Abstract

Based on the case of composite foundation with long-short CFG piles in handling the engineering accident, this paper analyzes the reasons for the insufficient bearing capacity of existing piles, proposes the reinforcement ideas and design calculation methods of composite foundation with long and short CFG piles, and gives the key construction techniques. The test and monitoring results show that the reinforcement ideas, design calculation methods and key construction techniques of composite foundation with long-short CFG piles are successful in this project, which can provide references for the design of composite foundation with long-short CFG piles and the handling of similar engineering accidents.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Ground treatment

- Composite foundation with long-short CFG piles

- Engineering quality accident treatment

- Design of composite foundation with multi-type-piles

1 Introduction

The composite foundation formed by reinforcements of different materials, lengths or diameters is called a multi-pile composite foundation. Multi-pile composite foundation [1,2,3,4] is usually used to treat special soil foundation. One type of reinforcement is used to treat the special soil to reduce or eliminate its engineering hazards, and then another reinforcement is used to meet the bearing capacity and deformation requirements. Besides, when the foundation soil of some sites has two good bearing layers, if all the pile tips fall on the shallow layer, the bearing capacity or deformation of the composite foundation cannot meet the design requirements. However, if all on the deep layer, the bearing capacity is too high, which leads to waste. Therefore, it is possible to consider placing pile tips on both the shallow layer and the deep layer to form a composite foundation with long-short piles. It not only meets the design requirements but also saves the cost. In addition, in some actual projects, when the existing single-piled composite foundation fails to pass the bearing capacity test, or the design requirements are not met due to the adjustment of the superstructure, the piles need to be reinforced. When the pile material, pile length or pile diameter of the newly added piles is different from the existing piles, the composite foundation with multi-type piles is formed.

The data represented by literature [2,3,4,5,6,7,8,9,10,11,12,13] has conducted a lot of researches on the stress and deformation behaviors, design calculation methods and engineering applications of composite foundation with long-short rigid piles by means of model tests, field tests and numerical simulations. However, there are few literatures on the application of composite foundation with long-short CFG piles in engineering accident treatment. This article discusses and analyzes its application based on a case of engineering accident treatment.

2 Project Overview

Building 8# of a residential project in Zhuozhou City, Hebei Province, China, has 27 floors above ground and 2 floors underground. The building has a shear wall structure with a raft foundation. The ±0.00 elevation is 32.30 m.

Within the scope of the survey depth, the distribution of the foundation soil layer and its parameters are shown in Table 1. The depth of stable water level is 2.50–9.30 m.

It is required that the characteristic value of the foundation bearing capacity after treatment is no less than 450 kPa, and the final settlement is less than 50 mm. The base soil layer is layer ②, and the characteristic value of the foundation bearing capacity is 120 kPa, which cannot meet the requirement and needs foundation treatment.

The original foundation treatment adopts CFG pile composite foundation. The long auger is used to form 646 piles with 1.2 m pile spacing, 400 mm diameter and 17.3 m effective pile length. The bearing layer is layer ⑥ and layer ⑥2. The designed characteristic value of the single pile bearing capacity is no less than 620 kN. The thickness of the cushion layer is 200 mm.

After construction, 4 CFG piles were randomly selected for the single pile static load test. The results are shown in Fig. 1. The characteristic values of the single pile bearing capacity are 558 kN, 496 kN, 372 kN and 434 kN, which do not meet the design requirements.

In addition, 474 CFG piles were randomly selected for low strain test to verify the integrity of the pile body. The test results show that there are 146 piles of type I, accounting for 30.8%; 100 piles of type II, accounting for 21.1% and 228 piles of type III, with obvious defects in the pile body, accounting for 48.1%.

Based on the above test results, a reinforcement treatment should be carried out.

3 Reinforcement Scheme Design

The design scheme is to add CFG piles (hereinafter referred to as long piles) on the layer ⑦ of fine sand as the bearing layer to form a composite foundation with long-short CFG piles, with existing CFG piles (hereinafter referred to as short piles).

Based on the results of the single pile static load test of the short piles, the characteristic value of the single pile bearing capacity is taken as 360 kN. The effective pile length of the long piles is 24.0 m, the pile diameter is 500 mm, and the calculated characteristic value of the bearing capacity of a single pile is 956 kN [14], taken as 820 kN. According to Eq. (1) in the “Technical Code for Ground Treatment of Buildings” [1], combined with the plan layout of the short piles, the long piles layout plan is determined and shown in Fig. 2. The calculated characteristic value of the bearing capacity of the composite foundation with long-short CFG piles is 453 kPa, which meets the design requirements.

