Abstract

The quantification of project time variations is important to project execution. However, so far, there has been still a lack of studies that focus on specific project schedules. Using structured and semi-structured interviews with contractors, this study develops a process in the planning phase of risk responses, which could help to assess the level of project time variations based on the impact of event chains. The application of the process is also illustrated using a case study, which is a part of the pre-validated actual project. The developed process could help to evaluate the precise impact of risk events with simple handling. The findings of this study could provide practitioners (e.g., project management teams) with a guideline to quantify the impact of risks on the dynamic levels of project time based on the analysis of the sensitivity chart of risk events. Hence, they could not only avoid the phenomena of excessive optimism and pessimism, but also allocate resources more appropriately during project implementation processes to reduce the unexpected impacts of risks.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Risk is a common concern of construction management because of specific distinctive characteristics [4, 14, 18]. Commonly, in a construction project, risks depend on its complexity and the strategic nature of its products. Each project is unique with certain characteristics such as various stakeholders, open production system, long time performance, and vulnerable environments by internal and external factors [16]. Risks and uncertainties always appear in any stage from preparation to operation regardless of size, characteristic, complexity, and place of construction projects [14]. Construction projects will receive detrimental consequences such as increasing costs and time delay, even project failure, if there exist failures to respond to risks and uncertainties [14, 18]. Therefore, previous studies have focused on risk management (e.g., risk identification, risk classification, qualitative risk analysis, and quantitative risk analysis), of which risk quantification is considered as one of the most complex issues.

The quantification of project time variations plays an important role in project execution. Although risks and uncertainties have significant influences on decision-making, they are vague, subjective, and uncertain [6]. Therefore, many authors attempted to quantify risks such as assessing the effect on risks [8], predicting the effect on risks [13], analyzing documents to evaluate risks [1], applying fuzzy theory to find probability density functions of risk [12], and applying Monte Carlo on schedule [10]. However, so far, there has been still a lack of studies that focus on specific project schedules. As such, there is a need to develop a process in the planning phase of risk responses, which could help to assess the level of project time variations based on the impact of event chains.

Accordingly, this study aims to help project managers to determine project completion time and milestones with corresponding probabilities and eliminate the probability and level of impact of each risk on a specific project. Based on a proposed process, construction organizations can assess the schedule viability of a project at distinct stages: biding, pre-construction, construction. This study offers a certain practical way to evaluate project schedules. Project managers will comprehend worst-case scenarios, most likely scenarios, and best-case scenarios, especially sensitive to risks. After that, construction firms use the report from evaluation to respond risks and uncertainties. In addition, the actual results of a specific project are compared with the simulation results to prove the reliability of the proposed process. This study explores the applicability of event chain methodology as a technique that can simplify the process of modeling risk and uncertainties while minimizing the effects of cognitive, confirmation, and psychological bias.

2 Literature Review

Many authors have expressed their concerns about quantifying risks on variations of project time. Most of them identified common risks and investigated their correlation. Furthermore, some authors have allocated these risks to stakeholders. Little research has been attempted to predict variations of project time based on quantitation risks.

Many previous studies have focused on risk factors, as well as risk relationships. When identifying and evaluating significant risks to allocate risks for stakeholders, El-sayegh [4] concluded that contractors were more responsible for risks than owners in the UAE construction industry. Likewise, with the aim of classifying risks according to organization and project levels, Subramanyan et al. [15] indicated that risk factors could relate to two groups of participants, who were working on construction sites and at offices, respectively. Such groups’ possibilities of appearance were also compared to predict their occurrence in a project. By allocating each construction risk based on contracting terms, Hanna et al. [7] concluded that most severe consequences were usually caused by legal terms. After identifying and classifying risk factors, some authors also developed models to explore their new relationships. Qazi et al. [11] used utility theory and Bayesian belief networks to find the relationship between project complexity and risks to classify risk and mitigate risk in the initial project phase. Reviewing methods, tools, and techniques relating to risk identification, Siraj and Fayek [14] indicated that most studies rely on their risk nature or available risks listed not only to identify but also to classify risks. More recently, Erol et al. [5] explored the relationship between complexity and risk in detail based on quantitative findings.

