum ultraviolet light and low-temperature (100 °C) bonding method is shown in Fig. 8.2 [30]. In order to introduce functional groups for antibody immobilization, the entire surface of a fused silica substrate was modified with aminopropyltriethoxysilane (APTES) in the gas phase to achieve uniform APTES layering. Upon irradiation with VUV light through a chromium photomask, reactive oxygen species generated from oxygen gas molecules absorbing the high-energy VUV light oxidatively decompose the APTES. Because the glass surface become super-hydrophilic and activated after decomposition of APTES, it was able to achieve strong glass bonding, which is critical for nano-fluidic control using a high-pressure flow system. For designing and regulating the size and position of the antibody immobilized region, a partially modified APTES layer was formed by masking part of the substrate area from VUV light irradiation with the photomask. The advantage of using VUV light is that both pattern formation and surface activation can be achieved simultaneously. The APTES-patterned substrate was then brought into contact with the upper glass substrate containing micro- and nano-channels, and the substrate was activated by fluorine-containing oxygen plasma. Then, substrates were bound by low-temperature bonding methods. After bonding, to reduce the potential for non-specific protein adsorption to the nano-channel surfaces, the surfaces were chemically modified with trimethoxysilane-poly (ethyleneglycol) (PEG) for reducing the potential non-specific protein adsorption in the nano-channel surfaces [31, 32]. Capture antibodies were chemically immobilized by crosslinking the amino groups of APTES molecules and antibodies using glutaraldehyde. Residual reactive groups were blocked with ethanolamine. As an important subject, modification in nano-space will be an essential problem to detect single-molecule using ELISA for single-cell analyst. In the future, this ultralow-volume molecular capture method could be developed into a nano-fluidics-based ELISA for quantification at the single-molecule level by integrating chemical amplification with the enzymatic reaction and high-sensitivity detection of colorimetric products with differential interference contrast thermal lens microscopy [21].

Example of local immunoassays in nano-space [30]

8.2.3 Detection Methods

Ultrasensitive detection methods in nano-channel are very important for miniaturization. In nano-space, the volume of the sample is usually aL-fL level. Therefore, single-molecule sensitivity is required. So far, single-molecule sensitivity detection methods have reported which are mainly on optical and electrochemistry methods. Recently, nano-pores were increasingly utilized for sensitive detection and have been reported to successfully detect single porphyrin molecules. The experimental principle is based on conductivity measurements that apply a constant voltage to the nano-pore to detect changes in conductivity that occur as molecules pass through the nano-pore. However, the combination with nano-channels is relatively difficult because of the complex structure of the nano-channels. On the other hand, optical methods can also be used for sensitive detection in nano-channels. For example, the now popular laser-induced fluorescence method can be used not only for detecting samples but also for observing imaging fluid movement. However, most of the molecules in a single cell are non-fluorescent (non-fluorescent proteins or DNAs), and we need sensitive detection methods for non-fluorescent molecules.

Thermal lens microscope (TLM) is one of the candidates for these purposes. Here, an ultrasensitive method for detection on the nanoscale was developed based on a differential interference contrast thermal lens microscope (DIC-TLM) [21, 33], our original and ultrasensitive detection method for non-fluorescent molecules in aL detection volumes. Thermal lens microscopy (TLM) is a kind of photothermal spectroscopy that measures absorption and thermal relaxation and has been reported to be more sensitive than absorption spectrometry. Although conventional TLM offers a very high sensitivity to determine concentration of single-molecule level in micro-channels, it is not applicable to nano-channel, because its working principle is based on “geometrical optics.” In this case, as the size of nano-channel is smaller than the beam spot diameter (~µm) and the confocal length (~1 µm), the refractive index distribution of the thermal lens might be too small to be detected.

