Abstract

Cellulose nanocrystals (CNCs), as a biorenewable resource, can form CNC chiral nematic iridescent nano-films by evaporation-induced self-assembly (EISA). CNC chiral nematic liquid crystal materials have become a hot spot in the current research on chiral photonic materials due to their rich sources, simple synthesis process, unique optical properties and good stability, and they are widely used in anti-counterfeiting, sensing, optical switches and other fields. CNC photonic materials have the problems of single color and non-uniformity. The CNC films are hard and brittle, which are not conducive to large-scale application. And they only reflect left-handed circularly polarized light, resulting in a dull color of the films. Currently, there is a large amount of prior researches that proposes corresponding solutions to different problems. This review mainly introduces the liquid crystal phase of CNCs, CNC iridescent films and the modification of CNC structural color materials. Finally, the application of CNC chiral nematic nano-materials is summarized and prospected, which will be helpful for the follow-up research.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

There are many natural structural color materials in nature, such as peacock feathers, cellulose in the fruit Polya Condensata, scales of lepidopteran adults, etc. With the continuous development of nanotechnology, researchers have succeeded in obtaining nanomaterials directly from biological resources. Cellulose nanocrystals (CNCs) are nanoscale 1D chiral nanorods obtained from cellulose. CNCs have excellent optical and electrochemical properties and can be used in many fields (Fig. 1) [1].

This review mainly introduces the preparation of CNC chiral nematic liquid crystal films and functional chiral nematic CNC film materials. Finally, the future development trend of chiral nematic CNC films is prospected.

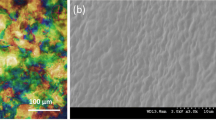

2 CNC Iridescent Films

As early as 1959, Marchessault et al. first observed birefringence phenomenon after evaporation of CNC suspensions and found that CNCs were lyotropic liquid crystals [2]. In 1992, Revol et al. observed that the periodic structure in CNC suspensions and films was a helical structure, and identified the lyotropic liquid crystal behavior of CNCs as chiral nematic [3]. Afterwards, they retained the chiral nematic structure of CNC suspensions (≈3.5 wt%) in solid films by EISA [4]. The CNC films preparation was limited to the laboratory. In 2021, Droguet et al. scaled up the production of iridescent films via an industrial route by casting CNC suspensions on a commercial R2R coating unit [5]. The nanostructured CNC films produced by this method had good optical response. The prepared CNC films could be ground into tiny particles after further heat treatment. The particles also maintained optical response after one year and did not discolor and disperse in water. The preparation process of CNC films is shown in Fig. 2. Since the iridescent and birefringent properties can be observed in CNC films, they have great application potential and have received extensive attention.

As a nanostructured material and a chiral nematic liquid crystal material with photonic properties, CNCs have a broad application prospect and have received great attention. Researchers have been trying for decades to tune the color of CNC chiral nematic liquid crystal materials, improve the flexibility of CNC films, and tune the polarization of CNC films.

2.1 Adjust the Color of CNC Films

CNC suspensions can form the iridescence films through the EISA process, many factors will change the color of the films. Researchers have found that temperature, sonication or magnetic fields can affect the films’ color during the evaporation process of CNC suspensions. Beck et al. found that increasing the temperature of drying CNC suspensions produced red-shifted films [6]. And when the CNC suspensions at the specific site were dried, a patterned membrane appeared. Guo et al. poured CNC suspensions on metal, metal alloy, polystyrene, stainless steel and other substrates to evaporate to form films [7]. They proposed the influence mechanism of three substrate effects and four shear effects on the structural color of the CNC films. Frka-Petesic et al. demonstrated that the magnetic field generated by ordinary NdFeB magnets could be used to control the self-assembly of CNC suspensions to form colored films [8]. They placed the CNC suspensions on a magnet for evaporation. When the applied magnetic field was perpendicular to the surface of the CNC films, a highly ordered chiral nematic structure was formed (Fig. 3). Tran and colleagues found that longer evaporation times of CNC suspensions produced blue-shifted films [9]. Meanwhile, patterned CNC films with gradient colors can be formed by differential evaporation. In addition, the use of a cellulose acetate (cellulose acetate itself does not significantly affect the pitch of the CNC films) mask confines evaporation to a defined area, resulting in a pattern with higher resolution.

