Abstract

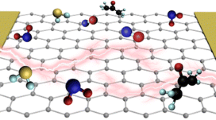

Sensors are technological device that detects the response of the materials on exposure to sensing gas. These electronic devices are very important for personal and infrastructure safety. Various types of materials are used for the design and fabrication of the sensors. However, selecting a particular material depends upon a few parameters like low detection limit, excellent response and recovery time, high selectivity, cheap, less power consumption, operational at ambient temperature and pressure, stability in harsh environmental conditions, etc. In this chapter, first, the basic attributes of bulk and nanostructured materials and their gas-sensing mechanisms are summarized. It also discusses the latest innovation and advancements in the utilization of a variety of materials for gas sensing. Generally, bulk materials are used in the fabrication of sensors due to their key benefits such as low cost and ease to fabricate, but their response is quite slow. Therefore, nanostructure materials, particularly two-dimensional (2D) nanostructures, are promising candidates for the design and development of highly sensitive gas sensors due to their very high surface-to-volume ratio and good compatibility with most device designs. Lately, nanostructured 2D materials, such as metal oxides, graphene, metal dichalcogenides, phosphorene, BN, and M-xenes, have demonstrated significant potential for gas sensors. In this chapter, various methods for the synthesis of 2D nanostructures are briefly summarized. Emphasis is also laid on the evolution of sensing performances provided by devices that integrate 2D nanostructures and strategies for optimizing the sensing features. The experimental along with the theoretical reports are used for the correlations of the structure–properties relationship. The conclusion outlines the open challenges and future prospects for the scientific and technological advancement on 2D nanostructures for high-performance gas-sensing devices.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

8.1 Introduction

A gas sensor is an electronic device or detector that is used to determine the appearance of gases or the concentration of gases in the atmosphere. As soon as, it detects a higher than average concentration of gas in the air using various techniques, it warns the people in any location through audible or visible indicators such as alarms or a combination of signals and lights. There is a huge need to develop and implement uncomplicated and responsible gas sensors for diverse fields such as house, scientific laboratory, mines, medical, aerospace, defense, and factory waste, especially in environmental monitoring systems [1, 2]. Mostly, countries have major air pollution problem due to rapid industrialization and traffic [3]. The large amount of dangerous gas like CO2 and NO2 are emitted due to vehicles and industrial combustions [4]. NO2 can also cause acidic rain and photochemical smog [5, 6]. Therefore, it is a typical air pollutant and dangerous for health, and its appearance limit is only 53 ppb. Another gas, ammonia, is a common air pollutant produced by industrial, agricultural production units, and manufacturing processes. The over-exposure to high concentrations of NH3 (greater than 30 ppm for 10 min) can annoy or swell the human eye, skin, and respiratory system. Therefore, detecting these dangerous gases has aroused widespread concerns because of their harmful effects on the respiratory systems. Sensors are electronic devices, commonly used to detect and identify different gases like toxic or explosive gases [7]. Gas sensors are primarily beneficial for gas transportation and to monitor the air quality and carbon monoxide in homes. They are also used in hotels and mines to prevent people from smoking and for fire safety. A gas sensor comes in handy for applications where one has to monitor the concentration of toxic gases to maintain the system safe and avoid/caution against any accidental threats. Therefore, with the increment of air pollution and the search for safe renewable energy sources like hydrogen, the demand for gas sensors has increased rapidly [8]. 2D nanomaterials with controlled morphology and enhanced surface activity are expected to play a prime role in the design and fabrication of the sensors having extraordinary performance [9].

This chapter aims to briefly summarize the recent progress of gas sensors, their construction, types, working principle, applications, and procedures to detect the required type and concentration of gas in our atmosphere. It also presents the latest review on the bulk and nanostructured sensing materials like graphene, MoS2/WO3, SnS2/RGO, etc., [10, 11] for the detection of gases such as O2, CO2, N2, NH3, and CH4.

8.2 Classifications of Gas Sensors

Sensors can be classified based upon the mechanism used for sensing the gas, properties of sensing gas, and the sensing element built with a different sensing material. The classification gas sensor based on the sensing element could be like optical sensor, electrochemical sensor, capacitance sensor, calorimetric sensor, acoustic sensor, and metal oxide gas sensor, etc. Here, four main types of gas detectors are discussed [12, 13]:

-

(a)

Electrochemical sensors

-

(b)

Catalytic sensors

-

(c)

Infrared sensors

-

(d)

Photoionization sensors.

