Abstract

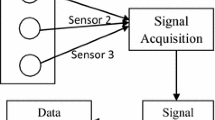

During operation, machines or objects generate vibration and there are unwanted vibrations that will disrupt the overall system, which results in faults such as imbalance, crack, wear, and misalignment. Thus, collecting and analyzing the vibration data has become an effective method in monitoring the condition of an object. There are many instruments to acquire vibration data and techniques to analyse the collected data. In this study, two types of vibration sensors are applied to collect and visualizes the vibration data in real-time, which are SW420 vibration sensors and ADXL345 accelerometers. The sensors are mounted on the rod, which is attached to the motor to determine the effect of the mounting position on the vibration. Then, a threshold value is set to see the reliability of these vibration sensors in detecting faults. Based on the results, mounting the vibration sensor closer to the source of vibration will generate higher vibration and both sensors can successfully detect a fault, set by the threshold values.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bernet, J.: Machine wear: How vibration analysis has evolved to increase uptime (2015). https://www.testequipmentdepot.com/fluke/

Kumar, S., Lokesha, S., Kumar, K., Srinivas, K.: Vibration based fault diagnosis techniques for rotating mechanical components. IOP Conf. Ser.: Mater. Sci. Eng. 376, 1–6 (2018). https://doi.org/10.1088/1757-899X/376/1/012109

Saucedo-Dorantes, J.J., Delgado-Prieto, M., Ortega-Redondo, J.A., Osornio-Rios, R.A., Romero-Troncoso, R.D.J.: Multiple-fault detection methodology based on vibration and cur- rent analysis applied to bearings in induction motors and gearboxes on the kinematic chain. Shock Vib. 2016, 1–13 (2016). https://doi.org/10.1155/2016/5467643

Sutar, S., Warudkar, V., Sutakhantar, R.: Vibration analysis of rotating machines with case studies. Int. J. Sci. Technol. Res. 7(7), 70–76 (2018)

Doscher, J.: ADXL105: a lower-noise, wider-bandwidth accelerometer rivals performance of more expensive sensors. Analogue Dialogue 33(6), 27–29 (1999)

Thanagasundram, S., Schlindwein, F.S.: Comparison of integrated micro-electrical-mechanical system and piezoelectric accelerometers for machine condition monitoring. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 220(8), 1135–1146 (2006). https://doi.org/10.1243/09544062C07405

Albarbar, A., Mekid, S., Starr, A., Pietruszkiewicz, R.: Suitability of MEMS accelerometers for condition monitoring: an experimental study. Sensors 8(2), 784–799 (2008). https://doi.org/10.3390/s8020784

Holovatyy, A., Teslyuk, V., Iwaniec, M., Mashevska, M.: Development of a system for monitoring vibration accelerations based on the raspberry pi microcomputer and the ADXL345 accelerometer. In: 2017 13th International Conference on Perspective Technologies and Methods in MEMS Design (MEMSTECH), 20–23 April, pp. 52–62 (2017)

Sukenda, S.T., WawanMaulana, S., Septiane, L., Irwan, Y., Lukman, N.S., Dimas, H.: Use of vibration sensor as detection of railway in mechanical signaling systems. PalArch’s J. Archaeol. Egypt/Egyptol. 17(5), 402–413 (2020)

Ismail, E.S.B., Habaebi, M.H., Islam, M.R.: Early concept low cost design of vibration chamber for landslide sensory and alarm system. In: 2017 IEEE 4th International Conference on Smart Instrumentation, Measurement and Application, Putrajaya, Malaysia, 28–30 November, pp. 1–5 (2017)

Acknowledgment

We would like to thanks Synvue Sdn Bhd (1236749-D) for insights and feedback of the project development. This work was supported by the Collaborative Research in Engineering, Science, and Technology (CREST) under grant 304/PELECT/6050424/C121.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Ghazali, M.H.M., Rahiman, W. (2022). Real-Time Vibration Monitoring Using MEMS Vibration Sensors. In: Mahyuddin, N.M., Mat Noor, N.R., Mat Sakim, H.A. (eds) Proceedings of the 11th International Conference on Robotics, Vision, Signal Processing and Power Applications. Lecture Notes in Electrical Engineering, vol 829. Springer, Singapore. https://doi.org/10.1007/978-981-16-8129-5_56

Download citation

DOI: https://doi.org/10.1007/978-981-16-8129-5_56

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-8128-8

Online ISBN: 978-981-16-8129-5

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)