Abstract

The passion fruit (Passiflora edulis) processing industry produces fruit wastes consisting of valuable compounds like phenolics, carotenoids, and flavonoids. Among these various phytochemicals, phenolics are the most common secondary metabolite in passion fruit. It contains multiple therapeutic features such as anti-inflammatory, antioxidant, and antibacterial properties. Thereby, the fruit gained popularity in several industries like medicine, food, and cosmetics. The researcher’s primary concern is the cost-effective, environment-friendly extraction of chemicals from plant portions. Supercritical fluid extraction is a suitable alternative using carbon dioxide as a green solvent to recover chemicals. In this investigation, supercritical carbon dioxide extraction was used to extract phenolics from the rind powder of yellow passion fruit by using 10% ethanol as a co-solvent. The CCD model of Design Expert software was used to conduct the RSM-based optimization analysis of the extracts. The results demonstrated that the chosen independent parameters (Pressure (A), Temperature (B), and Flow rate (C)) had a significant influence on the extracted phenolic yield. The ANOVA analysis of the suggested quadratic model revealed that the model was effective (p-value <0.0001) for supercritical carbon dioxide extraction with 10% ethanol as a co-solvent. The maximum predicted yield obtained in this study was 36.87 mg GAE/g with a desirability value of 0.984. Pressure (A) 278.48 bar, temperature (B) 53.84 °C, and flow rate (C) 18.3 g/min were the optimal conditions that offered the maximal response. The study results revealed that supercritical carbon dioxide is a green extraction technique for the extraction of phenolics from yellow passion fruit rind (YPFR).

Graphical Abstract

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

- Ethanol

- Passion fruit

- Phenolics

- RSM-based optimization

- Supercritical carbon dioxide extraction

- Yellow passion fruit rind

1 Introduction

In recent times, food waste remains as one of the very hard difficulties to be dealt. Based on the FWI (Food Waste Index) report, cited by Capanoglu, there were around 931 MT of food scraps produced in 2019 with 61% of it originating from residences, 13% from commercial and 26% from food services [1]. The food processing sector generates food waste with a high organic content in large quantities. Even though they have the potential to be repurposed in the food chain, they are mostly discarded [2]. The wastes are a plentiful source of organic bioactive chemicals that might be utilized as an ingredient for medications, cosmetics, food ingredients, and vitamins. These affordable natural food by-products open up economically appealing possibilities for their future uses. Although numerous synthetic dietary supplements are on the market, consumers have begun to reject them due to their health risks. Thus, the demand for the chemicals like phenolics, flavonoids, carotenoids, and vitamins extracted from natural sources has been rising consistently [3].

The tropical fruit passion fruit (Passiflora edulis) is mainly cultivated for commercial purposes in many countries. There are roughly 500 species of Passiflora sp., which is a member of the largest family, Passifloraceae (the family of the passion flower). This species, which is native to Brazil, is primarily found in tropical and warm temperate climates. They are infrequently found in tropical Africa, Australia, and Asia [4]. The Latin phrases “Passio” (which means “suffering”) and “floris” (which means “flower”) are the origins of the name “Passiflora”. This was found in Peru in 1569 by Spanish explorers, and missionaries in South America gave it the name because it represents Christ’s passion [5, 6]. It expands its popularity worldwide for nutritious juice production (commercially available), which has the most significant economic influence on the passion fruit industry. Around 1.5 million tonnes of passion fruit were produced globally in 2017, with Brazil being the leading grower and having great market value [7]. The juice processing industry makes a significant amount of inedible waste which is mostly discarded or utilized as fertilizer and feedstock [8]. Peel, pulp, and seed make up more than 60% of the entire amount of solid waste. [7]. These are rich in valuable chemicals such as phenolics, flavonoids, glycosides, carotenoids, vitamins, etc. Their numerous bioactivities with positive health effects, such as antioxidant capacity, anti-inflammatory activities, anti-diabetic, and anti-cancer characteristics [9, 10], are propelling up their demand scenarios on a daily basis [11]. Numerous studies conducted recently have provided evidence of the use of these phytochemicals in a variety of contexts (Table 1). Based on their bioactivity, numerous researchers demonstrated their in-vitro and in-vivo pharmaceutical applicability. Nanoparticles made from passion fruit waste were demonstrated by Nguyen affirmed both antibacterial and catalytic properties [12]. Passiflora edulis var. flavicarpa pulp’s cardioprotective properties were discovered by Soumya in an in-vitro investigation [13]. Additionally, many varieties of passion fruit have been utilized as sedatives [14], anti-diabetic agents [15], immune system boosters [16], anticancer remedies [17], and more. In the cosmetics sector, passion fruit is utilised as a moisturiser [18], antidermatophytic activity [19], anti-aging agents [20], depigmenting agent [21]. Passion fruit was used to create a variety of food products, including candy, beverages, and natural colorants. In the energy industry, passion fruit waste also produced charcoal [22], and biogas [23]. Among numerous phytochemicals, phenolics are the most typically observed secondary metabolite in passion fruit. They contain multiple therapeutic features such as antioxidant, anti-inflammatory, and antibacterial properties. Thus, the constituents in the extracted form are gaining popularity in several industries like medicine, food, and cosmetics. These plant-origin compounds protect body cells from oxidative damage caused primarily by the free radicals. This effect is due to the potent antioxidant properties of the phenolics [24].

