Abstract

The Soil Cement Mixing technology (SCM) has been widely applied for several applications such as soft ground improvement for highway embankments and earth levee embankments, seepage cutoff walls, and so on. The hydraulic conductivity of soilcrete made from clays was primarily studied. The hydraulic conductivity of soilcrete created from sand has limit research data, especially in Vietnam. This study aims at better understanding of the permeability behavior of dredging sand taken in Mekong delta mixing with some cement types at various cement contents of 200, 250, 300, 350 and 400 kg/m3, respectively. Three cement types of the ordinary Portland cement (OPC), Portland cement blended (PCB) and Portland cement slag (PCS) were utilized. All permeability tests followed the ASTM D5084 standard. The results indicate that the hydraulic conductivity of sand soilcrete (ks) was lower 1000 times than that of the compacted sand sample. The ks reduced with increasing in cement contents and in curing time. ks of soilcrete made from the PCS cement was lower than those made from the OPC and PCB cement. The ks varied from 8.07 × 10−8 m/s to 2.3 × 10−11 m/s.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Nowadays, the soil-cement mixture (soilcrete) has been commonly applied for various purposes such as soft soil reinforcement, impermeable cores for embankments, dams, containment walls, and so on. The SCM can improve the in-situ soil characteristics significantly after 28 curing days like strength, stiffness, and permeability. The mechanical and physical properties of soilcrete including compression strength, shear strength, and secant modulus were widely investigated [1,2,3,4]. The improved mechanical properties of soilcrete were the result of the chemical reactions occurring between minerals in soil, cement, and water which create cementitious products to fill void pores in the soilcrete and to set the soilcrete [2, 5]. The hydraulic conductivity of soilcrete is an important property for impermeable purposes [6]. The permeability of soilcrete made from clays was generally studied. Several studies on the soilcrete permeability created from sand were conducted to investigate various aspects such as cement content, curing time, water/cement ratio (w/c), and type of cement [5, 7,8,9,10]. However, the sand soilcrete permeability was partially examined. The hydraulic conductivity of cement stablilized sand decreased to compare with unmixed sand and decreased with increasing in cement contents [5, 8, 9]. The hydraulic conductivity of soilcrete made from different sands was divergent [8, 9]. Alkaya and Esener [8] found that the permeability of the sand-cement mixture reached 3.5 × 10−8 m/s at a cement content of 10%. Amhadi and Assaf [9] concluded that the permeability of the soilcrete made from desert sand mixing with cement was approximately 10−7 m/s. The effect of cement type and fine fraction on the permeability of cement-mixed limestone sand was studied by Markou and Droudakis [10]. The authors reported that the blended Portland cement can lead to lower permeability of soilcrete created by the ordinary Portland cement and the soilcrete permeability declined with increasing in the cement fine fractions. The soilcrete permeability decreased with curing time [5, 11, 12], and increased with increasing in w/c ratio [7]. The Southern Vietnam has commonly used dredging sands for rising elevations of highway embankments and earth leeves. Earth levees have been often failured during annual flood seasons. Lack of compaction is considered the cause of earth levee failures which are typical failure in the Mekong delta. The sand particles inside an earth levee body are washed by seepage flows enlarging void spaces gradually and causing the collapse of the earth levee. Soilcrete walls expecting to be low permeability that can protect earth levees against annual floods are highly potential solutions. The literature review suggests that sand mixed with cement can reduce the permeability of the mixture and can be considered as an impermeable material to create seepage cutoff walls for earth levees. However, fine grain sizes and organic contents in the dredging sand taken in the Mekong delta may cause unexpected high soilcrete permeability. The soilcrete permeability database is still limit in Vietnam. Therefore, this paper attempts to investigate the several impact factors such as cement content, cement type, and curing time on the soilcrete permeability made from the dredging sand mixing cement. Research results expect to be low the permeability of the soilcrete to be used as an impermeable material.

