Abstract

Compared with CO2 miscible flooding, near miscible flooding reduces the requirements of crude oil quality and reservoir pressure, CO2 source purity, and reduces the operation cost, which attracts more and more attention. High content CO2 (24%–90%) gas reservoir was found in an offshore x oilfield. It is difficult to realize miscible flooding by reinjection gas of high CO2 content, so it is necessary to evaluate the feasibility of near miscible flooding. This paper summarizes the main displacement mechanism of CO2 flooding, analyzes the main controlling factors of miscibility degree, and establishes an empirical formula suitable for impure CO2 near miscible displacement pressure, which can quickly evaluate the feasibility of pure/impure CO2 near miscible displacement for low permeability reservoirs. The results show that the purity of CO2 near miscible flooding is more than 64%, and the feasibility is very high by near miscible flooding. The research results provide technical basis for the feasibility and rapid evaluation of low permeability reservoir.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The natural gas with high CO2 content and industrial waste gas in offshore oilfield provide sufficient gas source for CO2 flooding. However, the existence of impurity gas aggravates the difficulty to realize miscible flooding. It is urgent to study the feasibility of CO2 near miscible flooding technology to provide theoretical and technical basis for its application. Shyeh Yung (1995) [1], Crigg (1997) [2], Schechter (1998) [3] and Dong (2000) [4] have confirmed that the near miscible region is the transition region between the miscible and immiscible zone, which is described as a region close to but lower than minimum miscible pressure( MMP). With the decrease of injection pressure, the oil recovery of this area does not decrease as obviously as that of slim-tube experiment. Li Yang [5] put forward the theory of incomplete miscible flooding based on miscibility degree, which reflects the actual process of CO2 flooding in low permeability reservoir. The degree of oil-gas miscibility is mainly related to oil-gas system, and depends on reservoir temperature, the composition of crude oil and injected gas [6]. For a specific reservoir, the temperature changes little, so the miscibility is mainly affected by the composition of crude oil and injected gas. Foreign scholars mainly use empirical formula method and numerical simulation to calculate the MMP, Rathmell [7] thought that MMP is related to volatile components and intermediate components in crude oil. Alston and others [8] found that it has a greater impact on the MMP when the content difference between volatile components and intermediate components is large. Yelling and Metcalfe [9] found that the change of gas oil ratio in saturated reservoir would lead to the change of MMP. Dong [10] and others systematically summarized the mixing mechanism of CO2 crude oil system, and considered that the content of dissolved gas and the ratio of light hydrocarbon to intermediate hydrocarbon are two important parameters affecting the value of MMP.

According to the characteristics of oil and fluid components in X oilfield, based on a large number of experiments and application data at home and abroad, this paper summarizes the CO2 miscible/near miscible displacement mechanism, and analyzes the main control factors affecting the miscibility degree. A new empirical formula for predicting miscible/near miscible pressure of impure CO2 is established by multivariate nonlinear fitting with the molar content of each component of impure CO2, C1 content of oil component and formation temperature as parameters.

2 Mechanism of Enhanced Oil Recovery by CO2 Flooding

2.1 Reduction the Viscosity of Crude Oil

When CO2 is dissolved in crude oil, the viscosity of crude oil decreases significantly, and the decreasing range depends on the pressure, temperature and the viscosity of no carbonic acid crude oil. Generally speaking, the higher the viscosity of crude oil, the higher the percentage of viscosity reduction under the action of carbonic acid.

2.2 Extraction and Vaporization of Light Hydrocarbons in Crude Oil

When the pressure exceeds a certain value, CO2 mixture can extract and vaporize light hydrocarbons of different components in crude oil. CO2 first extracts and vaporizes light hydrocarbons in crude oil, then vaporizes heavier hydrocarbons, and finally reaches stability. Extraction and vaporization are important mechanisms of CO2 flooding.

2.3 Expansion of Crude Oil Volume

A certain volume of CO2 dissolved in crude oil can increase the volume of crude oil by 10%–100% with difference of pressure, temperature and composition of crude oil. The dissolves CO2 in crude oil expands the volume of crude oil and increases the kinetic energy in the fluid, so as to improve the oil displacement efficiency.

