Abstract

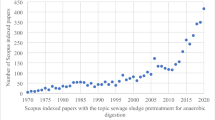

Sludge, a by-product or residue of wastewater treatment facilities, has considerably increased the generation over the years. Due to its large amount and content, organic matter, metals, and pathogens, sludge poses an environmental and health risk if not properly managed. Furthermore, stabilization and management of this residue maintain affordable costs on wastewater treatment plants (WWTPs). Anaerobic digestion (AD) is a promising technology to sludge valorization; however, it needs to be made more effective because this waste leads to low degradability and consequently low energy production. Pretreatments can be used to hydrolyze sludge and consequently improve biogas production, solid removal, and sludge quality after digestion, increasing the applicability of AD. Different technologies are being studied by physical-chemical and biological methods. This chapter addresses an overview of different technologies for pretreatment, focusing on thermal, ultrasonic, and enzymatic processes, discussing their effects on sludge properties and anaerobic digestion. Concerns related to pretreatment implementation, pathogen distribution, and directives around the world are also addressed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Sewage Sludge

Biological wastewater treatment processes have been widely used to treat municipal wastewater, as a result of efficient organic removal, despite the large amounts of sludge produced (Wang et al. 2017). Municipal wastewater treatment plants (WWTPs) generate sludge as a by-product of the physical and biological processes used (Appels et al. 2008). The adequate destination of biosolids is a task of great importance for growing populations and pollution reduction efforts aimed to limit the harmful by-product generation and spread (Praspaliauskas and Pedišius 2017). Nowadays, the treatment and disposal of sludge have become one of the major challenges faced by WWTPs (Xu et al. 2017), due to high costs to manage and dispose.

Sludge can be classified into primary and secondary sludge (or activated sludge). The primary wastewater treatment involves screening to remove large constituents, after by gravity sedimentation of the screened wastewater or by physical-chemical processes (i.e., coagulation, flocculation, flotation) with a solid diverted to a different stream (Elalami et al. 2019; Tyagi and Lo 2011). The residue from this process is a concentrated suspension, called primary sludge, which is further treated to become a biosolid; this step removes about 40–50% of solids in wastewater (Demirbas et al. 2017; Elalami et al. 2019). Secondary sludge is produced during biological process, consisting mainly of bacteria growing on organic and inorganic substances, extracellular polymeric substances (EPS), and recalcitrant organics from wastewater or formed during bacterial decay (Wang et al. 2017), being composed of 59–88% (w/v) organic matter, which is decomposable and produces the offensive odors and 95% is water (Tyagi and Lo 2011).

Sludges have higher pathogen concentration, such as bacteria, viruses, protozoa, and other parasitic helminths, as well as organic matter can create potential hazards to humans and animal health, needing additional treatments to ensure a product can be safely integrated back in the product chain (Neumann et al. 2016). Also, sludges are often contaminated by non-biological components such as heavy metals, polycyclic aromatic hydrocarbons, polychlorinated biphenyls, pharmaceuticals, and pesticides, among other contaminants (Wiśniowska 2019). The WWTPs developed over the years the concern about sludge treatment, the amount of sludge increased more and more, and with that treatment technologies are improved and change together (Praspaliauskas and Pedišius 2017).

The first directive created to standardize utilization of treated sludge in agriculture or soils in European Commission dates from 1986 (86/271). The estimative directive denotes the production of 25 kg/(P.E × year) and 68 g/(P.E × day) of dry matter (DM) in 15 member states (Kelessidis and Stasinakis 2012; Milieu 2010).

There is a huge variation in values in the world: Brazil and China possess the minimum values, counting with 5.4 and 6.2 g dry matter/(P.E × day). On the other hand, the countries with maximum values are Germany, the United Kingdom, Slovenia, Finland, and the Netherlands: 66.5 g DM/(P.E × day), 67.8 g DM/(P.E × day), 77.7 g DM/(P.E × day), 78.6, and 249 g DM/(P.E × day), respectively (LeBlanc et al. 2008). The discrepancy about the established values of minimum and maximum production of sludge per capita is based on the volume treated by person and involved level of treatment. There are other influences in production per capita, such as the type of sewerage system with capability of separation of rainwater from wastewater. Large cities possess an underground system of drainage to collect wastewater, causing dilution of the volume and diminishing COD removal efficiency as well as sludge production (Mininni et al. 2015).

Some countries are developing stringent limits to directive use of sludge, as, for example, Belgium, Austria, Finland, Denmark, Germany, Slovenia, Sweden, the Netherlands, the Czech Republic (European Union 2008). Several WWTPs in Europe don’t possess the technical equipment necessary to process sludge, making it suitable for other destinations. Due to the infrastructure dated from 1980s or even earlier, these plants are incapable of dovetail in new directives to dispose of landfill or via incineration (Mininni and Dentel 2013). Among this, WWTP aims to reduce sludge production turning to more feasible disposal costs via incineration or landfilling. At the same time, there are innovative processes that allow reduction of pathogens and diminish odor.

Among the contaminants there are some minerals that can be harmful when in high concentrations (mg/kg) in sludge with agricultural purposes, such as Se, Co, Zn, and Mo, that are not standardized by sludge directive (European Union 1998). Otherwise, there are concentrations allowed to potential toxic elements (PTE) in sludge with agriculture destination. Low limits are established in Finland, Latvia, Flanders, Belgium, Denmark, Sweden, the Netherland, Malta (for pH 5–6), and Carinthia (for pH 5.0–5.5).

Other countries allow limits like the sludge directive. Variation of pH in soil is utilized to determine the concentration limit of PTE in some places (Bulgaria, Spain, Portugal, Malta, and Carinthia). The amount of heavy metals is also limited during a period that can vary between 3 and 10 years in places such as Hungary, Luxembourg, Italy, France, Sweden, Finland, the Netherlands, Flanders, and Three Lander in Austria (Mininni et al. 2015). The procedures for agricultural use of sludge in Brazil are established by CONAMA Resolution 375/2006; criteria includes the determination of pathogen control (fecal coliform <3 MPN/100 g; Salmonella sp. absence in 10 g TS; viable helminths eggs <0.25 egg/g TS; virus <0.25 PFU g TS), bacteriological and inorganic substances, and the monitoring of 34 organic substances in sewage sludge, specifying maximum concentration maximum heavy metal contents in sludge for agriculture (as it follows: As = 41, Ba = 1300, Cd = 39, Pb = 300, Cu = 1500, Cr = 1000, Hg = 17, Mo = 50, Ni = 420, Se = 100, and Zn = 2800 mg/kg SS (dry matter basis)) (CONAMA 2006).

The aim of these regulations is to protect the environment, and different sludge treatment and disposal are studied, as composting, landfill, land application, drying-incineration, and anaerobic digestion (AD). Anaerobic digestion is commonly used in WWTP for degradation of sludge, being transformed into methane and carbon dioxide and some smaller amounts of biosolids as the final residue. The methane generation is an attractive feature because it can be used as energy. However, how to maximize methane production has been a subject of special consideration.

2 Pretreatments Applied to Improve Biodegradability During Anaerobic Digestion

The AD requires strict anaerobic conditions to proceed and depends on the successive activity of a complex microbial association to transform organic material into methane (CH4). However, hydrolysis is generally considered as rate-limiting step (Appels et al. 2008). The low efficiency of the microorganisms (hydrolysis stage) is due to sludge characteristics, mainly flocs, EPS aggregates, recalcitrant compounds of lipids and proteins, and cell walls/membrane that form strong barriers to degradation. These compounds also are responsible for increased hydraulic retention time of biodigester, once it spends more time to hydrolysis, and therefore methane production is slow (Abelleira-Pereira et al. 2015; Anjum et al. 2016).

As a result of sludge characteristics, various pretreatment methods have been developed over time to maximize biogas production. If properly designed, pretreatment process is recommended to (1) modify the physical and chemical structure of sludge, (2) solubilize organic matter, (3) increase the surface area and accelerate hydrolysis step, and (4) consequently improve methane generation (Elalami et al. 2019; Hu et al. 2019; Zhen et al. 2017). Pretreatment technology involving mechanical, chemical, physicochemical, and biological methods and their combinations have been tested in treating residual sludge.