In addition, several authors have attempted to develop general risk management processes and quantify the risk impact. Del Cano and de la Cruz [2] introduced a general process to manage construction risks from the views of clients and consultants. This process was appropriate for the requirements of other participants because it was easy to be adjusted based on a particular situation. Nasir et al. [10] employed Monte Carlo simulation as well as program evaluation and review technique for schedule risk analysis based on the activity duration value of a range. As a result, time performance was quantified by developing risk evaluation in construction-schedule model. In a research of Jannadi and Almishari [8], a risk assessor model was designed by using a computer program to assess risks for crucial construction activities relating to the probability, severity, and exposure of all hazards. Schatteman et al. [13] employed uncertainty to investigate the effects of schedules by integrating them. After predicting project time performance, they also developed a computer program to manage risks (e.g., identifying, analyzing, and quantifying risk elements). In another study, Choi and Mahadevan [1] employed project-specific documents to analyze risks by using relatively traditional ways like surveys. Sachs and Tiong [12] used fuzzy theory deriving customized probability density functions to quantify risks. Zeynalian et al. [19] developed a risk analysis and management model to consider potential risks based on the identification and probabilities of risks using the Delphi method.

The literature review indicates that the research area on variations of project time is context-specific. The study could contribute some valuable findings to not only Vietnam but also global knowledge. Moreover, in Vietnam as well as other similar developing countries, the quantification of the effects of risks on time variations with regard to different issues of project time has still received little attention. Thus, this study will attempt to fill the gap of research by directly quantifying the impact of risk events. By providing a process of directly quantifying risks on a specific project schedule, the results of this study could be applied to quantify the effects of risk events on project schedule in practice.

3 Research Method

The research framework (Fig. 1) includes three main phases: (1) building a risk list, (2) proposing a quantitative process, and (3) evaluating the process.

In Phase 1, a risk library was first created by reviewing risks encountered after bid selection and before project implementation. After synthesizing all major risks, this study conducted various face-to-face interviews to identify a list of potentially appropriate risk events. In such interviews, 15 experts (including 11 contractors, two consultants, one owner, and one governmental management agency), who had high experience and managerial positions, were invited to participate.

Then, in Phase 2, a quantitative process of risk events that could affect the time of construction works. Specifically, patterns and processes that quantify the risks in previous scholar documents or in construction companies were reviewed. For quantifying risks, a set of criteria were proposed. As a result, a process, which can quantity the effects of risk events on project time, was developed based on experts’ perspective.

Finally, in Phase 3, a construction package of bored piles was used as a case study to demonstrate the reliability and appropriateness of the developed process. The simulation results achieved after updated more risk events into this process were compared with the actual values of the package’s project schedule.

4 Proposing Detailed Process to Quantify Risks

Some important steps in the proposed process are detailed progress, qualitative analysis of risk events, quantitative risk analysis, and evaluation of results. These steps all appear in other risk management processes such as PMBOK and ISO31000:2018. This study extends such processes by building a detailed process (Fig. 2) with clear decentralized responsibility for each individual in assessment teams of risk events.

4.1 Preparation of Process Development

In this step, the evaluation team should have a detailed schedule with a specific hierarchy of work breakdown structure level 3 (PMBOK). The proposed process adds more parameters with regard to the probability of completing construction tasks to the project schedule created by the MS Project software. In terms of PERT analysis, a triangular distribution function is selected to show the probability of completing construction tasks. If there is adequate information about the project, the Crystal Ball software can be used to identify appropriate time distribution functions for construction tasks. Besides this, further considerations should focus on the reserved time, relationships, constraints, logic, and consistency of construction tasks according to technical specifications. In addition, project schedules need to be established in advance to determine project completion time periods.

Figure 3 shows the schedule of bored piles (i.e. case study), which is established by an anonymous contractor’s bidding department based on similar projects’ bill of quantities. The construction time for completing 148 piles (from beginning to handovering of foundation items) is 100 days. The project schedule is developed using a planned calendar with seven working days per week, including holidays. Further information about the case study is presented in Table 1.

In Table 2, various probability information of case study’s construction tasks is presented with three cases: optimistic (10% probability), most likely (50% probability), and pessimistic (90% probability). It can be seen that most simulated durations of construction tasks are lower than the planned durations (Fig. 3). For example, the pessimistic time (longest duration) of the preparation task is just 10.37 days, which is shorter than its planned time (12 days) in Fig. 3.

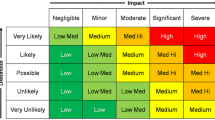

4.2 Check of Risk Events

This step aims to classify risk events into two groups based on their P (probability) and I (impact) values (measured on a 5-points Likert scale). Specifically, Group 1 (i.e. list of problematic issues) includes risk events with the calculated PxI values less than the standard PxI value. In Group 2, risk events will have their PxI values larger than the standard PxI value. It should also be noted that the PxI value depends on project to project. For example, if the budget contingency of a project is large, the PxI value is small, thereby more risk events should be considered and analyzed. If project managers just wish to focus on risk events with severe impacts, the PxI value will be larger.

