Abstract

In order to improve the vibration isolation performance of the powertrain five point mounting system of parallel hybrid electric vehicle, the dynamic model of the powertrain five point mounting system is established. The optimization objective is to decouple the six degree of freedom energy of the powertrain and distribute the natural frequency reasonably. The stiffness of the five mounting points is the design variable. The genetic algorithm is used to optimize the mounting system. The suspension system of a parallel diesel electric hybrid vehicle is optimized by the above method. The results of dynamic simulation and real vehicle test show that the steering wheel jitter is eliminated after the suspension optimization, which verifies the rationality of the proposed method. At the same time, the genetic algorithm overcomes the shortcoming that SQP is easy to converge to the local optimal solution. The decoupling performance of the suspension system is excellent, and the optimization result is stable and reliable.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The NVH performance (noise, vibration and harshness) is an important performance index to measure the quality of a car. The noise and vibration of a car mainly come from the road excitation and the powertrain (engine, clutch, transmission), so the vibration isolation performance of the powertrain mounting system directly affects the NVH performance of the car. At present, the optimization methods for powertrain mounting system of non hybrid electric vehicle mainly include frequency shift method, energy decoupling method, total transfer force minimization method, etc. at the same time, some researches combine ADAMS software to analyze and optimize the vibration isolation performance of mounting system, among which energy decoupling method has been widely used. Some scholars use the energy decoupling method to identify the static stiffness parameters of the mounting system which contribute a lot to the change of the natural frequency and decoupling rate of the mounting system, which provides a certain reference for the design of the mounting system [1].

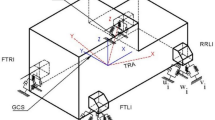

In parallel hybrid electric vehicle, because an ISG motor is paralleled at the output shaft of the powertrain, the vibration of the powertrain will be more complex. At this time, the vibration isolation performance of the mounting system will be particularly important. The five point mounting system of parallel hybrid electric vehicle is shown in Fig. 1. In this paper, the powertrain mounting system of hybrid electric vehicle is designed and optimized according to the energy decoupling method.

Traditional optimization algorithms rely on gradient information, and the results are easy to be local optimal solutions. However, as a global optimal search method, genetic algorithm is widely used in many engineering fields, and also in the design of mounting system. At the same time, the mathematical model of the energy decoupling method of the mounting system is extremely complex, so this paper takes the minimum six degree of freedom coupling degree of the mounting system as the optimization objective, takes the five point mounting stiffness of the powertrain as the optimization variable.

2 Control Structure of 4-DOF Manipulator

2.1 The Composition of Control System of 4-DOF Manipulator

The control system of Gugao four degree of freedom manipulator consists of SCARA four degree of freedom industrial manipulator, driving electrical box computer (including DSP motion control card and upper computer control software). For the multi axis control system, the chip with powerful data processing ability is needed, so the main control chip of the core motion control card is dsp2l81 high-speed processor. The general controller needs to deal with complex matrix operation, and the selection of the main control chip must be high-speed and high-precision. In the aspect of communication, standard ISA bus and PCI bus are provided. The real object can be seen in the figure below, in which joints 1, 2 and 3 are rotary joints, and joint 4 is vertical lifting joint. This manipulator provides a design mode of combining computer and development type motion control card. The developer does not spend too much energy on the drive design, but focuses more on the design and implementation of control strategy. Figure 1 is the outline drawing of the 4-DOF manipulator body and the electrical control box [2].

Due to the lighter load of moving objects, there are not too many requirements for the selection of motor control system. In order to study the selection of servo motor of mechanical arm in general, we do some basic research on the drive motor. Now the servo motor brands which are widely used in the market are Panasonic and Sanyo. In general, the appropriate motor and its control card should be selected for the occasion. Firstly, the torque on the reducer is calculated, and the corresponding servo driver and accessories are selected according to the driving capacity of the control card, and the analog voltage or pulse signal is output.

