Abstract

The purpose of the research article is to estimate the outcome of the experimental examination carried out on the properties of Mechanical short fibers with polyester composite. The maximum content and length of the fiber composite is sustained at 20 wt% and 15 cm. The roselle, sisal, and coconut coir fiber content and the length are differed between 5 to 15 wt% and 5 to 15 cm, respectively. But the strength of the tensile and flexural oselle/sisal/coir fiber hybrid polyester composite with 20 wt% and 15 cm are 17.07 MPa and 32.6 MPa respectively. It was low when compared to glass/polyester composite. Upon increasing the fiber content from 10 to 20 wt % and fiber length from 5 to 15 cm, the tensile strength increased from 7.43 to 17.07 MPa, and flexural strength increased from 27.2 to 32.6 GPa. The specimen with 20% fiber content of length 10 cm holds the highest impact strength of 6.21 kJ/m2. The specimen with 20% fiber content of 15 cm fiber length has the highest tensile strength of 19.07 MPa. This shows that these alkali treated fiber reinforced hybrid polyester composites can be employed successfully for better results.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In this work, we are fabricating the natural fiber composite based on mechanical properties. Based on the literature survey, the natural fibers from many plants have been undertaken by researchers in the global market for several years [1,2,3]. But in this work, new plants are chosen, which were not established in the engineering department; but they are used in the medical field also. There are many researches with the same view of keeping a pollution-free environment [4]. Besides, the natural fibers are comparatively cost-effective and naturally abundant. It is distinguished that the purposes behind the low strength are the imperfections, fiber substance and length of roselle, sisal and coconut coir strands [5]. The plant filaments can work viably through the restricted and controlled events of imperfections, which are unpredictably divided on the full length [6]. Accordingly, the rigidity of the strands diminishes with their length and an articulated strain rate impact is accomplished by combining the fibers to form a new composite plate. Moreover, we are choosing resin that will enhance the properties of Mechanical natural fibers [4]. The hybrid effect of roselle, sisal, and coconut coir fiber on the tensile and flexural strength is also discussed here. It is also identified that at the point when the substance and length of roselle, sisal, and coconut coir filaments are expanded, the tractability and the flexural strength of the composites have a low-level improvement [7]. It is recognized that disperse on the deliberate upsides of the effect strength of the mixture composites is very enormous and hence it is hard to reach inferences [8]. The salt-treated fiber-built-up composites show preferred mechanical properties over the untreated supported composites fiber in all perspectives beginning from malleable to the effect properties [9]. Upon expanding the fiber substance and length of roselle, sisal, and coconut coir filaments, the effect strength diminishes. Additionally, it is recognized that the purposes behind lower sway strength are the deformities, fiber substance, and length of roselle, sisal, and coconut coir filaments. The major benefits of composite materials are power and firmness which are blended with soft materials by using a suitable proposition of strengthening and matrix material, manufacturers could generate properties that are accurate in shape and fulfill the needs for a perfect shape for proper usage [10, 11].

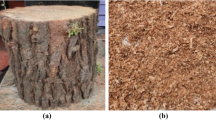

2 Materials and Methodology

2.1 Epoxy Resin

Epoxy resin is an extraordinary manufacturer known for its versatile nature. Being uncommonly useful, engineered combinations of the epoxy pitch have cut their claim to fame in different mechanical applications. It is referred to under some ordinary occupations of epoxy gum. Epoxies are used in the paint business as it dries quickly and gives protective layers that are significantly outrageous. Epoxies are used as hidden or planning pastes used in the improvement of planes, vehicles, boats, and other such applications.

2.2 Eglass Fiber

Glass fibers are among the majority of flexible mechanical materials known today. They are promptly created from crude materials, which are accessible in basically limitless stock. All glass strands depicted in this article are gotten from arrangements containing silica. They show helpful mass properties like hardness, straightforwardness, protection from compound assault, security, and dormancy, just as attractive fiber properties like strength, adaptability, and firmness.

