Abstract

Citrus mildew can lead to significant economic losses for both farmers and fruit processing companies. Compared with conventional cold storage and chemical preservation techniques, little is known about using low-temperature plasma technology to preserve navel oranges. In this study, Gannan navel oranges were studied, while pathogenic mold spores were collected from moldy Newhall oranges. The pathogenic spores were treated with argon, helium, and oxygen for 10 min and 20 min. Trypan blue staining demonstrated that only the low-temperature plasma produced by oxygen ionization effectively killed the pathogenic spores, while the spore death rate after 4 min and 2 min of treatment was nearly 100% and the spore death rate after 1 min treatment was 80.5 ± 5.5%. The mildew activity of pathogenic spores was significantly inhibited across several treatment times. There was no difference in phenotype and quality between the treated fruit and the control. Our experimental results demonstrate that low-temperature plasma with oxygen can be used to preserve navel oranges, kill mildew, significantly reduce the fruit mildewing probability during storage, and avoid significant economic losses.

Y. Sun, Y. X. Wang and Y. Xu—Co-first authors.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In recent years, the consumption of fruits and vegetables, which are rich in healthy nutrients, has increased. China currently has the largest planting area and overall production of fruits and vegetables in the world. However, the post-harvest loss of fruits and vegetables is ~30% and is only ~5% in developed countries. China’s annual post-harvest loss of fruits and vegetables is approximately 100 million tons, and causing ~100 billion economic losses. The loss of fruits and vegetables is primarily caused by improper harvesting, rudimentary post-harvest preservation technology, and inadequate storage conditions. Presently, low-temperature storage and chemical antibacterial agents are mainly used to preserve fruits and vegetables. Low-temperature storage modifies the atmosphere of the storage room by changing the gas composition. This method is durable, has low loss rates, and is safe, making it the primary method of storing fruits and vegetables in developed countries. As such, researching the biological effects of physical technology will aid a green preservation technology with no residue, high sterilization efficiency, and no side effects.

Plasma is a mixture of ionized gas molecules that are commonly recognized as matter’s “fourth state”. The temperature of ionized heavy particles is very low, meaning this mixture is in a low-temperature state. This is known as low-temperature plasma or non-equilibrium plasma. Ionized gas contains active particles such as ions, electrons, excited atoms, molecules, and free radicals, and low-temperature plasma technology has been used in material preparation and surface modification [1,2,3], chemical catalysis [4], toxic chemical removal [5,6,7,8], chemical analysis and detection [9, 10], biomedicine [11,12,13], and seed germination and growth [14,15,16]. Low-temperature plasma can also be used for non-thermophysical sterilization, due to its high sterilization efficiency, short action time, environmental benefits, and lack of pollution. It has been used to research the preservation of fruits, vegetables, and meat [17,18,19,20].

Citrus planting has become the largest fruit industry in China, and citrus consumption accounts for approximately 16% of China’s total fruit production and 27.4% of the world’s total citrus production. The cultivation of Gannan navel oranges is a high-quality industry located in southern Jiangxi province. It involves large-scale planting and production, giving rise to problems associated with fruit mildew and decay during the low-temperature and chemical preservation of navel oranges. This study primarily explores how low-temperature plasma technology affects the preservation of navel oranges and found that the low-temperature plasma produced by oxygen ionization can kill the pathogenic spores of fruit mildew in a few minutes. We observed significant reductions in the mildewing activity of pathogenic spores on inoculated fruit, and the low-temperature plasma did not affect the appearance or quality of the fruit. This indicates that citrus harvesting and processing enterprises can use low-temperature plasma technology to preserve citrus fruits during their cleaning, sorting, and storage processes.

2 Materials and Methods

2.1 Generation of Low-Temperature Plasma

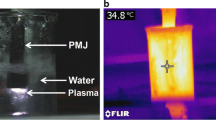

A high-frequency power supply (CTP-2000K) was used to generate low-temperature plasma. Its frequency stabilized at 8.87 kHz, and the input voltage was adjusted at 50 V. An axial flow discharge device was used, which had a total length of 20 cm. The upper end was sealed, the side end was an air inlet, and the plasma was collected at the tail end (Fig. 1). Figure 1A displays the schematic diagram and Fig. 1B displays the physical diagram. The discharge mode was set to dielectric barrier discharge (DBD). The periphery of the copper rod electrode (outer diameter 5.8 mm) was wrapped by a quartz tube (outer diameter 38 mm) to serve as a barrier medium, and the discharge gap was 5 mm wide. Helium, argon, and oxygen were used as gasses, and the inlet flow rate was 1 L/min. The discharge parameters were primarily measured using a digital oscilloscope (Tektronix TDS2012), which includes two channels. One channel was connected with a 1:1000 AC voltage probe (Tektronix P6015A) and was used to measure discharge voltage, while the second channel was connected to an AC current probe (Tektronix P6021) and was used to measure the real-time status of the output current.