2.2 Mechanical and Electrical Part of Four Degree of Freedom Manipulator

The manipulator model is simplified as shown in Fig. 2.

Estimated motor demand parameters:

-

Safety factor: n = 1.5

-

Torque calculation formula: T = Jan

-

Weight of machine arm parts in handling operation: 500 g

The moment of inertia of the four joints to the base of the manipulator is:

Similarly, the maximum moment of inertia of the fourth joint to the motor axis of the third joint is:

According to the demand, the maximum speed of the first joint is x/2rwd/s, and it needs 0.5 s to accelerate to the maximum angular speed. Combined with the motor type of googol company, the motor model can be determined as Panasonic AC msma5aza1g servo motor.

2.3 Software Implementation of Control System for 4-DOF Manipulator

The software of local manipulator control system is a program in the form of dialog box, and the human-machine interface is universal. In the program design, the robot base class is the core, and there are controller class and planner class. The data structures of manipulator attributes such as degree of freedom, joint state, joint motion speed, joint motion acceleration and joint position are defined in the base class. In addition to the data structure definition, various motion functions of the manipulator are also defined, such as single step motion, S-mode motion, etc. the four degree of freedom manipulator class derived from the robot base class is used to create specific objects [3]. The controller class is equivalent to the set of interface functions, which is mainly for the needs of future maintenance. The virtual function declares the corresponding public properties and interfaces of the motion control card, and derives the SG controller class that matches the actual control card. In the SG controller class, the control command response function 14 is specifically defined, and the selection of the shutdown motion mode, such as the servo power on, the control command response function 14 is defined, On/off control card, S/T joint movement mode, origin/limit point capture, etc. The planner class mainly designs the trajectory planning of the manipulator. The class design diagram of the 4-DOF manipulator control system is shown in Fig. 3.

Crobotbase is derived from the base class CObject. It defines some common variables, such as joint angular velocity and joint velocity, current joint position, and the array of temporarily saved variables. Two very important pointers * m controller and * m planner are defined. The first pointer points to the controller class, that is, the motion control class, calls the driving function, and the second pointer points to the planner class, that is, the planner class. In addition to these two class pointers, it also defines the member functions that DG needs to use, such as playback function, save teaching file function, and some function functions, such as the function connected to the controller class. This class mainly describes some common characteristics and functions of the manipulator. The cgrobot class is derived from Cobot base class. The member functions of this class in the control system of the manipulator are all virtual functions. Generally, it is only when solving the kinematics problems that it generates subclasses. The idea of subclass is to add the characteristics of the object to make the object more targeted. The kinematic solutions of the manipulator with different degrees of freedom are also different. The differences in the solutions can be added by subclass.

3 Kinematics Analysis and Trajectory Planning Method of Manipulator

The kinematics of industrial manipulator is an important field in the study of manipulator, which is the basis of manipulator design and control. Manipulator kinematics and robot kinematics are consistent, that is, the movement of the end effector of the manipulator relative to the base coordinate system is regarded as a function of time, regardless of the force and torque between the joints, and the relationship between the joint amount and the pose of the end effector is mainly studied. The kinematics of the manipulator is generally divided into forward solution and inverse solution. The forward solution of kinematics is to know the coordinate value and attitude from the beginning to the end of the industrial manipulator, and to calculate the position and attitude of the end effector relative to the base coordinate system from the coordinate point value in the whole trajectory process. The inverse kinematics solution is the inverse operation of the forward solution, which is to solve the joint angle variables that can drive the desired position of the end effector [4].

A robot arm can be regarded as a kinematic chain composed of a series of rigid bodies connected by joints. These rigid bodies are usually called connecting rods. The connecting rod has four basic attribute parameters, namely the connecting rod attribute parameters and the connecting position parameters of the two connecting rods. Specifically, the common normal distance a and the angle g perpendicular to the two axes in the plane where a is located describe the connecting rod itself; the relative position D of the two connecting rods and the angle between the two connecting rod normals can describe the position relationship as shown in Fig. 4.