However, the economically and environmentally feasible extraction techniques gained interest to efficiently recover targeted phytochemicals with maximum yield from various plant wastes. Several techniques for extraction (maceration, solvent extraction, soxhlet extraction, and hydrodistillation) have been used to extract active compounds present in the plant. However, these techniques are accompanied by a few drawbacks, such as a large volume of solvent consumption and low specificity [35], difficulties in releasing bound phenolics from raw materials [36, 37], and extreme heat, causing damage to targeted compounds (e.g., Soxhlet) [38]. Therefore, diverse solutions for the extraction of phytochemicals from bio-waste have been developed to meet the demand of a conscientious society for cost-effective and environmentally friendly approaches for sustainable production. The fundamental goal of green extraction has been to develop novel, energy-efficient extraction methods that rely on sustainable natural resources and non-hazardous substitute solvents to produce safe, high-quality extracts [39]. Ultrasound, microwave, supercritical fluid, pressurized liquid extractions, and other methods are among them which become more popular due to raising emphasis on the concentration of targeted molecules, and bioassays with high selectivity and sensitivity [40]. Among these methods, supercritical fluid extraction (SFE) is a feasible green technology [35]. In contrast to typical extraction techniques, the supercritical solvents utilized in this procedure have various beneficial physicochemical features, such as density, viscosity, and diffusivity. Supercritical fluids’ low viscosity and comparatively high diffusivity provide them with greater transport properties than liquids. Additionally, they can penetrate through solid materials more quickly, which causes extraction rates to increase. One of the major properties of a supercritical fluid is its capacity to change its density by altering its pressure and/or temperature. Since density and solubility are related, varying the extraction pressure will affect the fluid’s solvent strength [39]. The high diffusivities and low viscosity make it ideal for the extraction of natural compounds like essential oils, lipids, tocopherols, and carotenoids from plants/biomass [41]. Additional advantages over traditional extraction methods include the use of GRAS solvents, increased effectiveness, and shorter extraction times [39]. Carbon dioxide (CO2) is the most widely used solvent in supercritical fluid extraction (SFE). This is primarily due to its low cost, easy handling, and lack of harmful waste generation. Supercritical CO2 is an ideal solvent for thermosensitive substances due to its low critical pressure (74 bar) and temperature (31 °C) [42]. The lipophilic character of CO2, which is generally favorable for the recovery of non-polar and moderately polar chemicals, is the fundamental constraint of SFE. Small amounts of organic solvents as co-solvents like water, methanol, ethanol, etc., are frequently added to increase the capacity of solvating supercritical carbon dioxide and boost its affinity for polar molecules [2]. Several factors like co-solvent composition and quantity and extraction condition (pressure, temperature) need to be optimized to optionally extract a broader range of chemicals.

This article aims to maximize polyphenols’ extraction from Passion fruit rind using supercritical CO2. The response surface CCD model was used to optimize the factors (Temperature, Pressure, and Flow rate) for maximum extraction efficiency.

2 Experimental

2.1 Materials

The fresh yellow passion fruit (Passiflora edulis f. flavicarpa) samples were collected from the local market of Karbi Anglong, Assam, India. The fully grown, healthy fruits were washed and chopped to separate the rind and seed; and dried at 45 °C in an oven. The seeds were sealed in storage bags and stored at −20 °C. The dried rinds were grounded into fine particles and were sieved to less than 300 μm particle size with the BSS 52 mesh. The yellow passion fruit peel (YPFP) powder was stored in a refrigerator in a tightly packed Borosil glass bottle. Other reagents, i.e., absolute ethanol (Merck), sodium carbonate (Himedia), and folin-Ciocalteu (Merck), were purchased.