Following is the detail of each sensor

8.2.1 Electrochemical Sensors

Electrochemical sensors are required to measure the variation of oxygen in the air and to detect toxic gases. Interaction of the sensing gases with the sensing surface and the analytes convert the responsive information to the qualitative and quantitative electric signal [14]. This type of sensor tracks the electrochemical reactions by using electrodes when the gas reaches the working electrode. The electrochemical reaction occurs at the working electrode either through the oxidation or reduction process depending on the type of gases. These reactions generate the negative or positive current flow through said external circuit. A few examples of electrochemical sensors are the respiratory CO2 sensor, CO sensor, O2 sensor [15].

8.2.2 Catalytic Sensors

The gas sensors based upon the catalytic activities are consisting of a detector element that carries an inert compensator element and catalytic material that is sensitive to combustible gases. In such types of sensors, combustible gases are burned only on the detector element due to a rise in its temperature which leads to an imbalance in the bridge circuit and increases the resistance of the detector element. It may be noted that combustible gases do not burn on the compensator. The temperature and resistance of the compensator do not change in the presence of flammable gases [16].

8.2.3 Infrared Sensors

An infrared sensor is an electronic device widely used in motion detectors, alarm systems to detect uninvited guests, etc. In a specified angle range, infrared sensors can determine the heat evolved by an object and detect the movement of the object. It can provide information about the distance between source and object by emitting and receiving infrared radiation. This radiation falls on the objects and reflects back to the receiver of the device [17, 18].

8.2.4 Photoionization Sensors

A photoionization detector (PID) is a gas detector that uses ultraviolet rays to detect various organic compounds such as benzene and other gases in our environment but is unable to detect the semi-volatile compounds. Detection limits of PIDs are in the parts per million (ppm) range [18].

8.3 Design and Fabrication of Gas Sensor

Among the various types of sensors, metal oxide semiconductor-based gas sensors are extensively used. Figure 8.1 shows various components of the metal oxide gas sensor. It exhibits various parts such as the gas SnO2 sensing layer, heating coils, platinum electrode line, tubular ceramic, and gold electrode. Depending upon the gas concentration, a potential difference due to change in the electric resistance of material is the device generated that one can measure as an output voltage. If input voltage is not applied to the heater coil, then the output current is very small. But, when a sufficiently high voltage is implemented to heater coil, then the sensing layer is activated. It is able to sense the volatile gases present in the environment. Initially, if there will be no toxic gas near the sensor, then there will be no change in the resistance of the sensing layer. Therefore, the output current and voltage remained the same. The main purpose of the variable resistor is to stabilize the output voltage and maintain high sensitivity which can be enhanced by applying the higher value of the load resistance [19].

Schematic diagram of a typical metal oxide semiconductor sensor [19]

The following is the detail of the main components of the gas sensors:

Sensing layer

This is the leading segment in the sensors, which detect the change in the concentration of the gases and produce the signal. The sensing layer is a chemi-resistor that alters its resistance value depending upon the concentration of the sensing gas in the environment. In the case of a metal oxide semiconductor sensor, the sensing element is composed of tin dioxide (SnO2), which has surplus electrons. Therefore, on the detection of toxic gas, the resistance of the element changes that leads to the variation in the value of the current which indicates the absorption of the gas.

Heating coil

The main purpose of the heating coil is to increase the temperature of the sensing element which helps in the enhancement of the sensitivity and efficiency of the sensing component. Normally, it is made of high melting point alloys such as nickel–chromium to get heated up without melt.

Electrode line

The sensing element induces a minimal current as soon as the sensing gas is identified. It is most important to maintain efficiency by flowing very small currents. Therefore, highly conducting metal such as gold or platinum wires that help in the transportation of the electrons efficiently is used.

Metal electrode

This is a junction where the output of the sensing layer is interfaced to the electrode line through a sensing medium so that the output current can flow to the required area. Normally, the electrodes are made up of platinum or gold which have not only excellent conductivity but also provides ohmic contact.

Isolation ceramic

Between the heating coils and gas-sensing layer of a fragile area, the tubular ceramic made of aluminum oxide (Al2O3) is mounted. It has a high melting point and insulating in nature to maintain the preheating of the sensing layer, providing the sensing layer high sensitivity to get efficient output current.

Sensing element protector

A protector made of metal mesh is used to protect the sensing elements and the experimental setup. This also take care of the dust particles that are entering the mesh from the other sources of particles and prevent damage to the gas-sensing layers for moisture and corroding particles [19, 20].

8.4 Working Principle of Gas Sensor

Gas sensors are usually operated with batteries and fabricated as portable or stationary. Initially, gas detectors were fabricated to detect one gas, but nowadays, multifunctional or multi-gas devices that can detect several gases at once are used. The working principle of a gas sensor mainly depends upon the chemi-resister type to conduct current in the system [21].