2.1 Thermal Hydrolysis

Thermal pretreatment technology is a well-established, spread, and commercially implemented technology used to increase the degradability of sludge, being a process where the temperature of sludge is raised to a desired temperature to significantly increase the disintegration and solubilization of sludge solids (Pilli et al. 2015). Thermal pretreatment in the temperature range from 60 to 180 °C and is considered two types of thermal treatment process: low temperature (<120 °C) and high temperature (>120 °C). Normally, high-temperature treatment is associated with pressure in a range between 600 and 2500 kPa (Tyagi and Lo 2011; Pilli et al. 2015; Kor-Bicakci and Eskicioglu 2019).

The main advantages of thermal pretreatment includes the following: (1) increases biogas/methane yield; (2) improves sludge degradability; (3) allows increase organic loading rate, decreasing the size of biodigesters; (4) reduces sludge viscosity; (5) reduces odor and pathogens; and (6) reduces scum and foaming generation (Alfaro et al. 2014; Barber 2016; Xue et al. 2015). As other pretreatments, thermal pretreatment has some disadvantages, including increase in ammonia concentration, due to protein degradation, and costs with energy demand (Oosterhuis et al. 2014; Xue et al. 2015). Table 10.1 shows examples of thermal pretreatment effect on methane production, using different sludge types and different conditions.

The above studies of thermal pretreatment application, in general, show the increment on biogas/methane production, although in some studies this increase was not significant. The approach demonstrated that thermal pretreatment is conditioning between two variables: the exposure time temperature and pressure.

Biogas increment is linked to solubilization of organic matter (proteins, lipids, and carbohydrates) improved by higher temperatures and longer treatment times (Xue et al. 2015). As temperature increase, pretreatment is more efficient. However, temperatures above 180 °C lead to solubilization of recalcitrant and toxic organic compounds (melanoidins) reducing biodegradability (Pilli et al. 2015; Wilson and Novak 2009).

The viability of thermal pretreatment implementation in WWTPs is a crucial point, which must be analyzed, and it is necessary that energy demand of pretreatment does not exceed the biogas energy generation (Cano et al. 2015). Different pretreatment combination can be a promising alternative, generation one extra increment, and in this way contribute to viability implementation of pretreatment and consequently anaerobic digestion (Kor-Bicakci and Eskicioglu 2019).

Considering the advantages and researches over the time, the thermal pretreatment of sludge already implemented in full-scale WWTPs and is a commercial pretreatment technology, as described by Han et al. (2017), Kepp et al. (2000), Pérez-Elvira et al. (2008), and Zábranská et al. (2006), proving an increase on biogas/methane production, reduction on hydraulic retention time, and sludge proved to have high fertilizer value.

2.2 Ultrasound

Ultrasound is a mechanical process of propagation of acoustic waves at a frequency higher than 16 kHz. Several phenomena are related to ultrasound depending on the applied frequency. On frequencies around 20 kHz, the most explored effect is cavitation which consist of a combined sequence of formation, growth, and collapse of microbubbles that occur is a very small interval of time (milliseconds) and realizing large amounts of energy locally. This realization of energy results in high pressure (in the range of 100–5000 bar) and temperatures (in the range of 1000–10,000 K), and these effects are observed at millions of locations in the reactor (Suslick 1990). At these conditions, •OH free radicals and H+ ions are formed due to homolytic cleavage of water molecules. The recombination of these chemical species forms H2O2, a strongly oxidant compound, and therefore no selective chemical reactions can also occur in liquid media (Suslick 1990).

In sludge, the energy realized during cavitation disrupts bacterial cells by extreme shear forces, rupturing the cell wall and membranes (Bundhoo and Mohee 2018; Zou et al. 2016). The high temperature and pressure impact on physical and chemical characteristics of biomass or waste materials such as particle size, surface area, lignin, hemicellulose and cellulose content, and organic matter solubilization, among others. Sonication process for sludge treatment was studied by various researchers in laboratory and full-scale systems (Houtmeyers et al. 2014; Tyagi et al. 2014).

Dhar et al. (2012) showed the benefits of ultrasound on protein and carbohydrate solubilization on municipal waste-activated sludge. Pretreatment condition with ultrasound of 10,000 kJ/kg TSS for 10 min was used, and the temperature was maintained below 40 °C during the experiments. After pretreatment an increase in insolubilization of carbohydrate and protein of 730% and 764%, respectively, compared with the control (without the use of ultrasound) was observed. Besides, it promoted a sludge biochemical methane potential (BMP) increase of 24%. Na et al. (2007) studied the sonication and recognize a decrease in particle size of sewage sludge, due to floc disintegration, and the sludge dewater ability was improved.

The efficiency of ultrasonic disintegration is dependent on sludge characteristics, including type of sludge, primary or activated sludge, TS content and particle size, and sonification conditions (time, intensity, temperature, pH, amplitude, and power input) (Khanal et al. 2007; Tyagi et al. 2014). Based on kinetic models, ultrasonic disintegration was impacted in the order of the following: sludge pH > sludge concentration > ultrasonic intensity > ultrasonic density (Khanal et al. 2007). On the other hand, the opinion of many researchers is that the effect of ultrasonic density is supposed to be more vital than the sonication time to the acceleration of conversion of complex organics to biodegradable substrate (Pilli et al. 2011).

Numerous studies demonstrate the benefits and impact of ultrasound pretreatment on biogas/methane production using sewage sludge as substrate (Table 10.2), as well as the combination with other pretreatment types, like alkali (Bao et al. 2020; Zhang et al. 2017), low temperature (Neumann et al. 2017), and CaO2 (Li et al. 2019).

In addition to the impacts on biogas/methane production, studies evidenced changes on the methanogenic pathway after ultrasound pretreatment. Li et al. (2018) observed through microbial diversity analysis that hydrolytic and acidification bacteria were abundant in the reactors treating waste-activated sludge. Methanocorpusculum and Methanosaeta were the alternating dominant methanogens in the anaerobic reactors, with addition of sludge after different ultrasonic treatment times. As the ultrasonic time increased, the relative abundance of Methanocorpusculum, which can grow by using hydrogen as substrate, increased from 55.9% (control) to 80.0%, after 40 min of ultrasound, and decreased rapidly to 5.7% of abundance after 100 min of ultrasound. However, the trend in the change of the relative abundance of Methanosaeta was the opposite to that of Methanocorpusculum. Methanosaeta was 27.0% in the controlled reactor but as low as 0.9% after 40 min treatment, with the maximal value of 67.7% after 100 min. The authors observed that the dominant substrate for anaerobic methanogenesis changed from hydrogen to acetic acid.

According to Pilli et al. (2011), sludge ultrasound pretreatment is one of the emerging technologies for increasing the biodegradability, but optimizing the methane yield (net energy yield is more than energy input) is necessary for full-scale implementation.

Xie et al. (2007) evaluated full-scale pretreatment using ultrasound for treating mixed sludge (primary and secondary sludge) and showed an increase in biogas daily production, up to 45% compared without pretreatment. Barber (2005) presented data of full-scale part-stream ultrasound pretreatment plants (Germany, Austria, Switzerland, Italy, and Japan) and showed biogas increased by 20–50% (volume/kg fed), and VS reduction improved on previous performance between 20% and 50%. Tyagi et al. (2014) suggested one payback period of 2–3 years for a full-scale ultrasound installation.

High capital and operating costs of the ultrasonic system with high energy consumption and equipment maintenance are the main limitations of this technology (Elalami et al. 2019; Khanal et al. 2007; Tyagi et al. 2014). However, the use of ultrasound presents several advantages, like (1) no odor generation, (2) complete process automation, (3) easy maintenance, (4) potential to control filamentous bulking and foaming in the digester, (5) improved VS destruction, (6) biogas production and the quality of biosolids, (7) compact design and easy retrofit, (8) better digester stability, (9) low exposure time, and (10) a significant reduction in the size of digesters and the ultimate amount of sludge to be disposed (improved on dewater ability) (Elalami et al. 2019; Khanal et al. 2007; Tyagi et al. 2014; Pilli et al. 2011). Mass and energy balance on full-scale studies showed that 1 kW of ultrasonic energy used generates about 7 kW of electrical energy after losses (Pilli et al. 2011) which can overcome the limitations described above in a well-designed treatment plant.

2.3 Enzymes and Microorganisms

Biological pretreatment of sewage sludge offers an alternative to hydrolyze its structure by a cleaner and environmentally sustainable method by using enzymes and microorganisms as process catalysts. The use of biotechnologies is the focus of this type of pretreatment. In this scenario, enzymes and microorganisms encompass a multitude of possible relevant applications for the generation of bioenergy (Treichel et al. 2020; Zhen et al. 2017).