2.2 Optimization of Total Phenolic Content Extracted from Yellow Passion Fruit Rind

Supercritical CO2 extraction. The extraction was performed using a Supercritical fluid extraction unit (SFE 500, Supercritical fluid Technology, Waters, USA) which contains a CO2 pump (Waters, USA), a solvent pump (Waters, USA), an approximately 500 mL extraction cell (stainless-steel), a separation vessel, chiller (Accel 500LC, Thermo-Scientific, USA) and a pump to regulate the backpressure of the entire system (Waters, USA). Each extraction experiment entailed 20 g of powdered sample kept in the extraction cell along with a small number of glass beads to prevent the system from clogging. Ten-percent ethanol was delivered as co-solvent by a solvent pump (Waters, USA) and was mixed with supercritical CO2 at high pressure. Prior to this mixture’s entry into the extraction cell, it was heated with a heat exchanger (Waters, USA). The extractions were performed with a high-quality CO2 mixture (10% co-solvent) flowing at a 10–20 g min−1. The solvent-extract mixture was passed through the separator and depressurized to atmospheric pressure. After that, the extract was collected from the separator and kept in the refrigerator (4 °C) in airtight amber bottles for further investigation. For all trials, the extraction time was maintained at 120 min.

Experimental design. Variable levels were determined using the preliminary experimental results obtained by altering one independent factor at a time and for a fixed choice of other factors. On the basis of published literature, a range of three potential parameters have been selected for the optimization of Supercritical Carbon dioxide (SCO2) extraction. Response Surface Methodology (RSM) based on Central Composite Design (CCD) was employed to analyze the effects of the selected parameters namely, temperature, pressure, and flow rate on the phenolic yield. Table 2 shows the experimental parameter range for SCO2 extraction. Design-Expert® software 7.0 (Stat-Ease, inc., USA) was utilized to analyze the experimental outcomes using regression analysis.

To assess reproducibility, each experimental run was performed three times. The second-order polynomial model expresses the system that depicts the response as an independent variables’ function. This is elaborated in the following mathematical expression:

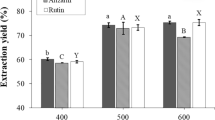

where Y—the predicted response parameter, β0—the constant intercept, βi—coefficient of the linear term, βii—coefficient of the quadratic term, βij—coefficient of the interaction term, Xi and Xj—uncoded independent variable of the experiment, the symbol € stands for the experimental error. Integer variables i, j, and n are used. When i < j is used, βij refers to the interaction effects between Xi and Xj variables. Fisher’s Satirical test (F-test) and ANOVA test with probability value (p < 0.05) were performed to determine the model’s statistical significance. The r2 value (regression coefficient) indicates that the model fits well with the experimental data (Fig. 1).

Determination of the Total Phenols Content (TPC) of the extracts. The Folin-Ciocalteu technique [43] was used to determine the phenolic content in the sample. A gallic acid calibration curve evaluated the total phenolic content as milligram gallic acid equivalents per gram of dried extract (mg GAE/g). In each test tube, 1 mL of tenfold diluted Folin-Ciocalteu reagent was added to an aliquot of 0.2 mL YPEP extract dissolved in Milli-Q purified water. After 5 min, 0.8 mL of 7.5% Na2CO3 was added, and the mixture was incubated in the dark for 30 min. The optical density was measured at 765 nm using UV-spectrophotometer (Orion Aquamate 8000, Thermo Scientific). All measurements were carried out in triplicate, and the average values were reported.

