Abstract

Materials fabrication and characterization are the foundations of materials research. Transmission Electron Microscope (TEM) is a very powerful and versatile instrument used for the characterization of materials at nanoscale. Compared to the Electron Backscattered Diffraction (EBSD), the Nano-Beam Diffraction (NBD) in TEM allows characterization of structural information with high spatial resolution at localized positions. Moreover, the precession electron beam can provide pseudo-kinematical diffractions and improve the accuracy for structural determination. Thus, using precession nano-beam diffraction technique, the phase of materials, crystallographic orientations, dislocations and lattice mismatches can be revealed at nanometer scale through scanning the electron beam at the area of interest.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The Electron Backscattered Diffraction (EBSD) and Transmission Kikuchi diffraction (TKD) are popular techniques to study the phase and crystallographic orientation mapping of crystalline materials. The measurements are usually carried out in a scanning electron microscope (SEM), and using Kikuchi patterns to identify the information required. The spatial resolution is around 10 nm [1].

In order to achieve a higher resolution mapping, precession nano-beam diffraction (P-NBD) in transmission electron microscope (TEM) has gained interests over the years as it provides solutions of crystal structures in nanoscale by acquiring electron diffraction patterns from rotating a tilted TEM electron beam at a cone-shaped angle at the area of interest [2]. Conventional dynamic diffraction significantly decreases the scattering intensity in TEM diffraction patterns, especially when the crystal is orientated at the zone axis. In the precession mode, the diffraction can be collected and shown in axis without tilting the crystal exactly along a particular zone axis. Using this technique, the dynamical effects are strongly reduced, and the intensity of reflections in the pattern can follow the quasi-kinematical diffraction for the sample thickness up to 100 nm. With the combination of precession mode and NBD, both the phase and crystallographic mapping at nanoscale are obtained and these are complementary to EBSD and TKD characterizations. These collected diffraction patterns are then matched against the pre-calculated diffraction templates and analysed to reveal grain structures, orientation mapping, etc. [2,3,4]. Here, we introduce the applications and examples of P-NBD on materials analysis, and show the comparison between EBSD, TKD and NBD techniques.

2 Methods

Comparison of the different techniques was performed using a shot peened Ti64 coupon [5, 6]. EBSD analysis was achieved on the cross-section surface of the coupon, using a 20 kV electron accelerating voltage with a scan step size of 1 μm. Thin electron transparent slice from the top surface was prepared using Focus Ion Beam (FIB) for TKD and NBD analysis. Both techniques use scan step size of 10 nm, with 20 kV and 200 kV acceleration voltage respectively.

3 Results and Discussion

Figure 1 shows the analysis results of Ti64 coupon after a shot peening process. Shot peening is a cold working process in which the metal surface is hammered by metal shots and thus creating plastic deformation close to the surface. Figure 1a presents the cross-section SEM image of Ti64 after shot peening that is partially overlapped with a Kernal average misorientation (KAM) map obtained by EBSD. The orientation mapping from EBSD can be obtained for a large area. The bulk phase of Ti64 remains intact and large grains are seen. The grain size decreases from the bulk to the surface. The top surface after shot peening are shown in black, indicating that they are unindexed under EBSD analysis. This unindexed region could be due to the presence of amorphous structures, pores or voids, or small grains which are beyond EBSD resolution limit and thus unrecognized [5].

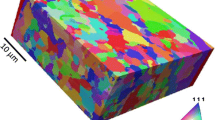

To address these doubts, an electron transparent slice was cut and prepared by FIB for TKD and NBD analysis. Figure 1b and 1c were taken at the same area of the sample. Although a few grains structures can be identified by TKD, most of the area is still dark and unidentified, probably owing to the poor quality Kikuchi patterns from lower acceleration voltage and larger electron beam size in SEM. However, NBD mapping using TEM is able to identify all areas unambiguously. From TEM phase and crystallographic mapping, the α-Ti grains and β-Ti strips (in black, crystal orientation is not shown here) can be indexed clearly. It is shown that the original large grains had been severely deformed and had broken into smaller ones with sizes from a few tens to a few hundreds of nanometres after shot peening had been applied on the surface.

From the example shown above, we can summarize the comparison of EBSD, TKD and NBD techniques in Table 1. SEM-EBSD can obtain information on large specimen but requires a flat and highly polished surface due to electron diffraction from backscattered electrons. The resolution can reach 20 nm using field emission SEM, but is difficult to be achieved on most samples due to poor quality Kikuchi patterns from small grains. TKD and NBD use transmitted elections, thus electron transparent samples are required which limits the scan area of the specimen. The resolution is much higher than EBSD and the grains as small as 10 nm can be easily shown by NBD mapping.

Figure 2 shows the TEM crystallographic orientation map of Ti64 sample with and without beam precession. Some noise is found at the bottom of the map without precession mode, which is highlighted by the rectangle. Typically, the bottom part of FIB prepared sample is thicker than the top, thus less electrons can pass through and less/weaker diffraction spots are produced. Hence, the diffraction is difficult to be identified due to limited presence of diffraction spots in the pattern. On the contrary, the precession mode can accumulate all the electron patterns when the beam is scanned by rotating in a cone-shape. More diffraction spots are obtained and the improved quality of the pattern can make the identification more accurate. In this case, the α-Ti grains can be identified and noise is minimized with precession mode.

4 Conclusion

Precession nano-beam electron diffraction in TEM plays a substantial role for full analysis of nanostructured materials, including high quality nanoscale phase and orientation mapping and achieves better resolution for smaller grain samples. It is complementary to SEM-EBSD and a combination of both would provide a comprehensive characterization of materials structures from bulk to nanometer scale.

References

Oxford Instruments. http://www.ebsd.com/ebsd-applications/ebsd-applications-by-technique/tkd. Accessed 10 June 2021

Brons, J.G., Thompson, G.B.: Orientation mapping via precession-enhanced electron diffraction and its applications in materials science. JOM 66(1), 165–170 (2013). https://doi.org/10.1007/s11837-013-0799-5

Darbal, A.D., Gemmi, M., Portillo, J., Rauch, E., Nicolopoulos, S.: Nanoscale automated phase and orientation mapping in the TEM. Microsc. Today 20(6), 38–42 (2012)

Rauch, E.F., Véron, M.: Automated crystal orientation and phase mapping in TEM. Mater. Charact. 98, 1–9 (2014)

Zhang, Z., et al.: Fatigue life enhancement in alpha/beta Ti-6Al-4V after shot peening: an EBSD and TEM crystallographic orientation mapping study of surface layer. Materialia 12, 100813 (2020)

Lim, S.H., et al.: Warm shot peening on Ti-6Al-4V alloy: effects of temperature on fatigue life, residual stress, microstructure and mechanical properties. J. Alloy. Compd. 882, 160701 (2021)

Acknowledgement

This research is supported by the Agency for Science, Technology and Research (A*STAR) under the Structural Metal Alloys Programme (A18b1B0061).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Teo, S.L., Tan, D.C.C., Lin, M. (2022). Application of Phase and Crystallographic Orientation Mapping for Materials Characterization. In: Wei, Y., Chng, S. (eds) Proceedings of the 2nd International Conference on Advanced Surface Enhancement (INCASE 2021). INCASE 2021. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-5763-4_20

Download citation

DOI: https://doi.org/10.1007/978-981-16-5763-4_20

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-5762-7

Online ISBN: 978-981-16-5763-4

eBook Packages: EngineeringEngineering (R0)