Regarding the above-mentioned case study, the durations of construction tasks are provided by its site/project managers and senior engineers based on their experience with previous similar projects. These durations are given based on optimistic, most likely, and pessimistic conditions. After that, the site management team will assess risk events based on their probability and impact. Risk events which have considerable impacts could be grouped into four categories as follows:

-

Event 1 (E1): Design changes (e.g., pile number and length) by design unit’s requests,

-

Event 2 (E2): Impact of weather and other force majeure issues,

-

Event 3 (E3): Subcontractors’ capability to supply materials and equipment, and

-

Event 4 (E4): Dealing with problems that may arise during underground construction processes.

4.3 Quantitative Analysis

In terms of quantitative analysis, risk events in Group 2 will be considered. Specifically, they are analyzed quantitatively with regard to their impacts on project schedule performance. Risks are integrated with project schedule by assigning risk events’ durations (start and finish time) and impacts on construction tasks that are directly affected. Besides this, the relationships between risk events are also considered in terms of possibilities of forming risk event chains, which in turns affect a certain task in the project schedule. After risk event assignment, simulations are performed. Finally, experts will preliminarily assess the simulation results.

Table 3 presents the results of integrating risk events on the case study’s project schedule. It can be seen that risk event E1 only affects task T2.1, T2.2, and T2.3. Commonly, risk event E1 happens at the beginning of construction works (0–60%), which may have a day delay due to changing old to new designs in terms of pile number and length. Risk event E2 (e.g., weather) affects all other construction tasks during the whole package (06/2018–09/2018) with a probability of 15% based on previous historical data. Risk event E3 only affects construction tasks necessarily using materials and equipment. Generally, risk event E3 appears at the beginning of construction works (0–80%). Due to previous relationships with subcontractors, the site management team proposes a 30% probability of occurring and a two-days delay for providing more materials and equipment. As risk event E4 cannot be known in advance, its duration is selected as equal to task duration. According to similar projects, a 30% probability of happening is proposed for risk event E4 and a two-days duration for troubleshooting.

4.4 Report of Simulation Results

Based on the results of risk integration and simulations, the site management team will focus on analyzing risk events that significantly affect the project schedule (e.g., risks with high sensitivity). Besides this, the site management team also assesses the project implementation time according to optimistic, most likely, and pessimistic conditions. Based on such analyses, reports will be made for the site management team to respond to risks (e.g., avoiding, transferring, mitigating, and ignoring). Such analyses can also be re-performed at other project stages such as periodic reviews, new technical/technological assessments, or allocation of responsibilities among parties.

5 Illustrative Example

The results of simulation (Fig. 4) indicate a 77% chance for the package completed on time (September 20, 2018) and a 50% chance completed on September 16, 2018 (most likely). In pessimistic situations, the package has a 90% chance to be completed on December 22, 2018. On the other hand, in optimistic conditions, the chance for completing the package on September 9, 2018 is 10%. As compared with the initial schedule, risk events extend project schedule performance for two days. Accordingly, the site management team re-assesses the results and add restrict construction at night (risk event E5) as a further condition, which was not considered for the previous check of risk events.

As shown in Fig. 5, the results of simulation have some changes in completion time milestones: September 9, 2018 (optimistic), September 12, 2018 (most likely), and September 16, 2018 (pessimistic). Despite the addition of risk event E5, the project implementation durations are reduced. This is not so surprising because the simulations use the probability values of risk events without depending on the number of such events.

A comparison with previous similar projects allows the site management team to assess the results of simulation being reasonable. The possibility of completing the package on time is relatively high. Therefore, the site management team considers to accept risk events and keeps following the initial as-planned schedule.

6 Conclusions

Although many previous studies have attempted to quantify risks, there is still a lack of research focusing on assessing risks visually. This study proposes a process of quantifying the impact of risk events on project schedule. The process includes four steps: preparation, check, analysis, and report. The project schedule is considered as the input data, on which some risk events are integrated. The result of the process is a report which includes various important information: project times in optimistic, most likely, and pessimistic conditions and risk events with sensitivity-based rankings. The proposed process is also applied to a case study, which is a bored pile package. The results of simulation show that this case study could have 90% and 50% chances to be completed four and eight days earlier than the initial project schedule, respectively. These results are assessed to be reasonable and, accordingly, the site management team suggest accepting risk events as their risk management strategy.