The most commonly used chemi-resistor is tin oxide. It is an n-type semiconductor having plenty of free electrons. Usually, the atmosphere contains more O2 than other gases (combustible gases). The O2 particles attract toward the free electrons exists in SnO2 molecules which force them to move toward the surface of the SnO2 molecules. As there are no free electrons in the surroundings, so the output current will be zero. Figure 8.2 display the schematic diagram of the interaction of gas molecular with sensing material.

It shows that the interaction of oxygen molecules (green color) with free electrons or donor electrons (brown color) inside the SnO2 molecules [22].

Figure 8.3 displays the schematic diagram of the interaction of combustible gas (reducing gas) with sensing material. As the sensor is placed in combustible gases systems, the reducing gas (black color) reacts to the adsorbed oxygen (green color). It breaks the chemical bond between oxygen and free electrons as a result of releasing the free electrons. They can now conduct current and free electrons are back to their initial point. This suggests that the conduction is directly proportion the concentration of carrier particularly free electrons in SnO2 molecules. If the sensing gas is highly toxic then there will be more number of free electrons [23].

Display the schematic diagram of the interaction of combustible gas (reducing gas) with sensing material [22]

8.5 Nanostructure Materials for Gas Sensors

Nanotechnology is playing a vital role in the development of the high efficacy gas sensor. It has a deep and broad impact on life cycle and production. It is creating new opportunities and challenges in the field of gas sensors due to associated key advantages like larger surface areas, better electron transitions, excellent response time, better selectivity, better performance, etc. Among various nanostructured materials, this chapter is mainly focused on graphene-based nanomaterials having advantages like sizeable conjugated structure, high specific surface area, high conductivity, and ease to synthesize, better sensitivity to gas molecules, etc. Graphene surfaces can quickly absorb molecules as NO2, NH3, CO2, and their conductivity also changes on the adsorption of target gas molecules. But, it has a poor selectivity. It has also been established that a high-performance gas-sensing material and cluster of target gas in the atmosphere can be easily identified by observing the change of conductivity in the sensor [23]. The factors that affect the performance of grapheme-based sensors include synthetic processes, chemical structure, and surface properties like the formation of π-π bonding and van der Waals forces that reduce the specific surface area between graphene and 2D graphene nanocomposites [24]. To develop full use of the significant stuff of graphene, 2D graphene is reorganized into a 3D framework. The main advantage of 3D graphene is that it is not only provides large free space and surface area to transport and store electrons but also provides versatile gas adsorption sites because of its highly ordered 3D porous structure and the internal structure of graphene. The imperfections and edge points on the 3D porous graphene also play a vital role in endorsing gas adsorption. The 3D graphene has excellent conductivity and super-high sensitivity but its selectivity is not good. If associates some 2D graphene structure through 3D porous graphene structures, for example graphene aerogels, graphene hydrogels, and graphene foams, the 3D porous graphene structures exhibit high performance. That is why 3D porous graphene structures are used as high-performance gas sensors. It is mentioned above; graphene has poor selectivity because diverse gas molecules may adsorb the similar 3D graphene sheets and variation their resistance. Therefore, it is challenging to quantitatively segregate individual target gas. To increase the selectivity by defect production techniques such as ion irradiation, high-temperature annealing, or controlled doping is necessary for the modulation of graphene. Recently, many review articles have been published on the progress of graphene-based sensors. A review of the synthesis of the graphene-based system with metal MOx was presented for chemical-resistive gas sensors, and conducting-based polymers as well as their sensing performance [25]. One article summarized the 3D structure graphene/MOx hybrids for sensors and resolved a variety of consistent strategies to plan the 3D nano-hybrids of reduced graphene oxide and metal oxides [25]. However, these reviews have not deliberated graphene for the air contamination monitoring systems. This chapter goes to summarize the recent progress of gas sensors based on 3D graphene structures and 2D materials in the detection of toxic gas or greenhouse gases, fumes (Table 8.1).

8.5.1 Production of 3D Graphene Structures

Graphene is a single sheet of carbon atoms with strong covalent bonds in the middle of each carbon atom. The atoms are arranged in hexagons. GO and rGO have a single-atom thickness in a 2D structure, which is detected by 2D conjugation-based nanosheet. They have ridiculous organic activities suitable for 3D self-assembly from side to side-compound arrangement technique to control the support in the middle of layers. Graphene-based hydrogel is one of the important preparations in this procedure. Graphene-based hydrogels are prepared by GO or rGO paste. It can be used for fabrication on the large scale. The graphene-based hydrogels can be synthesized by the following methods [33]:

-

(a)

Hydrothermal reduction

The hydrothermal reductions method is widely used to prepare reduced graphene oxide dispersion by hydrothermal treatment at elevated temperatures. It induces the self-assembly of GO in a sealed pressurized water container using an autoclave at moderately high temperatures (90–200 °C). It is simple, executable, and free of impurities technique. It is a valuable technique for growing single crystals by arranging for a suitable temperature gradient while preserving their composition. A temperature gradient is maintained between the facing ends of the growth chamber. The solute dissolves at the hotter end, whereas it is inserted on a grain crystal and the desired crystal is grown at the cooler end.