The increase in biogas production and higher volumes of gas recovery is directly related to pretreatment capable of breaking cell membranes of pathogens in order to reduce competitiveness with the microorganisms involved in the AD process and increase the availability of compounds that are used as substrates by these microorganisms (Zhen et al. 2017). In biological pretreatment processes, the approach comprises the application of enzymatic hydrolysis by the use of a single enzyme or enzyme cocktail or by the use of microorganisms or by thermophasic AD that consists of the pre-digestion of sludge in two stages of different temperatures (Bolzonella et al. 2012; Zhen et al. 2017).

Biological pretreatment offers some advantages over other treatments such as (1) no addition of chemical compounds during the process, ensuring greater environmental sustainability in the process; (2) increased biodegradation of the complex structure that makes up the sludge, releasing compounds that will serve as a substrate for microorganisms responsible for AD; (3) reduction of pathogens by cell membrane rupture; and (4) reduction in energy and thermal expenditure, enabling self-sufficiency in the process (Agabo-García et al. 2019; Treichel et al. 2020). Biological pretreatment presents some advantages in full scale (Ge et al. 2010; Recktenwald et al. 2008), but it still faces challenges. Mainly in terms of operation and optimization of the project due to the limitation by the complex hydrolysis mechanisms involved in the system that can vary with the characteristics of the biomass and negatively affect the efficiency of the process (Ding et al. 2017; Zhen et al. 2017).

The biological pretreatment based on the use of enzymes for sludge hydrolysis can be carried out by enzymatic cocktails, purified commercial enzymes, or enzymatic production in situ using microorganisms with a high production potential of the enzymes of interest (Yu et al. 2013). Proteases and glycosidases are the main enzymes used in sludge pretreatments, considering that the major components of this biomass are proteins and complex carbohydrates (Bonilla et al. 2018). Furthermore, due to the presence of other compounds in the sludge structural matrix, it is possible to apply different enzymes with different specificities such as lipases due to the presence of fatty acids and peroxidases for the oxidation of other compounds (Agabo-García et al. 2019; Elalami et al. 2019).

The application of a single enzyme in the pretreatment process can reduce the efficiency of the process due to the complexity of the sludge composition, with specificity for action on different substrates being important, as reported in the study of (Yang et al. 2010a) where the enzymatic pretreatment with a cocktail of amylases and proteases increased more than the application of each enzyme separately. This factor is related to the specificity of enzymes for different structural chains. Hydrolysis of sludge by enzymatic cocktails can be facilitated due to the synergistic action of enzymes, which may disintegrate through the action of some enzymes, the outermost matrix of the sludge. This process results in the solubilization of these compounds and exposing more internal compounds previously protected from enzymatic attack, increasing process efficiency (Yang et al. 2010a; Zhou et al. 2009).

The action of hydrolytic enzymes in the sludge occurs through the cleavage of specific substrates, releasing lower-molecular-weight products into the medium. This process causes the structure of the flakes to be reduced and proteins, peptides, and carbohydrates to be released for use by microorganisms in AD, inducing a greater biogas production (Recktenwald et al. 2008; Watson et al. 2004). Since it is already biologically active, sewage sludge has enzyme activity profiles that may vary according to the microbial population present in the environment, with enzyme activities such as α-glucosidase, β-glucosidase, alanine-aminopeptidase, esterase, dehydrogenase, proteases, phosphatases, and cellulases (Goel et al. 1998; Nybroe et al. 1992; Watson et al. 2004). The enzymatic activities present in the sludge are key elements to understand the profile of enzymes essential for greater efficiency of biological pretreatment.

The process of AD of sewage sludge depends on microorganisms’ action to metabolize and stabilize the sludge. However, the microbial community can also be inserted in the process as a form of pretreatment aiming at increasing the product generated. About 50% of the organic material present in the sludge refers to proteins released during hydrolysis by proteolytic enzymes or by the action of microorganisms capable of producing these enzymes (Li et al. 2009). Strains of microorganisms such as Penicillium sp., Serratia marcescens, Streptomyces sp., Rhizopus oryzae, Pseudomonas, Bacillus sp., Vibrio, Brevibacillus sp., Methanobrevibacter, Methanobacterium, Methanoculleus, and Methanocorpusculum in addition to fungi species called white-rot fungi were studied, found in sludge, and considered to be good sludge-hydrolyzing agents, in addition to producing proteases that can increase the pretreatment yield (Ben Rebah and Miled 2013; Treichel et al. 2020; Ventorino et al. 2018).

During pretreatment using hydrolytic microorganisms, the networks of the complex chains that make up the sludge structure and the cell walls of pathogens are depolymerized and result in the release of lower-molecular-weight compounds that are easily digested as a substrate for AD (Guo et al. 2014). This process usually occurs through the excretion or intracellular enzyme production, being advantageous mainly by dispensing the continuous addition of enzymes, reducing energy, and economic expenses (Ding et al. 2017). In addition, in contact with the sludge structural complex, microorganisms produce efficient enzymatic cocktails for degrading different parts of the structure, which act synergistically and can result in efficient solubilization processes.

Another type of biological pretreatment that has been treated as viable biotechnology mainly for full-scale application is the two-stage AD process (temperature-phased anaerobic digestion (TPAD)) (Zhen et al. 2017). This process consists of a pre-hydrolysis of the sludge before AD. It applies different temperatures to the system, aiming to separate the hydrolysis + acidogenesis and acetogenesis + methanogenesis in the reactors. This process is resulting in the enrichment of different groups of microorganisms in each reactor, increasing the efficiency of solubilization of the substrates for biogas production (Bolzonella et al. 2012; Elalami et al. 2019; Schievano et al. 2012). The enrichment of specific microorganisms for each stage of digestion will maximize the system’s overall reaction rate and improve the reduction in COD (Schievano et al. 2012).

One of the significant challenges of TPAD systems is associated with the high capacity to solubilize the compounds present in the sludge, which can result in the inhibition of the methanogenic phase, mainly due to the high sensitivity of this community to volatile fatty acids (Schievano et al. 2010). As it is a complex system with many different biochemical pathways, the AD system’s balance between controlling the biogas production in two stages still limits the development with the high efficiency of this system. Because it can lead to substantial changes in biochemical pathways and in the formation of metabolites, strongly influencing the population and subpopulations present in the environment (Chen et al. 2008; Schievano et al. 2012).

In the single-stage AD process, the main challenge remains the slow rates of hydrolysis for complex biomass, such as sewage sludge, and biological disintegration methods that focus on using cleaner and economical technologies are increasingly being explored in recent research. As commonly reported approaches, the use of commercial enzymes and protease-producing microorganisms in batch systems followed by single-stage AD has often been reported (Table 10.3).

The biological pretreatment is relevant considering the scenario of sewage sludge recovery to produce biogas by improving sludge biodegradability through efficient technologies and ecological sustainability. The advancement of studies is based on the use of biological pretreatment, and the challenges of this technology must be solved, such as the high cost of enzyme cocktails, the reaction time of enzymes and microorganisms to affect the hydrolysis of sludge, the efficient inactivation of pathogens, the need of a robust process with operational stability and low loss of efficiency due to biological inactivation of the microorganisms and enzymes involved, and moreover, finally, the main challenge of expanding scale for industrial applications (Treichel et al. 2020).

3 Pathogens and Antibiotic Resistance in Sludge and the Pre- and Post-treatment as the Controller in WWTPs

The rise of antibiotic administration to the population and animals naturally leads to its accumulation, especially in residues. Human residues are concentrated in WWTPs, being in general not efficiently treated and consequently reaching the sludge after treatment. The battle against resistant bacteria is one of the biggest world concerns of our century. In 2015 an estimate demonstrated that antibiotic resistance was responsible for more than 23,000, 25,000, and 38,000 deaths every year in the United States, the European Union, and Thailand, respectively (Berglund 2015). Developed countries face the addendum of facilitated antibiotic handling, being a concern by self-medication and lack of education about the use of antibiotics, resulting in exaggerated use (Planta 2007; Wellington et al. 2013). Beyond that, globalization carries resistant bacteria of specific regions to different areas, via travels around the world.