3 Results and Discussion

3.1 ANOVA and Model Validation

The F-test of ANOVA was performed to evaluate the response of the chosen parameter on the phenolic yield using the SCO2-ethanol system. From the analysis, it can be deduced that the experimental and predicted phenolic yield levels were reasonably close. The significance of the model and the independent parameters were decided by p-value and F-value. The bigger the magnitude of the F-value, the lower the “Prob > F” value and hence more significant will be the analogous variable. The ANOVA analysis (Table 3) of the predicted quadratic model indicated that the model was highly significant with a p-value less than 0.0001. Therefore, this model could be used for the optimization of the extraction process. Among the independent variables, flow rate had the most significant (p-value < 0.0001) effect on the extraction yield with an F-value of 224.49, followed by pressure and temperature with F-values of 74.65 and 9.36 respectively. All quadratic terms of the process variables pressure (A2), temperature (B2), and flow rate (C2) were significant and had a p-value less than 0.001. In contrast, the probability value for interaction between pressure and temperature was 0.0008. The reliability of the model and the experimental results were tested with a lack of fit test (F-value of 0.33 and p-value of 0.88) that indicated there was no proof that data was not fitted to experimental data (Table 4). The statistical model was a good fit as the adjusted regression coefficient (radj2 = 0.99) was relatively close to the regression coefficient (r2 = 0.99). The predicted coefficient of regression value (rpred2 = 0.98) demonstrated that the model could appropriately rely on the expected response range with its associated independent variable. A relatively low coefficient of variation (CV = 1.41%) was the precision and reliability of the experiment. The quadratic model came up with polynomial equations, where Eq. 2 denotes coded, and Eq. 3 represents actual factors.

In coded terms, A (pressure (bar)), B (temperature (°C)), and C (flow rate (g/min)) were parameters. x (pressure (bar)), y (temperature (°C)), and z (flow rate (g/min)) were all expressed in terms of actual parameters.

3.2 Interaction Effects of the Independent Variable on the Phenolic Yield

The interaction between the independent and dependent factors on the phenolic output was demonstrated by the graphical representation of the regression equation in a 3D contour plot (Fig. 2). The individual parameters and their quadratic terms significantly affect the phenolic output with a p-value less than 0.0001. Figure 2a displayed the influence of temperature and pressure on the response (TPC output). The interaction of pressure and temperature substantially influenced the rate of extraction with a probability value of <0.001. The phenolic output increased as the pressure rapidly increased up to 270 bar and thereafter gradually decreased. With increasing pressure, the viscosity of supercritical carbon dioxide decreases at static temperature and as well increases the solubility of the supercritical carbon dioxide. Reduced viscosity decreases the intermolecular distances, thus increasing the interaction between analytes and carbon dioxide and enhancing the extraction yield [44]. In contrast, a further pressure increase beyond 270 bar caused a rapid reduction in phenolic output. As reported by Bimakr et al. [45], the diffusion rate of solutes reduced at the higher pressure is related to the supercritical fluid medium.

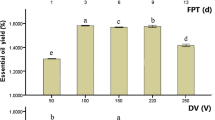

Figure 2b exhibits the 3D response graphic of the combined effect of pressure and flow rate. The yield increased up to the temperature of 55 °C; further, increase in the temperature, affirmed no significant improvement. Upon increasing the rate of flow of carbon dioxide from 10 to 20 g/min, the response output increased up to 15 g/min before stabilizing. This could be due to the high flow rate that drives the solvent through the sample, that facilitates only passage around the matrix of the sample and not through the pores. Thereby, it prevented carbon dioxide from moving in and out of the sample. Due to intra-particle diffusion resistance, low rates increase the analytes’ trapping ability and improve extraction efficiency. A low flow rate promotes mass transfer, extending the contact time between the solvent and the solutes of interest. As a result, the fluid’s sluggish movement allows for deeper intrusion into the solute matrix while also lowering the linear velocity. This resulted in excellent efficiency of extraction [44].

Figure 2c conveyed the combined impact of temperature and flow rate on the response and for the constant pressure of the system. During the initial phase, the response yield increased rapidly with the flow rate, and thereafter reduced marginally. The effect of temperature on the extraction yield had a synonymous influence with pressure. The output increased upto an increase in the temperature of 54 °C. Thereafter, the phenolic yield was reduced due to the thermos-sensitivity of extracted compounds. Also, at constant pressure, increasing temperature decreases the solvent strength by lowering the density of carbon dioxide. Near the critical pressure, the fluid density depends on the temperature. Therefore, the extraction yield fluctuated over a temperature range of 45–65 °C. A moderate increase in temperature might cause a significantly lowered solubility of the solvent through a reduction in the density. An increasing temperature improves the mass transfer from solute to solvent and increases extraction efficiency [45].