2.2 Collection of Pathogenic Spores of Fruit Mildew and Microscopic Observation

Moldy Citrus sinensis Osbeck Newhall oranges, was stored under cold conditions at 4 ℃. The moldy pathogen spore powder on the fruit surface was collected and transferred into a sterilized 200 mL reagent bottle. 1.0 g of spore powder was then weighed on the analytical balance, 400 mL sterile water was stirred in, and the suspension mixture was filtered into a 50 mL centrifuge tube with gauze. 10 μL of the spore suspension was drawn onto a blood cell counting plate, where the morphology and quantity of pathogenic spores were observed with a microscope (Leica DM4 B). This prepared pathogen spore suspension was used in subsequent experiments analyzing low-temperature plasma treatments.

2.3 Low-Temperature Plasma Treatment and Pathogenic Spore Staining

The low-temperature plasma produced by the ionization of argon, helium, and oxygen was introduced into the pathogenic spore suspension from the tail outlet. The low-temperature plasma produced by the different gasses were treated at 1 min, 2 min, 4 min, 10 min, and 20 min. 1mL of the treated pathogen spore suspension was added to a 1.5 mL centrifuge tube, and 2 drops of 0.4% trypan blue staining solution were added. After staining for 2 min, 10 μL was placed on the blood cell counting plate, after which the morphology and staining color of the pathogenic spores were observed using a microscope (Leica DM4 B). The dead cells were dyed blue using a trypan blue staining solution, while the living cells were not stained.

2.4 Identification of Mildewing Activity of Pathogenic Spores

The pathogen spore suspension was treated with low-temperature plasma, which was generated by oxygen ionization, for 1 min, 2 min, and 4 min. The fruit was then inoculated with this solution, on its surface, using an in vivo drilling method. The untreated pathogen spore suspension and sterile water were used as positive and negative controls, respectively. The mildewing phenotype of the treated and untreated pathogenic spores and sterile water was observed after 3 days of inoculation at room temperature (28 ℃).

2.5 Determination of Fruit Quality

Citrus sinensis Osbeck Newhall was treated with a low-temperature plasma produced by oxygen ionization. Six fruits were selected from the treated and untreated groups to determine their quality. The peel brightness value, L, and the color indexes, a and b, were measured using a color difference instrument (Lovibond RT500). The six fruits were then juiced, while the TSS (Total soluble solids) in the fruits was determined by ATAGO PAL-1 digital display refractometer and the TA (Titratable acids) was determined by an ATAGO PAL-Easy ACID1 citrus acidity tester. Three replicates were performed for each experiment.

3 Results

3.1 Lethal Effect of Low-Temperature Plasma Produced by Different Gases on Pathogenic Spores of Navel Orange Mildew

The production of Gannan navel oranges is a high-quality industry based in the south of Jiangxi province. As the planting area of Gannan navel oranges expands, mildew and decay during the storage process becomes an issue (Fig. 2A, B), particularly when the oranges are subjected to extreme weather and there is a surplus of oranges after harvest. This makes timely harvesting and the proper storage of navel oranges particularly important. As such, we selected mildewed Newhall oranges that were stored at 4 ℃ (Fig. 2C), collected the mildewed pathogen spore powder from the fruit surface, suspended it in sterile water, and filtered it into a spore suspension with gauze. The morphology of the pathogen spores on the navel oranges can be observed with a blood cell counting plate and a microscope (Leica DM4 B), where its cell wall structure can be seen (Fig. 2D).

The pathogen spore suspension was treated with low-temperature plasma produced by the ionization of argon (Ar), helium (He), and oxygen (O2) for 10 min and 20 min, after which the pathogen spore suspension was identified using a trypan blue staining solution. The low-temperature plasma produced by the ionization of argon and helium was not lethal to pathogenic spores. The cell wall of the pathogenic spores was wathet blue, but the interior of pathogenic spore cells was colorless (Fig. 3A–D). The low-temperature plasma produced by oxygen ionization killed all pathogenic spores, while the interior of the pathogenic spore cells was dyed blue with a trypan blue staining solution (Fig. 3E, F).