2.4 Improvement Mobility Ratio

A large amount of CO2 dissolved in crude oil and water will acidify the crude oil and water. The viscosity of crude oil decreases after carbonation. Since the mobility of oil and water tends to be close after carbonation, it can improve the mobility ratio of oil and water and expand the swept volume.

2.5 Reduction the Interfacial Tension

The oil-water interfacial tension (IFT) of most reservoirs is 10–20 mN/m. In order to make the residual oil saturation close to zero, the oil-water interfacial tension must be reduced to 0.001 mn/m or lower, and the oil recovery will be significantly improved if the interfacial tension is reduced to below 0.04 mN/m. The main function of CO2 flooding is to extract and vaporize light hydrocarbons in crude oil. A large number of light hydrocarbons mixed with CO2 can greatly reduce the oil-water interfacial tension, reduce the residual oil saturation, and improve the crude oil recovery.

2.6 Function of Dissolved Gas Flooding

When a large amount of CO2 is dissolved in crude oil, it has the effect of dissolved gas drive. With the decrease of pressure, CO2 escapes from the liquid, and gas driving force is generated in the liquid, which improves the displacement effect. In addition, some CO2 displaces crude oil and occupies a certain pore space to become bound gas, which can also increase crude oil production.

3 Influence Factors of Near Miscibility of Impure CO2

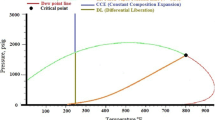

Previous studies have shown that MMP mainly depends on the purity of CO2, crude oil composition and reservoir temperature [11, 12]. MMP increases with the rise of reservoir temperature and the relative molecular weight of components of C5+. If the critical temperature of impurities is lower than that of CO2, MMP decreases; otherwise, MMP increases. Through statistical analysis of a large number of slim-tube experimental data, the main controlling factors of MMP are analyzed with the help of the empirical formula established by yuan [6]. Reservoir temperature, volatile component content and C7+ molar mass are positive correlation variables with the value of MMP, MMP increases with the increase of these three parameters, in turn, the influence degree decreases. C2–C4 and C5–C6 are negative correlation variables, and the miscibility degree increases with the increase of above parameters. It is obvious that reservoir temperature is the primary influencing factor of miscibility and near miscibility, followed by volatile component content and C7+ molar mass, which are positive correlation variables of MMP and MNMP; while C2–C4 and C5–C6 content in crude oil are negative correlation variables, and miscibility increases with the increase of content (Fig. 1).

4 Prediction of Near Miscible Pressure of Impure CO2

4.1 Existing Empirical Formula

The empirical formula is not as accurate as the slim-tube experiment and the slim-tube simulation, but it is simple and convenient, so it is widely studied to calculate the MMP by foreign scholars. Based on the existing empirical formula [6, 11,12,13], the pure CO2 and impure CO2 flooding pressures of the target reservoir were calculated and compared with the results of thin tube experiment. The results were shown in Table 1 and 2. It can be seen from Table 1 that the empirical formula error of Lee (1979), Orr (1986) and Yuan (2004) methods is less than 10% compared with the slim-tube experiment. Considering the wide range of impurity gas content, Glaso (1985) is not suitable, and Yuan (2004) is used to calculate MMP of impure CO2 flooding, but the error is more than 15%.

4.2 New Empirical Formula of MMP

Based on a large number of slim-tube experimental data in domestic and foreign literatures, the empirical formula of MMP for pure/impure CO2 flooding is established.

-

(1)

Empirical formula of pure CO2.

When the injected gas is pure CO2, the formation temperature, the molar content of (C2–C4), the molar content of (C5–C6) and the average molar mass of C7+ are taken as independent variables, MMP is taken as dependent variable, and the linear regression is carried out by the regress function:

where, TR, reservoir temperature,℃; Mwc7+, molar mass of C7+ in crude oil, g/mol; Xc1, molar content of C1 + N2 in crude oil, mol%; Xc2–c4, mole content of C2–C4 in crude oil; Xc5–c6,mole content of C5–C6 in crude oil, mol%.

