Abstract

Because of the globe's expanding community and industrialization, there is a greater need for fresh water supplies worldwide. Coatings serve an important part in wastewater purification operations, with innovative applications, continual technological advancements, or cost savings. The much more popular approach to producing biomaterials is stage reversal. Nevertheless, many industrial films are composed of aquaphobic substances, making these highly sensitive to chemical deposition or adsorption on their interface from within their holes. This condition, known colloquially as clogging, is among the most serious operating risks in surface technology. Membrane technology, multiple surface transformation approaches to reduce fouling and increasing porosity at the film interface, application of nanofiltration (NF) membranes, and future potentials are discussed in this chapter. This chapter also covers the advanced modifications and crosslinking techniques to enhance the porosity and longevity of the films used in pressure-driven isolation.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

9.1 Introduction

Water is the most significant requirement for humankind's nourishment, and its cleansing and supply are now key concerns. The present global freshwater crisis results from global expansion and dramatic environmental degradation. The planet's population is predicted to reach billion by 2050, considerably increasing the demand for economic goods. Water usage increases due to urbanization (Gehrk et al. 2015). As a result, water consumption, especially from food supplies, is increasing significantly, as 70% of the planet's freshwater resources are being used for irrigated agriculture each year. Even though the world is mainly surrounded by groundwater, only a small part of such an ocean is available to humans. Different parts of the planet have different access but lack access to safe and pure water. As a result, a good plan is important to deal with the water problem. Membrane filtration is a reliable alternative to water purification due to its strong financial and ecological benefits (Yin and Deng 2015). The surface technique has been proven widespread use during wastewater cleaning methods like industrial and municipal waste cleaning, saltwater distillation, membrane filtration, and ultrafiltration (UF) generation. Compared to traditional techniques such as oxidation, adsorption, cryogenic distillation and chemical coagulation, it has many advantages such as a small area, good quality control, low capital cost, simple servicing simplicity of handling and monitoring (Tul Munthaet et al. 2017).

Nanofiltration (NF) films, as reverse osmosis (RO) film surface, can effectively eliminate small organic compounds and inorganic salts. Nevertheless, the fundamental difference between the NF and RO films includes the most denial of ionic species, a decreased denial of the multivalent ionic species, and an increase in flow. Because of these qualities, the NF film may be used in various activities, including treating wastewater, biotechnology, pharmaceuticals, and food engineering (Mukherjee et al. 2013). Particles are generated on the surface of the membrane and in the porous membrane as ionizable functional groups dissociate. Depending on the individual material used in the synthesis method, these units may be basic, acidic, or a mix of both (Minjing et al. 2008). Because the chemical nature of the film is basic, the pH of the interacting water has a large effect on surface chemical dispersion.

Nevertheless, the film may see an isoelectric range during certain pH levels. Electrostatic interaction or repulsive might arise depending on the membrane's fixed ions and neutral atoms. Two conflicting hypotheses describe the type of encounter: (i) the solubilization power restriction process and (ii) the visual dynamics phenomenon (Vignati et al. 2005). The NF membrane is a tension film with features similar to UF and RO membranes. NF membranes have many advantages, including high flow, minimum maintenance, low operating cost, low operating stress, and significant ionic salt retention. Such benefits have extended the global use of NF films. Many materials have already been used and produced in various separation processes. Commercial exploitation of membrane technology has been achieved in Japan and the United States. The nanocomposite film approach is the best efficient way to make NF film. To form a nanocomposite, an extremely narrow layer is produced on a permeable layer.

Nevertheless, a variety of additional approaches might be used to create an NF nanocomposite (Raoufi et al. 2014). Many investigations have been conducted in the latest days to investigate contamination's management and causation. On the other hand, coating clogging became a severe issue in an array of applicants. As a result, the physical and chemical factors driving fouling should be investigated. The latest research has found that geometry and interface appearance determine their specific function membrane interface characteristics such as hardness, average pore diameter, electrokinetic properties, geometry, and chemical characteristics, all studied to see how they affect membrane performance. On the other hand, the stiffness of the interface of the film has a considerable impact on the degree and speed of contamination (Peng et al. 2011). The main purpose of this chapter is to provide a critical evaluation of NF film studies. The first section of the chapter includes a variety of membranes and NF membrane modification methods. NF film has been used in biotechnology, pharmacology, food sector and water treatment. In addition, the future perspective is also discussed in this chapter.

9.2 Membrane Technology

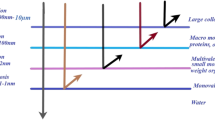

Membrane technology accounts for more than half of the global treatment of wastewater potential. The emphasis is placed on the elimination of pollutants in water purification, including such organic, chemical and biological contaminants, and in addition to obtaining sufficiently pure and good tasting water, also the dispersed particles contained in the water (Razmjou et al. 2011). In recent times, membrane technology has been increasingly employed in wastewater and desalination treatment in biotechnology, manufacturing and food processing industries, due to its specific and cost-efficiency. A membrane can be defined as “a selected protective boundary that places undesirable substances at the interface, while allowing certain chemicals to flow based on their physical and chemical characteristics when a driving factor is provided on the film” (Díez and Rosal 2020). The different types of membranes for water cleaning in terms of intact species and pore size are shown below in Fig. 9.1.

9.3 Membrane-Based Filtration and Separation

9.3.1 Ultrafiltration

At limited transmembrane operative pressures (TMP), UF is employed. Since the UF film holes may be bigger for the heavy metals, chemicals may be attached to ionic species to increase their size. So, polymer enhanced ultrafiltration (PEUF) and enhanced micellar ultrafiltration (MEUF) are presented as a result (Zahid et al. 2018). MEUF is created by combining a surfactant as well as for UF. MEUF has resulted in minimal energy consumption, large flow and specificity, a small footprint, and high removal efficiency. MEUF is best suited for sewage with low amounts of heavy metals. In MEUF, a surfactant with a proportion greater than the critical micellar concentration (CMC) is combined with wastewater. In addition to CMC, emulsifier molecules enhance and combine the formation of certain microspheres in the liquid. A watery cap and a polar end are included in the surfactants (Daufin et al. 2001). The interior wet center of the microspheres can dissolve organic materials (with a small chemical mass) as a solubilizate. At the same time, the interface activated carbon opposing metals on its surfaces owing to electrical interactions. Surfactants, whose electric current is diametrically opposed to metallic ions, often have the greatest average rates. Ionic surfactants (e.g., sodium dodecyl sulfate (SDS)) and polyelectrolytes (PE) are employed to remove heavy metals (Qasem et al. 2021) effectively.

MEUF efficiency is affected by a numeral of parameters, such as the kind of membranes utilized, the solute molecules supplied the operational parameters, and the type of surfactants employed. PEUF is created by combining UF with attaching materials. Bridging polymeric’ organic molecules might be phosphonic, sulfonate, amine, or carboxylated, and chelating or electrical bonds will join them. PEUFs are also called polymer-assisted, polymer-supported, size improved, and complexation enhanced UF (Zeng et al. 2020).