Classical antibiotics intervene in biochemistry and physiology of bacteria, culminating in cell death or cessation, which diminishes or stops cell replication. There are five targets of antibiotics from out to inside: bacteria cell wall, cell membrane, protein synthesis, DNA and RNA synthesis, and folic acid metabolism. The efficiency of antibiotics depends exclusively on the non-existence of these targets on the eukaryotic cells, or different compositions when there is a similarity, being relatively non-toxic, only in situations of exacerbated use. An excellent example is the β-lactam antibiotics such as cephalosporins, penicillins, and carbapenems, and their activity consists in blocking the synthesis of bacteria cell wall, which is a fundamental structure to bacteria but absent in eukaryotic cells (Wright 2010).

The selective pressure exercised in bacteria to the strong exposition to antibiotics has selected resitant microorganisms. The resistance can be acquired in horizontal dissemination, being distributed into the same species and genera by means of incorporation of dispersed plasmids on the environment. Resistance can also be reached vertically through generations of microorganisms due to mutations resulting from successive challenges with antibiotics (Martinez 2009).

A strong evidence is the comparison between bacteria in the pre-date of the antibiotic era and in our days. Nonetheless, in the dynamic nature of microorganisms, the resistance is forthcoming. Emergence of resistance is related for decades occurring in parallel between clinic cases and bacteria that produce antibiotics. In recent years, studies demonstrated that most of the non-pathogenic soil bacteria are multidrug resistant. This reinforces the difference between bacteria which evolved in an environment being challenged with small bioactive compounds and a variety of toxins plentiful. On the other hand, pathogens with more virulent forms compared to commensal bacteria have not been exposed to toxins and compounds that challenge their existence (Wright 2010).

In addition, LaPara et al. (2011) relate the rise of antibiotic resistance genes (ARG) and resistant bacteria (ARB) in effluent of wastewater, considering that classical WWTPs were not designed for removal of ARG and ARB, ever after the process of disinfection of mixed filtration due to the wastewater compile the residues of city dwellers and concentrate at WWTPs (Calero-Cáceres et al. 2014; Su et al. 2015). Characteristics of sewage sludge such as microbial diversity with high density can facilitate horizontal gene transfer (HGT) by plasmids, known as mobile genetic elements (MGE) (Gaze et al. 2011; Sentchilo et al. 2013; Zhang et al. 2011). The techniques utilized to identify the presence of ARG and ARB are quantitative PCR and metagenomic investigation (Yang et al. 2013; Zhang and Zhang 2011). The incorrect treatment of sludge can lead to the input of ARG, ARB, and antibiotics such as fluoroquinolones, macrolides, and tetracyclines into the soil (Kinney et al. 2006; Rahube et al. 2014; Sabourin et al. 2012).

Degradation of antibiotics and ARGs is related to the process applied to manure composting (Qiao et al. 2012; Sharma et al. 2009; Wang et al. 2012). Nevertheless, few studies evaluated the effect of methods of digestion of sludge, specifically tetracyclines, sulfonamides, macrolides, and resistance genes (Ma et al. 2011). The focus on sludge as mentioned is related due to the rich reservoir of ARGs and variety commonly found in sludge (Andrés et al. 2011; Rahube et al. 2014). Consequently, the post-treatment is evidenced as necessary.

In this sense, the control of pathogens is most important in WWTPs. Pretreatment methods, like ultrasound and thermal, may also impact sludge hygienization and could be used as both pretreatment and post-treatment, depending on the requirements of the WWTP (Ruiz-Hernando et al. 2014). According to studies mesophilic anaerobic digestion is inactive around 2 log10 of pathogens and sludge containing up to 7 log10 (Lizama et al. 2017).

The inactivation of three microbial indicators at 80 °C, for 30 min, behaved differently: there was a slight reduction for SSRC (spores of sulfite-reducing clostridia) (0.84 log10 of reduction), approximately 5 log10 of reduction for SOMCPH (somatic coliphage) and a high hygienization for E. coli (>4.01 log10 of reduction) (Ruiz-Hernando et al. 2014). According to Yin et al. (2016), thermal pretreatment (70 °C) is highly efficient to inactivate pathogens and the complete inactivation (approximately 6 log) of fecal coliform, Salmonella spp., and fecal streptococcus. The pretreatment effect was evaluated at different times (20, 40, 60, 80, 100, and 120 min) for different TS concentrations of fecal sludge (between 1% and 12%). Considering the results of ultrasound pretreatment, a reduction of pathogens was observed where the concentration of fecal coliforms and Salmonella spp. decreased by 4 (99.99%) and 3 (99.9%) log units, respectively, at 35,000 kJ/kg. The authors tested TS concentration without continuous stirring and did not achieve the same inactivation, so these two conditions interfere on ultrasound pathogen inactivation capability (Lizama et al. 2017). According to Kumar (2011), the pathogen concentration decreased as sonication time and frequency increased, and reduction is mainly caused by the effects of cavitation and decreased the bacterial cells showing ruptured shapes.

During ultrasonic treatment of sewage sludge, using 22 kHz, the load of Giardia lamblia cysts and Cryptosporidium parvum oocysts was reduced to non-detectable levels (control parasite density, 12–17 no./g of Cryptosporidium and 22–32 no./g of Giardia), at 15 min of sonication time for following applied amplitudes (10, 12, 14, 16 μm). The hydrodynamic shear force was considered as a factor responsible for the damaged oocyst (Graczyk et al. 2008).

Besides the treatment and pretreatment efficiency, some matrices may need addition of a post-treatment for reaching the standard established in directives for sludge use. There are some well-known options, such as the use of polishing ponds, which is common in developing countries such as India, Brazil, and China (Ali et al. 2013). This system requires large land areas, being also quite slow; however it can reduce helminth eggs and reach the discharge standards for urban wastewaters from the European Community for nitrogen (von Sperling and Mascarenhas 2005). Constructed wetlands are another example of natural post-treatment, being especially efficient on phosphorus and nitrogen removal (Ali et al. 2013). One of the advantages of this technique is the use of natural organic matter degradation processes, associated with the macrophytes’ biologic filtration, being able to reduce coliforms and even viruses (Platzer et al. 2016; Stefanakis et al. 2014).

Coagulation and flocculation are other examples of a post-treatment process; however their efficacy must be increased using disinfectants such as chlorine (Jaya Prakash et al. 2007). Down-flow hanging sponge (DHS) is a reactor developed in Japan, composed of sponge cubes diagonally linked through nylon string, providing vast areas for microbiological growth under non-submerged conditions, while the effluent passage provides the nutrients for the resident microorganism development (Agrawal et al. 1997). Down-flow hanging sponges enable the recovery of dissolved methane and thus the removal of 3.5 logs10 of fecal contaminants (Machdar et al. 2000). Another post-treatment method for fecal contaminant removal is the use of moving bed biofilm reactors, showing a 2.3 logs10 removal (Tawfik et al. 2008). In these systems the predation by protozoa and metazoan along with adsorption into the media was the main inactivation mechanisms responsible for pathogen reduction.

Slow sand filtration systems show great sanitization power for anaerobic digestate treatment, being able to reduce 4 logs10 of fecal contaminants, reaching most of the directives for effluent reuse (Tyagi et al. 2009). There are other techniques focused on mineral element removal, involving aeration processes, variating from micro-aeration, i.e., flash aeration, to high rate aerobic methods, such as sequential batch reactors. Micro-aeration is a great option for sulfides’ biological oxidation into elemental sulfur, which can be easily recovered and commercialized (Chen et al. 2010; Khan et al. 2011). These techniques can be applied for a greater effluent sanitization and thus safer agricultural use, land application, or discharge, being all feasible options. However, the most suitable sanitization option depends on the effluent and treatment plant characteristics.

4 Final Remarks

The WWTP’s sludge is a by-product that contains a large amount of organic matters, heavy metals, and pathogens and may represent an environmental risk. In this sense, AD is a promising technology for the recovery of sludge, dependent on physical, chemical, and biological pretreatments to promote the increase in biogas production and increase the sanitary quality of the digested, aiming at valuing and recycling the final product.