We further explored the fungicidal effect of low-temperature plasma produced by oxygen ionization by shortening the treatment time to 1 min, 2 min, and 4 min. During these treatments, the lethal effect of low-temperature plasma produced by oxygen ionization on pathogenic spores became apparent (Fig. 4). The spore lethal rate of 4 min (Fig. 4D, H) and 2 min (Fig. 4C, G) treatments approached 100%, while the spore lethal efficiency of the 1 min treatment was 80.5 ± 5.5% (Fig. 4B, F). Figure 4A and E display untreated controls. Our results demonstrate that the low-temperature plasma produced by oxygen ionization can be used to green preservation of navel oranges.

3.2 Low-Temperature Plasma Inhibits Activity of Pathogenic Spores of Fruit Mildew

Pathogenic spores can be effectively killed by low-temperature plasma in vitro, though further research is needed to identify the in vivo effect that reduces the mildewing activity of pathogenic spores in navel oranges. The mildewing phenotype of pathogenic spores at the Newhall orange inoculation sites was less than the control 3 days after it was inoculated with a pathogenic spore suspension by low-temperature plasma treatment (Fig. 5). The first row of holes was inoculated with sterile water (negative control) and had no mildewing phenotype. The second row was inoculated with untreated pathogenic spores (positive control), and mold circles quickly grew 3 days after inoculation. The third row was inoculated with the spore suspension after 1 min, 2 min, or 4 min of low-temperature plasma treatment. We found that the mildewing activity of pathogenic spores was inhibited after 1 min of low-temperature plasma treatment, and that longer treatments more effectively inhibited the mildewing activity of pathogenic spores (Fig. 5B).

3.3 Physical Characteristics of Low-Temperature Plasma Produced by Oxygen Ionization

The biological effects of low-temperature plasma are due to an abundance of active particles, including ions, electrons, excited atoms and molecules, and free radicals. The preservation and sterilization effect of low-temperature plasma is primarily due to differences in superoxide ion components produced by the ionization of different gases. Optical Emission Spectra (Taiwan Ultramicro Optics Co., Ltd, SE2030-025-FUV2A) was used to identify the primary effective components of low-temperature plasma produced by oxygen ionization. The emission spectra are concentrated at 282 nm, 309 nm, and 738 nm, which represent ·OH and excited Oxygen atoms. Therefore, the superoxide ion component contributes to the fungicidal effect of low-temperature plasma.

4 Conclusion and Discussion

This study explores how low-temperature plasma technology can be used to preserve navel oranges. Our results demonstrated that the low-temperature plasma produced by oxygen ionization can quickly and effectively kill the pathogenic spores of mildew on navel oranges (1 min–4 min) Our follow-up study found that after one month of low-temperature plasma treatment, there was no significant difference in the appearance phenotype and internal quality (total soluble solids and titratable acid) of untreated and treated navel oranges (Table 1). This indicates that this technology has no side effects on either fruit appearance or quality.

Previous studies have also reported that low-temperature plasma technology has no side effects and can improve food quality. For example, there is no significant difference in surface color and internal anthocyanin content between grapes treated with low-temperature plasma and the control [21]. Low-temperature plasma can improve the eating quality of brown rice [22], improve the storage quality of fresh-cut broccoli [18], maintain the vitamin C content of strawberries [20], and maintain the color of beef and fish [19,20,21,22,23]. As such, low-temperature plasma technology is a safe method of preserving food that maintains quality.