9.3.2 Nanofiltration

NF is utilized to extract components with an atomic mass of more than 1000 Da and to eliminate melted materials with particle sizes more than 200 Da. Consequently, the NF working frequency is among RO and UF processes. The NF films are made of polymeric materials with numerous layers of negatively charged chemical structures (Abdullah et al. 2019).

9.3.3 Microfiltration

Microfiltration (MF) is a technique that utilizes a micro-porous film to remove bacteria, micrometers materials, protozoa, viruses, contaminants, and other micron-sized particles from a solution. The MF process is similarly a lower pressure-driven membrane method, with film pits extending from 0.1 to 10 m. Ceramics, silica, alumina, zirconia, polysulfone, PVC, polypropylene, PTFE, polyamides, PVDF, cellulose acetate, polycarbonate, composite materials, or cellulose esters are used in the manufacture of certain MF films. Furthermore, the MF method may be used in particle separation from wash water in the electronics sector, clarity of various cider and juices, sterilization of wine and beer, and effluent treatment (Huang et al. 2017). Due to its limited elimination capabilities, the use of MF in reducing heavy metals has received insufficient consideration. It has, nevertheless, been employed by altering the membranes or chemically pre-treating the concentrated solution. The MF method is accessible in two major variants, based on the manner of usage: dead-end and crossflow (Tanhaei et al. 2014).

9.3.4 Reverse Osmosis

RO is a pressure-driven separating method that uses a semi-permeable film (pore size 0.5–1.5 nm) to enable only tiny particles to flow through. The RO method replicates the typical filtration method by adding pressure (20–70 bar) to the source solution's osmosis tension. The inhibited solute molecules’ particle mass is typically in the 0.00025–0.003 m range. The RO technique could extract 95–99% of charged organic and inorganic salts. The RO method is minor and has a remarkable refusal rate. The main drawback of the RO process, however, is film contamination and degradation (Baharuddin et al. 2015).

9.3.5 Forward Osmosis

Forward osmosis (FO) is a type of filtration that uses a substrate to combine specificity and penetrated liquid flux. A semi-permeable film divides a feed-in FO. The solvent has a higher concentration of solutes than the feed water. Fluid crosses from the feedstuff water to the draw solution because of the osmosis pressure gradient between the feeding and draw situations, retaining rejecting dissolved substances on the feed solution and purified liquid on the drew solution. FO does not need mechanical power and hence saves fuel. Because the FO method is also simple to wash, ecologically safe, and has minimal clogging, it is extensively employed in effluent treatment. Nonetheless, FO has film selection problems, drawing solution re-concentration and external and internal intensity polarization (Abdelkader et al. 2018).

9.3.6 Electrodialysis

Electrodialysis (ED) is a technique for separating ions based on electrical differences. ED employs a sequence of cation exchange membranes (CEM) and anion exchange membranes (AEM) that are interchangeably stacked in parallel to divide electrical substance molecules. Anions flow via AEM during the ED procedure, whereas metal ions move via CEM. The processed flow is generated through one of the ED towers tubes, whereas the concentrate flow is discharged from another half (Jamil et al. 2018). ED has a minimal stage shift, rising water return rate, no molecular involvement, and no reactivity, and thus can function across the pH range. Nevertheless, ED suffers from foulants, a large need for electromotive force, and expensive membrane costs.

9.3.7 Other Membrane-Based Methods

Liquid membrane (LM) and membrane distillation (MD) are also utilized for sewage remediation. MD is a dual heat-driven pore division technology that uses a permeable carbon wet film to divide cold and warm chambers. Only vapor can pass through MD's holes, whereas other particles are blocked. MD may be classified into four types: direct contact MD, air gap MD, sweeping gas MD, and vacuum MD (Samaei et al. 2020). On the other hand, LM is composed of a water form organic layer that serves as a wall among two water phases. LM is insoluble with both the feed water and the recirculated solution, and the peeling procedures may be completed in one stage. LM is extremely efficient, selective, and capable of achieving precise molecule recognition. However, the membrane's lengthy durability is a concern (Al-Amshawee et al. 2020).

9.4 Membrane Fouling

Polysulfone (PSU), polyethersulfone (PES), polyacrylonitrile (PAN), cellulose acetate (CA), polyamides (PA), polyvinylidene fluoride (PVDF) are the most often utilized polymer resources for creating UF, MF, RO, and NF films due to which great chemical, mechanical and thermal stability. However, one downside of such polymeric is that they are susceptible to settling certain chemicals on their uppermost layer or within their permeable assembly, resulting in a reduction in infuse fluidity (Zaheri et al. 2015). This condition is known as fouling. It necessitates costly cleaning and periodic regeneration methods to minimise membrane performance loss and alleviate the requirement for increased energy and pressure consumption that would be essential to preserve steady fux. Membrane emmeshing also shortens their valuable provision life. Fouling is described by the International Union of Pure and Applied Chemistry as “the process that results in a deterioration in membrane performance caused by the deposition of suspended or dissolved particles on the external membrane surface, on the membrane pores, or within the membrane pores” (Díez and Rosal 2020).

As a result, there are four forms of membrane fouling:

9.4.1 Inorganic Fouling

Inorganic fouling, often known as precipitated pollution, is caused by the precipitation or deposition of inorganic materials in the intake and the crystallization of trace minerals, hydroxide ions, and oxide (Padaki et al. 2015).

9.4.2 Organic Fouling

Organic fouling is mostly composed of natural organic materials. Organic matter contains proteins, polysaccharides, humic compounds, nucleic acids, and fatty acids produced by the bacterial decomposition of vegetables and plants; such substances aid in forming a coating of chemical hydrogel over the surfaces, as well as within their holes. Adsorption is the first precursor of such a layer (Alvarado et al. 2016).

9.4.3 Colloid/Particulate Fouling

Colloids range from a few nanometres to a few micrometers in dimensions. The classification of particle substance in usual waterways and effluents is as follows. Supra-colloidal solids >100 µm, settleable solids 1–100 µm, colloidal objects 0.001–1 µm. Materials that are near in dimension to film holes might obstruct them. Still, larger particles can aggregate on the membrane surface, forming a solid coating that provides additional mechanical susceptibility to water flow (Ly et al. 2019).

Five clogging types could be detected based on the kind of blockage:

-

1.

Total porosity refers to the full closing of apertures with materials. May include dimensions greater than film holes are required for this blockage.

-

2.

Pore-blocking relates to the occlusion of the porous membrane caused by the adhesion and accumulation of tiny particles on the porous interior structure.

-

3.

Transitional pores obstructing is a hybrid of the previous two. Materials obstruct pores and adhere to certain other materials on the substrate, forming porosity bridged.

-

4.

Cakes coating is the exterior membrane leading to creating a filter cakes coating.

-

5.

Bacterial pollution or membrane fouling is the growth of biofilm communities on undesired surfaces.