-

(b)

Chemical reduction

The chemical reduction technique is used in research laboratories for the synthesis of nanoparticles. The chemical reduction methods are normally separated keen on two major classes liable on the nature of decreasing agents and their compound reactions apparatuses using graphene oxide. The chemical reduction process is one of the usual procedures to prepare graphene in bulky amounts. In this method, a reduction agent in the form of liquid or gas is added to the GO to eliminate functional groups.

-

(iii)

Electrochemical reduction

The graphene-based hydrogel is ready by this technique. Hydrogel is directly applied to the electrode and also can be put on the tools of the electrochemical devices.

-

(iv)

Vacuum filtration

Graphene-based hydrogels developed by vacuum filtration technique. It developed with higher conductivity, anisotropy of molecules, and quick to respond intoxicant. Figure 8.4 shows the schematic diagram for the synthesis of 3D graphene frameworks.

Reproduced from [22]

Schematic diagram shows the methods for the synthesis of 3D graphene-based frameworks Copyright@2021 MDPI.

In Fig. 8.4, the following process can achieve graphene-based hydrogels:

The preparation of the 3D graphene generally in a carbon-based system can be formed by the thermal solvent process. Highly ordered rGO aerogels can be achieved by freeze-drying and microwave mode processes.

The directional freezing process is a prominent dealing technology of porous materials. We can prepare graphene aerogels with this technology. The controllable heat treatment process can restore the system's conductivity and reduce graphene oxides. The parameter of the compound structure of GO can modify the morphology and bounciness of graphene aerogels. For example, the oxygen functional groups in graphene oxides sensitively affect the morphology and bounciness of the gels [34].

8.5.2 Nanostructure Materials Sensing of Toxic Gases

Nanostructured materials such as graphene oxide, reduced graphene oxide (rGO), SnS2, MoS2, and WO3 are used for the sensing of various gases such as NO2, NH3, and phenol.

8.5.2.1 NO2 Gas Sensors

NO2 gas is a harmful gas for humans and as well as the atmosphere. Several nanomaterials are widely used to build NO2 gas sensors. Graphene and arranged carbon multiple materials provide greater efficiency (i.e., better sensitivity, superior response, and advanced recovery time) for sensing the NO2 gases in comparison with usual carbon nanomaterials. Graphene and slanted carbon materials are vastly sensitive have higher efficiency and also selectivity is good for NO2 gas that is why these materials are widely used to create the sensing setup.

-

(a)

Graphene nanostructures

In a 2D material, graphene exhibits a very high sensitivity for various gases and that makes it a suitable candidate for gas sensors. Latest studies show that 3D graphene structures can not only enhance the gas sensitivity and lower the limit of detection (LOD) from ppm level to more than a few ppb levels but also improve the response and relaxation times nearly 100 ms. 3D graphene aerogel spheres (GASs) are unique, super light, and promising sensing materials for temperature sensing and force sensing. This can be used to fabricate high-performance flexible sensors in healthcare applications. It can able to detect forces at 360° from all directions due to the 3D spherical shape, which demonstrates the proficiency of this material for sensing pressure, material elasticity, and temperature. In lower than 100 ppb, graphene, rGO, and rGOH materials cannot detect the NO2 gas. Therefore, varieties of methods are used to fabricate graphene materials. The response time at a particular temperature and concentration of nitrogen dioxides is reported in the form of rate of change (∆R/R0) or (∆G/G0) [35]. Sensitivity is increased for graphene with a 3D structure. We can improve the LOD of the device from ppm level to some ppb levels by using this material [35]. The development of an extremely selective device for the purpose of NO2 gas sensing with a ppb detection limit. The detection limit is an essential requisite for early analysis of lungs diseases and ceaseless environmental intensive care.