4 Concept of Control Trajectory Planning for 4-DOF Manipulator

The trajectory planning of manipulator does not involve artificial intelligence, but studies the method of trajectory generation of terminal actuator in space based on the kinematics and dynamics of manipulator, and describes the trajectory generation with a series of interpolation points. Trajectory not only refers to the generalized route of the end effector, but also includes the displacement, velocity and acceleration of the manipulator in the process of motion. Trajectory planning calculates the desired trajectory according to the needs of customers. Firstly, the motion path of the manipulator, such as the space position of the starting point, the state of the manipulator, such as the space pose required by the starting end, is modeled. Secondly, the path interpolation point to the terminal and the motion speed of the interpolation point end are determined. The coordinate parameters of the starting point are input into the trajectory planner to generate the trajectory. The velocity and acceleration in the process are only expressed in the planning process [5].

There are many common methods to deal with trajectory planning problems. Complex systems can be established to unify all planning problems. The current method has default to black box model as the standard to deal with this kind of problems in manipulator industry. The black box can be used as a platform to apply to all kinds of manipulators. The input variables of path setting, path constraints and dynamic constraints are used as the input of the black box, and the planner calculates the path coordinates under all kinds of constraints. The starting position and attitude lead to the middle position and attitude on the path of the manipulator, and the terminal attitude determines the operation mode of the manipulator. The traditional trajectory planning is divided into two kinds, one is joint space planning, the other is Cartesian space planning. Trajectory planning in joint space refers to the angle change trend of joint amount in each trajectory segment, and the operation time of each trajectory segment is the same. These joint functions and their first and second derivatives are used to describe the expected motion of the robot. Joint space planning method is often used in some high torque occasions, mining heavy industry commonly used joint planning to calculate the loadable capacity, at the same time, it can obtain the desired pose of the middle point of the trajectory, and it can directly use the controlled variables to plan the trajectory; Cartesian coordinate space trajectory planning is mostly used in the actual path needs, because its trajectory is more intuitive and can be simulated in the workplace, Due to the strict constraints on the spatial position, the operation accuracy is high.

5 Conclusion

Firstly, this paper investigates the development trend and status of industrial manipulator at home and abroad. According to the needs of the subject, on the local system of Gugao four degree of freedom manipulator, the trajectory planning of straight line and arc of four degree of freedom manipulator is designed under the development environment of VC + + 6.0, and the trajectory of the manipulator end effector is simulated on MATLAB.

References

An analysis of Wang Lu's ways to cultivate college students’ entrepreneurial ability. J. Ankang Univ. 23 (2011)

Saeed, B.: NIKU, Introduction to Robotics. Electronic Industry Press, Beijing (2004)

Cai, Z.: Robot Guidance. Tsinghua University Press, Beijing (2009)

Bi, S.: Development status of industrial robot at home and abroad, mechatronics of door 2, 6–9 (2006)

Yuan, K.: Development status and trend of industrial robots. Mech. Eng. 7, 5–7 (2008)

Acknowledgements

Application and research of FP-growth algorithm in data mining”, Natural Science Research Projects in Anhui Universities in 2020 (Project No. KJ2020A0806).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Zhu, H. (2022). Decoupling Optimization of Vehicle Powertrain Mounting System Based on Genetic Algorithm. In: Hung, J.C., Yen, N.Y., Chang, JW. (eds) Frontier Computing. FC 2021. Lecture Notes in Electrical Engineering, vol 827. Springer, Singapore. https://doi.org/10.1007/978-981-16-8052-6_191

Download citation

DOI: https://doi.org/10.1007/978-981-16-8052-6_191

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-8051-9

Online ISBN: 978-981-16-8052-6

eBook Packages: EngineeringEngineering (R0)