3.3 Optimization of Process Variables

Design-Expert software’s desirability function was utilized to forecast the optimal condition for achieving maximal phenolic yield within selected parameters. The predicted maximum yield was 36.87 mg GAE/g, with a desirability value of 0.984. The desirability profile to achieve maximum phenolic yield with Supercritical carbon dioxide was found at 278.48 bar, 53.84 °C temperature, and at 18.3 g/min of flow rate with 10% ethanol co-solvent (Table 5). The experiment performed at the recommended condition resulted in 36.04 mg GAE/g, and had a 2.1% deviation from the RSM predicted value. Thus, it could be stated that the suggested quadratic model could explain the phenolic yield within the chosen parameter range. Pereira found a TPC of 119 mg GAE/L in the passion fruit rind extracts, extracted with 70% ethanol as solvent by ultrasound-assisted pressurized liquid extraction at 60 °C [46]. Asiimwe extracted phenolics from purple passion fruit pulp using 80% methanol in the ultrasonic method. They observed that the TPC value of the passion fruit pulp-CMC mixture was 351.9 mg/100 g solids GAE [47]. A study on extraction of value-added compounds from two varieties of passion fruit, namely, Passiflora edulis Sims and Passiflora cincinnata Mast, by liquid–liquid extraction, using ethyl acetate and for 5 min agitation. Thereby, the total phenolic contents are 476.1 and 365 mg/kg GAE, respectively [48]. Traditional techniques such as MAE are expected to provide a lower recovery of target compounds. The low extraction efficiency of these techniques is the primary reason for the same. It has been proven that new extraction techniques are more sustainable, fast, and efficient, and due to these reasons, they yield higher phenolic content in the extract [46] (Table 6).

4 Conclusions

SFE demonstrated a sustainable technology for the extraction of phenolics from the yellow passion fruit rind (YPFR) using carbon dioxide as a renewable green solvent. Ten-percent ethanol has been used as a solvent modifier to extract the polar compounds. According to the RSM analysis, the chosen process parameters (temperature, pressure, and flow rate) significantly impacted the phenolic output. The solvent flow rate primarily affects the outcome, followed by pressure and temperature. The RSM approach yielded the following ideal settings for maximizing phenolic content: 278.48 bar (treatment pressure), 53.84 °C (temperature), and 18.3 g/min (flow rate) for SCO2 with 10% ethanol as a co-solvent. With desirability values of 0.984, the estimated yield was 36.87 mg GAE/g. Thus, plant waste like passion fruit rind may introduce new natural food products in the market that are healthier and prevent oxidative damage that commonly occurs in our bodies due to the processing of the food.

References

Capanoglu, E., Nemli, E., Tomas-Barberan, F.: Novel approaches in the valorization of agricultural wastes and their application. J. Agric. Food Chem. 70, 6787–6804 (2022)

Campone, L., Celano, R., Piccinelli, A. L., Pagano, I., Carabetta, S., Di Sanzo, Russo, M., Ibanez, E., Cifuentes, A., Rastrelli, L.: Response surface methodology to optimize supercritical carbon dioxide/co-solvent extraction of brown onion skin by-product as source of nutraceutical compounds. Food Chem. 269, 495–502 (2018)

Younas, M., Hano, C., Giglioli-Guivarch, N., Abbasi, B.: Mechanistic evaluation of phytochemicals in breast cancer remedy: current understanding and future perspectives. RSC Adv. 8(52), 29714–29744 (2018)

Dhawan, K., Dhawan, S., Sharma, A.: Passiflora: a review update. J. Ethnopharmacol. 94(1), 1–23 (2004)

Deshmukh, N., Patel, R., Okram, S., Rymbai, H., Roy, S., Jha, A.: Passion fruit (Passiflora spp.). Magnes 100, 200 (2017)

Pruthi, J.: Physiology, chemistry, and technology of passion fruit. Adv. Food Res. 12, 203–282 (1963)

Pereira, D., Zabot, G., Reyes, F., Iglesias, A., Martinez, J.: Integration of pressurized liquids and ultrasound in the extraction of bioactive compounds from passion fruit rinds: impact on phenolic yield, extraction kinetics and technical-economic evaluation. Innov. Food Sci. Emerg. Technol. 67, 102549 (2021)

Ghada, B., Pereira, E., Pinela, J., Prieto, M., Pereira, C., Calhelha, R., Stojkovic, D., Sokovic, M., Zaghdoudi, K., Barros, L., Ferreira, I.: Recovery of anthocyanins from passion fruit epicarp for food colorants: extraction process optimization and evaluation of bioactive properties. Molecules 25(14), 3203 (2020)