Patterning CNC films by applying a magnetic field. A, B) Examples of films that were cast spanning two magnets, as indicated by the schematic in (C). D) CNC suspension was cast on a polydomain magnet. Interesting patterns are created upon film formation [8]. Copyright 2017, John Wiley & Sons, Inc.

The above works are all in changing the external environmental conditions during the evaporation of CNC suspensions. In fact, the photonic properties of CNC films can be improved and further tuned by using additives. Beck et al. prepared blue-shifted membranes by adding NaCl [10]. They showed that at higher salt concentrations, the reflection wavelength decreasesd from 550 to 390 nm. Mu et al. added glucose (GLU) to the CNC suspensions, which increased the pitch, resulting in a red-shift of the CNC films [11].

Through the above control methods, CNC iridescent films have new applications. Zhang et al. treated CNC films by ultrasonic, and the prepared CNC chiral photonic microparticles retained the optical properties of CNC chiral photonic films and could be mixed with polymer matrices to fabricate flexible coatings for anti-fake and identification [12].

In the introduction of the works in this section, although the researchers adjusted the color of the CNC films by changing the external environment during the evaporation of the CNC suspensions or adding additives such as salt and glucose, the prepared CNC films were hard, brittle and fragile. It made CNC chiral nematic liquid crystal materials unsuitable for some flexible materials.

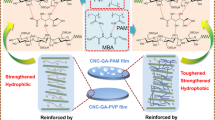

2.2 Tuning CNC Films Flexibility

In addition to tunable optical color, the use of additives imparts new functionalities to CNC nanomaterials, including flexibility and crack-freeness. Guidetti et al. added the 3-(N,N-dimethylmyristylammonio)propanesulfonate (DMAPS) to the CNC suspensions, resulting in nanoscale CNC-DMAPS complexes [13]. The chiral nematic structure is still preserved through the CNCs EISA process, and the CNC films show tunable photonic properties and mechanical properties. Liu et al. added 1-allyl-3-methylimidazolium chloride (AmimCl) to the CNC films by vacuum filtration, and obtained the soft red-shifted CNC films. The prepared AmimCl plasticized CNC films can be further toughened by hot pressing [14]. Nan et al. immersed the CNC films in sodium hydroxide. With the longer treatment time, the CNC films blue-shifted and the tensile strength and flexibility of the films increased [15]. Yao et al. added polyethylene glycol (PEG) to CNC suspensions and successfully fabricated flexible chiral nematic CNC/PEG composite membranes with uniformly tunable structural colors from blue to red [16]. Huang et al. introduced polyethylene glycol diacrylate (PEGDA) into the CNC suspensions, and the mixed solution of CNCs and PEGDA self-assembled in the dark. PEGDA was made into a three-dimensional network structure by UV light curing [17]. The PEGDA chain can form hydrogen bonds with the hydroxyl groups on the CNCs to improve the mechanical properties of the films. At the same time, the three-dimensional network structure constructed by PEGDA encapsulates the CNCs and improves the water resistance of the films. Kim et al. added 3,4,5-trihydroxyphenethylamine hydrochloride (TOPA) and polyethylene glycol (PEG) to the CNC suspensions under dark conditions, and formed the CNC films by capillary action after filling through the capillary [18]. Such films have uniform birefringence and can be rapidly dried to form films under restricted conditions. TOPA enhances the intermolecular hydrogen bonding ability. As a result, the generation and propagation of cracks are suppressed under capillary confinement, resulting in smooth, uniform, and crack-free birefringent films.