Recently, Kitamori group has introduced the interferometry principle into TLM, which is referred as differential interference contrast TLM (DIC-TLM ) and succeeded in TLM detection in ~102 nm space [21, 33]. The principle is shown in Fig. 8.3. The probe beam is separated by a DIC prism into two beams with perpendicular polarization. On the other hand, the excitation beam is not separated, as its polarization plane is rotated at an angle of 45°. The excitation beam is absorbed by an analyte, and a thermal lens effect is induced. Then, phase contrast appears between the two probe beams due to the difference in refractive index. In the next step, the probe beams are combined again by another DIC prism, which results in a new polarization component. Finally, only this new component is detected as signal by removing the initial polarization component using a polarization filter. DIC-TLM extracts only the information of phase shift of probe beam caused by the change of refractive index. The principle is based on not geometric optics but wave optics, and therefore, DIC-TLM can measure molecules in the nano-space which is smaller than the wavelength of the light. In addition, DIC-TLM realizes background-free detection of thermal lens effects because the intensity of the transmitted probe beam is zero when no analyte is in the focus area of the excitation beam.

Principle of differential interference contrast thermal lens microscopy [33]

8.3 Fluidic Control Methods

Fluid control of nano-channels is generally divided into electroosmotic flow and pressure-driven flow. Electroosmotic flow has been recognized as a most popular fluid control method for micro-fluidic chips. A number of research groups have reported the integration of electrophoretic systems in nano-channels for the analysis of DNA and proteins. However, the pressure-driven flow is more suitable for the analysis of single cells in nano-channels. Therefore, it is essential to develop the pressure-driven nano-fluidic control system for nano-spaces and to evaluate the fluidic behavior in them.

In order to control the behavior of the fluid in the nano-channel, high pressure and low volume flow are required, because of its quite large pressure drop in nano-spaces. Because nano-space requires very strong and stable pressure, commercial syringe pumps cannot be utilized to drive a liquid in nano-channels. Therefore, Tamaki et al. developed a backpressure-based nano-fluid control system, in which was consisting of a backpressure regulator and an HPLC pump with flow rate detection [20, 34]. In the experiment, the aqueous solution of the benzenediol probe molecule was introduced into a U-shaped micro-channel by HPLC pump, and then the flow rate was detected after entering the nano-channels. The results show that the measured flow rate is linear with the pressure applied, and the measured flow rate is lower than the flow rate expected by Hagen–Poiseuille’s law. However, this method depended on the response times of backpressure regulators, such as backward flow in the nano-space channel. Tsukahara et al. improved a backpressure-based system to an air-pressure-based nano-fluidic control system (Fig. 8.4), and evaluated its performance [35]. This fluidic system allows a high pressure of MPa and a low flow rate of pL min−1 to control the nano-fluidics.

Overview of experimental setup for nano-channel fluidic control. a Schematic illustration of air-pressure-based nano-fluidic control system. b Enlarged view of the fabricated microchip with U-shaped micro-channels and the Y-shaped nano-channels A and B. c A fluorescence image by mixing two different solutions; a fluorescein solution and a buffer solution flowing into the Y-shaped nano-channel [35]

8.4 Single Analysis on Nano/Microfluidic

8.4.1 Sampling from Single Cell

Single-cell analysis is of increasing importance in many fields, but is challenging due to the ultrasmall volumes (pL) of single cells. A single cell is typically 101 μm in diameter and has a volume of several pL, and so analysis of a specific analyte might require the analysis of a single molecule or several molecules. Consequently, single-cell analysis is quite challenging. Analytical processes typically include three steps: (1) sampling, (2) chemical processing, and (3) detection. Among them, many papers reported the chemical processing and detection methods [36,37,38,39,40]. However, sampling for pL single cells is still challenging due to the difficulty of volume control at fL level and maintaining the viability. Sampling is an essential process for general analytical chemistry.

Development of a sampling interface would permit determination of controlling sample volume and keeping cell viability for living single-cell analysis. Although there are many studies that focus on nanotechnology for single-cell analysis [41, 42], their usage was limited to observation of cellular activities or morphologies. Sampling from living single cell would expand the study of intracellular bimolecular, that are expected to be present in low numbers of around a few tens of thousands [43].

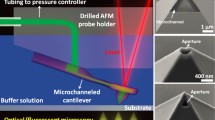

However, a key technical challenge that must be overcome to realize sampling interface is how to achieve fL sampling volume from living single cell. The critical issue in developing a sampling interface of exploring the nano-space is to ensure that formed nano-order hole on cell membrane and tight connection between cell and nano-channel. Here, Lin et al. developed a micro-/extended-nano-sampling interface from living single cell [44]. A single-cell chamber and a micro-fluidic channel were used to handle and isolate single cells by micro-fluidic control. The nano-channel worked as a femtoliter pipette for sampling. The major technical challenge was to connect the single cell with the extended-nano-pipette, and a micro-/extended-nano-sampling interface was developed utilizing lipid fusion (Fig. 8.5). With these technical advancements, they demonstrated fL level sampling of the cytoplasm of a living single human aortic endothelial cell (HAEC).