The term “biofilm” refers to a kind of microorganism that forms an “aggregate of microorganisms in which cells that are typically embedded inside a self-produced matrix of extracellular polymeric substance (EPS) attach to one other and/or to a surface” (Cui and Choo 2014). Maturation, adhesion, and dispersion are the three stages of bacterial development. The adhesive method can be divided into two stages: irreversible adhesion and reversible adhesion. It starts with the movement of planktonic cells and minerals from the source to the interface. Cells are originally lightly applied to the top due to physicochemical factors. Flagella and Fimbriae could also be used to give physical adhesion to the surfaces. Then, over seconds to several hours, cells produce EPS, which aids microbial adhesion to the interface, resulting in irreparable bacterial adhesion to the ground (Guo et al. 2012). Bacteria that have matured have a higher diversity and cell density. There seem to be routed for nutrient and water flow inside the bacterial membrane that keep cells alive. As a result, cross-species microorganisms may communicate with one another while understanding the different types of resources. Eventually, certain biofilm and bacteria clumps can be freed from the framework, enabling the biofilm to grow and colonise habitats on the surfaces. EPS is a term used to describe a group of people that work together to achieve the same goal “polymeric conglomeration generally composed of extracellular biopolymers such as polysaccharides and proteins, in various structural forms” (Amosa 2017). Microbe organisms benefit from EPS formation because it provides physical stability for the microbial population and insulation from climate factors such as salt and dryness. Biofilm generation and microbial quorum sensing (QS) are two phenomena that are intimately linked. This mechanism is guided by tiny genic particles known as autoinducers. The quantity of such signaling particles controls the declaration of a numeral of genes, letting cells control superficial adherence, EPS generation, biofilm, and maturation dissolution. QS is a complicated communication mechanism that can sense cell bulk in a given microbial communal and control gene transcription in response to environmental stimuli (Iritani 2013). Membrane surface chemistry and membrane-solute connections are widely known to be significant inconsiderate snarling. Membrane snarling is a complicated phenomenon caused by various factors, which may be categorized into three groups:

-

1.

Physical and chemical configuration of the feed water: Due to specific connections between both the membrane and the foulants revealed in the liquid, physical and chemical characteristics of personal graze particles like concentration, morphology, hydrophobic interactions, and start charging have an effect on the production of layer clogging (Matin et al. 2011).

-

2.

Operating conditions: Operating factors like feed crossbow velocity, transmembrane pressure (TMP), feed concentration, pH influence membrane performance or temperature and have a consequence on membrane snarling. A concise overview of the many aspects is provided somewhere else (Vert et al. 2012).

-

3.

Membrane properties: Membrane properties such as hydrophobicity or surface roughness or hydrophilicity, surface charge, and pore size have a significant impact on Film clogging is caused by dissolved exchanges. Hydrogel films are thought to be less susceptible to clogging than dry films. Rough textured surfaces also make biofouling easier Surface protuberances contribute to membrane fouling by trapping adjourned inorganic and organic resources, whereas smoother surfaces are less sensitive to fouling (Crozet et al. 2014).

9.5 Strategies for Reducing Fouling and Biofouling

Since their initial discovery in the 1960s, several changes have been suggested to improve phase transition coating fouling and biofouling behavior. The first successful method was to use PVP as an addition in the molding mixture of PES UF films, which was shown to alter pore size (Rabin et al. 2015). Following are summaries and comments on recently suggested coating, grafting or blending procedures targeted at refining membrane biofouling or fouling behavior (Solano et al. 2014). Antifouling strategies in desalination, marine environment and wastewater treatment are shown below in Fig. 9.2.

9.5.1 Surface Grafting

The adding of functional moieties, hydrophilic chains or electrostatically charged groups to the film exterior. Interface grafted continuously modifies the interface by forming a chemical bond between the grafted chains and the membrane. This method offers several advantages, including the ease with which it may be modified that allows for spatial control and substantially higher chemical stability of grafting onto the required surface (Toyofuku et al. 2016). Current research using surface-grafting modification approaches is shown below in Table 9.1.

However, it has the drawback of necessitating energy-intensive processes, raising membrane costs, and making scaling-up difficult. Table 9.1 provides a review of the current surface grafting research. Different approaches can be used to stimulate the membrane surface for grafting.

9.5.1.1 Plasma-Induced Grafting

Plasma is the fourth phase of the material, consisting of a partly ionized electrical semi gas. The liquid is formed whenever atoms are stimulated into an explosive state by radiofrequency radiation or microwaves (Jaleh et al. 2019). Multiple operational groups can be defined on the surface of a polypropylene material once it is subjected to it, which can then be exploited for future grafted or bridging processes. Plasma therapy may be divided into two types in this fashion.

-

1.

Plasma Activation or Functionalization:

Surfaces charges are generated when ions and electrons form the plasma phase collide with the surface. The adhesion of ligands is determined by the kind of mixture of gases utilized, which might be reactive or inert (Wang et al. 2018). When ionized is activated with gaseous products like hydroxyl, oxygen, or peroxide, functional groups are presented. Atmospheric plasma therapy to engage the surfaces of polypropylene (PP) films allowed the insertion of oxygen supply organic compounds and promoted nanocrystals’ coating by soak. Plasma generated from carbon monoxide or carbon dioxide contains carboxylic acid units and aldehyde, hydroxyl, ketone, and ester groups. Surface primary, secondary, and tertiary amides, and amines are produced by ammonia and nitrogen plasmas (Garcia-Ivars et al. 2016). While inert gas particles like argon or helium do not produce functional groups on the surface, they are less aggressive, resulting in more stable membranes.

-

2.

Plasma Polymerization or plasma Deposition:

Plasma polymerization, also known as plasma deposition, involves using a plasma discharge to fragment monomers and generate radical sites on the membrane surface. In the gaseous state, reacting particles can reunite to make monomers, yielding a polymeric particle covering the surface. As a result, rather than attaching free radicals, functional groups on the surface might induce graft polymerization (Rahman and Seman 2018).

9.5.1.2 UV-Induce Grafting

Because of its simplicity, adaptability, photochemical-initiated graft polymerization, and cheap cost, one of the greatest commonly utilized methods for surface morphology alteration is UV grafting. This method modifies the surface layer by introducing functional groups while retaining the bulk properties. Even without or with the use of a photo activator, photo-initiated grafting polymer could be performed. If illuminated, polyarylsulfone films are inherently sensitive, which means they may create active sites or free radicals without the need for photoinitiators (Igbinigun et al. 2016). Owing to the combination of phenoxy–phenyl chromophores in the framework of the PES polymer network, UV light absorbance has been observed, leading to the heterolytic breakdown of the C–S bond at the position of a sulfonate group. This reaction produces two radical positions: a sulfonyl radical and an aryl radical that sheds its sulfonic label, leading to the development of an additional aryl radical, which induces grafting. Using an acrylic acid monomer solution, UV photo-grafting was used to modify polyacrylic–polyethersulfone NF membranes, resulting in decreased reverse salt diffusion and better water permeability (Kaneda et al. 2019). UV light of Fuse allylamine monomer to the surface of PES membranes, then transplant graphene nanofibers on top. Increased hydrophilicity, smooth surfaces, higher water flux, and decreased fouling attachment were seen in functionalized membranes. To begin the grafting procedure, some composite membranes require the addition of a photo activator or photocatalyst and an additional step called the photo-activation stage. PVDF membranes are permanently grafting graphene oxide (GO) nanosheets under UV irradiation through a benzophenone-initiated crosslinking process. Enhanced antimicrobial property over Escherichia coli was achieved without affecting solvent storage or permeability. Acrylate polymer on the interface of PP cylindrical strand surfaces during UV irradiation using benzophenone as a photographic activator to produce membranes with higher flux and reduced rejection rates (Yang et al. 2016).