References

Abe N, Tang YQ, Iwamura M, Morimura S, Kida K (2013) Pretreatment followed by anaerobic digestion of secondary sludge for reduction of sewage sludge volume. Water Sci Technol 67:2527–2533. https://doi.org/10.2166/wst.2013.154

Abelleira-Pereira JM, Pérez-Elvira SI, Sánchez-Oneto J, de la Cruz R, Portela JR, Nebot E (2015) Enhancement of methane production in mesophilic anaerobic digestion of secondary sewage sludge by advanced thermal hydrolysis pretreatment. Water Res 71:330–340. https://doi.org/10.1016/j.watres.2014.12.027

Agabo-García C, Pérez M, Rodríguez-Morgado B, Parrado J, Solera R (2019) Biomethane production improvement by enzymatic pre-treatments and enhancers of sewage sludge anaerobic digestion. Fuel 255:115713. https://doi.org/10.1016/j.fuel.2019.115713

Agrawal LK, Ohashi Y, Mochida E, Okui H, Ueki Y, Harada H, Ohashi A (1997) Treatment of raw sewage in a temperate climate using a uasb reactor and the hanging sponge cubes process. Water Sci Technol 36:433–440. https://doi.org/10.1016/S0273-1223(97)00552-0

Alfaro N, Cano R, Fdz-Polanco F (2014) Effect of thermal hydrolysis and ultrasounds pretreatments on foaming in anaerobic digesters. Bioresour Technol 170:477–482. https://doi.org/10.1016/j.biortech.2014.08.013

Ali A, Zahid R, Ahmad A, Lew B (2013) Sustainable post treatment options of anaerobic effluent. In: Chamy R, Rosenkranz F (eds) Biodegradation - engineering and technology. InTechOpen, London. https://doi.org/10.5772/56097

Andrés P, Mateos E, Tarrasón D, Cabrera C, Figuerola B (2011) Effects of digested, composted, and thermally dried sewage sludge on soil microbiota and mesofauna. Appl Soil Ecol 48:236–242. https://doi.org/10.1016/j.apsoil.2011.03.001

Anjum M, Al-Makishah NH, Barakat MA (2016) Wastewater sludge stabilization using pre-treatment methods. Process Saf Environ Prot 102:615–632. https://doi.org/10.1016/j.psep.2016.05.022

Appels L, Baeyens J, Degre J, Dewil R (2008) Principles and potential of the anaerobic digestion of waste-activated sludge. Prog Energy Combust Sci 34:755–781. https://doi.org/10.1016/j.pecs.2008.06.002

Bao H, Yang H, Zhang H, Liu Y, Su H, Shen M (2020) Improving methane productivity of waste activated sludge by ultrasound and alkali pretreatment in microbial electrolysis cell and anaerobic digestion coupled system. Environ Res 180:108863. https://doi.org/10.1016/j.envres.2019.108863

Barber WP (2005) The effects of ultrasound on sludge digestion. Water Environ J 19:2–7. https://doi.org/10.1111/j.1747-6593.2005.tb00542.x

Barber WPF (2016) Thermal hydrolysis for sewage treatment: a critical review. Water Res 104:53–71. https://doi.org/10.1016/j.watres.2016.07.069

Ben Rebah F, Miled N (2013) Fish processing wastes for microbial enzyme production: a review. 3 Biotech 3:255–265. https://doi.org/10.1007/s13205-012-0099-8

Berglund B (2015) Environmental dissemination of antibiotic resistance genes and correlation to anthropogenic contamination with antibiotics. Infect Ecol Epidemiol 5:28564. https://doi.org/10.3402/iee.v5.28564

Bolzonella D, Cavinato C, Fatone F, Pavan P, Cecchi F (2012) High rate mesophilic, thermophilic, and temperature phased anaerobic digestion of waste activated sludge: a pilot scale study. Waste Manag 32:1196–1201. https://doi.org/10.1016/j.wasman.2012.01.006

Bonilla S, Choolaei Z, Meyer T, Edwards EA, Yakunin AF, Allen DG (2018) Evaluating the effect of enzymatic pretreatment on the anaerobic digestibility of pulp and paper biosludge. Biotechnol Rep 17:77–85. https://doi.org/10.1016/j.btre.2017.12.009

Bougrier C, Delgenès JP, Carrère H (2007) Impacts of thermal pre-treatments on the semi-continuous anaerobic digestion of waste activated sludge. Biochem Eng J 34:20–27. https://doi.org/10.1016/j.bej.2006.11.013

Bundhoo ZMA, Mohee R (2018) Ultrasound-assisted biological conversion of biomass and waste materials to biofuels: a review. Ultrason Sonochem 40:298–313. https://doi.org/10.1016/j.ultsonch.2017.07.025

Calero-Cáceres W, Melgarejo A, Colomer-Lluch M, Stoll C, Lucena F, Jofre J, Muniesa M (2014) Sludge As a Potential Important Source of Antibiotic Resistance Genes in Both the Bacterial and Bacteriophage Fractions. Environ Sci Technol 48:7602–7611. https://doi.org/10.1021/es501851s

Cano R, Pérez-Elvira SI, Fdz-Polanco F (2015) Energy feasibility study of sludge pretreatments: a review. Appl Energy 149:176–185. https://doi.org/10.1016/j.apenergy.2015.03.132

Çelebi EB, Aksoy A, Sanin FD (2020) Effects of anaerobic digestion enhanced by ultrasound pretreatment on the fuel properties of municipal sludge. Environ Sci Pollut Res 27:17350–17358. https://doi.org/10.1007/s11356-020-08230-4

Chen Y, Cheng JJ, Creamer KS (2008) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99:4044–4064

Chen C, Ren N, Wang A, Liu L, Lee DJ (2010) Enhanced performance of denitrifying sulfide removal process under micro-aerobic condition. J Hazard Mater 179:1147–1151. https://doi.org/10.1016/j.jhazmat.2010.02.065

Conama. CONAMA – Conselho Nacional do Meio Ambiente. Ministério do Meio Ambiente, Brasil (2006) Resolução No. 375

Demirbas A, Edris G, Alalayah WM (2017) Sludge production from municipal wastewater treatment in sewage treatment plant. Energ Sources Part A Recover Util Environ Eff 39:999–1006. https://doi.org/10.1080/15567036.2017.1283551

Dhar BR, Nakhla G, Ray MB (2012) Techno-economic evaluation of ultrasound and thermal pretreatments for enhanced anaerobic digestion of municipal waste activated sludge. Waste Manag 32:542–549. https://doi.org/10.1016/j.wasman.2011.10.007

Ding HH, Chang S, Liu Y (2017) Biological hydrolysis pretreatment on secondary sludge: enhancement of anaerobic digestion and mechanism study. Bioresour Technol 244:989–995. https://doi.org/10.1016/j.biortech.2017.08.064

Elalami D, Carrere H, Monlau F, Abdelouahdi K, Oukarroum A, Barakat A (2019) Pretreatment and co-digestion of wastewater sludge for biogas production: recent research advances and trends. Renew Sust Energ Rev 114:109287. https://doi.org/10.1016/j.rser.2019.109287

European Union (1998) Directive 2008/98/Ec of the European Parliament and of the council of 19 November 2008 on waste and repealing certain Directives. EC, Brussels

European Union (2008) Regulation (Ec) No 1272/2008 of the European Parliament and of the Council of 16 December 2008. EC, Brussels

Ferrer I, Ponsá S, Vázquez F, Font X (2008) Increasing biogas production by thermal (70°C) sludge pre-treatment prior to thermophilic anaerobic digestion. Biochem Eng J 42:186–192. https://doi.org/10.1016/j.bej.2008.06.020

Gaze WH, Zhang L, Abdouslam NA, Hawkey PM, Calvo-Bado L, Royle J, Brown H, Davis S, Kay P, Boxall ABA, Wellington EMH (2011) Impacts of anthropogenic activity on the ecology of class 1 integrons and integron-associated genes in the environment. ISME J 5:1253–1261. https://doi.org/10.1038/ismej.2011.15

Ge H, Jensen PD, Batstone DJ (2010) Pre-treatment mechanisms during thermophilic–mesophilic temperature phased anaerobic digestion of primary sludge. Water Res 44:123–130. https://doi.org/10.1016/j.watres.2009.09.005

Goel R, Mino T, Satoh H, Matsuo T (1998) Enzyme activities under anaerobic and aerobic conditions in activated sludge sequencing batch reactor. Water Res 32:2081–2088. https://doi.org/10.1016/S0043-1354(97)00425-9

Graczyk TK, Kacprzak M, Neczaj E, Tamang L, Graczyk H, Lucy FE, Girouard AS (2008) Occurrence of Cryptosporidium and Giardia in sewage sludge and solid waste landfill leachate and quantitative comparative analysis of sanitization treatments on pathogen inactivation. Environ Res 106:27–33. https://doi.org/10.1016/j.envres.2007.05.005

