Abstract

Vertical wells are widely used in the development of thick multi-layer oil reservoirs. The reservoir permeability and perforation location have a great impact on the oil productivity. This study presents the development and application of a new steady-state productivity equation for partially perforated vertical wells in the thick multi-layer oil reservoir, which is of great significance for the reservoir development plan design. Following the hydro-electricity similarity principle and the equivalent percolation resistance law, the entire flow process is divided into planer radial flow and approximate hemispherical flow, which takes into account the reservoir’s multi-layer heterogeneity and vertical wells’ partial perforation. For the approximate hemispherical flow near well bore, the horizontal plate oil layers was transformed to annular layers with different permeability following the principle of constant volume. The flow resistance of each part is calculated respectively, and the steady-state productivity equation of partially perforated vertical well is derived. The new equation’s feasibility is verified by actual well of B oilfield in Iraq, which shows good agreement between the calculated productivity and actual performance. Besides, a type curve template of dimensionless productivity versus perforation ratio is plotted for reservoirs with different permeability ratio. The template shows a nonlinear correlation between the well productivity and perforation ratio, which can be used to establish the perforation principle for vertical wells. To sum up, the application examples reveals that the productivity equation established in this study can reflect the impact of reservoir’s multi-layer heterogeneity and the perforation thickness on well productivity, and the prediction accuracy is acceptable and competitive.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Due to the advantages of easy drilling, low cost, and convenient operation management, vertical wells have been widely used in the development of oilfields [1,2,3]. Vertical wells can generally achieve good performance with high production and easy water shut-off operation especially for the thick multi-layer reservoirs [4,5,6,7]. Although there is almost no interlayer in the thick reservoir and the net to gross (NTG) is close to 1.0, there is still great heterogeneity between each layer. Besides, only part of the top layers is usually perforated in order to slow down bottom water breakthrough from the oil-water transitional zone. Taking into account both the multi-layer heterogeneity and partial perforation, it is difficult to predict the productivity of vertical wells [8,9,10,11,12].

The classical productivity equation was developed to calculate the productivity of vertical wells penetrating through multiple oil layers with different permeability [1].

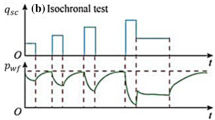

Further, using the hydro-electricity similarity principle and the equivalent percolation resistance law, the steady state productivity of a partially perforated vertical well in the center of a circular thick homogeneous reservoir can be estimated as follows [4] (Fig. 2):

Equation (1) and Eq. (2) have been widely used in the oilfield development, but are not feasible for vertical wells that penetrate multi-layers with different permeability and are partially perforated [8]. The objective of this study is to propose a new productivity equation for this kind of vertical wells based on the hydro-electricity similarity principle and the equivalent percolation resistance law. The flow line model of vertical wells, penetrating thick multi-layer reservoir and partially perforated, is divided into two types: planar radial flow and approximate hemispherical flow. The flow resistance is calculated for each part respectively and the new productivity equation is developed combining all the resistance items. Hopefully, this research can provide technical guidance for the development of thick oil reservoirs.

2 Development of Productivity Equation

2.1 Model Assumptions

In order to develop the new productivity equation, the subsurface flow model is established and assumed as follows. One vertical well is drilled in the center of a horizontal circular formation. The formation is equal-thickness and have multiple oil layers with different properties. The well only penetrates some oil layers at the top of formation. There is sufficient liquid supply on the edge of the formation. As is shown in Fig. 1, the radius of supply edge is Re, the wellbore radius is Rw. the formation includes n layers, the thickness of each layer is h1, h2,…, hn, and the permeability of each layer is k1, k2,…, kn. The fluid viscosity of each layer is μ, the effect of gravity is ignored, the pressure at the supply edge is Pe, the flowing pressure of each layer at the well bottom is Pw, and the formation thickness that is penetrated by the vertical well is hp. Both fluid and porous media are incompressible, and single-phase fluid has steady state flow which follows Darcy’s law.

2.2 Deviation of New Equation

As is shown in Fig. 3, the flow types of the partially opened vertical well can be divided into two parts. The first part is the planer radial flow in the layers penetrated by well, whose flow resistance can be calculated as follows:

Where \({R}_{1}^{^{\prime}}\) is the flow resistance of planer radial flow in the layers penetrated by vertical wells, \({10}^{5}Pa\cdot s/{cm}^{3}\). μ is fluid viscosity, \(mPa\cdot s\). Re is radial flow radius, cm. Rw is the well bore radius, cm. hp is thickness of opened layers, cm. ki is the permeability of each layer, μm2. h is the total formation thickness, cm.

The second part is the flow in the unpenetrated layers, including planer radial flow in the formation far away wellbore and approximate hemispherical flow near the wellbore. The planer radial flow can be calculated as follows:

Where \({R}_{2}^{^{\prime}}\) is the flow resistance of planer radial flow in the unpenetrated layers, \({10}^{5}Pa\cdot s/{cm}^{3}\). \({R}_{p}\) is the radius of hemispherical flow, cm.