Concept of micro-/nano-sampling interface. A lipid bilayer was modified on the nano-channel by vesicle. When the pressure was increased, the lipid bilayers on the cell and nano-channel contact and form a new lipid bilayer after the fusion. As a result, a hole with same size with the nano-channel is formed, and the proteins inside the single cell can be sampled by applying pressure without leakage [44]

8.4.2 Separation of Sample

Miniaturization of liquid chromatography separation columns is a key trend in chemical and biochemical areas, particularly in single-cell analysis. This separation method relies on a novel analytical platform that can separate much smaller sample volumes than cells. A basic experimental setup of extended-nano-chromatography is shown in Fig. 8.6 [45]. In order to realize a separation mode of the sample in the micro/nano-chip, a pressure-driven and fluid control system is required. As shown in Fig. 8.7, pressures are applied from the top and left and right sides to fill the sample solution in a loading channel and the mobile phase in a separation channel (Fig. 8.7a). Then, the pressure from the right side is turned off to leak a small volume of sample into the separation channel (Fig. 8.7b). After a time lag, the pressure from the top side is turned off to cut off the sample in the separation channel (Fig. 8.7c). The injected sample is detected downstream of the separation channel (Fig. 8.7d). Based on this principle, a liquid chromatography system providing pressure-driven flow in nano-channels in a micro/nano-fluidic chip permits highly efficient separation of molecules in attoliter-volume samples [20, 46,47,48].

Overview of experimental setup for extended-nano-chromatography. Two pressure controllers are used to push solutions of the sample and mobile phase in vials. The vials are connected to a glass microchip, which has micro-channels for introduction and nano-channels. Two nano-channels, the loading and separation channels, cross orthogonally at the center of the microchip [45]

Flow control of sample injection by pressure switching. a Sample is loaded from the loading channel. Pressures from the top, left, and right sides are balanced at the intersection of nano-channels. b Sample is injected from the loading channel to the separation channel by switching off the pressure from the right side. c Sample is cut off by switching off the pressure from the top side after a time lag. d Sample diffuses in the separation channel [45]

Recently, Smirnova et al. reported step-mixing generation and reversed phase chromatographic separation were implemented on a chip with nano-channels, which was tested for use in amino acids analysis. As shown in Fig. 8.8, this on-chip nano-chromatography platform completed 17 amino acids separation and analyses in 50 s. It was the first demonstration of liquid chromatography separation of complex mixtures on an open tubular nano-channel. Such unique characteristics of separation in extended-nano-space can be applied for the separation of proteins and large molecules and for applications to biological samples, especially for living single-cell analysis [49]. This study demonstrates that this method has the potential for analysis of the intracellular contents, to elucidate the transmembrane transport, and to study protein synthesis in cells.

Extended-nano-fluidic device for handling and sorting samples at aL [49]

8.4.3 Detection of Sample

Sample volumes used in single-cell research are becoming smaller and concentrations [50]. Therefore, ultrasmall volume sample should be precisely processed and detected for analysis. Here, Shirai et al. reported a single-molecule ELISA (enzyme-linked immunosorbent assay) device utilizing micro-/nano-fluidic technology. Both chemical processing [51] and detection [52] were integrated into nano-channels, and the integration allowed precise processing and detection of a specific single molecule (protein) for the first time.

In chemical processing part, they developed nano-fluidic immunoassay device that has highly-efficient (near 100%) immunochemical reactions on a seconds timescale. In this study, the technical challenge was to ensure proper antibody patterning on the inner surface of nano-channels. They developed a chemical method employing a photolithographic technique with VUV light with low-temperature bonding that allows for patterning prior to bonding. They developed a chemical method employing a photolithographic technique with VUV light and low-temperature bonding that allows for patterning prior to bonding. As shown in Fig. 8.9, the nano-fluidic immunoassay device requires pressure-driven fluid control to introduce and capture targeted molecules through regulation of liquid volume and liquid exchange. In the chemical processing part, high-efficient antigen-antibody reaction in the nano-space was developed. Extremely small amount of analyte can be captured without loss. However, the limit of detection did not reach to single or countable molecules region.