2.3 Experimental Procedure

The mechanical characteristics of the composites are dictated by standard testing techniques. The different properties are rigidity, flexural strength, and Impact strength. The tractable and flexural tests were performed by ASTM standard testing strategies. The flexibility of the composites was assessed with an electronic FIE far and wide testing machine according to the ASTM D638 technique at a crosshead speed of 10.5 mm/min. The flexural tests were performed on a comparable machine, using the 3-point bowing strategy according to ASTM D790 with a crosshead speed of 10.5 mm/min. In the influence test, the strength of the models was assessed using an Izod influence test machine. All test tests were scored. The procedure used for influence testing was ISO 180. The test model was maintained as a vertical cantilever shaft and broken by a lone swing of a pendulum. The pendulum strikes the substance of the score. For the verifiable explanation, a total of six models for each test were finished at room temperature. Figures. 1 and 2 show the results of alkali treated and non-treated fiber.

The above Table 1 shows that the results increase up to the time duration of 6 h and after that, it begins to drop. We are performing the alkali treatment for this specific time limit by conforming to this result.

3 Result and Discussion

3.1 Strength Effect of Fiber Content and Length on Tensile Strength

Untreated fiber reinforced composites

As estimated, fiber strengthening has outcome in a noteworthy rise in tensile strength. 20% fibers content showed better reinforcements than 10% fibers content. It gives a detailed report that there is an inclination in fiber length direct to a rise in tensile strength for the composite materials. The table shows the tensile strength of untreated Roselle, sisal, and coconut coir composite for various proportions of fiber content and fiber length. The specimen with 5 cm length and 10% wt of fiber content exhibits the least tensile strength of 6.83 MPa, whereas the specimen with 15 cm length of fiber content exhibits the maximum tensile strength of 18.6 MPa (Table 2).

3.2 Alkali Treated Reinforced Composites Fiber

The outcome shows that there is an augment in the characteristics as compared to the untreated one. We can visualize here that the properties of the alkali treated reinforced composites fiber are better in tensile, impact, and flexural properties. The time of the alkali treatment can be determined by the following result. The variation in the tensile properties of the composite with fiber composition variation and fiber length variation is shown in Fig. 3.

3.3 Effect of Fiber Content and Length on Flexural Strength

Untreated reinforced composites fiber

Table 3 shows the Flexural strength is increased based on fiber content. 20% fiber content showed better performance than other fiber content with the flexural strength of 32.6 MPa whereas 10% fiber content showed poor performance which leads to a reduction in flexural strength of 27.25 MPa. The variation in the flexural properties of the composite with fiber composition variation and fiber length variation is shown in Fig. 4. The effect of the alkali treatment is also depicted (Figs. 5, 6, 7, and 8).

3.4 Fiber Content and Length on Impact Strength

Untreated reinforced composites fiber

Table 4 presents the output strength of untreated roselle, sisal, and coconut coir fiber reinforced polyester composite. The specimen with 20% fiber content of length 10 cm shows high impact strength. The specimen with a fiber content of 20% and length 15 cm exhibits lower impact strength. There is no uniformity in the variation.

Alkali treated reinforced composites fiber

The alkalization of fiber does not show a significant increase in the impact strength of the composites as in the case of tensile strength. From the table, it is concluded that the specimen with 20% fiber content and length 10 cm holds the highest impact strength of 6.2 kJ/m2, whereas the specimen with 10% fiber content and length 15 cm exhibits the least impact strength of 3.8 kJ/m2. Here also no uniform variation can be noticed. The variation in the impact properties of the composite with fiber composition variation and fiber length variation is shown. The effect of the alkali treatment is also depicted.

4 Conclusion

The roselle fibers are more reasonable than sisal fiber for malleable and flexural strength in light of the fact that the sisal filaments are explicitly appropriate to affect properties. Further expanding roselle fiber substance and length may build the rigidity and flexural strength. Upon increasing the fiber content from 10 to 20 wt.% and the fiber length from 5 to 15 cm, the rigidity increased from 7.43 to 17.07 MPa and flexural strength increased from 27.2 to 32.6 GPa.