9.5.2 Surface Covering of a Membrane

Surface coating is a cost-effective, straightforward, and ecologically acceptable surface modification approach that includes a film deposited on the membrane's interface. This method aims to reinforce surface qualities while generating minimum structural impacts. The main drawback of this approach is that the covering layer might be uneven (Capozzi et al. 2017). In this way, coating materials having a high covalent bond at the potting medium contact increase efficiency and durability. A high-molecular-weight polymer is also used to keep the covered film from penetrating the micropores. The following are recent research of films that various coating materials have changed in Table 9.2.

-

1.

Coating with polydopamine

Polydopamine is a biomaterial influenced by mussels' good adhesion capability. It can quickly conscience in basic conditions (pH typically between 7.5 and 8.5) with oxygen as an oxidizing, resulting in a quite fine layer on a range of surfaces. The experiment consisted of coating's anti-organic fouling, and surface hydrophilicity properties are outstanding. Polydopamine also possesses many functional groups that may react with a wide range of biological compounds, giving it an excellent framework for forming chemically grafted active coatings over a substrate (Kumar and Jaafar 2018).

-

2.

Electrospun nanofiber layer

It is a technology that provides certain distinct advantages owing to the nanofibers' better qualities, including tunable porosity, high interconnectivity, a high surface area to volume ratio, and tunable functionalization. Electrospun films can also contain antimicrobic compounds such as carbon nanomaterials, metallic nanoparticles, or antimicrobial biopolymers, which help to minimize biofilm development (Mujtaba et al. 2018). Electroplating seems to be the only technology that can produce fibers with extremely small dimensions. A higher potential supply, a spinneret, as well as a capturing screen, which is typically a metallic screening slab or spinning gadget, make up an electrospun device. A large power generator is being utilized to infuse charge into a polymeric mixture of a specific orientation, which is then pushed toward that goal (Bokhary et al. 2018).

9.5.3 Blending Method

The process of manually combining two or so more chemicals into the colloidal solution using the same solvents is known as polymeric mixing. Inorganic nanofillers or polymeric materials are commonly used as solid dispersion method additions to change film properties. This method is regarded as the simplest way to avoid contamination and increase membranes solubility because the bulk of such compounds is highly hydrophilic. The limitations of this technology are the restricted compatibility of hydrophobic polymers and hydrophilic additives and the leaching of blended components after long-term usage.

9.5.3.1 Blending Inorganic Materials

MMMs are films that mix the qualities of filler particles with the characteristics of polymer composites. MMMs attempt to make use of polymers’ durability, processability, selectivity and permeability, by providing a unique surface chemistry. Introducing inorganic additives to the polymer matrices increases the heat (e.g., thermal conductivity or thermal stability) and physical (e.g., young's modulus, tensile strength, hardness, and stiffness) characteristics of the polymeric membrane when compared to the pure membrane materials. Moreover, the homogeneous dispersion of inorganic materials in the matrix material increases material characteristics, including crystallinity, viscoelasticity, conductivity, density, morphology, and structure (Zeng et al. 2020). Current research on composite and blended polymeric membranes is shown above in Table 9.3.

Nanocomposite membranes have higher viscoelastic characteristics than virgin membranes. The polymeric substrate of MMMs screens has been infused with a variety of solid elements, including metallic nanoparticles (inorganic NPs) are a potential addition that may increase membrane fluidity and characteristics. Several kinds of inorganic materials, such as GO, TiO2, Ag or Al2O3, and CuNPs, have indeed been directly embedded into the suitable solvent throughout film formation (Abdullah et al. 2019). TiO2 is an excellent choice because of its low toxicity, chemical and thermal stability, super hydrophilicity, self-cleaning capability, and photocatalytic activity, all of which may be employed to prevent fouling. To manufacture UF porous material by phase inversion, TiO2 NPs are added into the PVDF/PAN colloidal solution. Better purified water flux, Greater hydrophilic nature, and better antifouling capabilities were found in mixed films. AgNPs have sparked a lot of attention due to their broad range of antibiotic action and low toxicity. AgNPs operate as a local supply of Ag+ ions, which prevents reduced solute adhesion and bacteria growth to film surfaces (Tanhaei et al. 2014). PES films were combined with AgNPs utilizing the splash precipitate method to develop films with strong anti-biofouling and antibacterial properties. However, there are two major drawbacks to using inorganic compounds. On one side, nanomaterials prefer to clump together during the drug production step. Nevertheless, NP leaks into the ecosystem are a concern. Several porosity nanomaterials, such as silica nanoparticles and nano-minerals (sepiolite, halloysite nanotubes), have been developed to solve these difficulties (Jamil et al. 2018).

Mesoporous silica particles have grown in popularity in recent years owing to their beneficial properties such as consistent pore size between 2 and 50 nm, high specific surface area and ease of functionalization. Mesoporous silica may be manufactured in basic and acidic conditions and is typically generated using a surfactant template. Santa Barbara Amorphous and Mobil crystalline material (MCM-41) are the two most frequent forms of mesoporous nanoparticles (SBA-15). PES membranes are synthesized using titanium and zirconium nanoparticles on functionalized SBA-15 material to increase membrane hydrophilicity and permeability. An attentiveness of as little as 0.6 wt% SBA-15 was used to achieve antifouling behavior (Samaei et al. 2020). A co-condensation approach was used to increase the surface porosity, functionalize SBA-15 with carboxylic groups and amine, the permeability of PES membranes and hydrophilicity. Composite membrane antifouling capabilities have improved, particularly against irreversible fouling. Halloysite nanotubes (HNT) are natural zeolite found alumina naturally—silicate nanoparticle material with the chemical equation Al2Si2O5(OH)4H2O. Its crystal lattice is a multi-walled inorganic nanotube with a long tubular form and consistent wide pores of octahedral (Al–OH) and tetrahedral (Si–O) sheets. It has a tubular shape, large surface area, excellent dispersity, and a well-crystallized structure; it is often utilized as a filler in polymeric matrices (Zaheri et al. 2015). PES UF films with HNTs supplied using copper ions (Cu2+) as an antibacterial agent were produced via a phase inversion approach. Cu2+-HNTs/PES membrane was much more porosity and hydrophilic was greater. Mg8Si12O30(OH)4(H2O)48 H2O is the equation for zeolite, a hydrated silicate. Adjacent layers split a base unit configuration of bricks in its layout.

As a consequence of this structure, a syringe particle form with excellent athletic properties and a huge surface area emerges. After magnesium lixiviation in acid, sepiolite was utilized as a substrate to incorporate nanomaterial into the silicate matrix. Phase inversion is also used to create composite PSU/PVP UF membranes with sepiolite-supported nanometals. No nanoparticles moved to the filtrate, confirming NP stability. Antimicrobial activity inhibited bacterial colonization in both gram-negative and gram-positive microorganisms. Zeolites are hydrating aluminosilicate crystals having the general formula Mx/m[(AlO2)x(SiO2)y], wherein Mx/m denotes an ion that can be exchanged (Padaki et al. 2015). The addition of zeolites to a polymeric substrate improved membrane fluidity as well as heat resistance, chemical stability, and good mechanical. NPs can also be included in zeolites for antibacterial purposes.