In Eq. (1), the subscripts of the long piles and short piles are 1 and 2 respectively; \(\lambda_1\) and \(\lambda_2\) take the larger value of 0.9 because the characteristic value of the single pile bearing capacity is conservative; \(\beta\) takes the median value of 0.95; \(f_{sk}\) takes the characteristic value of natural foundation bearing capacity of 120 kPa due to the use of the long auger to form piles.

According to Eq. (2) and Eq. (3) [1], the soil compressive modulus improvement coefficients \(\zeta_1\) in the long-short-pile composite reinforcement area and \(\zeta_2\) only in the long-pile reinforcement area are calculated respectively, which are 3.77 and 1.98, respectively.

In the Eqs. (2) and (3), \(f_{ak}\) is the characteristic value of the bearing capacity of the natural foundation under the foundation (kPa); \(f_{spk1}\) is the characteristic value of the bearing capacity of the composite foundation only reinforced by long piles (kPa).

According to the deformation calculation theory of Code for Design of Building Foundations [15], the deformation of the composite foundation with long-short piles is estimated according to Eq. (4):

The settlement calculation experience coefficient \(\psi_s\) is 0.2, and the calculated deformation is 29.94 mm, which meets the design requirements.

The design and calculation parameters of the composite foundation are shown in Table 2.

4 Composite Foundation Construction

The construction of the long piles also adopts the long auger central pressure grouting technique and the ready-mixed concrete.

Here are three main difficulties in the pile construction:

-

(1)

The groundwater level of the site is high, and there is a thick layer of saturated sand and saturated silt in the range of pile length. The interruption of pouring in this range may cause the concrete to segregate, shrink the diameter of the pile or even break the pile;

-

(2)

The bearing layer of the long and short piles is the main water-bearing layer, which has strong water permeability and high water pressure. It may cause the drill door to fail to open, and need to redrill many times, resulting in collapsed holes, channeling holes or concrete segregation;

-

(3)

The distance between short piles is only 1.2 m, which may lead to hole channeling during construction, and then may cause pile tops sinking, piles body mixed with mud, pile diameter reduction and even pile breakage.

In view of Difficulty (1), the supply of the mixture should be ensured, and the pumping speed of the mixture should be controlled to match the lifting speed of the drill pipe, especially in the saturated sand or saturated silt layer. Aiming at Difficulty (2), the drilling rig should use a downward-opening drill bit. For comprehensive Difficulties (1), (2) and (3), it is advisable to adopt jumping pile driving [2]. During the construction of the long pile, the above requirements were strictly implemented.

The bearing capacity of short piles does not meet the design requirements, and the proportion of type III piles with obvious defects in the pile body is as high as 48.1%. After investigation and analysis, it is believed that the main reason is that jumping pile driving was not adopted and the pump had been stopped many times in the saturated silt layer.

Before the construction of the long pile, the short pile had been excavated to the effective pile top elevation. Therefore, the site is backfilled and compacted with plain soil first, with a thickness of about 0.5 m, which satisfies the safe walking of the long auger drill. The long piles are constructed after meeting the requirements for the thickness of the protective soil layer. After the construction is completed, a small excavator with manual cooperation was used to clear and transport the pile-driving spoil and the protective soil between the piles. The shallow defect piles within a depth of 1m were connected with the original piles.

5 Reinforcement Effect and Evaluation of Composite Foundation

5.1 Composite Foundation Inspection

After the completion of the CFG pile construction, the inspection unit conducted three static load tests on the long piles and three composite foundation with long-short piles static load tests.

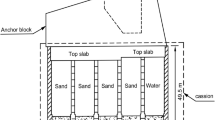

The test area contains 1 length and 4 short piles, using a square steel bearing plate with a side length of 2.4 m × 2.4 m, as shown in Fig. 3. A 200 mm-thick crushed stone cushion is laid under the pressure-bearing board.

The static load test results show that the characteristic value of the bearing capacity of the composite foundation is not less than 450 kPa, and the characteristic value of the bearing capacity of the single long pile is not less than 820 kPa, both of which meet the design requirements. The static load test curve is shown in Fig. 4.

Meanwhile, 130 long piles were randomly selected for low-strain testing. The results showed that there were 121 piles of type I, 9 piles of type II, and no piles of type III and IV.