2.3 Tuning the Polarization of CNC Films

As mentioned earlier, the CNC films only reflect left-handed circularly polarized light and transmit right-handed circularly polarized light. Therefore, the maximum reflectivity of CNC chiral nematic films is only 50%, resulting in dull color of CNC films. The previously presented works did not alter this property of CNC films. So Fernandes et al. inserted the nematic liquid crystal 4-cyano-4′-pentylbiphenyl (5CB) as a λ/2 retardation plate in the middle of two left-handed cholesteric domains [19]. The CNC films can reflect the left-handed circularly polarized light and the right-handed circularly polarized light at the same time. The intensity of the reflected right circularly polarized light depends on the birefringence of the liquid crystal and can be reversibly adjusted by changing the temperature or applying an electric field. Anusuyadevi et al. added GLU to CNC suspensions to obtain CNC/GLU composite membranes [20]. Then 4-n-butyl-4'-methoxyazobenzene (BMAB) and 5CB were mixed to prepare a liquid crystal mixture and dissolved in chloroform. Then it was dropped on the CNC/GLU composite films, and the liquid crystal molecules remained on the surface of the composite films. The results show that specific wavelengths of reflected light can be generated in the visible spectral range by varying the GLU content. The reflected light color of the nanophotonic structure can be controlled by the polarization state of the illumination (LCP light or RCP light) (Fig. 4). Li et al. added ferroferric oxide (Fe3O4) and luminophores (e.g. Quinine sulfate, rhodamine b, etc.) to CNC suspensions, which were then placed in a magnetic field to self-assemble into films, resulting in a left-handed chiral nematic structure with perpendicular concentric helical orientations in a planar texture [21]. It is demonstrated that these unique left-handed chiral nematic structures are capable of selectively reflecting LCP light and converting self-luminescence to RCP emission on the film plane and sides.

A) Simplified schematic of two LC droplets (BMAB/5CB mixture) on top of a CNC/GLU film. B) Optical polarized images in reflectance mode of two LC droplets (black and white arrows) residing on top of a CNC/GLU = 39/61 film (red arrow), when illuminated by incident LCP (top) or RCP (bottom) light. Scale bars: 250 µm. C) Reflectance results for the CNC/GLU film, see red arrow in (B). D) Reflectance results for a region with an LC droplet, measured close to the center of the droplet (the black arrow in (B) points to the droplet) prior to UV exposure (nematic phase). E–F) Reflectance results after UV exposure as a function of time (t = 32, 60, 120, and 300 s) for incident LCP (E) or RCP (F) light. Measurements were performed on the same droplet as in (D). At t = 32 s, the LC is in the isotropic state and with time a gradual reversal back to the nematic phase is observed (steady state at 300 s) [20]. Copyright 2021, John Wiley & Sons, Inc.

3 Summary and Outlook

In this review, it is detailed that CNC suspensions can form chiral nematic liquid crystal film nanomaterials through EISA. CNC iridescent films have excellent optical properties. And the optical properties and mechanical properties of CNC iridescent films can be changed by a series of means. This liquid crystal materials prepared from renewable, sustainable, non-toxic, and low-cost biomass materials will have great application potential and commercial value in the future. It can be of great value in bionics research, anti-counterfeiting labels, security, sensing, optical applications, cosmetics, etc. However, the development time of cellulose-based liquid crystal materials is relatively short, so there are still many problems that need to be solved urgently. For example, the EISA process takes a lot of time, and it is necessary to find a convenient way to shorten the preparation time. Secondly, the mechanism research of these materials is still lacking. Finally, it is necessary to find a commercialized route to open up new directions, and then let these materials go out of the laboratory and into the public.

References

Duan, C.L., Cheng, Z., Wang, B., et al.: Chiral photonic liquid crystal films derived from cellulose nanocrystals. Small 17(30), 2007306 (2021)

Marchessault, R., Morehead, F., Walter, N.: Liquid crystal systems from fibrillar polysaccharides. Nature 184(4686), 632–633 (1959)

Revol, J.F., Bradford, H., Giasson, J., et al.: Helicoidal self-ordering of cellulose microfibrils in aqueous suspension. Int. J. Biol. Macromol. 14(3), 170–172 (1992)

Revol, J.F., Godbout, L., Gray, D.G.: Solid self-assembled films of cellulose with chiral nematic order and optically variable properties. J. Pulp Pap. Sci. 24(5), 146–149 (1998)

Droguet, B.E., Liang, H.L., Frka-Petesic, B., et al.: Large-scale fabrication of structurally coloured cellulose nanocrystal films and effect pigments. Nat. Mater. 21(3), 352–358 (2022)

Beck, S., Bouchard, J., Chauve, G., et al.: Controlled production of patterns in iridescent solid films of cellulose nanocrystals. Cellulose 20(3), 1401–1411 (2013)