To eliminate heavy metals from water, PSU films were produced impregnated with zeolite particles. PVDF UF membranes with Ag-loaded zeolite nanoparticles were also produced with a longer antibacterial activity. MOFs are crystallized microporous substances formed by a periodic matrix of metallic ions connected through versatile organic compounds (Alvarado et al. 2016). They offer some, including a large surface area, distinguishing features, high pore volumes, high metal content, and tunable pore size, which all offer useful active sites. The GO NPs are used in a silver-based MOF to create a fine nanocomposite barrier with improved antifouling properties. PES NF films were created via a phase inversion method and subsequently altered with nanocrystalline Ce (III) MOFs.

Composite membranes demonstrated better permeability, antifouling behaviour, and dye rejection capability during wastewater treatment and hydrophilicity. A composite CA UF membrane by MOF-GO and incorporating GO into the matrix was created. CA/MOF-GO hybrid membranes with modified pores have smoother surfaces and bigger pores. The water flux and hydrophilicity were also enhanced, resulting in a good performance in the water purification process (Cui and Choo 2014).

9.5.3.2 Blending Organic Molecules

PEG or PVP, for example, are often used as aqueous polymeric additions to make membrane manufacture or improve membranes performance easier. PVP is an efficient pore generating chemical due to its hydrophilic nature. It serves as a phase separation booster in terms of expediting phase inversion and thermodynamics, resulting in better membrane flow, contributing to creating a homogenous finger-like porous structure. Furthermore, raising PVP content decreases highly diffused development, lowering permeability. PEG is a fluid chemical that may be utilised to increase pore formation and improve porosity in polymer films. PEG comes in a range of molecular weights and has the general formula H(OCH2CH2)nOH, where n is the average of repeated oxyethylene groups (Guo et al. 2012). PEG also reduces the thermodynamic stability of the casting solution, causing finger-like porous structures to emerge. The membranes form changed from needle pore porosity to ellipsoids or spheres when the PEG molecular mass in the foundry liquids was increased from 200–10,000 Da. This resulted in inferior physical efficiency. Dendritic polymers, including random hyperbranched polymers (HBPs) and dendrimers, have sparked a great deal of interest in developing a variety of nanostructured materials. A dendrimer is a polymer with a set of nodes that is extremely branched and contains many terminating functional groups. Aptamers are made in a controlled and repetitive production process, beginning with a core structure and continuing to a new “generation” of dendrimers for every step. The amount and dimension (generation) of terminating organic compounds might affect their quality. The very first group of dendrimers to be commercialized was main ending polyamidoamine (PAMAM). The phase inversion approach created PSU hybrid films with diverse semi constituents. In gas separation procedures, PAMAM-dendrimers (G0) were added directly into the polymer solutions, generating a selected surface for CO2 absorption (Vert et al. 2012). Dendrimers can also be used as a pattern to enclose or attach to other materials in their internal vacant areas.

In-situ manufactured PAMAM (G1) dendrimers as containers and hosts for platinum NPs were used to develop a simple approach for manufacturing catalytic PVDF membranes. PAMAM dendrimers were used to make dendrimer encased AgNPs, which were then transplanted onto the interface of PVDF membranes through an interfacial process and showed permeability, good solubility, and antibacterial properties. Hyperbranched polymers (HBPs) are extremely twisted polymers with many terminating organic compounds, spatially gaps, and unique physicochemical characteristics, similar to dendrimers. Despite dendrimers, HBPs can be easily synthesized in one-step polymerization methods, giving them a limited alternative to dendrimers with promising uses on a wide scale. PVDF films containing polymerized polyglycerol as an additive were made via phase inversion. Coatings with surface pore size and a larger water-soluble characteristic were created using increased water flux. By combining epoxy/amine click chemistry with fluorinated carbon chains and epoxy-containing coumarin moieties (EC) Ji et al. produced a novel amphiphilic hyperbranched poly (ether amine) (hPEA) (CF6). PVDF was dissolved, and the resulting copolymer (hPEA-EC-CF6) was used to make the mixed solutions. Disbanding PVDF and the associated copolymers (hPEA-EC-CF6) produced the blending liquid, and phase transition films displayed significant properties to aqueous dyes in aqueous systems.

9.6 Nanofiltration Membrane Applications

NF films are a newer invention that bridges the space among two well-known separation techniques: UF and RO. The ability of NF films to allow soluble ions over the membranes yet refuse multivalent and divalent particles, including such sodium sulfate, is one of the most remarkable features. This versatility opens up many possibilities for customizing method uses across a wide range of industries. Because filtration is typically utilized in processing systems, adding NF films to an already diverse technology line of MF and UF membranes was a logical fit. NF film methods are used in various segments, such as the food, chemical industry, metal finishing, textiles, pharmaceutical, biotechnology and pharmaceutical applications, power generation, and pulp and paper. The following are some of the most commonly cited applications:

-

1.

Use in the petrochemical sector

-

2.

Purification of food businesses [juice processing, dairy, sugar industry, soft drinks, beverage products, baker's yeast, fish meal, olive processing, and meat processing], and use in pharmaceutical manufacturing.

-

3.

Whey dehydration in part,

-

4.

Optical brighteners and textile dyes desalination

-

5.

Nickel, Metal, and chrome plating in the metal fin fishing, including leather sectors, are being phased out.

-

6.

Wastages clean-in-place (CIP) solvents are purified.

-

7.

Applications in biotechnology and pharmaceuticals

9.6.1 NF Application by Industry

9.6.1.1 Dairy, Food, Plant Extracts and Beverage

-

1.

Lactose demineralization and concentration: Lactose may be demineralized and concentrated concurrently using NF films, with various levels of cleanliness depending on the procedure.

-

2.

Sugar Syrup Intensity: NF Can Be Utilized to Reduce Both Processing Time and Costs Compared to Standard Boiling Reduction Techniques for Thick Maple Syrup.

Gibberellins [pharma /plant]: Gibberellins are plant enzymes promoting development and plant growth. NF is a reliable approach to increase total product outputs by focusing on phytohormones such as gibberellins (Rahimpour et al. 2010).

9.6.1.2 Dyes and Textiles

-

1.

Dye absorption: By enabling salts water and to flow over an NF film, NF can be a viable option for the desalination and concentration of textile colors.

-

2.

Removal of dye penetration: NF is commonly used in dye recovery to fulfill discharge requirements following penetration challenges with fluorescent dyes.

-

3.

Concentration of desalination and optical brightening agents: Optical improving mediators can improve the look of colors. To decrease operational expenses, NF can be utilized to enhance the concentration of agent brightening that can be reused (Mohammad et al. 2007).

9.6.1.3 Wastewater and Industrial Processes

-

1.

Removal of liquified natural organic materials to assist manufacture for industrial process water or natural organic matter—enriched water natural organic matter may be removed from groundwater using NF superficial water:

-

2.

Treatment of Leachate from landfills: NF can be used to remediate some landfills as a low-energy option. Leachate can be improved by lowering COD and TOC levels, eliminating contaminants, and lowering turbidity.