-

It is likewise recognized that when the substance and length of roselle, sisal, and coconut coir filaments are expanded, the ductility and the flexural strength of the composites have a low-level improvement.

-

It is distinguished that the disperse on the deliberate upsides of the effect strength of the half breed composites is very huge and thusly it is hard to make determinations.

-

The roselle/sisal/coir cross breed composite with 10 wt% and 10 cm length shows the most extreme degree of effect strength (2.87 kJ/m2). For this effect, strength, the sisal fiber has higher reasonableness of effect, strength than that of roselle strands.

-

The soluble base treated fiber supported composites show preferable mechanical properties over the untreated built up composites fiber in all perspectives beginning from malleable to the effect properties. This can be effectively perceived by considering the correlation diagrams and tables.

-

The specimen with 20% fiber content of length 10 cm holds the highest impact strength of 6.21 kJ/m2. The specimen with 20% fiber content and 15 cm fiber length has the highest tensile strength of 19.07 MPa. This shows that these alkali treated fiber reinforced hybrid polyester composites can be employed successfully for better results.

References

Devaraju A (2015) Influence of fiber percentage on mechanical properties of hybrid composite materials. J Mater Sci Mech Eng 2(13):1–5

Jino R, Pugazhenthi R, Ashok KG, Ilango T, Chakravarthy PR (2017) Enhancement of mechanical properties of Luffa fiber/epoxy composite using B4C. J Adv Microsc Res 12(2):89–91

Ramasamy M, Daniel AA, Nithya M, Kumar SS, Pugazhenthi R (2021) Characterization of natural–Synthetic fiber reinforced epoxy based composite–Hybridization of kenaf fiber and kevlar fiber. Mater Today Proc 37:1699–1705

Devaraju A, Babu K, Gnanavelbabu A (2018) Investigation on the mechanical properties of coconut bunch fiber reinforced epoxy with Al2O3 nano particles composites for structural application. Mater Today Proc 5(6):14252–14257

Girimurugan R, Pugazhenthi R, Maheskumar P, Suresh T, Vairavel M (2021) Impact and hardness behaviour of epoxy resin matrix composites reinforced with banana fiber/camellia sinensis particles. Mater Today Proc 39:373–377

Mamidi VK, Pugazhenthi R, Manikandan G, Kumar MV (2020) Mechanical and microscopic study on Tinospora cordifolia and Tectona grandis composites. Mater Today Proc 22:772–775

Devaraju A, Sivasamy P (2018) Comparative analysis of mechanical characteristics of sisal fibre composite with and without nano particles. Mater Today Proc 5(6):14362–14366

Dinesh S, Elanchezhian C, Devaraju A, Sivalingam SK, Velmurugan V (2021) Comparative study of mechanical and morphological analysis of NaOH treated and untreated banana fiber reinforced with epoxy hybrid composite. Mater Today Proc 39:861–867

Sumesh KR, Kanthavel K (2020) Optimizing various parameters influencing mechanical properties of banana/coir natural fiber composites using grey relational analysis and artificial neural network models. J Ind Textiles, 1528083720930304

Kazi AM, Waddar S, DVA R (2021) Characterization of Roselle fiber composites for low load bearing structures. Polymer Compos 42(5):2589–2597

Hamdan MHM, Siregar JP, Ahmad MR, Asghar A, Tezara C, Jamiluddin J, Zalinawati M (2021) Characterisation of the woven fabric of jute, ramie and roselle for reinforcement material for polymer composite. Mater Today Proc 46:1705–1710

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Kamalakannan, K., Sivaganesan, S., Dhanasekaran, C., Pugazhenthi, R. (2022). A Study on the Mechanical Properties of Alkali Treated Natural Reinforced Fiber Composites. In: Palani, I.A., Sathiya, P., Palanisamy, D. (eds) Recent Advances in Materials and Modern Manufacturing. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-0244-4_64

Download citation

DOI: https://doi.org/10.1007/978-981-19-0244-4_64

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-0243-7

Online ISBN: 978-981-19-0244-4

eBook Packages: EngineeringEngineering (R0)