Guo, M.N., Li, Y., Yan, X.Y., et al.: Sustainable iridescence of cast and shear coatings of cellulose nanocrystals. Carbohyd. Polym. 273, 118628 (2021)

Frka-Petesic, B., Guidetti, G., Kamita, G., et al.: Controlling the photonic properties of cholesteric cellulose nanocrystal films with magnets. Adv. Mater. 29(32), 1701469 (2017)

Tran, A., Hamad, W.Y., Maclachlan, M.J.: Fabrication of cellulose nanocrystal films through differential evaporation for patterned coatings. ACS Appl. Nano Mater. 1(7), 3098–3104 (2018)

Beck, S., Bouchard, J., Berry, R.: Controlling the reflection wavelength of iridescent solid films of nanocrystalline cellulose. Biomacromol 12(1), 167–172 (2011)

Mu, X.Y., Gray, D.G.: Formation of chiral nematic films from cellulose nanocrystal suspensions is a two-stage process. Langmuir 30(31), 9256–9260 (2014)

Chang, T., Wang, B.C., Yuan, D., et al.: Cellulose nanocrystal chiral photonic micro-flakes for multilevel anti-counterfeiting and identification. Chem. Eng. J. 446(1), 136630 (2022)

Guidetti, G., Atifi, S., Vignolini, S., et al.: Flexible photonic cellulose nanocrystal films. Adv. Mater. 28(45), 10042–10047 (2016)

Liu, P., Guo, X., Nan, F.C., et al.: Modifying mechanical, optical properties and thermal processability of iridescent cellulose nanocrystal films using ionic liquid. ACS Appl. Mater. Interfaces. 9(3), 3085–3092 (2017)

Nan, F.C., Nagarajan, S., Chen, Y.W., et al.: Enhanced toughness and thermal stability of cellulose nanocrystal iridescent films by alkali treatment. ACS Sustain. Chem. Eng. 5(10), 8951–8958 (2017)

Yao, K., Meng, Q., Bulone, V., et al.: Flexible and responsive chiral nematic cellulose nanocrystal/poly(ethylene glycol) composite films with uniform and tunable structural color. Adv. Mater. 29(28), 1701323 (2017)

Huang, Y.Y., Chen, G.W., Liang, Q.M., et al.: Multifunctional cellulose nanocrystal structural colored film with good flexibility and water-resistance. Int. J. Biol. Macromol. 149, 819–825 (2020)

Kim, M., Pierce, K., Krecker, M., et al.: Monolithic chiral nematic organization of cellulose nanocrystals under capillary confinement. ACS Nano 15(12), 19418–19429 (2021)

Fernandes, S.N., Almeida, P.L., Monge, N., et al.: Mind the microgap in iridescent cellulose nanocrystal films. Adv. Mater. 29(2), 1603560 (2017)

Anusuyadevi, P.R., Shanker, R., Cui, Y.X., et al.: Photoresponsive and polarization-sensitive structural colors from cellulose/liquid crystal nanophotonic structures. Adv. Mater. 33(36), 2101519 (2021)

Li, P., Li, L., Jeong, K.J., et al.: Homeotropic concentric helix orientations in chiral nematic cellulose nanocrystal films by local magnetic fields. Adv. Opt. Mater. 10(7), 2102616 (2022)

Acknowledgement

This work is supported by National Natural Science Foundation (No. 61973127), Guangdong Provincial Science and Technology Program (No. 2017B090901064), and Huagong-Liyan (Guangdong) New Material Technology Co. Ltd. (High-tech industrialization entrepreneurship team project of Foshan High-tech Zone, FSBG2021021).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Xie, Y., Zhu, Q., Chen, G. (2023). Development and Application of Chiral Nematic Cellulose Nanocrystalline Iridescent Films. In: Xu, M., Yang, L., Zhang, L., Yan, S. (eds) Innovative Technologies for Printing and Packaging. CACPP 2022. Lecture Notes in Electrical Engineering, vol 991. Springer, Singapore. https://doi.org/10.1007/978-981-19-9024-3_70

Download citation

DOI: https://doi.org/10.1007/978-981-19-9024-3_70

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-9023-6

Online ISBN: 978-981-19-9024-3

eBook Packages: EngineeringEngineering (R0)