Schematic illustrating fluidic control and the immunochemical reaction in the molecular capture region [51]

In detection part, Shirai et al. improved the limit of detection to single-molecule level using combination of chemical amplification by enzymatic reaction and ultrahigh-sensitive detection by DIC-TLM . This device allowed both the chemical processing and detection of a specific single molecule, capabilities that are essential for single-molecule analytical chemistry (Fig. 8.10). The experimental conditions were designed for enabling single analyte molecule detection including optimal channel size for DIC-TLM detection and enzymatic reaction time. Then, the signal of ELISA in the extended-nano-channel was successfully obtained. Moreover, the developed device had the performance for the analysis of countable number of molecules. This methodology would be applied to the analysis of ultrasmall volume sample such as single cell and single bacteria. In addition, the antigen-antibody reaction timescale would enable ultrafast immunoassay which has the potential to shorten clinical assay time dramatically.

Concept of single-molecule ELISA based on micro/nano-fluidic technology [52]

8.4.4 Other Applications

The nano-space has drawn great attention regarding device engineering due to its effective use of a unique property and small scale. The volume of the nano-channel (aL-fL) is much smaller than single-cell volumes (pL), and the nano-space will be promising for living single-cell analysis by analyzing small volumes of sample from single cells in nano-space. However, a large size gap exists between a single cell and the nano-channel. A basic platform is required to bridge the cell and the nano-channel. A novel micro-fluidic platform was developed by integrating a single-cell chamber and an extended-nano-channel (Fig. 8.11a) [53]. A single cell was isolated and cultured for more than 12 h by pressure-driven flow control. In addition, an electric resistance measurement method was developed to monitor the cell viability without fluorescence labeling. This platform will provide a new method for living single-cell analysis by utilizing the novel analytical functions of the extended-nano-space. Additionally, the living single-cell sampling was first proposed using a micro/extended-nano-sampling interface [54]. After fL sampling, single cells were analyzed while maintaining cell viability. This method would work as a connection for single cell and nano-space. A connection with a mass spectrometer (MS) is important for single-cell analysis. For this purpose, a nano-pillar array was embedded in a nano-channel using two-step electron beam lithography and dry-etching process. The basic principle of the Laplace nano-valve was verified, and a 1.7 fL droplet was successfully generated and handled (Fig. 8.11b) [55]. Furthermore, the fL-valve made of glass and other rigid materials (such as plastic) was developed. An fL-valve based on an analytical material deformation model was designed and developed a valve fabrication process (Fig. 8.11c). Then, using 308 fL-valve chamber test valve open/close state, the nano-valve has a four-stepped nano-structure fitting an arc-shape of deflected glass, confirmed its stability and durability over 50 open/close operations, and successfully stopping/flowing an aqueous solution under 209 fL s−1 under 100 kPa pressure in nano-channel, quick response with ~0.65 s [56]. Moreover, a valve system was developed in the nano-space for sample injection control. They replaced the open/closed pressure control system (Fig. 8.11d). This method can be achieved by integrating a valve in the nano-channel [57]. In the future, nano-channels are expected to contribute to living single-cell analysis and ultrasensitive detection with small volume. Moreover, basic measurement methods for the nano-space including flow velocimetry would explain the molecular behavior in the nano-channels [58, 59].