Despite the above contributions, the limitations of this study should also be noted. Quantifying risk events independently may be a limitation of this study. The chains and interrelationships of risk events are not considered. On the other hand, this study has not attempted to quantify the impact of risk events on project cost due to the difficulties of collecting full data of real project costs. Future studies should focus on quantifying risk events at other project stages and/or the effects of risk events on both project time and cost.

References

Choi HH, Mahadevan S (2008) Construction project risk assessment using existing database and project-specific information. J Constr Eng Manag 134(11):894–903

Del Cano A, de la Cruz MP (2002) Integrated methodology for project risk management. J Constr Eng Manag 128(6):473–485

Diab MF, Varma A, Panthi K (2017) Modeling the construction risk ratings to estimate the contingency in highway projects. J Constr Eng Manag 143(8):1–9

El-Sayegh SM (2008) Risk assessment and allocation in the UAE construction industry. Int J Proj Manag 26(4):431–438

Erol H, Dikmen I, Atasoy G, Birgonul MT (2020) Exploring the relationship between complexity and risk in megaconstruction projects. J Constr Eng Manag 146(12):1–14

Gonzalez P, González V, Molenaar K, Orozco F (2014) Analysis of causes of delay and time performance in construction projects. J Constr Eng Manag 140(1):1–9

Hanna AS, Thomas G, Swanson JR (2013) Construction risk identification and allocation: Cooperative approach. J Constr Eng Manag 139(9):1098–1107

Jannadi OA, Almishari S (2003) Risk assessment in construction. J Constr Eng Manag 129(5):492–500

Kim HJ, Reinschmidt KF (2011) Effects of contractors’ risk attitude on competition in construction. J Constr Eng Manag 137(4):275–283

Nasir D, McCabe B, Hartono L (2003) Evaluating risk in construction-schedule model (ERIC–S): construction schedule risk model. J Constr Eng Manag 129(5):518–527

Qazi A, Quigley J, Dickson A, Kirytopoulos K (2016) Project complexity and risk management (ProCRiM): Towards modelling project complexity driven risk paths in construction projects. Int J Proj Manag 34(7):1183–1198

Sachs T, Tiong RL (2009) Quantifying qualitative information on risks: Development of the QQIR method. J Constr Eng Manag 135(1):56–71

Schatteman D, Herroelen W, Van de Vonder S, Boone A (2008) Methodology for integrated risk management and proactive scheduling of construction projects. J Constr Eng Manag 134(11):885–893

Siraj NB, Fayek AR (2019) Risk identification and common risks in construction: Literature review and content analysis. J Constr Eng Manag 145(9):1–13

Subramanyan H, Sawant PH, Bhatt V (2012) Construction project risk assessment: development of model based on investigation of opinion of construction project experts from India. J Constr Eng Manag 138(3):409–421

Taroun A (2014) Towards a better modelling and assessment of construction risk: Insights from a literature review. Int J Proj Manag 32(1):101–115

Zayed T, Amer M, Pan J (2008) Assessing risk and uncertainty inherent in Chinese highway projects using AHP. Int J Proj Manag 26(4):408–419

Zeng J, An M, Smith NJ (2007) Application of a fuzzy based decision-making methodology to construction project risk assessment. Int J Proj Manag 25(6):589–600

Zeynalian M, Trigunarsyah B, Ronagh HR (2013) Modification of advanced programmatic risk analysis and management model for the whole project life cycle’s risks. J Constr Eng Manag 139(1):51–59

Acknowledgements

The authors fully acknowledge the support of time and resources from the affiliated organizations for this study. This research is funded by Vietnam National University Ho Chi Minh City (VNU-HCM) under grant number B2021-20-08. We would like to thank Ho Chi Minh City University of Technology (HCMUT), VNU-HCM for the support of time and facilities for this study.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Le, DA., Le-Hoai, L., Dang, C.N. (2023). Developing a Detailed Process to Quantify Risks on Variations of Project Time. In: Reddy, J.N., Wang, C.M., Luong, V.H., Le, A.T. (eds) ICSCEA 2021. Lecture Notes in Civil Engineering, vol 268. Springer, Singapore. https://doi.org/10.1007/978-981-19-3303-5_17

Download citation

DOI: https://doi.org/10.1007/978-981-19-3303-5_17

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-3302-8

Online ISBN: 978-981-19-3303-5

eBook Packages: EngineeringEngineering (R0)