Li, C., Xin, M., Li, L., He, X., Liu, G., Li, J., Sheng, J., Sun, J.: Transcriptome profiling helps to elucidate the mechanisms of ripening and epidermal senescence in passion fruit (Passiflora edulia Sims). PLoS ONE 15(9), 0236535 (2020)

Oliveira, D., Angonese, M., Gomes, C., Ferreira, S.: Valorization of passion fruit (Passiflora edulis sp.) by-products: sustainable recovery and biological activities. J. Supercrit. Fluids 111, 55–62 (2016)

Dos Santos, O., Vieira, E., Soares, S., Da Conceicao, L., Nascimento, F., Teixeira-Costa, B.: Utilization of agroindustrial residue from passion fruit (Passiflora edulis) seeds as a source of fatty acids and bioactive substances. Food Sci. Technol. 41, 218–225 (2020)

Nguyen, T., Nguyen, T., Nguyen, T., Tuong-Van Pham, N., Ly, Q., Tran, T., Thach, T., Nguyen, C., Banh, K., Le, V., Nguyen, L., Nguyen, D., Dang, C., Nguyen, T.D.: Biosynthesis of metallic nanoparticles from waste Passiflora edulis peels for their antibacterial effect and catalytic activity. Arab. J. Chem. 14(4), 103096 (2021)

Soumya, R., Raj, K., Abraham, A.: Passiflora edulis (var. Flavicarpa) Juice Supplementation Mitigates Isoproterenol-induced Myocardial Infarction in Rats. Plant Foods Hum. Nutr. 76(2), 189–195 (2021)

Christoffoli, M., Bachesk, A., Farah, G., Ferreira, G.: Assessment of Passiflora incarnata L for conscious sedation of patients during the extraction of mandibular third molars: a randomized, split-mouth, double-blind, crossover study. Quintessence Int. 52(10), 868 (2021)

Salles, B., Salles, B., Leme, K., da Silva, M., da Rocha, C., Tangerina, M., Vilegas, W., Figueiredo, S., Duarte, S., Rodrigues, M., de Araújo Paula, F.: Protective effect of flavonoids from Passiflora edulis Sims on diabetic complications in rats. J. Pharm. Pharmacol. 73(10), 1361–1368 (2021)

Song, Y., Song, Y., Zhu, M., Hao, H., Deng, J., Li, M., Sun, Y., Wang, H., Yang, R., Huang, R.: Structure characterization of a novel polysaccharide from Chinese wild fruits (Passiflora foetida) and its immune-enhancing activity. Int. J. Biol. Macromol. 136, 324–331 (2019)

Kido, L., Hahm, E., Kim, S., Baseggio, A., Cagnon, V., Singh, S., Marostica, M., Jr.: Prevention of prostate cancer in transgenic adenocarcinoma of the mouse prostate mice by yellow passion fruit extract and antiproliferative effects of its bioactive compound piceatannol. J. Cancer Prev. 25(2), 87 (2020)

Guzman, C., Rojas, M., Aragon, M.: Optimization of ultrasound-assisted emulsification of emollient nanoemulsions of seed oil of Passiflora edulis var. edulis. Cosmetics 8(1), 1 (2021)

Santhoshkumar, J., Sowmya, B., Kumar, S., Rajeshkumar, S.: Toxicology evaluation and antidermatophytic activity of silver nanoparticles synthesized using leaf extract of Passiflora caerulea. South African J. Chem. Eng. 29, 17–23 (2019)

Yepes, A., Ochoa-Bautista, D., Murillo-Arango, W., Quintero-Saumeth, J., Bravo, K., Osorio, E.: Purple passion fruit seeds (Passiflora edulis f. edulis Sims) as a promising source of skin anti-aging agents: Enzymatic, antioxidant and multi-level computational studies. Arab. J. Chem. 14(1), 102905 (2021)

Krambeck, K., Silva, V., Silva, R., Fernandes, C., Cagide, F., Borges, F., Santos, D., Otero-Espinar, F., Lobo, J., Amaral, M.: Design and characterization of Nanostructured lipid carriers (NLC) and Nanostructured lipid carrier-based hydrogels containing Passiflora edulis seeds oil. Int. J. Pharm. 600, 120444 (2021)

Lin, Y., Zheng, N.: Biowaste-to-biochar through microwave-assisted wet co-torrefaction of blending mango seed and passion shell with optoelectronic sludge. Energy 225, 120213 (2021)