Guo L, Lu M, Li Q, Zhang J, Zong Y, She Z (2014) Three-dimensional fluorescence excitation–emission matrix (EEM) spectroscopy with regional integration analysis for assessing waste sludge hydrolysis treated with multi-enzyme and thermophilic bacteria. Bioresour Technol 171:22–28. https://doi.org/10.1016/j.biortech.2014.08.025

Han D, Lee CY, Chang SW, Kim DJ (2017) Enhanced methane production and wastewater sludge stabilization of a continuous full scale thermal pretreatment and thermophilic anaerobic digestion. Bioresour Technol 245:1162–1167. https://doi.org/10.1016/j.biortech.2017.08.108

Houtmeyers S, Degrève J, Willems K, Dewil R, Appels L (2014) Comparing the influence of low power ultrasonic and microwave pre-treatments on the solubilisation and semi-continuous anaerobic digestion of waste activated sludge. Bioresour Technol 171:44–49. https://doi.org/10.1016/j.biortech.2014.08.029

Hu K, Chen W, Jia S, Wang W, Han F (2019) Enhanced degradation of waste activated sludge in microbial electrolysis cell by ultrasonic treatment. Front Microbiol 10:00128. https://doi.org/10.3389/fmicb.2019.00128

Jaya Prakash K, Tyagi VK, Kazmi AA, Kumar A (2007) Post-treatment of UASB reactor effluent by coagulation and flocculation process. Environ Prog 26:164–168. https://doi.org/10.1002/ep.10192

Kelessidis A, Stasinakis AS (2012) Comparative study of the methods used for treatment and final disposal of sewage sludge in European countries. Waste Manag 32:1186–1195. https://doi.org/10.1016/j.wasman.2012.01.012

Kepp U, Machenbach I, Weisz N, Solheim OE (2000) Enhanced stabilisation of sewage sludge through thermal hydrolysis - three years of experience with full scale plant. Water Sci Technol 42:89–96. https://doi.org/10.2166/wst.2000.0178

Khan AA, Gaur RZ, Lew B, Mehrotra I, Kazmi AA (2011) Effect of aeration on the quality of effluent from UASB reactor treating sewage. J Environ Eng 137:464–471. https://doi.org/10.1061/(ASCE)EE.1943-7870.0000348

Khanal SK, Grewell D, Sung S, van Leeuwen J (2007) Ultrasound applications in wastewater sludge pretreatment: a review. Crit Rev Environ Sci Technol 37:277–313. https://doi.org/10.1080/10643380600860249

Kinney CA, Furlong ET, Zaugg SD, Burkhardt MR, Werner SL, Cahill JD, Jorgensen GR (2006) Survey of organic wastewater contaminants in biosolids destined for land application. Environ Sci Technol 40:7207–7215. https://doi.org/10.1021/es0603406

Kor-Bicakci G, Eskicioglu C (2019) Recent developments on thermal municipal sludge pretreatment technologies for enhanced anaerobic digestion. Renew Sust Energ Rev 110:423–443. https://doi.org/10.1016/j.rser.2019.05.002

Kumar K (2011) Influence of ultrasonic treatment in sewage sludge. J Waste Water Treat Anal 2:2. https://doi.org/10.4172/2157-7587.1000115

Kumar Biswal B, Huang H, Dai J, Chen GH, Wu D (2020) Impact of low-thermal pretreatment on physicochemical properties of saline waste activated sludge, hydrolysis of organics and methane yield in anaerobic digestion. Bioresour Technol 297:122423. https://doi.org/10.1016/j.biortech.2019.122423

LaPara TM, Burch TR, McNamara PJ, Tan DT, Yan M, Eichmiller JJ (2011) Tertiary-treated municipal wastewater is a significant point source of antibiotic resistance genes into duluth-superior harbor. Environ Sci Technol 45:9543–9549. https://doi.org/10.1021/es202775r

LeBlanc RJ, Matthews P, Richard RP (2008) Global atlas of excreta, wastewater sludge, and biosolids management: moving forward the sustainable and welcome uses of a global resource. United Nations Human Settlements Programme (UN-HABITAT). https://unhabitat.org/sites/default/files/download-manager-files/Global%20Atlas%20of%20Excreta%2C%20Wastewater%20Sludge%2C%20and%20Biosolids%20Management.pdf

Li X, Ma H, Wang Q, Matsumoto S, Maeda T, Ogawa HI (2009) Isolation, identification of sludge-lysing strain and its utilization in thermophilic aerobic digestion for waste activated sludge. Bioresour Technol 100:2475–2481. https://doi.org/10.1016/j.biortech.2008.12.019

Li X, Guo S, Peng Y, He Y, Wang S, Li L, Zhao M (2018) Anaerobic digestion using ultrasound as pretreatment approach: changes in waste activated sludge, anaerobic digestion performances and digestive microbial populations. Biochem Eng J 139:139–145. https://doi.org/10.1016/j.bej.2017.11.009

Li X, Liu Y, Xu Q, Liu X, Huang X, Yang J, Wang D, Wang Q, Liu Y, Yang Q (2019) Enhanced methane production from waste activated sludge by combining calcium peroxide with ultrasonic: performance, mechanism, and implication. Bioresour Technol 279:108–116. https://doi.org/10.1016/j.biortech.2019.01.115

Liao X, Li H, Zhang Y, Liu C, Chen Q (2016) Accelerated high-solids anaerobic digestion of sewage sludge using low-temperature thermal pretreatment. Int Biodeterior Biodegradation 106:141–149. https://doi.org/10.1016/j.ibiod.2015.10.023

Lizama AC, Figueiras CC, Herrera RR, Pedreguera AZ, Ruiz Espinoza JE (2017) Effects of ultrasonic pretreatment on the solubilization and kinetic study of biogas production from anaerobic digestion of waste activated sludge. Int Biodeterior Biodegradation 123:1–9. https://doi.org/10.1016/j.ibiod.2017.05.020

Ma Y, Wilson CA, Novak JT, Riffat R, Aynur S, Murthy S, Pruden A (2011) Effect of various sludge digestion conditions on sulfonamide, macrolide, and tetracycline resistance genes and class I integrons. Environ Sci Technol 45:7855–7861. https://doi.org/10.1021/es200827t

Machdar I, Sekiguchi Y, Sumino H, Ohashi A, Harada H (2000) Combination of a UASB reactor and a curtain type DHS (downflow hanging sponge) reactor as a cost-effective sewage treatment system for developing countries. Water Sci Technol 42:83–88. https://doi.org/10.2166/wst.2000.0362

Martinez JL (2009) The role of natural environments in the evolution of resistance traits in pathogenic bacteria. Proc R Soc B Biol Sci 276:2521–2530. https://doi.org/10.1098/rspb.2009.0320

Milieu L (2010) Environmental, economic and social impacts of the use of sewage sludge on land. https://ec.europa.eu/environment/archives/waste/sludge/pdf/part_ii_report.pdf

Mininni G, Dentel SK (2013) State of sewage sludge management in EU members states and in the United States. In: IWA Holistic Sludge Management Conference Proceedings, Sweden

Mininni G, Blanch AR, Lucena F, Berselli S (2015) EU policy on sewage sludge utilization and perspectives on new approaches of sludge management. Environ Sci Pollut Res 22:7361–7374. https://doi.org/10.1007/s11356-014-3132-0

Mirmasoumi S, Ebrahimi S, Saray RK (2018) Enhancement of biogas production from sewage sludge in a wastewater treatment plant: evaluation of pretreatment techniques and co-digestion under mesophilic and thermophilic conditions. Energy 157:707–717. https://doi.org/10.1016/j.energy.2018.06.003

Na S, Kim YU, Khim J (2007) Physiochemical properties of digested sewage sludge with ultrasonic treatment. Ultrason Sonochem 14:281–285. https://doi.org/10.1016/j.ultsonch.2006.06.004

Neumann P, Pesante S, Venegas M, Vidal G (2016) Developments in pre-treatment methods to improve anaerobic digestion of sewage sludge. Rev Environ Sci Biotechnol 15:173–211. https://doi.org/10.1007/s11157-016-9396-8

Neumann P, González Z, Vidal G (2017) Sequential ultrasound and low-temperature thermal pretreatment: process optimization and influence on sewage sludge solubilization, enzyme activity and anaerobic digestion. Bioresour Technol 234:178–187. https://doi.org/10.1016/j.biortech.2017.03.029