2 Implementation

2.1 Materials

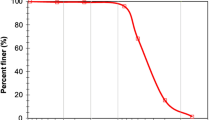

The dredging sand samples were taken in Dong Thap province, Vietnam. The site was the location of field Jet Grouting experiments to treat differential settlement of bridge abutments. The key properties of sand were determined and presented in Table 1. The results of the standard sand compaction and grain size distribution tests are shown in Fig. 1. The three cement types of the OPC40, PCB40, and Portland cement with 50% blast furnace slag (PCS) were used. The cement properties are displayed in Table 2. Tap water was utilized for mixing soilcrete specimens and testing permeability. The water properties meet the requirements printed in Table 3.

2.2 Specimen Preparations

Unmixed sand specimen. The dredging sand was dried at a temperature of 105 °C ± 5 °C. Tap water was added to rise a moisture content up to the optimum water content of 15.15%. The sand was placed in the cylindrical plastic mold with dimensions of D × H = (62 × 140) mm in 3 layers and compacted at the standard energy (ASTM D698) [13]. The specimen was saturated under water at a vacuum pressure of −80 to −90 kPa for 24 h.

Soilcrete specimens. The dredging sand was mixed with the three cement types of the OPC, PCB, and PCS at various cement contents, respectively, to form several soilcrete specimens. The OPC cement was added with cement contents of 200, 250, 300, 350, and 400 kg/m3, respectively. A content of 300 kg/m3 was used for the PCB and PCS cements. Table 4 presents parameters of the soilcrete specimens. The sand was mixed with water to have a water content of 15.15% and asumpted to be a common natural moisture sand. Appropriate cement contents calculated by the volume of moist sand were added. Additional water amount was added to make the mixture more liquid. The actual water content of the sand and the mixture after mixing was determined. The moisture content of soilcrete mixture varied depending on cement contents (Table 4). The wet mixture was placed and compacted in cylindrical plastic molds with 65 mm height and 62 mm diameter in 3 layers. A mini vibrating compactor was employed to eliminate air bubbles as much as possible. The preparation duration of a specimen was less than 30 min. The all specimens were covered by plastic wraps and immersed in water for 2 days. The set soilcrete specimens were removed out of the molds and saturated in water at a vacuum pressure of −80 to −90 kPa for at least 24 h before permeability tests.

2.3 Permeability Tests

The hydraulic conductivity of the compacted sand specimen, ksoil, was measured using the falling head-constant tailwater method on a rigid wall permeameter (ASTM D5856) [14]. Low hydraulic gradients of 2–5 were applied to avoid the rigid-wall leakage. For the soilcrete specimens, the permeability tests were conducted on the flexible wall permeameters specifically designed basing on the ASTM D5084 [15] (Fig. 2) following the falling head-constant tailwater method under hydraulic gradients of 30–45 or the falling head-rising tailwater method under hydraulic gradients of 100–150. During a permeability test, a cell water pressure was applied and maintained higher than water head-in pressures about 10–20 kPa. A specimen was carefully installed in the permeameters to keep the specimen fully saturated. Data were periodically obtained every day and carefully analyzed to investigate the hydraulic conductivity variation with time.

The hydraulic conductivity at the laboratory temperature is calculated using Eqs. (1), or (2) depending on the tested method.

The falling head—constant tailwater method:

The falling head—rising tailwater method:

Hydraulic conductivity at the temperature of 20 °C, k20, converted by Eq. (3).

where k—hydraulic conductivity at a room temperature (m/s), L—length of specimen (m), A—cross sectional area of specimen (m2), a—cross sectional area of head-in pipe (m2), (ain = aout = a), t = t1 − t2—reading duration (seconds) at head-in of h1 and h2, h1—head loss in at reading time t1 (m), h2—head loss in at reading time t2 (m), RT—converting ratio (ASTM D5084).