Zhao, C., Yan, H., Liu, Y., Huang, Y., Zhang, R., Chen, C., Liu, G.: Bio-energy conversion performance, biodegradability, and kinetic analysis of different fruit residues during discontinuous anaerobic digestion. Waste Manag. 52, 295–301 (2016)

Restrepo-Serna, D., Alzate, C.: Economic pre-feasibility of supercritical fluid extraction of antioxidants from fruit residues. Sustain. Chem. Pharm. 25, 100600 (2022)

Calderon, A., Salas, J., Dapello, G., Gamboa, E., Rosas, J., Chávez, J., Retuerto, F., Mayta-Tovalino, F.: Assessment of antibacterial and antifungal properties and in vivo cytotoxicity of Peruvian Passiflora mollisima. J. Contemp. Dent. Pract. 20(2), 145–151 (2019)

Yepes, A., Ochoa-Bautista, D., Murillo-Arango, W., Quintero-Saumeth, J., Bravo, K., Osorio, E.: Purple passion fruit seeds (Passiflora edulis f. edulis Sims) as a promising source of skin anti-aging agents: Enzymatic, antioxidant and multi-level computational studies. Arab. J. Chem. 14(1), 102905 (2020)

Karmila, K., Nuryanti, S..: Analisis vitamin C pada buah rambusa (Passiflora foetida L.). Media Eksakta 17(1), 46–51 (2021)

Shanmugam, S., Sandes, R., Rajan, M., Neta, M., dos Santos Lima, B., de Jesus, M., Denadai, M., Narain, N., Thangaraj, P., Serafini, M., Quintans-Junior, L., de Souza Araujo, A.: Volatile profiling and UHPLC-QqQ-MS/MS polyphenol analysis of Passiflora leschenaultii DC. fruits and its anti-radical and anti-diabetic properties. Food Res. Int. 133, 109202 (2020)

Urooj, A.: Development of fruit candies from wood apple (Limonia acidissim) and passion fruit (Passiflora edulis), nutritional and acceptability study during storage. J. Food Diet. Res. 1(1), 14–18 (2021)

Costa, C.F., Fusieger, A., Andretta, M., Camargo, A.C., Carvalho, A.F., Menezes, D.R., Nero, L.A.: Potential use of passion fruit (Passiflora cincinnata) as a biopreservative in the production of coalho cheese, a traditional Brazilian cheese. J. Dairy Sci. 103(4), 3082–3087 (2020)

Kawasoe, H., Wakamatsu, M., Hamada, S., Arata, Y., Nagayoshi, K., Uchida, R., Yamashita, R., Kishita, T., Yamanouchi, H., Minami, Y., Kajiya, K.: Analysis of natural colourant extracted from the pericarp of passion fruit. LWT 136, 110412 (2021)

Santos, R., Biasoto, A., Rybka, A., Castro, C., Aidar, S., Borges, G., Silva, F.: Physicochemical characterization, bioactive compounds, in vitro antioxidant activity, sensory profile and consumer acceptability of fermented alcoholic beverage obtained from Caatinga passion fruit (Passiflora cincinnata Mast). LWT 148, 111714 (2021)

Guedes, C., Guedes, A., Silva, J., Silva, E., Santos, E., Stamford, T., Stamford, T.: Development of vegetal probiotic beverage of passion fruit (Passiflora edulis Sims), yam (Dioscorea cayenensis) and Lacticaseibacillus casei. Food Sci. Technol. 41, 619–626 (2021)

Jain, S., Purohit, S., Kumar, D., Goud, V.: Passion fruit seed extract as an antioxidant additive for biodiesel; shelf life and consumption kinetics. Fuel 289, 119906 (2021)

Essien, S., Young, B., Baroutian, S.: Recent advances in subcritical water and supercritical carbon dioxide extraction of bioactive compounds from plant materials. Trends Food Sci. Technol. 97, 156–169 (2020)

Lee, W., Tan, C., Sulaiman, R., Hee, Y., Chong, G.: Storage stability and degradation kinetics of bioactive compounds in red palm oil microcapsules produced with solution-enhanced dispersion by supercritical carbon dioxide: a comparison with the spray-drying method. Food Chem. 304, 125427 (2020)

Santos, T., Feitosa, P., Gualberto, N., Narain, N., Santana, L.: Improvement of bioactive compounds content in granadilla (Passiflora ligularis) seeds after solid-state fermentation. Food Sci. Technol. Int. 27(3), 234–241 (2020)