Neumann P, Barriga F, Álvarez C, González Z, Vidal G (2018) Process performance assessment of advanced anaerobic digestion of sewage sludge including sequential ultrasound–thermal (55 °C) pre-treatment. Bioresour Technol 262:42–51. https://doi.org/10.1016/j.biortech.2018.03.057

Nybroe O, Jørgensen PE, Henze M (1992) Enzyme activities in waste water and activated sludge. Water Res 26:579–584. https://doi.org/10.1016/0043-1354(92)90230-2

Oosterhuis M, Ringoot D, Hendriks A, Roeleveld P (2014) Thermal hydrolysis of waste activated sludge at Hengelo Wastewater Treatment Plant, The Netherlands. Water Sci Technol 70:1–7. https://doi.org/10.2166/wst.2014.107

Pérez-Elvira SI, Fernández-Polanco F, Fernández-Polanco M, Rodríguez P, Rouge P (2008) Hydrothermal multivariable approach. Full-scale feasibility study. Electron J Biotechnol 11:1–10. https://doi.org/10.2225/vol11-issue4-fulltext-14

Pilli S, Bhunia P, Yan S, LeBlanc RJ, Tyagi RD, Surampalli RY (2011) Ultrasonic pretreatment of sludge: a review. Ultrason Sonochem 18:1–18. https://doi.org/10.1016/j.ultsonch.2010.02.014

Pilli S, Yan S, Tyagi RD, Surampalli RY (2015) Thermal pretreatment of sewage sludge to enhance anaerobic digestion: a review. Crit Rev Environ Sci Technol 45:669–702. https://doi.org/10.1080/10643389.2013.876527

Planta MB (2007) The role of poverty in antimicrobial resistance. J Am Board Fam Med 20:533–539. https://doi.org/10.3122/jabfm.2007.06.070019

Platzer C, Hoffmann H, Miglio RM (2016) Long term experiences with dimensioning and operation of vertical flow constructed wetlands in warm climate regions of South America. In: Proceeding of the IWA special conference on Wetland Systems for water pollution control. http://brasil.rotaria.net/wp-content/uploads/2017/08/IWA-2016-wetland_vertical_expierences.pdf

Praspaliauskas M, Pedišius N (2017) A review of sludge characteristics in Lithuania’s wastewater treatment plants and perspectives of its usage in thermal processes. Renew Sust Energ Rev 67:899–907. https://doi.org/10.1016/j.rser.2016.09.041

Qiao M, Chen W, Su J, Zhang B, Zhang C (2012) Fate of tetracyclines in swine manure of three selected swine farms in China. J Environ Sci 24:1047–1052. https://doi.org/10.1016/S1001-0742(11)60890-5

Rahube TO, Marti R, Scott A, Tien YC, Murray R, Sabourin L, Zhang Y, Duenk P, Lapen DR, Topp E (2014) Impact of fertilizing with raw or anaerobically digested sewage sludge on the abundance of antibiotic-resistant coliforms, antibiotic resistance genes, and pathogenic bacteria in soil and on vegetables at harvest. Appl Environ Microbiol 80:6898–6907. https://doi.org/10.1128/AEM.02389-14

Recktenwald M, Wawrzynczyk J, Dey ES, Norrlöw O (2008) Enhanced efficiency of industrial-scale anaerobic digestion by the addition of glycosidic enzymes. J Environ Sci Health Part A 43:1536–1540. https://doi.org/10.1080/10934520802293693

Riau V, De la Rubia MA, Pérez M (2015) Upgrading the temperature-phased anaerobic digestion of waste activated sludge by ultrasonic pretreatment. Chem Eng J 259:672–681. https://doi.org/10.1016/j.cej.2014.08.032

Ruffino B, Campo G, Genon G, Lorenzi E, Novarino D, Scibilia G, Zanetti M (2015) Improvement of anaerobic digestion of sewage sludge in a wastewater treatment plant by means of mechanical and thermal pre-treatments: performance, energy and economical assessment. Bioresour Technol 175:298–308. https://doi.org/10.1016/j.biortech.2014.10.071

Ruiz-Hernando M, Martín-Díaz J, Labanda J, Mata-Alvarez J, Llorens J, Lucena F, Astals S (2014) Effect of ultrasound, low-temperature thermal and alkali pre-treatments on waste activated sludge rheology, hygienization and methane potential. Water Res 61:119–129. https://doi.org/10.1016/j.watres.2014.05.012

Sabourin L, Duenk P, Bonte-Gelok S, Payne M, Lapen DR, Topp E (2012) Uptake of pharmaceuticals, hormones and parabens into vegetables grown in soil fertilized with municipal biosolids. Sci Total Environ 431:233–236. https://doi.org/10.1016/j.scitotenv.2012.05.017

Schievano A, D’Imporzano G, Malagutti L, Fragali E, Ruboni G, Adani F (2010) Evaluating inhibition conditions in high-solids anaerobic digestion of organic fraction of municipal solid waste. Bioresour Technol 101:5728–5732. https://doi.org/10.1016/j.biortech.2010.02.032

Schievano A, Tenca A, Scaglia B, Merlino G, Rizzi A, Daffonchio D, Oberti R, Adani F (2012) Two-stage vs single-stage thermophilic anaerobic digestion: comparison of energy production and biodegradation efficiencies. Environ Sci Technol 46:8502–8510. https://doi.org/10.1021/es301376n

Sentchilo V, Mayer AP, Guy L, Miyazaki R, Green Tringe S, Barry K, Malfatti S, Goessmann A, Robinson-Rechavi M, van der Meer JR (2013) Community-wide plasmid gene mobilization and selection. ISME J 7:1173–1186. https://doi.org/10.1038/ismej.2013.13

Sharma R, Larney FJ, Chen J, Yanke LJ, Morrison M, Topp E, McAllister TA, Yu Z (2009) Selected antimicrobial resistance during composting of manure from cattle administered sub-therapeutic antimicrobials. J Environ Qual 38:567–575. https://doi.org/10.2134/jeq2007.0638

Souza TSO, Ferreira LC, Sapkaite I, Pérez-Elvira SI, Fdz-Polanco F (2013) Thermal pretreatment and hydraulic retention time in continuous digesters fed with sewage sludge: assessment using the ADM1. Bioresour Technol 148:317–324. https://doi.org/10.1016/j.biortech.2013.08.161

von Sperling M, Mascarenhas LCAM (2005) Performance of very shallow ponds treating effluents from UASB reactors. Water Sci Technol 51:83–90. https://doi.org/10.2166/wst.2005.0432

Stefanakis A, Akratos CS, Tsihrintzis VA (2014) Vertical flow constructed wetlands. Elsevier Science, Philadelphia, PA. https://doi.org/10.1016/C2012-0-01288-4

Su JQ, Wei B, Ou-Yang WY, Huang FY, Zhao Y, Xu HJ, Zhu YG (2015) Antibiotic resistome and its association with bacterial communities during sewage sludge composting. Environ Sci Technol 49:7356–7363. https://doi.org/10.1021/acs.est.5b01012

Suslick KS (1990) The chemical effects of ultrasound. Science 247:1439–1445. https://doi.org/10.1126/science.247.4949.1439

Tawfik A, El-Gohary F, Ohashi A, Harada H (2008) Optimization of the performance of an integrated anaerobic–aerobic system for domestic wastewater treatment. Water Sci Technol 58:185–194. https://doi.org/10.2166/wst.2008.320

Tongco JV, Kim S, Oh BR, Heo SY, Lee J, Hwang S (2020) Enhancement of hydrolysis and biogas production of primary sludge by use of mixtures of protease and lipase. Biotechnol Bioprocess Eng 25:132–140. https://doi.org/10.1007/s12257-019-0302-4

Toutian V, Barjenbruch M, Unger T, Loderer C, Remy C (2020) Effect of temperature on biogas yield increase and formation of refractory COD during thermal hydrolysis of waste activated sludge. Water Res 171:115383. https://doi.org/10.1016/j.watres.2019.115383

Treichel H, Fongaro G, Scapini T, Frumi Camargo A, Spitza Stefanski F, Venturin B (2020) Waste biomass pretreatment methods. In: Treichel H, Fongaro G, Scapini T, Camargo AF, Stefanski FS, Venturin B (eds) Utilising biomass in biotechnology. Springer International Publishing, Cham, pp 19–48. https://doi.org/10.1007/978-3-030-22853-8_3