-

(b)

3D MoS2/rGO

2D-layered MoS2 is a very good material for gas detecting due to its great surface-to-volume ratio and outstanding microelectronic material properties. On the other hand, 2D-layered MoS2 has a tendency to collect nanoparticles, which limits its characteristics. Then, MoS2 deposited on 3D graphene could be a well choice to prevent the accumulation of MoS2. The counterpart of MoS2/rGO can be prepared with a self-assembly process and also prepared by the hydrothermal method in any contrast. The minor synthesis procedure can be used to check the uniform distribution of MoS2 on the three-dimensional rGO platform. The accommodation of MoS2 was expressively improved which leads to enhancement in the low-temperature sensing performance [22, 36]. The selectivity of the fabricated graphene-based sensors can be characterized for different gases. This sensing device showed a better response time as compared to other devices. Once the device is open to nitrogen dioxides atmosphere, at that moment the smaller charge carriers (electrons) in the oxides compounds transfer to nitrogen dioxides due to the higher electron negativity of nitrogen dioxides. Accordingly, the dimension of the junction is reduced which leads to a drop in resistivity. jj barrier height and breadth due to gas adsorption can have a major effect on the conductance. The sensing performance of nitrogen dioxide was achieved at 80 °C with a response of 2483% toward a 10 ppm level (Fig. 8.5).

Reproduced from [22]

Fabrication process of 3D MoS2/rGO Copyright@2021 MDPI.

-

(iii)

3D SnS2/rGO nanostructures

There is significant difference in the physical properties of the rGO and SnS2. The indirect bandgap of p-type rGO and n-type SnS2 is 2.2 eV. SnS2 can make a bond to nitrogen dioxides because of its much weaker electro-negativity than NO2. However, because of the very high electric resistance of SnS2, it is not appropriate for detecting nitrogen dioxides at room temperature. That is why arranged 3D SnS2/rGO heterojunction was prepared by the simplistic hydrothermal synthesizes method. Figure 8.6 shows the SEM image of 3D SnS2/rGO, dynamic gas responses of the SnS2/rGO sensor. Now, for minor NO2 molecules, the 3D nanostructure improves the adsorption as well as diffusion ratio, while SnS2 can help the e− relocation from rGO to nitrogen dioxide via developing a heterojunction through rGO. The electron-depletion area and the hole absorption of the p-type rGO have increased produced by the adsorption of NO2 molecules on SnS2 and the transfer of the e− from SnS2 to NO2. Therefore, the SnS2/rGO resistance is decreased.

Reproduced from [22]

a SEM image of 3D SnS2/rGO, b dynamic responses of SnS2/rGO to NO2 Copyright@2021 MDPI.

-

(iv)

3D Porous B- and N-Doped rGOH

Modern studies reported that doping is a possible approach to creating a bandgap under the unchanging adsorption pattern. Several components of graphene can display different gas-detecting performances due to the distance between doped molecules and gas particles and diverse adsorption energy. The most recent article reported that boron and nitrogen doping could increase the selectivity of the graphene-based sensor. As reported earlier, graphene has a 3D porous structure that provides advanced surface area and additional space for the accumulation and transportation of electrons [26]. The porous surface of the B- and N-doped rGOH critically affects the sensing parameters such as recovery time, response times, sensitivity, and selectivity of sensors. It has been also observed that the smaller the particles have the greater the porosity 3D porous B- and N-doped rGOH. The porosity also influences the conductivity of the materials. If the conductivity of the material is less, then there would be a large difference between the conductivity in the body and the surface layer of the particle. Moreover, the deficiencies and boundary locations on the 3D porous graphene also show a dynamic role in supporting gas adsorption. We can use 3D porous graphene structures as high-performance gas sensors. Diverse gas molecules possibly will adsorb in a similar three-dimension graphene area, and due to this resistance, it varies in sensors. Therefore, 3D graphene doped with a suitable impurity is the best configuration for the sensing application. Figure 8.7 shows the fabrication process and doped 3D rGOH sensor. By hydrothermal self-assembly method, we can be synthesized Boron and nitrogen-doped rGOH with the aid of boric acid (H3BO3) and dicyandiamide (C2H4N4). It shows that they can significantly improve the sensing process by the combination of 3D configuration and the doping of boron and nitrogen heteroatoms. NO2 gas is quickly reacted with the combination of B- and N-doped rGOH in comparison to rGOH. rGOH response is lower than one order of magnitude as compared to B- and N-doped rGOH. It is noted that with the concentration of NO2 the response of boron and nitrogen-doped rGOH devices varies very linearly.

Reproduced from [38]

a Fabrication process of B-rGOH sensors Copyright@2021 MDPI.

8.5.2.2 Ammonia Gas Sensors

The (NH3) sensor is important in industries and daily life. But, its complex preparation technique, strict environmental necessity, desorption of remaining NH3 molecules, high manufacturing cost make it struggle the market acceptance. Due to multiple steps of gas adsorption and desorption progressions on the surface of the material, NH3 gas sensor display a slow recovery process and reduces response time in the co-presence of NH3 and ethanol [26]. NH3 gas and NO2 gas are reductive and oxidative gas due to this response of the semi-conductive graphene-based sensors toward NH3 gas is lesser than NO2 gas. For the superior performance detection of ammonia gas and NO2 gas, one article was published a green synthesis process at room temperature for 3D-based functionalized graphene. They determine the LOD is 500 and 100 ppb levels for NH3 and NO2 [37].