For the hemispherical flow into the well bottom hole, the horizontal plate oil layers is transformed to annular layers with different permeability following the principle of constant volume. The schematic diagram of equivalent transformation is shown in Fig. 4.

The radius of each annular layer can be calculated as follows:

Where \({r}_{i}\) is the out radius of each annular layer, cm. R is radius of hemispherical flow, cm. \({H}_{i}\) is the top surface height of horizontal plate layers, cm. If \(i=1\), \({r}_{0}={R}_{w}\).

As is shown in Fig. 5, the permeability of each annular layer is \({k}_{1},{k}_{2},\)…,\({k}_{n},\) the fluid viscosity is \(\mu \), the hemispherical flow resistance of multi-layer horizontal plate formation can be approximately characterized by that of heterogeneous annular layers.

Where \({R}_{3}^{^{\prime}}\) is the hemispherical flow resistance of the unpenetrated layers, \({10}^{5}Pa\cdot s/{cm}^{3}\). \({r}_{i}\) the radius of annular formation, cm.

Following the hydro-electricity similarity principle and the equivalent percolation resistance law, the new proposed productivity equation is as follows:

Where Q is the subsurface flow rate, cm3/s. Pe is the pressure at formation edge, 105 Pa. Pw is the flowing pressure at well bottom hole, 105 Pa.

During the deviation process, part of the horizontal plate layers is transformed to annular layers with different permeability following the principle of constant volume. In order to verify feasibility of this transformation, the numerical method and analytical method are comparatively used to estimate the vertical well productivity. The radius of circular formation is 500 m, there are 4 horizontal layers whose thickness are 10 m, 5 m, 15 m, and 10m from the top to bottom respectively. The corresponding permeability of 4 layers are 100 \(\times {10}^{-3}{\mu m}^{2}\), 50 \(\times {10}^{-3}{\mu m}^{2}\), 30 \(\times {10}^{-3}{\mu m}^{2}\) and 100 \(\times {10}^{-3}{\mu m}^{2}\). \({\mu }_{o}=0.92 \,\,mPa\cdot s\), \({B}_{o}=1.415\,\,{m}^{3}/{m}^{3}\). The vertical well, located in the center of the circular formation, penetrates 10m oil layer at the top of formation, the well bore radius is 0.074 m. The productivity indexes calculated by numerical method and the new proposed model are 48.6 m3/d/MPa and 48.8 m3/d/MPa respectively. The relative difference of two results is about 0.4%, which indicates that the equivalent transformation of horizontal plate formation into annular heterogeneous formation is acceptable to characterize the hemispherical flow resistance near well bore.

Under more general condition, the vertical well penetrates all the oil layers and complete by casing. And then perforate according to the development requirement. As shown in Fig. 6, the fluid flow in the layers with perforation is planer radial flow, and the fluid flow in layers with no perforation includes planer radial flow and hemispherical flow near well bore.

Ignoring the skin caused by perforation, the flow resistance of each part can be characterized.

The resistance of radial flow in layers with perforation:

The flow resistance in layers above perforation:

The flow resistance in layers below perforation:

Following the hydro-electricity similarity principle and the equivalent percolation resistance law, the new productivity equation for vertical well in Fig. 6 is as follows:

Where, \({h}_{u}\) is the thickness of layers above perforation, cm. \({h}_{d}\) is the thickness of layers below perforation, cm. \({R}_{pu}\) is the radius of hemispherical flow in layers above perforation, cm. \({R}_{pd}\) is the radius of hemispherical flow in layers below perforation, cm. \({n}_{u}\) is the number of layers above perforation, integer. \({n}_{d}\) is the number of layers below perforation, integer. \(R^{\prime\prime}_{1}\) is resistance of radial flow in layers with perforation, \({10}^{5}\,\,Pa\cdot s/{cm}^{3}\). \(R^{\prime\prime}_{2}\) is the flow resistance in layers above perforation, \({10}^{5}\,\,Pa\cdot s/{cm}^{3}\). \(R^{\prime\prime}_{3}\) is the flow resistance in layers below perforation, \({10}^{5}\,\,Pa\cdot s/{cm}^{3}\).

3 Results and Discussion

Taking one well of B oilfield in Iraq as an example, the reservoir and fluid properties are as follows. \({R}_{e}=400\,\,\mathrm{m}\), \({R}_{w}=0.074\,\,m\), \({P}_{e}=35\,\,MPa\), \({P}_{w}=30\,\,MPa\), \(\mathrm{h}=83.5\,\,\mathrm{m}\), \({\mu }_{o}=0.92\,\,mPa\cdot s\), \({B}_{o}=1.415\,\,{m}^{3}/{m}^{3}\), the perforation thickness from the top surface \({h}_{p}=13\,\,m\). The thickness and permeability for each layer of the formation are shown in Table 1.

The productivity of this well is calculated as 362 m3/d by Eq. (7), and the actual initial productivity of this well is 338 m3/d. the relative difference between calculated result and actual productivity is 7.2%.