Nano-fluidic for single-cell analysis. a Living single-cell electric resistance measurement method utilizing micro-/nano-fluidic technology [49]. b SEM and AFM images of the nano-valve and nano-pillar array [50]. c Schematic illustration of an nano-channel open/close valve. Image below shows the valve chamber with the four-stepped nano-structure, which is connected to the nano-channels, observed by an optical profiler) [56]. d Nano-valve system in nano-space for sample injection control [51]

8.5 Concluding Remarks and Future Perspectives

In the future, various biochemistry applications will be opened by utilizing the advantages of micro/nano-channel chip platform. In this chapter, we documented the advances in coupling micro/nano-chips for single-cell analysis in the past decade, covering both fabrication of micro/nano-chip and their applications in single-cell research, for example, single-cell sampling, chemical processing and detection, while complex and precise fluidic controls are required. Artificial and size-controlled nano-channels will be the appropriate platform for this purpose compared with porous materials and carbon nanotube. As a preliminary research, micro/nano-sampling interface, nano-ELISA, and nano-chromatograph were integrated into nano-channel, and the basic principles were reported. These features will provide new tools for single-cell research because the volume of single cell is picoliter and larger than the volume of the nano-space. Therefore, concept and methodologies for designing tool of the chemical processes and realization of single-cell analysis devices will also be important subjects. By using these new methods and combining with micro-chemical processes, new bioanalytical tools will be possible which are difficult by conventional microtechnologies.

References

Spudich JL, Koshland DE (1976) Non-genetic individuality chance in single cell. Nature 262:467–471

Spiller DG, Wood CD, Rand DA, White MRF (2010) Measurement of single-cell dynamics. Nature 465:736–745

Rubaknin SS, Romanova EV, Nemas P, Sweedler JV (2011) Profiling metabolites and peptides in single cells. Nat Methods 8:20–29

Frei AP, Bava F-A, Zunder ER, Hsieh EWY, Chen SY, Nolan GP, Gherardini PF (2016) Highly multiplexed simultaneous detection of RNAs and proteins in single cells. Nat Methods 13:269–275

Sassolas A, Leca-Bouvier BD, Blum LJ (2008) DNA biosensors and microarrays. Chem Rev 108:109–139

Mao S, Zhang W, Huang Q, Khan M, Li H, Uchiyama K, Lin JM (2018) In situ scatheless cell detachment reveals connections between adhesion strength and viability at single-cell resolution. Angew Chem Int Ed 57(1):236–240

Levsky JM, Shenoy SM, Pezo RC, Singer RH (2002) Single-cell gene expression profiling. Science 279:836–840

Zhuang Q, Wang S, Zhang J, He Z, Li H, Ma Y, Lin JM (2016) Nephrocyte-neurocyte interaction and cellular metabolic analysis on membrane-integrated microfluidic device. Sci China Chem 59:243–250

Yu X, Gong J, Zhang Z, Zhao Z, Zhang X, Tan W (2017) Nanocarrier based on the assembly of protein and antisense oligonucleotide to combat multidrug resistance in tumor cells. Sci China Chem 60:1318–1323

Chang HH, Hemberg M, Barahona M, Ingber DE, Huang S (2008) Transcriptome-wide noise controls lineage choice in mammalian progenitor cells. Nature 453:544–547

Tanihuchi Y, Choi PJ, Li GW, Chen H, Bahu M, Hearn J, Emili A, Xie XS (2010) Quantifying E. coli proteome and transcriptome with single-molecule sensitivity in single cells. Science 329:533–538

Sims CE, Allbritton NL (2007) Analysis of single mammalian cells on chip. Lab Chip 7:423–440

Huang Y, Cai D, Chen P (2011) Micro-and nanotechnologies for study of cell secretion. Anal Chem 83:4393–4406

Lin L, Chen Q, Sun J (2018) Micro/nanofluidics-enabled single-cell biochemical analysis. TrAC-Trends Anal Chem 99:66–74

Reyes DR, Iossifidis D, Auroux PA, Manz A (2002) Micro total analysis systems. 1. Introduction, theory, and technology. Anal Chem 74:2623–2636

Reyes DR, Iossifidis D, Auroux PA, Manz A (2002) Micro total analysis systems. 2. Analytical standard operations and applications. Anal Chem 74:2637–2652

Vilkner T, Janasek D, Manz A (2002) Micro total analysis systems. 3. Recent developments. Anal Chem 74:3373–3385

Lin L, Lin X, Lin L, Feng Q, Kitamori T, Lin JM, Sun J (2017) Intergrated microfluidic platform with multiple functions to probe the tumor-endothelial cell interaction. Anal Chem 89:10037–10044

Hibara A, Saito T, Kim H-B, Tokeshi M, Ooi T, Nakao M, Kitamori T (2002) Nanochannels on a fused-silica microchip and liquid properties investigation by time-resolved fluorescence measurements. Anal Chem 74:6170–6176