All the data points of the slim-tube experiment under pure CO2 condition are within 10% of the error of the fitting formula, and the fitting effect is good.

-

(2)

Empirical formula of impure CO2.

Since the impurity gases contained in the injection gas are generally N2, H2S, C1, C2–C6, the impurity gases should be considered in the empirical formula fitting process of impure CO2. In addition, the influence of C1 content in injected gas on MMP is closely related to the existing C1 content in crude oil. Taking the MMP difference of under the condition of impure CO2 and under the condition of pure CO2 as the dependent variable, taking the molar content of each component of impurity gas, C1 content of oil component and reservoir temperature as the parameter variables, the multivariate nonlinear fitting is carried out, and the empirical formula of MMP for impure CO2 flooding is established.

where, MMPIMP,minimum miscible pressure with impure CO2, MPa; Xinjc1, molar content of C1 in the injection gas, mol%; XinjN2, molar content of N2 in injection gas, mol%;; XinjH2S,mole content of H2S in injection gas, mol%; Xinjc2–c6, mole content of C2–C6 in injection gas, mol%; Vol, mole content of C1 and N2 in formation oil, mol%.

Based on the data points of thin tube experiment, the error of the new empirical formula of MMP for impure CO2 flooding is less than 10%, as shown in Fig. 2. Taking the target reservoir E-5 (3303–3330 m) as an example, the newly established pure/impure CO2 flooding empirical formula is used to calculate the MMP. Compared with the results of thin tube experiment/numerical simulation, the relative error is less than 7%, and the calculation accuracy is higher, as shown in Table 3.

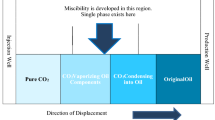

4.3 Near Miscible Pressure of Impure CO2

Using reference [14] to determine the upper and lower limits of near miscible pressure region, and comparing with the method of slim-tube to determine MMP, the relationship between the low and up limit of near miscible pressure (MNMP) is obtained under different CO2 purity, as shown in Table 4 and Fig. 3. Compared with the experimental results, the relative error of the new formula is less than 7%. With the decrease of CO2 purity, both MMP and MNMP increase linearly. By comparing with formation pressure, it can be concluded that the CO2 purity range corresponding to near miscible flooding in E5 well is 64%–100%, which indicates that the potential space of impure CO2 near miscible flooding in the target reservoir is relatively large.

5 Development Effect of Different Miscibility Degree

A three-dimensional reservoir model was built by Eclipse software by the target reservoir characteristics. The grid is divided into 20 × 20 × 3, the grid size is 10 × 10 × 1 m. The reservoir pressure is 33 MPa and oil saturation is 60%. The injection wells and production wells are located at two opposite corners of the model respectively. The change of oil saturation at the same time of gas flooding was calculated by numerical simulation under different CO2 purity, as shown in Fig. 4. CO2 purity of 40% represents immiscible flooding, CO2 purity of 80% represents near miscible flooding, and CO2 purity of 100% represents miscible flooding. It can be seen that the sweep range and displacement efficiency of CO2 near miscible flooding are closer to miscible flooding. The cumulative recovery of immiscible flooding, near miscible flooding and miscible flooding was 42.27%, 54.8% and 58.68% respectively. The recovery degree of near miscible flooding is 1.29 times of that of immiscible flooding, which is only 3.88% lower than that of miscible flooding, it indicates that the development effect of CO2 near miscible flooding is closer to that of miscible flooding. Considering the difficulty and cost of CO2 separation and purification, and miscible flooding is very limited to improve oil recovery, so the feasibility is very high by near miscible flooding with 80% CO2 purity.

6 Conclusions and Suggestions

-

1)

The main influencing factors of miscibility degree of CO2 flooding is as flowing: reservoir temperature, C7+ mole fraction in crude oil, content of volatile components (CH4 + N2), (C2–C4) and (C5–C6), content of CH4, N2, H2S and intermediate components (C2–C6) in injected gas.