-

(a)

3D Graphene for NH3 sensing

Generally, it has been observed that when we improved the sensor at room temperature then the gas molecules cannot be absorbed fully due to reduced stability and poor recovery time. But, using the infrared light source, we can increase the desorption of the ammonia. This is allocated to the formation of charge carriers by captivating infrared light. This can be also done by heating which accelerates the desorption process established on the norm of thermally excited gas particles [38]. Figure 8.8 shows a schematic diagram of the laser direct writing setup, microscopy image of laser-irradiated on Polyimide [26, 39]. On a polyimide(PI) insulating tape to basically build for NH3 gas sensor device, we can use a laser direct writing type pen to make three corresponding porous 3D graphene lines proceeding this. NH3 sensor is sandwiched, and the other margins are used for instance heating systems. Here, we can give voltage toward the heater to decrease absorption.

Reproduced from [22]

a Schematic of laser direct writing, b electron microscopy image of the laser-irradiation polyimide Copyright@2021 MDPI.

-

(b)

MoS2/WO3 Nanosheet for Detection of Ammonia

The MoS2/WO3-based device utilizes a p-MoS2/n-WO3 heterojunction that provides an advanced sensitivity and provides an ultra-selective chemiresistive NH3 gas-sensing device that activates the temperature of 200◦C. This composite sensor has improved NH3 gas-sensing properties significantly compared to the counterparts of WO3 (n-type) and MoS2 (p-type). It displays 70 and 80 s recovery times, respectively, with the comparative response of ammonia are 207% for 200 ppm, respectively (Fig. 8.9).

Reproduced from [38]

Structure of the MoS2/WO3 nanosheet device.

The device as well exhibited excellent features like response-recovery above a wide-ranging of NH3 absorption and superior selectivity toward NH3 than acetone, C2H5OH, CH3OH, isopropanol, HCHO, benzene (C6H6), and hydrogen sulfide [38].

8.5.2.3 Phenol Gas Sensors

Phenol is the usual element of various materials and is common in nature. It is produced through chemical processes at a rate of more than 6 million tons per year in the world and is also existing in naturally animal wastes, coal tar, and creosote. It can be emitted from the combustion of coal oil, natural gas, decomposing plants, and animals, and tobacco, etc. The production and shipping of phenol as per its various uses in the industries may lead to employee contacts to this substance with health hazards. In 2013, one study [39] reported an electrochemical sensor by using accumulated 3D graphene. Limit of detection of the C6H6O sensor well achieved less than 50-ppm value. In 2016, another article reported RGO/MOx p-n heterojunction graphene-based aerogels as effective 3D sensing structures are prepared for phenol exposure [40]. This sensor detects phenol not only at room temperature but also displays a good sensitivity, repeatability, and stable system at room temperature. It shows a linear connection is in the range of 10–80 ppb level. rGO/SnO2 combination aerogel has a considerably advanced sensitivity to phenol as compared to CH3CH2OH, toluene, and methanol.

8.5.3 Conclusions

There are various kinds of toxic pollutants; for example, NO2, NH3, CO, CH2O, and phenol are present in the air. Compared to old metal oxide sensing substrates, graphene-based sensors exhibit superior properties like much lower operating temperature, very high conductance, and low energy consumption. In addition, graphene also has very good mechanical power, a high-temperature resistance value, and stability under harsh environments which can be further improved by the combination of 3D graphene with flexible materials. These properties are very important for the fabrication of wearable good sensors. We can increase the sensitivity of graphene-based sensors as compared to individual organic compounds and semiconductor metal oxides. Indicator transduction of 3D graphene structures is more than higher as compared to the performance of the different types of 2D graphene nanostructure, due to the growth of contact surface area and the total amount of dynamic adsorption surfaces. On the other way, 3D graphene-based sensors have capable of using in harsh atmospheres, have good mechanical strength, good structural properties. 3D porous backgrounds are more advantageous for practical application as compared to the 2D structural characteristics of graphene. Its contexts have more entry space, which is good for the dispersion of gas molecules and adsorption. Overall, the limit of detection has been reached from ppm level to numerous ppb levels, which are very important to the stoppage of poisonous and contaminated harmful air pollutants and greenhouse gases to the environment. However, 3D graphene has limited applications because of its imperfect gas-sensing kinds of materials, and 3D graphene is frequently sensitive to NO2 and NH3 gases. There are lots of scores to improve the adsorption of the gas molecule and desorption of 3D-based graphene for the reduction of the responsivity and sensor recovery times. Finally, at that time, 3D graphene-based devices are static in the platform of the research laboratory for investigation, and extra work is wanted to put onward these improvements to the commercialization platform.