-

3.

Brine retrieval: NF films may contain large castoff volumes of sulfate while allowing sodium chloride ions to flow over, making brine recovery in industrial processes a feasible option (Misdan et al. 2013).

9.6.1.4 Pharmaceutical/Biotech

-

1.

Production of antibiotics: NF membranes have shown to be an appealing separation process technique, with applications in the concentration, separation, and synthesis of antibiotics and hormones.

-

2.

Fluid from the Plasma: After Separating Blood Plasma and Serum, NF Can Be Employed to Collect Fibrinogen and Other Clotting Components.

9.6.2 New NF Applications

9.6.2.1 Water Softening Systems

Ions of magnesium (Mg2+), calcium (Ca2+), and bicarbonate (HCO3−) create stiffness. Hardness minerals or ions promote gauge development in equipment and potable water pipelines and systems that utilise water processes such as heat exchangers. To remove scale-forming ions from water, softening units can be used.

9.6.2.2 Municipal Effluent Action

An innovative action combination for cleaning community wastewater in order to replenish safe groundwater was studied. Biofouling on the NF membrane (De a greater speed of crossflow of roughly 1 m/s can regulate the surface. It is necessary to perform proper pretreatment, such as gradual sand filtration (Dražević et al. 2013).

9.6.2.3 Water Purification

Membrane cleansing innovation is commonly used in the food sector, especially for the treatment of effluents. Effluent from the food sector causes fouling and fast concentration of the membrane layer, especially when operating at high pressure.

Tiny beverage and food industry organizations develop cost-effective technology to collect water using effluents due to the increasing price of water. One typical method for adequately cleaning and recovering water is to use a fermenter in combination with an NF unit. COD in the effluent is reduced by roughly 95% in the reactor. As per German drinking water, the produced water is similar to potable water. The reclaimed groundwater can be utilized to satisfy some of the company's needs. In addition to treating wastewater, NF may be employed in process water or lower MW salt extraction. Consequently, NF can be employed to retain sulfate during seawater filtration and the processing of petroleum products (Amarie et al. 2017).

9.6.2.4 Parting Methods

NF may play a significant part in unraveling valued compounds or undesired components or removing harmful after fluid watercourses that could improve the industry's environmental effect and save money to replace liquids, NF could be used. Material concentration and pH are two main factors that may influence efficiency improvement. With such membrane production materials, barrier specificity cannot be preserved. Dye manufacturing wastewater must be cleaned before even being released to minimize the negative effect on aquatic life and human. Adsorption, oxidation, coagulation, and biological treatment are conventional color removal methods. Reversing microemulsion extraction is a relatively new method of decolorization.

On the other hand, older methods of elimination have proven to be highly effective. Different elimination processes can be utilized to obtain a satisfactory dye removal rate considering its adverse effect on all organisms. To improve the integrity of sewage, the scientific industry has the right to identify cost-effective and more effective removal solutions (Zhang et al. 2018).

9.7 Conclusion and Future Prospective

Creating nanocomposite membranes is vital for the fabrication of UF, MF, RO, NF, and FO membranes for desalination and wastewater treatment. It has recently received a lot of attention. The inclusion of nanoparticles profoundly affects the physical and chemical properties of the outer layer of the membrane (porosity, hydrophilicity, membrane durability, charge density, chemical, thermal, and mechanical stability). Compared to a normal membrane, and also has the wonderful possibility of fixing the permeability-selectivity barter's situation. The techniques for reducing film biofouling and fouling are discussed in this chapter. The concentration is on phase-inverted membranes that incorporate a variety of inorganic and organic additives and methods for modifying the surface layer. The purpose of the research covered in the chapter is to see if adding new chemicals with functional groups, either on the membrane surface or in the mass, may help reduce the amount of flux produced by inorganic and organic substrate coating. Comparable arguments have been made to support changing films to make them resistant to biofouling and bacterial adhesion. PEG and PVP are well-known polymeric additions for enhancing the asymmetric structure and causing pore growth of phase-inverted films. Various organic and inorganic mixed substances have been recommended to modify pore structure, enhance hydrophilicity, most notably metals with antibacterial activity, or produce a reservoir of different chemicals, all with the same purpose in mind. Surface treatment can be accomplished by coating or grafting reply procedures to introduce specific compounds. The interface of the comparatively inert films used in the bulk of industrial expulsion is activated using irradiation and plasma.

The bulk of the studies inside this chapter is still in the field, providing little information into realistic difficulties such as behavior under real-world operating conditions, long-term stability, or cost restrictions related to complicated membranes. Further research should stress continuous quasi-size film monitoring over timeframes at a minimum comparable to the average lifespan of commercialized films. Operations in applicable contexts include the use of authentic streams or effluents and the evaluation of clean-up systems. Nanofiber films for wastewater purification are in the early stages of commercialization. There are several pilot-scale research and laboratory efforts on polymeric membrane applications, but fewer publications on huge manufacturing and commercial use are available. So much study is required to create manufacturing nanofiber membrane development and processing, like effective practices for nanoscience inclusion, the synthesizing and producing appropriate nanoparticles, and assessing the long-term stabilization of fabricated membrane surface under different scenarios. In the twenty-first century, major challenges, including water, energy, and a clean and safe ecosystem, will have to be overcome. Membrane filtration and advancements are vital to effectively overcoming such challenges via innovative development and research and internal transaction advancements.

Abbreviations

- AEM:

-

Anion exchange membranes

- BSA:

-

Bovine serum albumin

- CA:

-

Cellulose acetate

- CEM:

-

Cation exchange membranes

- CF6:

-

Fluorinated carbon chains

- CIP:

-

Clean-in-place

- CMC:

-

Critical micellar concentration

- EC:

-

Epoxy-containing coumarin moieties

- ED:

-

Electrodialysis

- EIPS:

-

Evaporation-induced phase separation

- EO:

-

Ethylene oxide

- EPS:

-

Extracellular polymeric substance

- FO:

-

Forward osmosis

- GO:

-

Graphene oxide

- HBPs:

-

Hyperbranched polymers

- HNTs:

-

Halloysite nanotubes

- LM:

-

Liquid membrane

- MD:

-

Membrane distillation

- MEUF:

-

Micellar enhanced ultrafiltration

- MF:

-

Microfiltration

- MMMs:

-

Mixed matrix membranes

- MOFs:

-

Metal–organic frameworks

- MSPs:

-

Mesoporous silica particles

- NF:

-

Nanofiltration

- NIPS:

-

Non-solvent-induced phase separation

- NPs:

-

Nanoparticles

- PA:

-

Polyamides

- PAA:

-

Poly (acrylic acid)

- PAMAM:

-

Poly (amido amine)

- PAN:

-

Polyacrylonitrile

- PD:

-

Polydopamine

- PE:

-

Polyelectrolytes

- PEA:

-

Poly (ether amine)

- PEG:

-

Poly (ethylene glycol)

- PEI:

-

Poly (ether imide)

- PES:

-

Poly (ether sulfone)

- PET:

-

Poly (ethylene terephtlate)

- PEUF:

-

Polymer enhanced ultrafiltration

- PO:

-

Propylene oxide

- PP:

-

Polypropylene

- PSU:

-

Polysulfone

- PVA:

-

Poly (vinyl alcohol)

- PVDF:

-

Poly (vinylidene fuoride)

- PVP:

-

Poly (vinyl pyrrolidone)

- QS:

-

Quorum sensing

- RO:

-

Reverse osmosis

- SDS:

-

Sodium dodecyl sulphate

- TIPS:

-

Thermally induced phase separation

- TMP:

-

Transmembrane operative pressures

- UF:

-

Ultrafiltration

- UV:

-

Ultraviolet

- VIPS:

-

Vapour-induced phase separation

References

Abdelkader BA, Antar MA, Khan Z (2018) Nanofiltration as a pretreatment step in seawater desalination: a review. Arab J Sci Eng 43:4413–4432

Abdullah N, Yusof N, Lau WJ, Jaafar J, Ismail AF (2019) Recent trends of heavy metal removal from water/wastewater by membrane technologies. J Ind Eng Chem 76:17–38

Al-Amshawee S, Yunus MYBM, Azoddein AAM, Hassell DG, Dakhil IH, Hasan HA (2020) Electrodialysis desalination for water and wastewater: a review. Chem Eng J 380:122231

Alvarado C, Farris K, Kilduff J (2016) Membrane fouling, modelling and recent developments for mitigation. Emerg Member Technol Sustain Water Treat 433–462

Amariei N, Manea LR, Bertea AP, Bertea A, Popa A (2017) The influence of polymer solution on the properties of electrospun 3D nanostructures. IOP Conf Ser: Mater Sci Eng 209:012092. IOP Publishing

Amosa MK (2017) Towards sustainable membrane filtration of palm oil mill effluent: analysis of fouling phenomena from a hybrid PAC-UF process. Appl Water Sci 7:3365–3375

Baharuddin NH, Sulaiman NMN, Aroua MK (2015) Removal of heavy metal ions from mixed solutions via polymer-enhanced ultrafiltration using starch as a water-soluble biopolymer. Environ Prog Sustain Energy 34:359–367

Bokhary A, Tikka A, Leitch M, Liao B (2018) Membrane fouling prevention and control strategies in pulp and paper industry applications: a review. J Member Sci Res 4:181–197

Capozzi LC, Mehmood FM, Giagnorio M, Tiraferri A, Cerruti M, Sangermano M (2017) Ultrafiltration membranes functionalized with polydopamine with enhanced contaminant removal by adsorption. Macromol Mater Eng 302:1600481

Cassano A, Conidi C, Ruby-Figueroa R, Castro-Muñoz R (2018) Nanofiltration and tight ultrafiltration membranes for the recovery of polyphenols from agro-food by-products. Int J Mol Sci 19:351

Crouzet M, Le Senechal C, Brözel VS, Costaglioli P, Barthe C, Bonneu M, Garbay B, Vilain S (2014) Exploring early steps in biofilm formation: set-up of an experimental system for molecular studies. BMC Microbiol 14:1–12

Cui X, Choo KH (2014) Natural organic matter removal and fouling control in low-pressure membrane filtration for water treatment. Environ Eng Res 19:1–8

Daufin G, Escudier JP, Carrère H, Bérot S, Fillaudeau L, Decloux M (2001) Recent and emerging applications of membrane processes in the food and dairy industry. Food Bioprod Process 79:89–102

Díez B, Rosal R (2020) A critical review of membrane modification techniques for fouling and biofouling control in pressure-driven membrane processes. Nanotechnol Environ Eng 5:1–21

Ding YH, Floren M, Tan W (2016) Mussel-inspired polydopamine for bio-surface functionalization. Biosurface Biotribol 2:121–136

Dolez PI (2019) Application of nanomaterials in textile coatings and finishes. In: Nanomaterials-based coatings. Elsevier, pp 139–169

Dražević E, Košutić K, Dananić V, Pavlović DM (2013) Coating layer effect on performance of thin-film nanofiltration membrane in removal of organic solutes. Sep Purif Technol 118:530–539

Garcia-Ivars J, Iborra-Clar MI, Alcaina-Miranda MI, Mendoza-Roca JA, Pastor-Alcañiz L (2016) Surface photomodification of flat-sheet PES membranes with improved antifouling properties by varying UV irradiation time and additive solution pH. Chem Eng J 283:231–242

Gehrk I, Geiser A, Somborn-Schulz A (2015) Innovations in nanotechnology for water treatment. Nanotechnol Sci Appl 8:1

Gude GG (2018) Emerging technologies for sustainable desalination handbook. Butterworth-Heinemann

Guo W, Ngo HH, Li J (2012) A mini-review on membrane fouling. Bioresour Technol 122:27–34

Huang J, Qi F, Zeng G, Shi L, Li X, Gu Y, Shi Y (2017) Repeating recovery and reuse of SDS micelles from MEUF retentate containing Cd2+ by acidification UF. Colloids Surf A Physicochem Eng 520:361–368

Igbinigun E, Fennell Y, Malaisamy R, Jones KL, Morris V (2016) Graphene oxide functionalized polyethersulfone membrane to reduce organic fouling. J Member Sci 514:518–526

Iritani E (2013) A review on modeling of pore-blocking behaviors of membranes during pressurized membrane filtration. Dry 31:146–162

Jaleh B, Etivand ES, Mohazzab BF, Nasrollahzadeh M, Varma RS (2019) Improving wettability: deposition of TiO2 nanoparticles on the O2 plasma-activated polypropylene membrane. Int J Mol Sci 20:3309

Jamil TS, Mansor ES, Abdallah H, Shaban AM, Souaya ER (2018) Novel antifouling mixed matrix CeO2/Ce7O12 nanofiltration membranes for heavy metal uptake. J Environ Chem Eng 6:3273–3282

Kaneda M, Lu X, Cheng W, Zhou X, Bernstein R, Zhang W, Kimura K, Elimelech M (2019) Photografting graphene oxide to inert membrane materials to impart antibacterial activity. Environ Sci Technol Lett 6:141–147

Kumar M, Jaafar J (2018) Preparation and characterization of TiO2 nanofiber coated Pvdf membrane for softdrink wastewater treatment. Agric Ecosyst Environ 2:35–38

Kumar R, Ismail AF (2015) Fouling control on microfiltration/ultrafiltration membranes: effects of morphology, hydrophilicity, and charge. J Appl Polym Sci 132

Laohaprapanon S, Vanderlipe AD, Doma BT Jr, You SJ (2017) Self-cleaning and antifouling properties of plasma-grafted poly (vinylidene fluoride) membrane coated with ZnO for water treatment. J Taiwan Inst Chem Eng 70:15–22

Lee XJ, Show PL, Katsuda T, Chen WH, Chang JS (2018) Surface grafting techniques on the improvement of membrane bioreactor: State-of-the-art advances. Bioresour Technol 269:489–502

Ly QV, Hu Y, Li J, Cho J, Hur J (2019) Characteristics and influencing factors of organic fouling in forward osmosis operation for wastewater applications: a comprehensive review. Environ Int 129:164–184

Matin A, Khan Z, Zaidi SMJ, Boyce MC (2011) Biofouling in reverse osmosis membranes for seawater desalination: phenomena and prevention. Desalination 281:1–16