-

2)

An empirical formula for calculating the pressure region of pure/impure CO2 miscible flooding is established. The relative error is less than 10%, which can quickly evaluate the feasibility of impure CO2 near miscible flooding in low permeability reservoirs.

-

3)

The lower limit of CO2 purity of near miscible flooding is more than 64%, the recovery degree of near miscible flooding is 1.29 times of that of immiscible flooding, which is only 3.88% lower than that of miscible flooding, the feasibility is very high by near miscible flooding.

-

4)

The implementation of near miscible flooding not only reduces the pressure requirements, but also relaxes the requirements of gas source purity, and reduces the operation cost, which is conducive to promoting the implementation of CO2 near miscible flooding technology.

References

Shyeh-Yung, J.J.: Effect of injectant composition and pressure on displacement of oil by enriched hydrocarbon gases. SPE Reserv. Eng. 10(2), 109–115 (1995)

Grigg, R.B., Gregory, M.D., Purkaple, J.D.: The effect of pressure on improved oilflood recovery from tertiary gas injection. SPE Reserv. Eng. 12(3), 179–188 (1997)

Schechter, D.S., Grigg, R., Guo, B., et al.: Wellman unit CO2 flood: Reservoir pressure reduction and flooding the water/oil. In: Proceedings of the SPE Annual Technical Conference and Exhibition. Society of Petroleum Engineers (1998)

Dong, M., Huang, S., Srivastava, R.: Effect of solution gas in oil on CO2 minimum miscibility pressure. J. Can. Pet. Technol. 39(11), 87–91 (2000)

Li, Y.: Technical advancement and prospect for CO2 flooding enhanced oil recovery in low permeability reservoirs. Pet. Geol. Recovery Effi. 29(1), 1–10 (2020)

Yuan, H., Johns, R.T., Egwuenu, A.M., et al.: Improved MMP correlations for CO2 floods using analytical gas flooding theory. SPE Reservoir Eval. Eng. 8(5), 6–18 (2004)

Rathmell, J.J., Stalkup, F.I., Hassinger, R.C.: A laboratory investigation of miscible displacement by carbon dioxide. Fall Meeting of the Society of Petroleum Engineers of AIME. Society of Petroleum Engineers (1971)

Alston, R.B., Kokolis, G.P., James, C.F.: CO2 minimum miscibility pressures: A correlation for impure CO2 streams and live oil systems. SPE J. (4), 268–274 (1985). SPE-11959-PA

Yellig, W.F., Metcalfe, R.S.: Determination and prediction of CO2 minimum miscibility pressures. J. Petrol. Technol. 32(01), 160–168 (1980)

Dong, M., Huang, S.S., Srivastava, R.: A laboratory study on near-miscible CO2 injection in steelman reservoir. J. Can. Pet. Technol. 40(2), 53–60 (2001)

Bon, J., Sarma, H.K.: Investigation of the effect of injection gas composition on CO2-rich flooding and its implications in an onshore Australia oilfield. Can. Int. Pet. Conf. Petroleum Society of Canada (2009)

Glaso, O.: Generalized minimum miscibility pressure correlation. SPE J. 25(6), 927–934 (1985)

Yellig, W.F., Metcalf, R.S.: Determination and prediction of CO2 minimum miscibility pressures. J. Pet. Tech. 32(1), 160–168 (1980)

Zhang, X., Chen, H., Li, B.: Discussion on controlling conditions of optimal near miscible flooding by impure CO2 in low permeability reservoir. China Offshore Oil and Gas 29(6), 75–77 (2017)

Acknowledgments

The research was financially supported by Open Foundation of State Key Laboratory of Offshore Oil Exploitation 2015-YXKJ-001).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Zhang, Xs., Li, Bz. (2022). Influencing Factors of Impure CO2 Near Miscible Flooding and Its Feasibility Evaluation. In: Lin, J. (eds) Proceedings of the International Field Exploration and Development Conference 2021. IFEDC 2021. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-2149-0_99

Download citation

DOI: https://doi.org/10.1007/978-981-19-2149-0_99

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-2148-3

Online ISBN: 978-981-19-2149-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)