References

C.D. Koolen, G. Rothenberg, Air pollution in Europe. Chemsuschem 12(1), 164–172 (2019)

S. Tong, Air pollution and disease burden. Lancet Planet. Health 3(2), e49–e50 (2019)

P. Ranscombe, Wearable technology for air pollution. Lancet Respir. Med. 7(7), 567–568 (2019)

J. Liu, Mapping high resolution national daily NO2 exposure across mainland China using an ensemble algorithm. Environ. Pollut. 279, 116932 (2021)

S.S. Sinharoy, T. Clasen, R. Martorell, Air pollution and stunting: a missing link? Lancet Glob. Health 8(4), e472–e475 (2020)

C. Chen, W. Li, L. Dong, X. Li, The effect of meteorological factors, seasonal factors and air pollutions on the formation of particulate matter, in IOP Conference Series: Earth and Environmental Science, vol. 450, no. 1 (IOP Publishing, 2020), p. 012012

Y. Zhang, X. Wen, Z. Wen, D. Wang, T. Hao, A. Tang, X. Liu, Atmospheric deposition of inorganic nitrogen in a semi-arid grassland of Inner Mongolia, China. J. Arid. Land 9(6), 810–822 (2017)

D.R. Widiana, Y.-F. Wang, S.-J. You, H.-H. Yang, L.-C. Wang, J.-H. Tsai, H.-M. Chen, Air pollution profiles and health risk assessment of ambient volatile organic compounds above a municipal wastewater treatment plant, Taiwan. Aerosol Air Qual. Res. 19(2), 375–382 (2019)

S. Naseem, A.J. King, Ammonia production in poultry houses can affect health of humans, birds, and the environment-techniques for its reduction during poultry production. Environ. Sci. Pollut. Res. 25(16), 15269–15293 (2018)

National Research Council, Acute exposure guideline levels for selected airborne chemicals: Vol. 3, (2003)

P. Vyas, K. Thakur, Classification and characteristics of sensors. Adv. Modern Sens. 2–1 (2020)

P.K. Kulriya, M. Kumar, J. Singh, D.K. Avasthi, Hydrogen pressure dependent in-situ electrical studies on Pd/C nano-composite. Int. J. Hydrogen Energy 42(5), 3399–3406 (2017)

V. Singh, B.R. Mehta, S.K. Sengar, P.K. Kulriya, S.A. Khan, S.M. Shivaprasad, Enhanced hydrogenation properties of size selected Pd–C core–shell nanoparticles; effect of carbon shell thickness. J. Phys. Chem. C 119(25), 14455–14460 (2015)

E. Bakker, M. Telting-Diaz, Electrochemical sensors. Anal. Chem. 74(12), 2781–2800 (2002)

C.-H. Han, D.-W. Hong, S.-D. Han, J. Gwak, K.C. Singh, Catalytic combustion type hydrogen gas sensor using TiO2 and UV-LED. Sens. Actuators, B Chem. 125(1), 224–228 (2007)

D. Rossberg, Optical properties of the integrated infrared sensor. Sens. Actuators, A 54(1–3), 793–797 (1996)

R. Flooding, Identification of sub resolution high temperature sources using a thermal IR sensor. Photogram. Eng. Remote Sens 9 (1981)

G. Korotcenkov, Handbook of gas sensor materials. Conventional Approaches 1 (2013)

L. Ge, X. Mu, G. Tian, Q. Huang, J. Ahmed, Z. Hu, Current applications of gas sensor based on 2-D nanomaterial: a mini review. Front. Chem. 839 (2019)

J. Cervera Gómez, J. Pelegri-Sebastia, R. Lajara, Circuit topologies for MOS-type gas sensor. Electronics 9(3), 525 (2020)

S. Yang, C. Jiang, S.-H. Wei, Gas sensing in 2D materials. Appl. Phys. Rev. 4(2), 021304 (2017)

Q. Dong, M. Xiao, Z. Chu, G. Li, Y. Zhang, Recent progress of toxic gas sensors based on 3d graphene frameworks. Sensors 21(10), 3386 (2021)

S. Ranwa, P.K. Kulriya, V.K. Sahu, L.M. Kukreja, M. Kumar, Defect-free ZnO nanorods for low temperature hydrogen sensor applications. Appl. Phys. Lett. 105(21), 213103 (2014)

S.S. Varghese, S. Lonkar, K.K. Singh, S. Swaminathan, A. Abdala, Recent advances in graphene based gas sensors. Sens. Actuators, B Chem. 218,160–183 (2015)