Minjing Z, Gang L, Qiang W, Hualei C, Ling L (2008) Preparation of porous TiO2/Ti composite membrane for immunoisolation. Appl Surf Sci 255:2256–2258

Misdan N, Lau WJ, Ismail AF, Matsuura T (2013) Formation of thin-film composite nanofiltration membrane: effect of polysulfone substrate characteristics. Desalination 329:9–18

Mohammad AW, Hilal N, Al-Zoubib H, Darwish NA, Ali N (2007) Modelling the effects of nanofiltration membrane properties on system cost assessment for desalination applications. Desalination 206:215–225

Mujtaba IM, Majozi T, Amosa MK (eds) (2018) Water management: social and technological perspectives. CRC Press

Mukherjee J, Malhotra D, Gautam S, Gupta MN (2013) Green synthesis of nanocomposites consisting of silver and protease alpha chymotrypsin. Ultrason Sonochem 20:1054–1061

Padaki M, Murali RS, Abdullah MS, Misdan N, Moslehyani A, Kassim MA, Hilal N, Ismail AF (2015) Membrane technology enhancement in oil-water separation. A review. Desalination 357:197–207

Peng J, Su Y, Shi Q, Chen W, Jiang Z (2011) Protein fouling resistant membrane prepared by amphiphilic pegylated polyethersulfone. Bioresour Technol 102:2289–2295

Pichardo-Romero D, Garcia-Arce ZP, Zavala-Ramírez A, Castro-Muñoz R (2020) Current advances in biofouling mitigation in membranes for water treatment: An overview. Process 8:182

Qasem NA, Mohammed RH, Lawal DU (2021) Removal of heavy metal ions from wastewater: a comprehensive and critical review. Npj Clean Water 4:1–15

Rabin N, Zheng Y, Opoku-Temeng C, Du Y, Bonsu E, Sintim HO (2015) Biofilm formation mechanisms and targets for developing antibiofilm agents. Future Med Chem 7:493–512

Rahimpour A, Jahanshahi M, Mortazavian N, Madaeni SS, Mansourpanah Y (2010) Preparation and characterization of asymmetric polyethersulfone and thin-film composite polyamide nanofiltration membranes for water softening. Appl Surf Sci 256:1657–1663

Rahman AFHBA, Seman MNBA (2018) Polyacrylic-polyethersulfone membrane modified via UV photographing for forward osmosis application J Environ Chem Eng 6:4368–4379

Raoufi N, Surre F, Rajarajan M, Sun T, Grattan KT (2014) Optical sensor for pH monitoring using a layer-by-layer deposition technique emphasizing enhanced stability and re-usability. Sens Actuators B Chem 195:692–701

Razmjou A, Mansouri J, Chen V (2011) The effects of mechanical and chemical modification of TiO2 nanoparticles on the surface chemistry, structure and fouling performance of PES ultrafiltration membranes. J Member Sci 378:73–84

Samaei SM, Gato-Trinidad S, Altaee A (2020) Performance evaluation of reverse osmosis process in the post-treatment of mining wastewaters: Case study of Costerfield mining operations, Victoria Australia. J Water Process Eng 34:101116

Sandoval-Olvera IG, Gonzalez-Munoz P, Palacio L, Hernandez A, Avila-Rodriguez M, Pradanos P (2019) Ultrafiltration membranes modified by PSS deposition and plasma treatment for Cr (VI) removal. Sep Purif Technol 210:371–381

Solano C, Echeverz M, Lasa I (2014) Biofilm dispersion and quorum sensing. Curr Opin Microbiol 18:96–104

Tafreshi J, Fashandi H (2019) Environmentally Friendly modification of polysulfone ultrafiltration membrane using organic plant-derived nanoparticles prepared from basil seed gum (BSG) and Ar/O2 low-pressure plasma. J Environ Chem Eng 7:103245

Tanhaei B, Chenar MP, Saghatoleslami N, Hesampour M, Laakso T, Kallioinen M, Sillanpää M, Mänttäri M (2014) Simultaneous removal of aniline and nickel from water by micellar-enhanced ultrafiltration with different molecular weight cut-off membranes. Sep Purif Technol 124:26–35

Toyofuku M, Inaba T, Kiyokawa T, Obana N, Yawata Y, Nomura N (2016) Environmental factors that shape biofilm formation. Biosci Biotechnol Biochem 80:7–12

Trachevskyi V, Vakuliuk P, Kartel N, Bo W (2018) Surface polymerization of monomers on the polyethylene terephthalate membrane in low temperature plasma for water treatment

Tul Muntha S, Kausar A, Siddiq M (2017) Advances in polymeric nanofiltration membrane: a review. Polym Plast Technol Eng 56:841–856

Vert M, Doi Y, Hellwich KH, Hess M, Hodge P, Kubisa P, Rinaudo M, Schué F (2012) Terminology for biorelated polymers and applications (IUPAC Recommendations 2012). Pure Appl Chem 84:377–410

Vignati DAL, Camusso M, Dominik J (2005) Estimation of the truly dissolved concentrations of Cd, Cu, Ni, and Zn in contrasting aquatic environments with a simple empirical model. Ecol Modell 184:125–139

Wang J, Chen X, Reis R, Chen Z, Milne N, Winther-Jensen B, Kong L, Dumée LF (2018) Plasma modification and synthesis of membrane materials—a mechanistic review. Membranes 8:56

Yang SJ, Yu B, Cong HL, Liu Q, Ji YT (2016) Preparation of hydrophilic polypropylene hollow fiber membranes by UV modification. Integer Ferroelectr 169:83–89

Yin J, Deng B (2015) Polymer-matrix nanocomposite membranes for water treatment. J Member Sci 479:256–275

Zaheri P, Mohammadi T, Abolghasemi H, Maraghe MG (2015) Supported liquid membrane incorporated with carbon nanotubes for the extraction of Europium using Cyanex272 as carrier. Chem Eng Res Des 100:81–88

Zahid M, Rashid A, Akram S, Rehan ZA, Razzaq W (2018) A comprehensive review on polymeric nanocomposite membranes for water treatment. J. Member. Sci. Technol 8:1–20

Zeng J, Qi P, Shi J, Pichler T, Wang F, Wang Y, Sui K (2020) Chitosan functionalized iron nanosheet for enhanced removal of As(III) and Sb(III): synergistic effect and mechanism. Chem Eng J 382:122999

Zhang X, Zhang S, Wang Y, Zheng Y, Han Y, Lu Y (2018) Polysulfone membrane treated with NH3-O2 plasma and its property. High Perform Polym 30:1139–1144

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Chauhan, P., Sharma, M., Nehra, S., Pachwarya, R.B., Sharma, R., Kumar, D. (2023). Modified Nanofiltration Membrane for Wastewater Treatment. In: Ahmad, A., Alshammari, M.B. (eds) Nanofiltration Membrane for Water Purification. Sustainable Materials and Technology. Springer, Singapore. https://doi.org/10.1007/978-981-19-5315-6_9

Download citation

DOI: https://doi.org/10.1007/978-981-19-5315-6_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-5314-9

Online ISBN: 978-981-19-5315-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)