5.2 Building Settlement Monitoring

From the beginning of the construction of the structure, the monitoring unit conducted settlement observations on Building #8, and the settlement-time curve of the building is shown in Fig. 5. It can be seen that the maximum settlement of the building is less than 25 mm. The east and west sides of the post-pouring belt have settled evenly. According to estimates, the final settlement will be less than 30 mm, which meets the design requirements, indicating that the project is successful in using existing CFG piles and newly added CFG piles to form a composite foundation with long-short CFG piles.

6 Conclusion

In this project, because the bearing capacity of the existing CFG pile composite foundation does not meet the design requirements, long piles with a larger diameter are used for reinforcement to form a composite foundation with long-short piles with the existing CFG piles. The following conclusions can be drawn from this project:

-

(1)

When designing a composite foundation with long-short CFG piles, a relatively good soil layer should be selected for the long pile as the pile end bearing layer, which can effectively improve the bearing capacity and control the deformation of the foundation.

-

(2)

When using long auger center pressure grouting to form piles, if the groundwater level of the site is high and there is saturated sand or saturated silt layer, the drill pipe should be continuously lifted, and the pump should not be stopped to wait for mixture; if the pile spacing is small, jumping pile driving should be adopted.

-

(3)

The results of building settlement monitoring show that the use of composite foundation with long-short CFG piles has a good effect, which can provide a reference for similar engineering accident treatment.

References

Technical Code for Fround Treatment of Buildings (JGJ79-2012), p. 69. China Architecture & Building Press, Beijing (2012)

Ji, M., Zhang, D.G., Zhang, Z., Yan, M.L.: Design of the composite foundation with long-short piles. Geotech. Eng. Tech. J. 2, 86–91 (2001)

Yan, M.L., Wang, M.S., Yan, X.F., Zhang, D.G.: Study on the calculation method of multi-type-pile composite foundation. Chin. J. Geotech. Eng. J. 3, 352–355 (2003)

Yan, M.L., Zhang, D.G.: CFG Pile Composite Foundation Technology and Engineering Practice, pp. 23, 144–158. China Water & Power Press, Beijing (2006)

Tong, J.X., Sun, X.H., Yang, X.H., Wang, M.S., Luo, P.F.: Experimental study on pile-soil bearing behavior and thickness-diameter ratio of composite foundation with long and short piles. Chin. J. Geotech. Eng. J. 35(05), 955–960 (2013)

Ge, X.S., Gong, X.N., Zhang, X.M.: FEM analysis and design of long-short-pile composite foundation. J. Build. Struct. J. 4, 91–96 (2003)

Deng, C.: The bearing capacity and settlement calculation of the long-short-pile composite foundation. MA thesis, Zhejiang University (2002)

Lu, W.Z.: FEM analysis for consolidation behavior of composite foundation with long-short-piles. MA thesis, Zhejiang University (2005)

Shi, S.W.: Study of engineering characteristics of composite foundation with long and short piles for deep soft ground. MA thesis, Zhejiang University (2006)

Chen, C.F., Xiao, S.J., Niu, S.S.: Optimization design method of long-short-pile composite foundation. J. Eng. Geol. 2, 229–232 (2006)

Sun, X.H.: Effect of foundation rigidity and cushion thickness on rigid pile composite foundation bearing capacity. PhD dissertation, China Academy of Building Research (2010)

Deng, C., Gong, X.N.: Application of long-short-pile composite foundation to high-rise building. Build. Construct. J. 1, 18–20 (2003)

Zhao, Z.P., Tong, J.X., Sun, X.Z., Feng, G.R.: Design and application of a composite foundation with two different pile types. Build. Sci. J. 32(Suppl. 2), 277–281 (2016)

Technical Code for Building Pile Foundations (JGJ94-2008), p. 19. China Architecture & Building Press, Beijing (2012)

Code for Design of Building Foundation (GB50007-2011), p. 28. China Architecture & Building Press, Beijing (2012)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2022 The Author(s)

About this paper

Cite this paper

Tang, Q., Tong, J., Jia, N., Yang, X., Sun, X., Yan, M. (2022). Application of Composite Foundation with Long-Short CFG Piles in Engineering Accident Treatment. In: Feng, G. (eds) Proceedings of the 8th International Conference on Civil Engineering. ICCE 2021. Lecture Notes in Civil Engineering, vol 213. Springer, Singapore. https://doi.org/10.1007/978-981-19-1260-3_16

Download citation

DOI: https://doi.org/10.1007/978-981-19-1260-3_16

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1259-7

Online ISBN: 978-981-19-1260-3

eBook Packages: EngineeringEngineering (R0)