3 Results and Discussions

3.1 Influence of Cement Content on Soilcrete Hydraulic Conductivity

Figure 3 displays the hydraulic conductivity of the compacted sand specimen and the all soilcrete specimens made from the dredging sand mixing with the OPC cement at a curing time of 28 days. The hydraulic conductivity of the soilcrete specimens (ks) was from 103 to 105 times lower than that of the untreated sand. The ks decreased markedly with increasing in cement contents. The similar reports can be found from other researchers [5, 8, 9]. When the OPC cement was mixed with the moist sand, the cement hydration took place immediately creating the primarily products in gel forms of calcium-silicate-hydrate (CSH) and calcium-aluminate-hydrate (CAH). These cementitious products reduced pore spaces in the soilcrete specimen leading a reduction of ks [16]. Soilcrete specimen made with higher cement content produced more gel products, resulting in lower hydraulic conductivity. The research results suggest that the correlation between hydraulic conductivity of the soilcrete specimen made from the dredging sand and cement content can be estimated by Eq. (4):

where ks—hydraulic conductivity of sand soilcrete (m/s), Ac—OPC40 cement content (kg/m3).

3.2 Influence of Cement Types on Soilcrete Hydraulic Conductivity

Effect of cement types on the hydraulic conductivity was evaluated by comparing ks of the soilcrete specimens made from mixing the dredging sand with the three cement types of OPC, PCB, and PCS, respectively, at the same cement content of 300 kg/m3. The results presented in Fig. 4 indicate that the ks made from the PCB cement-mixed sand was higher than those created from the OPC and PCS cement-mixed sand, respectively. ks of the OPC soilcrete was lower than that of the PCS soilcrete for the first 35 days. However, after the first 35 days, ks of the PCS soilcrete declined significantly and became lower than ks of the OPC soilcrete. Markou and Droudakis [10] found the comparable trend. The OPC is a pure cement containing a larger proportion of clinker compared to the PCS cement. In the short term, the OPC cement-mixed sand produced more gels (CSH and CAH) due to the hydration reactions, resulting in lower hydraulic conductivity. In contrast, the PCS cement contains more pozzolans (SiO2, Al2O3). These pozzolans reacted with Ca2+ ions released from the hydration reactions to continue to generate additional gel products. In the long term, the PCS cement produced more gels in soilcrete specimens than the OPC cement at the same cement content to lead to lower hydraulic conductivity [10]. Additionally, the PCS cement has a higher fineness than the OPC cement resulting in an increment in filling pores in a soilcrete specimen to cause lower hydraulic conductivity [10].

3.3 Soilcrete Hydraulic Conductivity Versus Curing Time

The hydraulic conductivity of the soilcrete specimens varying with curing time is shown in Fig. 5. It can be seen that ks of the all soilcrete specimens diminished with curing time. The identical trends were reported by the authors [5, 11, 12]. Figure 5 exhibits that ks of the soilcrete specimens at the lower cement contents of 200 and 250 kg/m3 were almost stabilized after the first 15 days. However, for the soilcrete specimens at the higher cement contents of 300, 350, and 400 kg/m3, ks dropped sharply after the first 15 days. This result shows that the hydration process may need longer time to complete inside a soilcrete specimen at the higher cement content [17].

4 Conclusions

The several soilcrete specimens formed from the dredging sand taken in the Mekong delta to mix with the three cement types of OPC, PCB, and PCS at various cement contents, respectively were used for the hydraulic conductivity investigation. The all soilcrete specimens were carried out the permeability tests on the flexible wall permeameters by the falling head methods. For the compacted sand specimen, the hydraulic conductivity was determined on the rigid wall permeameter implementing the falling head-constant tailwater method. The permeability of the soilcrete was profoundly influenced by curing time, the types and the contents of the cements. The ks decreased with increasing in the cement contents and in curing time. The PCS cement induced long-term reduction of soilcrete permeability to compare with the OPC and PCB cement.

References

Schnaid, F., Prietto, P.D.M., Consoli, N.C.: Characterization of cemented sand in triaxial compression. Jour. Geotechnical & Geoenvironmental Eng. 127(10), 857 – 868 (2001).

Kamruzzaman, A.H.M.: Physico-Chemical and Engineering of cement treated Singapore marine clay. M.E. Thesis, National University of Singapore (2002).