Tyagi VK, Lo SL (2011) Application of physico-chemical pretreatment methods to enhance the sludge disintegration and subsequent anaerobic digestion: an up to date review. Rev Environ Sci Biotechnol 10:215–242. https://doi.org/10.1007/s11157-011-9244-9

Tyagi VK, Khan AA, Kazmi AA, Mehrotra I, Chopra AK (2009) Slow sand filtration of UASB reactor effluent: a promising post treatment technique. Desalination 249:571–576. https://doi.org/10.1016/j.desal.2008.12.049

Tyagi VK, Lo SL, Appels L, Dewil R (2014) Ultrasonic treatment of waste sludge: a review on mechanisms and applications. Crit Rev Environ Sci Technol 44:1220–1288. https://doi.org/10.1080/10643389.2013.763587

Ventorino V, Romano I, Pagliano G, Robertiello A, Pepe O (2018) Pre-treatment and inoculum affect the microbial community structure and enhance the biogas reactor performance in a pilot-scale biodigestion of municipal solid waste. Waste Manag 73:69–77. https://doi.org/10.1016/j.wasman.2017.12.005

Wang L, Oda Y, Grewal S, Morrison M, Michel FC, Yu Z (2012) Persistence of resistance to erythromycin and tetracycline in swine manure during simulated composting and lagoon treatments. Microb Ecol 63:32–40. https://doi.org/10.1007/s00248-011-9921-9

Wang Q, Wei W, Gong Y, Yu Q, Li Q, Sun J, Yuan Z (2017) Technologies for reducing sludge production in wastewater treatment plants: state of the art. Sci Total Environ 587–588:510–521. https://doi.org/10.1016/j.scitotenv.2017.02.203

Watson SD, Akhurst T, Whiteley CG, Rose PD, Pletschke BI (2004) Primary sludge floc degradation is accelerated under biosulphidogenic conditions: enzymological aspects. Enzym Microb Technol 34:595–602. https://doi.org/10.1016/j.enzmictec.2004.01.004

Wellington EM, Boxall AB, Cross P, Feil EJ, Gaze WH, Hawkey PM, Johnson-Rollings AS, Jones DL, Lee NM, Otten W, Thomas CM, Williams AP (2013) The role of the natural environment in the emergence of antibiotic resistance in Gram-negative bacteria. Lancet Infect Dis 13:155–165. https://doi.org/10.1016/S1473-3099(12)70317-1

Wilson CA, Novak JT (2009) Hydrolysis of macromolecular components of primary and secondary wastewater sludge by thermal hydrolytic pretreatment. Water Res 43:4489–4498. https://doi.org/10.1016/j.watres.2009.07.022

Wiśniowska E (2019) Sludge activation, conditioning, and engineering. In: Vara Prasad MN, de Campos Favas PJ, Vithanage M, Mohan SV (eds) Industrial and municipal sludge emerging concerns and scope for resource recovery. Elsevier Science, Philadelphia, PA, pp 181–199. https://doi.org/10.1016/B978-0-12-815907-1.00009-X

Wright GD (2010) Q & A: Antibiotic resistance: where does it come from and what can we do about it? BMC Biol 8:123. https://doi.org/10.1186/1741-7007-8-123

Xiao B, Tang X, Yi H, Dong L, Han Y, Liu J (2020) Comparison of two advanced anaerobic digestions of sewage sludge with high-temperature thermal pretreatment and low-temperature thermal-alkaline pretreatment. Bioresour Technol 304:122979. https://doi.org/10.1016/j.biortech.2020.122979

Xie R, Xing Y, Ghani YA, Ooi K, Ng S (2007) Full-scale demonstration of an ultrasonic disintegration technology in enhancing anaerobic digestion of mixed primary and thickened secondary sewage sludge. J Environ Eng Sci 6:533–541. https://doi.org/10.1139/S07-013

Xu Q, Li X, Ding R, Wang D, Liu Y, Wang Q, Zhao J, Chen F, Zeng G, Yang Q, Li H (2017) Understanding and mitigating the toxicity of cadmium to the anaerobic fermentation of waste activated sludge. Water Res 124:269–279. https://doi.org/10.1016/j.watres.2017.07.067

Xue Y, Liu H, Chen S, Dichtl N, Dai X, Li N (2015) Effects of thermal hydrolysis on organic matter solubilization and anaerobic digestion of high solid sludge. Chem Eng J 264:174–180. https://doi.org/10.1016/j.cej.2014.11.005

Yang Q, Luo K, Li X, Wang D, Zheng W, Zeng G, Liu J (2010a) Enhanced efficiency of biological excess sludge hydrolysis under anaerobic digestion by additional enzymes. Bioresour Technol 101:2924–2930. https://doi.org/10.1016/j.biortech.2009.11.012

Yang X, Wang X, Wang L (2010b) Transferring of components and energy output in industrial sewage sludge disposal by thermal pretreatment and two-phase anaerobic process. Bioresour Technol 101:2580–2584. https://doi.org/10.1016/j.biortech.2009.10.055

Yang Y, Li B, Ju F, Zhang T (2013) Exploring variation of antibiotic resistance genes in activated sludge over a four-year period through a metagenomic approach. Environ Sci Technol 47:10197–10205. https://doi.org/10.1021/es4017365

Yin F, Li Z, Wang D, Ohlsen T, Dong H (2016) Performance of thermal pretreatment and mesophilic fermentation system on pathogen inactivation and biogas production of faecal sludge: initial laboratory results. Biosyst Eng 151:171–177. https://doi.org/10.1016/j.biosystemseng.2016.08.019

Yu S, Zhang G, Li J, Zhao Z, Kang X (2013) Effect of endogenous hydrolytic enzymes pretreatment on the anaerobic digestion of sludge. Bioresour Technol 146:758–761. https://doi.org/10.1016/j.biortech.2013.07.087

Zábranská J, Dohányos M, Jeníček P, Kutil J (2006) Disintegration of excess activated sludge – evaluation and experience of full-scale applications. Water Sci Technol 53:229–236. https://doi.org/10.2166/wst.2006.425

Zhang XX, Zhang T (2011) Occurrence, abundance, and diversity of tetracycline resistance genes in 15 sewage treatment plants across china and other global locations. Environ Sci Technol 45:2598–2604. https://doi.org/10.1021/es103672x

Zhang T, Zhang XX, Ye L (2011) Plasmid metagenome reveals high levels of antibiotic resistance genes and mobile genetic elements in activated sludge. PLoS One 6:e26041. https://doi.org/10.1371/journal.pone.0026041

Zhang B, Ji M, Wang F, Li R, Zhang K, Yin X, Li Q (2017) Damage of EPS and cell structures and improvement of high-solid anaerobic digestion of sewage sludge by combined (Ca(OH) 2 + multiple-transducer ultrasonic) pretreatment. RSC Adv 7:22706–22714. https://doi.org/10.1039/C7RA01060E

Zhen G, Lu X, Kato H, Zhao Y, Li YY (2017) Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: current advances, full-scale application and future perspectives. Renew Sust Energ Rev 69:559–577. https://doi.org/10.1016/j.rser.2016.11.187

Zhou J, Wang YH, Chu J, Luo LZ, Zhuang YP, Zhang SL (2009) Optimization of cellulase mixture for efficient hydrolysis of steam-exploded corn stover by statistically designed experiments. Bioresour Technol 100:819–825. https://doi.org/10.1016/j.biortech.2008.06.068

Zou S, Wang X, Chen Y, Wan H, Feng Y (2016) Enhancement of biogas production in anaerobic co-digestion by ultrasonic pretreatment. Energy Convers Manag 112:226–235. https://doi.org/10.1016/j.enconman.2015.12.087

Zou X, Yang R, Zhou X, Cao G, Zhu R, Ouyang F (2020) Effects of mixed alkali-thermal pretreatment on anaerobic digestion performance of waste activated sludge. J Clean Prod 259:120940. https://doi.org/10.1016/j.jclepro.2020.120940

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Tápparo, D.C. et al. (2022). Sewage Sludge Pretreatment Strategies for Methane Recovery and Sanitization. In: Meghvansi, M.K., Goel, A.K. (eds) Anaerobic Biodigesters for Human Waste Treatment. Environmental and Microbial Biotechnology. Springer, Singapore. https://doi.org/10.1007/978-981-19-4921-0_10

Download citation

DOI: https://doi.org/10.1007/978-981-19-4921-0_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-4920-3

Online ISBN: 978-981-19-4921-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)