C. Yu, Q. Liu, Z. He, X. Gao, W. Enxiu, J. Guo, C. Zhou, Z. Feng, Epitaxial graphene gas sensors on SiC substrate with high sensitivity. J. Semicond. 41(3), 032101 (2020)

X. Li, X. Li, Z. Li, J. Wang, J. Zhang, WS2 nanoflakes based selective ammonia sensors at room temperature. Sens. Actuators, B Chem. 240, 273–277 (2017)

D. Gu, X. Li, H. Wang, M. Li, Y. Xi, Y. Chen, J. Wang, M.N. Rumyntseva, A.M. Gaskov, Light enhanced VOCs sensing of WS2 microflakes based chemiresistive sensors powered by triboelectronic nangenerators. Sens. Actuators, B Chem. 256, 992–1000 (2018)

D.J. Late, T. Doneux, M. Bougouma, Single-layer MoSe2 based NH3 gas sensor. Appl. Phys. Lett. 105(23), 233103 (2014)

, S. Singh, S. Sharma, R.C. Singh, S. Sharma, Hydrothermally synthesized MoS2-multi-walled carbon nanotube composite as a novel room-temperature ammonia sensing platform. Appl. Surface Sci. 532, 147373 (2020)

B. Cho, J. Yoon, S.K. Lim, A.R. Kim, D.-H. Kim, S.-G. Park, J.-D. Kwon, et al., Chemical sensing of 2D graphene/MoS2 heterostructure device. ACS Appl. Mater. Interfaces 7(30), 16775–16780 (2015)

K. Lee, R. Gatensby, N. McEvoy, T. Hallam, G.S. Duesberg, High-performance sensors based on molybdenum disulfide thin films. Adv. Mater. 25(46), 6699–6702 (2013)

D.J. Late, Y.-K. Huang, B. Liu, J. Acharya, S.N. Shirodkar, J. Luo, A. Yan, et al., Sensing behavior of atomically thin-layered MoS2 transistors. ACS nano 7(6), 4879–4891 (2013)

J. Wu, K. Tao, Y. Guo, Z. Li, X. Wang, Z. Luo, S. Feng, et al., A 3D chemically modified graphene hydrogel for fast, highly sensitive, and selective gas sensor. Adv. Sci. 4(3), 1600319 (2017)

L. Li, S. He, M. Liu, C. Zhang, W. Chen, Three-dimensional mesoporous graphene aerogel-supported SnO2 nanocrystals for high-performance NO2 gas sensing at low temperature. Anal. Chem. 87(3), 1638–1645 (2015)

J. Wu, W. Zixuan, H. Ding, Y. Wei, W. Huang, X. Yang, Z. Li, L. Qiu, X. Wang, Three-dimensional graphene hydrogel decorated with SnO2 for high-performance NO2 sensing with enhanced immunity to humidity. ACS Appl. Mater. Interfaces. 12(2), 2634–2643 (2020)

C. Tyagi, P.K. Kulriya, S. Ojha, D.K. Avasthi, A. Tripathi, Investigation of graphene oxide-hydrogen interaction using in-situ X-ray diffraction studies. Int. J. Hydrogen Energy 43(29), 13339–13347 (2018)

F.-L. Meng, Z. Guo, X.-J. Huang, Graphene-based hybrids for chemiresistive gas sensors. TrAC Trends Anal. Chem. 68, 37–47 (2015)

S. Singh, J. Deb, U. Sarkar, S. Sharma, MoS2/WO3 nanosheets for detection of ammonia. ACS Appl. Nano Mater. 4(3), 2594–2605 (2021)

G. Busca, S. Berardinelli, C. Resini, L. Arrighi, Technologies for the removal of phenol from fluid streams: a short review of recent developments. J. Hazard. Mater. 160(2–3), 265–288 (2008)

J. Gao, M. Liu, H. Song, S. Zhang, Y. Qian, A. Li, Highly-sensitive electrocatalytic determination for toxic phenols based on coupled cMWCNT/cyclodextrin edge-functionalized graphene composite. J. Hazard. Mater. 318, 99–108 (2016)

Acknowledgements

One of the authors Ankita Rawat is thankful to CSIR for awarding Junior Research Fellowship with file no. 09/263(1233)/2020-EMR-l.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Rawat, A., Kulriya, P.K. (2022). 2D/3D Material for Gas Sensor. In: Sonker, R.K., Singh, K., Sonkawade, R. (eds) Smart Nanostructure Materials and Sensor Technology. Springer, Singapore. https://doi.org/10.1007/978-981-19-2685-3_8

Download citation

DOI: https://doi.org/10.1007/978-981-19-2685-3_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-2684-6

Online ISBN: 978-981-19-2685-3

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)