Pakbaz, M.S., Farzi, M.: Comparison of the effect of mixing methods (dry vs. wet) on mechanical and hydraulic properties of treated soil with cement or lime. Applied Clay Science, 1–14 (2014).

Tran-Nguyen, H.H., Kitazume, M., Luong, B.T., Bui, T.T.: Laboratory investigation on An Giang soil mixed with dry cement. Malaysian Journal of Civil Eng. 26(1),77 – 88 (2014).

Bellezza, I., Fratalocchi, E.: Effectiveness of cement on hydraulic conductivity of compacted soil–cement mixtures. Proceedings ICE - Ground Improvement 10(2),77-90 (2006).

Yuzhen, Y., Jialiu, P., Keizo, U., Takashi, H.: A study on permeability of soil – cement mixture. Japanese geotechnical society 39(5), 145-149 (1999).

Pantazopoulos, A., Atmatzidis, D.K., Basas, V.G., Papageorgopoulou, S.K.: Effect of Grout Bleed Capacity on the Engineering Properties of Cement Grouted Sands. Proceedings of the 18th Int. Conf. Soil Mechanics & Geotechnical Eng., 2569–2572. Paris (2013).

Alkaya, D., Esener, A.B.: Usability of sand-bentonite-cement mixture in the construction of unpermeable layer. Scientific Research and Essays 6(21), 4492-4503 (2011).

Amhadi, T.S., Assaf, G.J.: Strength and permeability potentials of cement-modifed desert sand for roads construction purpose. Innovative Infrast. Solutions 5:79, 1-10 (2020).

Markou, I.N., Droudakis, A.I.: Factors Affecting Engineering Properties of Microfine Cement Grouted Sands. Geotech Geology Engineering 31, 1041–1058 (2013).

Akbulut, S., Saglamer, A.: Modification of hydraulic coductivity on granular soils using waste materials. Waste Management 24, 491-499 (2004).

Helson, O., Eslami, J., Beaucour, A., Noumowe, A., Gotteland, P.: Hydro-mechanical behaviour of soilcrete through a parametric laboratory study. Construction and Building Materials 166, 657-667 (2018).

American Society for Testing and Materials. Standard test method for laboratory compaction characteristics of soil using standard effort (600 kN-m/m3). ASTM D 698, 8 p. (1998).

American Society for Testing and Materials. Standard test method for measurement of hydraulic conductivity of porous material using a rigid wall, compaction mold permeameter. ASTM D5856, 8 p. (1995).

American Society for Testing and Materials. Standard test method for measurement of hydraulic conductivity of saturated porous material using a flexible wall permeameter. ASTM D5084, 24 p. (2010).

Abbey, S.J., Ngambi, S., Olubanwo, A.O., Tetteh, F.K.: Strength and Hydraulic Conductivity of Cement and By – Product Cementitious Materials Improved Soil. International Journal of Applied Engineering Research 13, 8684-8694 (2018).

Bahar, R., Benazzoug, M., Kenai, S.: Performance of compacted cement – stabilised soil. Cement and concrete composites 26, 811-820 (2004).

Acknowledgement

The authors thank Vietnam National University in Ho Chi Minh City (VNU-HCM) and Ho Chi Minh City University of Technology (HCMUT) for funding this research under grand No. B2018-20-04.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Luong, B.T., Tran-Nguyen, HH., Nguyen, P.D. (2022). Investigation of Hydraulic Conductivity of Soilcrete Specimens Made from Dredging Sand and Cement. In: Ha-Minh, C., Tang, A.M., Bui, T.Q., Vu, X.H., Huynh, D.V.K. (eds) CIGOS 2021, Emerging Technologies and Applications for Green Infrastructure. Lecture Notes in Civil Engineering, vol 203. Springer, Singapore. https://doi.org/10.1007/978-981-16-7160-9_72

Download citation

DOI: https://doi.org/10.1007/978-981-16-7160-9_72

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-7159-3

Online ISBN: 978-981-16-7160-9

eBook Packages: EngineeringEngineering (R0)