Tsukahara T, Mawatari K, Hibara A, Kitamori T (2008) Development of a pressure-driven nanofluidic control system and its application to an enzymatic reaction. Anal Bioanal Chem 391:2745–2752

Shimizu H, Mawatari K, Kitamori T (2010) Sensitive determination of concentration of nonfluorescent species in an extended-nano channel by differential interference contrast thermal lens microscope. Anal Chem 82:7479–7484

Zhou J, Jiang D, Chen H-Y (2017) Nanoelectrochemical architectures for high-spatial-resolution single cell analysis. Sci China Chem. 60:1277–1284

Haywood DG, Saha-Shah A, Baker LA, Jacobson SC (2015) Fundamental studies of nanofluidics: nanopores, nanochannels, and nanopipets. Anal Chem 87:172–187

Napoli M, Eijkel JC, Pennathur S (2010) Nanofluidic technology for biomolecule applications: a critical review. Lab Chip 10:957–985

Tsukahara T, Mizutani W, Mawatari K, Kitamori T (2009) NMR studies of structure and dynamics of liquid molecules confined in extended nanospaces. J Phys Chem B 113:10808–10816

Sato K, Kawanishi H, Tokeshi M, Kitamori T, Sawada T (1999) Sub-zeptomole detection in a microfabricated glass channel by thermal-lens microscopy. Anal Sci 15:525–529

Ng HC, Uddayasankar U, Wheeler AR (2010) Immunoassays in microfluidic systems. Anal Bioanal Chem 397(3):991–1007

Xu Y, Wang C, Dong Y, Li L, Jang K, Mawatari K, Suga T, Kitamori T (2012) Low-temperature direct bonding of glass nanofluidic chips using a two-step plasma surface activation process. Anal Bioanal Chem 402(3):1011–1018

Xu Y, Wang C, Li L, Matsumoto N, Jang K, Dong Y, Mawatari K, Suga T, Kitamori T (2013) Bonding of glass nanofluidic chips at room temperature by a one-step surface activation using an O2/CF4 plasma treatment. Lab Chip 13(6):1048–1052

Otha R, Mawatari K, Takeuchi T, Morikawa K, Kitamori T (2019) Detachable glass micro/nanofluidic device. Biomicrofluidics 13:024104

Heyes CD, Kobitski AY, Amirgoulova EV, Nienhaus GU (2004) Biocompatible surfaces for specific tethering of individual protein molecules. J Phys Chem B 108:13387–13394

Tessler LA, Reifenberger JG, Mitra RD (2009) Protein quantification in complex mixtures by solid phase single-molecule counting. Anal Chem 81:7141–7148

Shimizu H, Mawatari K, Takehiko T (2009) Development of differential interference contrast thermal lens microscope (DIC-TLM) for sensitive individual nanoparticle detection in liquid. Anal Chem 81:9802–9806

Tamaki E, Sato K, Tokeshi M, Sato K, Aihara M, Kitamori K (2002) Single cell analysis by a scanning thermal lens microscope with a microchip: direct monitoring of cytochrome-c distribution during apoptosis process. Anal Chem 74:1560–1564

Tamaki E, Hibara A, Tokeshi M, Kitamori T (2003) Microchannel-assisted thermal-lens spectrometry for microchip analysis. J Chromatogr A 987:197–204

Huh D, Matthews BD, Mammoto A, Montoya-Zavala M, Hsin HY, Ingber DE (2010) Reconstituting organ-level lung functions on a chip. Science 328:1662–1668

Khademhosseini A, Langer R, Borenstein J, Vacanyi JP (2006) Microscale technologies for tissue engineering and biology. Proc Natl Acad Sci USA 103:2480–2487

Gobaa S, Hoehnel S, Roccio M, Negro A, Kobel S, Lutolf MP (2011) Artificial niche microarrays for probing single stem cell fate in high throughput. Nat Methods 8:581–593

Lee H, Sun E, Ham D, Weissleder R (2008) Chip–NMR biosensor for detection and molecular analysis of cells. Nat Med 14:869–874