The active components of low-temperature plasma exhibit a fungicidal effect [24], a biological effect that primarily depends on the superoxide components produced by gas ionization [21,22,23,24,25]. The lethal effects of low-temperature plasma produced by air ionization on Escherichia coli are due to changes in cell membrane permeability caused by the electric field of charged particles on the surface of bacteria. This results in cytoplasmic overflow and cell death. Moreover, the low-temperature plasma produced by argon and nitrogen has no fungicidal effect on Escherichia coli, which is consistent with the results of this study. The lethal effect of low-temperature plasma produced by oxygen ionization is closely related to ·OH and excited oxygen atoms (Fig. 6). Therefore, improving the yield of specific functional components is needed to advance green preservation technologies. For example, the combination of low-temperature plasma technology and catalytic technology can accelerate the reaction rate and improve the selectivity and energy utilization of the products [26]. The effects of factors associated with functional components, including the discharge electrode area, peak, and peak discharge voltage, gas type, and volume flow rate, also require further study [27], as does changing the ionization mode and materials to produce low-temperature plasma in mild environments [28]. Therefore, research on the biological effects and mechanism of low-temperature plasma and improvements in related physical materials and equipment will increase the future use of low-temperature plasma technology in agriculture.

References

Shi, Y., Hu, G.J., Wu, M.J., Li, F.: Applications of low temperature plasma for the materials in Li-ion batteries. Chem. J. Chin. Univ. 42(5), 1315–1330 (2021). (in Chinese)

Yang, D., Liu, L.Y., Li, T., Hang, Y.L., Bai, J.N.: Analyses on the properties of knitted tube reinforced PVDF hollow fiber membrane with low temperature plasma pretreatment. Adv. Text. Technol. 29(3), 16–22 (2021). (in Chinese)

Li, J.L., et al.: Surface modification of TC4Ti-Alloy by acid/plasma etching and by low temperature plasma nitriding. Chin. J. Vac. Sci. Technol. 41(2), 132–138 (2021). (in Chinese)

Chen, H., Liu, H.M., Wu, T., Wang, F., Zhuang, C.J.: 1D fluid model of catalytic ammonia synthesis enhanced by low temperature plasma. Trans. China Electrotechnical Soc. 36(13), 2730–2739 (2021). (in Chinese)

Fan, H., et al.: Experimental study on the treatment of mercury contained soil by thermal analytical low temperature plasma based on cold atomic absorption spectrophotometry. Spectro. Spectral Anal. 38(7), 2279–2283 (2018). (in Chinese)

Janić Hajnal, E., Vukić, M., Pezo, L., et al.: Effect of atmospheric cold plasma treatments on reduction of alternaria toxins content in wheat flour. Toxins (Basel). 11(12), 704 (2019)

Wang, C.Y., Zhu, L., Xu, D.Y., Luo, Q.Y.: Process parameters optimization for degradation of benzene by non-thermal plasma. Chem. Ind. Eng. Prog. 39(1), 402–412 (2020). (in Chinese)

Xu, Y.Q., Ma, D.S., Sun, S.Y., Zhao, F.F., Liu, G.S., Sun, Y.J.: Study of flonicamid pesticide residues on apple surface degradated by atmospheric low temperature plasma. J. Henan Agric. Univ. 55(2), 321–327 (2021). (in Chinese)

Wang, S., Wang, Z., Hou, K.Y., Li, H.Y.: Thermal desorption low temperature plasma ionization mass spectrometry for rapid and sensitive detection of pesticides in Broomcorn. Chin. J. Anal. Chem. 45(2), 175–182 (2017). (in Chinese)

Zhang, L., Ma, M.Y., Li, B.Q., Kong, J.L., Zhang, S.C., Zhang, X.R.: Rapid detection of chemical warfare agent simulants using gold nanoparticles substrate-assisted enhanced low temperature plasma-mass spectrometry. Chin. J. Anal. Chem. 48(10), 1416–1421 (2020). (in Chinese)

Duarte, S., Panariello, B.H.D.: Comprehensive biomedical applications of low temperature plasmas. Arch. Biochem. Biophys. 693, 108560 (2020)

Yadav, D.K., et al.: Cold atmospheric plasma generated reactive species aided inhibitory effects on human melanoma cells: an in vitro and in silico study. Sci. Rep. 10(1), 3396 (2020)

Boekema, B., et al.: Antibacterial and safety tests of a flexible cold atmospheric plasma device for the stimulation of wound healing. Appl. Microbiol. Biotechnol. 105(5), 2057–2070 (2021). https://doi.org/10.1007/s00253-021-11166-5

Volkov, A.G., Xu, K.G., Kolobov, V.I.: Cold plasma interactions with plants: morphing and movements of Venus flytrap and Mimosa pudica induced by argon plasma jet. Bioelectrochemistry 118, 100–105 (2017)

de Groot, G.J.J.B., Hundt, A., Murphy, A.B., Bange, M.P., Mai-Prochnow, A.: Cold plasma treatment for cotton seed germination improvement. Sci. Rep. 8(1), 14372 (2018)