Reverchon, E., De Marco, I.: Supercritical fluid extraction and fractionation of natural matter. J. Supercrit. Fluids 38(2), 146–166 (2006)

Da Silva, R., Rocha-Santos, T., Duarte, A.: Supercritical fluid extraction of bioactive compounds. TrAC Trends Anal. Chem. 76, 40–51 (2016)

Grunovaite, L., Pukalskiene, M., Pukalskas, A., Venskutonis, P.: Fractionation of black chokeberry pomace into functional ingredients using high pressure extraction methods and evaluation of their antioxidant capacity and chemical composition. J. Funct. Foods 24, 85–96 (2016)

Tamkute, L., Liepuoniute, R., Pukalskiene, M., Venskutonis, P.: Recovery of valuable lipophilic and polyphenolic fractions from cranberry pomace by consecutive supercritical CO2 and pressurized liquid extraction. J. Supercrit. Fluids 159, 104755 (2020)

Temelli, F.: Perspectives on supercritical fluid processing of fats and oils. J. Supercrit. Fluids 47(3), 583–590 (2009)

Derakhshan, Z., Ferrante, M., Tadi, M., Ansari, F., Heydari, A., Hosseini, M., Conti, G., Sadrabad, E.: Antioxidant activity and total phenolic content of ethanolic extract of pomegranate peels, juice and seeds. Food Chem. Toxicol. 114, 108–111 (2018)

Khanyile, A., Andrew, J., Paul, V., Sithole, B.: A comparative study of supercritical fluid extraction and accelerated solvent extraction of lipophilic compounds from lignocellulosic biomass. Sustain. Chem. Pharm. 26, 100608 (2022)

Bimakr, M., Rahman, R., Ganjloo, A., Taip, F., Salleh, L., Sarker, M.: Optimization of supercritical carbon dioxide extraction of bioactive flavonoid compounds from spearmint (Mentha spicata L.) leaves by using response surface methodology. Food Bioprocess Technol. 5(3), 912–920 (2012)

Pereira, D., Barrales, F., Pereira, E., Vigano, J., Iglesias, A., Reyes, F., Martinez, J.: Phenolic compounds from passion fruit rinds using ultrasound-assisted pressurized liquid extraction and nanofiltration. J. Food Eng. 325, 110977 (2022)

Asiimwe, A., Kigozi, J., Baidhe, E., Muyonga, J.: Optimization of refractance window drying conditions for passion fruit puree. LWT 112742 (2021)

Barbosa Santos, T., De Araujo, F., Neto, A., De Freitas, S., de Souza Araujo, J., de Oliveira Vilar, S., Lima, M.: Phytochemical compounds and antioxidant activity of the pulp of two Brazilian passion fruit species: Passiflora cincinnata Mast. and Passiflora edulis Sims. Int. J. Fruit Sci. 22, 1–15 (2021)

Vigano, J., Zabot, G., Martinez, J.: Supercritical fluid and pressurized liquid extractions of phytonutrients from passion fruit by-products: economic evaluation of sequential multi-stage and single-stage processes. J. Supercrit. Fluids 122, 88–98 (2017)

Kobo, G., Kaseke, T., Fawole, O.: Micro-encapsulation of phytochemicals in passion fruit peel waste generated on an organic farm: effect of carriers on the quality of encapsulated powders and potential for value-addition. Antioxidants 11(8), 1579 (2022)

Acknowledgements

Miss Kakali Borah appreciates the Prime Minister’s Research Fellow provided by the Education Ministry-Government of India. The authors are grateful to the School of Energy Sciences and Engineering and Central Instrumentation Facility (CIF), Indian Institute of Technology Guwahati, for offering research laboratory facilities and instrumentation facilities.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Borah, K., Kumar, R., Goud, V.V. (2023). Extraction of Phenolics from Yellow Passion Fruit Rind Using Supercritical Carbon Dioxide Extraction. In: Uppaluri, R.V., Das, C., Goud, V., Anandalakshmi, R. (eds) Agro and Food Processing Technologies. NERC 2022. Springer, Singapore. https://doi.org/10.1007/978-981-19-9704-4_8

Download citation

DOI: https://doi.org/10.1007/978-981-19-9704-4_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-9703-7

Online ISBN: 978-981-19-9704-4

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)