Neuzil P, Giselbrecht S, Lange K, Huang TJ, Manz A (2012) Revisiting lab-on-a-chip technology for drug discovery. Drug Discov 11:620–632

Yan R, Park J-H, Choi Y, Heo C-J, Yang S-M, Lee LP, Yang P (2012) Nanowire-based single-cell endoscopy. Nat Nano 7:191–196

Zheng XT, Li CM (2013) Single cell analysis at the nanoscale. Chem Soc Rev 41:2061–2071

Schwanhausser B, Busse D, Li N, Dittmar G, Schuchhardt J, Wolf J, Chen W, Selbach M (2013) Corrigendum: global quantification of mammalian gene expression control. Nature 495:126–127

Lin L, Mawatari K, Morikawa K, Pihosh Y, Yoshizaki A, Kitamori T (2017) Micro/extended-nano sampling interface from living single cell. Analyst 142:1689–1696

Shimizu H, Smirnova A, Mawatari K, Kitamori T (2017) Extended-nano chromatography. J Chromatogr A 1490:11–20

Ishibashi R, Mawatari K, Kitamori T (2012) Highly efficient and ultra small volume separation by pressure driven liquid chromatography in extended nanochannels. Small 8:1237–1242

Ishibashi R, Mawatari K, Kitamori T (2012) Development of a pressure-driven injection system for precisely time controlled attoliter sample injection into extended nanochannels. J Chromatogr A 1228:51–56

Shimizu H, Toyoda K, Mawatari K, Terabe S, Kitamori T (2019) Femtoliter gradient elution system for liquid chromatography utilizing extended-nano fluidics. Anal Chem 91(4):3009–3014

Smirnova A, Shimizu H, Pihosh Y, Mawatari K, Kitamori T (2016) On-chip step-mixing in a t-nanomixer for liquid chromatography in extended-nanochannels. Anal Chem 88:10059–10064

Ferreira J, Santos MJL, Rahman MM, Brolo AG, Gordon R, Sinton D, Girotto EM (2009) Attomolar protein detection using in-hole surface plasmon resonance. J Am Chem Soc 131:436–437

Shirai K, Mawatari K, Kitamori T (2014) Extended nanofluidic immunochemical reaction with femtoliter sample volumes. Small 10(8):1514–1522

Shirai K, Mawatari K, Kitamori T (2018) Single-molecule ELISA device utilizing nanofluidics. Analyst 143:943–948

Lin L, Mawatari K, Morikawa K, Kitamori T (2016) Living single cell analysis platform utilizing microchannel, single cell chamber, and extended-nano channel. Anal Sci 32:75–78

Lin L, Mawatari K, Morikawa K, Kitamori T (2015) Femtoliter sampling method from living single cell by extended-nano/micro interface. Proc MicroTAS 1:54–56

Mawatari K, Kubota S, Xu Y, Priest C, Sedev R, Ralston J, Kitamori T (2012) Femtoliter droplet handling in nanofluidic channels: a laplace nanovalve. Anal Chem 84:10812–10816

Kazoe Y, Pihosh Y, Takahashi H, Ohyama T, Sano H, Morikawa K, Mawatari K, Kitamori T (2019) Femto-liter nanofluidic valve utilizing glass deformation. Lab Chip 19:1686–1694

Xu Y, Shinomiya M, Harada A (2016) Soft matter-regulated active nanovalves locally self-assembled in femtoliter nanofluidic channels. Adv Mater 28:2209–2216

Kazoe Y, Mawatari K, Kitamori T (2015) Behavior of nanoparticles in extended nanospace measured by evanescent wave-based particle velocimetry. Anal Chem 87:4087–4091

Kazoe Y, Iseki K, Mawatari K, Kitamori T (2013) Evanescent wave-based particle tracking velocimetry for nanochannel flows. Anal Chem 85:10780–10786

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Lin, L. (2019). Micro/Nano fluidics Enabled Single-Cell Biochemical Analysis . In: Lin, JM. (eds) Microfluidics for Single-Cell Analysis. Integrated Analytical Systems. Springer, Singapore. https://doi.org/10.1007/978-981-32-9729-6_8

Download citation

DOI: https://doi.org/10.1007/978-981-32-9729-6_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-32-9728-9

Online ISBN: 978-981-32-9729-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)