Bafoil, M., Le Ru, A., Merbahi, N., Eichwald, O., Dunand, C., Yousfi, M.: New insights of low-temperature plasma effects on germination of three genotypes of Arabidopsis thaliana seeds under osmotic and saline stresses. Sci. Rep. 9(1), 8649 (2019)

Xu, H.Q., Yan, J.H., Tang, L.L., Deng, S.G., Miu, W.H.: Effect of cold atmospheric plasma on quality maintenance of Penaeus vannamei during cold storage. Mod. Food Sci. Technol. 37(4), 116–123, 138 (2021). (in Chinese)

Zhang, Y., Zhang, Z.W., Cheng, C.X., Zhang, X.F., Yang, S.L.: Storage quality improvement of fresh-cut Broccoli by cold plasma treatment. Mod. Food Sci. Technol. 37(2), 164–170 (2021). (in Chinese)

Qiao, W.W., Huang, M.M., Wang, J.M., Yan, W.J., Zhang, J.H., Yang, L.P.: Effect of cold plasma on sterilization and color of fresh beef. Food Sci. 38(23), 237–242 (2017). (in Chinese)

Ren, C.R., Liu, J.G., Wang, S.Q., Jiang, W.L., Peng, J.X.: Effect of strawberry preservation by atomospheric pressure low temperature plasma. J. Qingdao Agric. Univ. (Nat. Sci.) 34(3), 228–234 (2017). (in Chinese)

Jian, G.: Study on Sterilization Mechanism of Low Temperature Plasma and Sterilization of Active Water. Zhejiang University, Hangzhou (2016)

Meng, N., et al.: Effect of low-temperature plasma current intensity on the edible quality of brown rice. Food Res. Dev. 42(7), 20–27 (2021). (in Chinese)

Wang, J.M., Peng, F., Fu, T.F.: Effect of different cold plasma treatment conditions on quality of Trachinotus ovatus. Food Ind. 41(9), 30–34 (2020). (in Chinese)

Ambrico, P.F., et al.: Surface dielectric barrier discharge plasma: a suitable measure against fungal plant pathogens. Sci. Rep. 10(1), 3673 (2020)

Xu, Z., et al.: In vitro antimicrobial effects and mechanisms of direct current air-liquid discharge plasma on planktonic Staphylococcus aureus and Escherichia coli in liquids. Bioelectrochemistry 121, 125–134 (2018)

Wang, T., Chen, S., Wang, H.Q., Liu, Z., Wu, Z.B.: In-plasma catalytic degradation of toluene over different MnO2 polymorphs and study of reaction mechanism. Chin. J. Catal. 38(5), 793–804 (2017). (in Chinese)

Li, X.H., et al.: Comparative analysis on characteristics in non-thermal plasma reactor with oxygen and air. Trans. Chin. Soc. Agric. Eng. 32(11), 103–108 (2016). (in Chinese)

Gharib, M., Mendoza, S., Rosenfeld, M., Beizai, M., Alves Pereira, F.J.: Toroidal plasmoid generation via extreme hydrodynamic shear. Proc. Natl. Acad. Sci. U.S.A. 114(48), 12657–12662 (2017)

Acknowledgments

We would like to thank the undergraduate students enrolled in the horticulture 2002 class in Gannan Normal University, who helped with fruit cleaning, selection, and storage, but are not credited as authors. This research was funded by the Major Science and Technology R& D Program of Jiangxi Province (20194ABC28007), the Talent Introduction and Scientific Research Program of Gannan Normal University (414738), and the Science and Technology Project of Jiangxi Provincial Department of Education (GJJ201414).

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sun, Y. et al. (2022). Insights into the Fungicidal Activity of Low-Temperature Plasma Against the Pathogen of Navel Orange Fruit Mildew. In: Liang, X., Li, Y., He, J., Yang, Q. (eds) The proceedings of the 16th Annual Conference of China Electrotechnical Society. Lecture Notes in Electrical Engineering, vol 890. Springer, Singapore. https://doi.org/10.1007/978-981-19-1870-4_88

Download citation

DOI: https://doi.org/10.1007/978-981-19-1870-4_88

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1869-8

Online ISBN: 978-981-19-1870-4

eBook Packages: EngineeringEngineering (R0)