Abstract

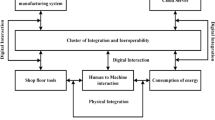

Through the digitalization of manufacturing, an abundance of data is available from machines, sensors and operations. This trend requires technical colleges and universities to enhance their syllabus. This paper describes a cloud-based data pipeline for a digital manufacturing lab that utilizes machine-to-machine communication and the internet of things (IoT). The factory model consists of four stations, i.e., a vacuum gripper robot, an automated high-bay warehouse, a sorting line with color detection, and a multi-processing station with an oven, and these stations can demonstrate a fully working digital production line prototype that is in line with Acatech Industrie 4.0 Maturity Index. The Programmable Logic Controller (PLC) on-site passes data via the internet to the Amazon Web Services (AWS) cloud computing platform. Data Analytics uses methods from statistics and machine learning to optimize processes, continuously monitor product quality and improve maintenance of equipment. The factory model and the data pipeline provide an intuitive hands-on learning experience for teaching Industry 4.0 and digital manufacturing at technical colleges and universities.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Lasi, H., Fettke, P., Kemper, H.-G., Feld, T., Hoffmann, M.: Industry 4.0. Bus. Inf. Syst. Eng. 6(4), 239–242 (2014). https://doi.org/10.1007/s12599-014-0334-4

Moore, M.: What is Industry 4.0? Retrieved from techradar. https://www.techradar.com/news/what-is-industry-40-everything-you-need-to-know 22, May 2020

Banton, C.: Mass production. Retrieved from investopedia: https://www.investopedia.com/terms/m/mass-production.asp 30, September 2020

Hussen, Y.D.: National fourth industrial revolution (4IR) policy. Perpustakaan Negara Malaysia cataloguing-in-publication data (2020)

Alexander, W.: A work process supporting the implementation of smart factory technologies developed in smart factory compliant laboratory environment (2019)

Zuehlke, D.: Smart factory towards a factory-of-things. Annu. Rev. Control. 34(1), 129–138 (2010)

Günther Schuh, R.A.: Using the industrie 4.0 maturity index in industry (2020)

Retrieved from Switzerland innovation (2021). https://www.sipbb.ch/wp-content/uploads/2021/08/Overview_2021_web.pdf

Gorecky, D., Weyer, S.: SmartFactoryKL systemarchitektur for industrie 4.0 production plants. whitepaper. technologie-initiative smartfactory kl e. v., Kaiserslautern. http://dfki-3036.dfki.de/pdf/Whitepaper/SF_WhitePaper_EN.PDF (2016). Accessed on 17 Apr 2017

Seif, A., Toro, C., Akhtar, H.: Implementing industry 4.0 asset administrative shells in mini factories. Procedia Comput. Sci. 159, 495–504 (2019). https://doi.org/10.1016/j.procs.2019.09.204

Sudip Phuyal, D.B.: Challenges, opportunities and future directions of smart manufacturing: a state of art review. ScienceDirect 2, 100023 (2020)

Fishertechnik Lernfabrik 4.0 (2020). file:///C:/Users/User/Downloads/fabrik_2019_englisch_neu%20.pdf

Plc Training Factory 24v.: Retrieved from github. https://github.com/fischertechnik/plc_training_factory_24v 8, June 2021

AWS IoT Analytics - How it works (3:01): Amazon Web Services, Inc. https://aws.amazon.com/iot-analytics/. Accessed on 30, July 2021

Coleman, C.S.: Predictive maintenance and the smart factory. Retrieved from Deloitte. https://www2.deloitte.com/content/dam/Deloitte/us/Documents/process-and-operations/us-cons-predictive-maintenance.pdf (2017)

Yung, C.: Vibration analysis: what does it mean? Retrieved from Plant Services Articles. https://www.plantservices.com/articles/2006/154/ 9, June 2006

Christiansen, B.: A complete guide to predictive maintenance. Retrieved from LimbleCMMS. https://limblecmms.com/predictive-maintenance/ 15 Jan 2021

Ngamthonglor, J.: Onunkeep. https://www.onupkeep.com/learning/maintenance-types/predictive-maintenance 21 Mar 2021

What is AWS IoT Greengrass? (1:51): Amazon Web Services, Inc. https://aws.amazon.com/greengrass/. Accessed on 25, July 2021

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Goh, P.J. et al. (2022). Conceptual Design of Cloud-Based Data Pipeline for Smart Factory. In: Ali Mokhtar, M.N., Jamaludin, Z., Abdul Aziz, M.S., Maslan, M.N., Razak, J.A. (eds) Intelligent Manufacturing and Mechatronics. SympoSIMM 2021. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-8954-3_4

Download citation

DOI: https://doi.org/10.1007/978-981-16-8954-3_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-8953-6

Online ISBN: 978-981-16-8954-3

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)