Besides, this study define the productivity under full perforation condition as \({Q}_{max}\), the productivity with the perforation thickness of \({h}_{p}\) from the top is \(Q\), the dimensionless productivity \({Q}_{D}=Q/{Q}_{max}\). The perforation ratio \(\beta ={h}_{p}/h\). The multi-layer formation is simplified into two-layer formation. \({h}_{1}=10\mathrm{m}\), \({h}_{2}=70m\), \({k}_{1}=100\times {10}^{-3}{\mu m}^{2}\). When \({k}_{1}/{k}_{2}=0.1, 1, 10, 100,\) the productivity is calculated by Eq. (7), and the type curve template of dimensionless productivity versus perforation ratio is drawn in Fig. 7. The type cure template can be used to develop perforation principles for this kind of reservoirs.

As is shown in Fig. 7, the dimensionless productivity has a non-linear relationship with the perforation ratio \(\beta \). Further, it indicates that the productivity has a non-linear relationship with the perforation thickness. The productivity is increasing with the augment of perforation thickness. With the augment of \({k}_{1}/{k}_{2}\), the dimensionless productivity under the same perforation ratio \(\beta ={h}_{1}/h\) increases obviously.

4 Conclusion

A new analytical steady-state productivity equation for vertical wells was proposed, which take into account the reservoir’s multi-layer heterogeneity and vertical wells’ partial perforation. This equation successfully correlated productivity to the flow resistance of different flow types, including planer radial flow and approximate hemispherical flow near well bore. For the hemispherical flow near well bore, the horizontal plate layers was transformed to annular layers with different permeability following the principle of constant volume. The feasibility of new productivity equation was verified by the actual well performance of B oilfield in Iraq. A type curve template of dimensionless productivity versus perforation ratio was drawn for reservoirs with different \({k}_{1}/{k}_{2}\) and it can be used to develop perforation principles for the vertical wells.

-

(1)

The little relative difference between the productivity indexes, comparatively calculated by numerical method and the new proposed equation, indicates that the equivalent transformation of horizontal plate formation into annular heterogeneous formation following constant volume is acceptable to characterize the hemispherical flow resistance near well bore.

-

(2)

The application result in B oilfield shows good agreement between the calculated productivity and actual well performance, which verifies the feasibility of proposed equation.

-

(3)

The well productivity has a non-linear relationship with the perforation thickness for the partially perforated vertical wells in multi-layer heterogeneous reservoirs. The type curve template can be used to establish perforation principles for this kind of vertical wells.

References

Zhang Jianguo, D., Dianfa, H., et al.: Reservoir seepage mechanics. China University of Petroleum Press, Dongying (2009)

Hui, L.I.U., Rui, G.U.O., Junchang, D.O.N.G., Li, L.I.U., Yang, L.I.U., Yingjie, Y.I.: Productivity evaluation and influential factor analysis for Sarvak reservoir in South Azadegan oil field, Iran. Pet. Explor. Dev. 40(5), 627–634 (2013). https://doi.org/10.1016/S1876-3804(13)60082-8

Zhengfu, N., Shugang, H., Linsong, C., et al.: Productivity calculation method of fractured horizontal wells in low permeability oil or gas field. Acta Petrolei Sinica 23(2), 68–71 (2002)

Linsong, C.: Advanced reservoir seepage mechanics. Petroleum Industry Press, Beijing (2011)

Yanfeng, H., Xiaodong, W., Zengjun, H., et al.: A new method for capacity prediction of oil wells in low permeability reservoirs. J. China Univ. Pet. 31(5), 69–73 (2007)

He, C., Mu, L., Xu, A., et al.: A new model of steam soaking heating radius and productivity prediction for heavy oil reservoirs. Acta Petrolei Sinica 36(12), 1564–1570 (2015)

Wenchao, L., Dengke, T., Shiming, Z.: A new method for calculating productivity of horizontal well in low-permeability heavy oil reservoir. Acta Petrolei Sinica 31(3): 458–462 (2010)

Longlong, L., Minglu, W., Jun, Y., et al.: Calculation method of the productivity of partially perforated vertical well. Pet. Drill. Tech. (2014)

Botao, K., Yingchun, Z., Jian, P., et al.: Rapid prediction method for critical formation pressure of asphalt contamination in large carbonate oilfield: take Buzurgan oilfield as an example. Sci. Technol. Eng. (26), 84–90 (2018)

Baojian, D., Linsong, C., Renyi, C., et al.: Development effects of the volumetric fracturing horizontal well in tight oil reservoirs. Pet. Geol. Oilfield Dev. Daqing 33(1), 96–101 (2014)

Yisheng, L., Yuetian, L., Changyong, L., et al.: Division of flow units in thick carbonate reservoirs:taking mf reservoir in middle east as an example (in chi). J. Xi’an Shiyou Univ.(Nat. Sci.) 34(2), 104–111 (2019)

Liu, Y., Liu, Y., Zhang, Q., Li, C., Feng, Y., Wang, Y., Xue, Y., Ma, H.: Petrophysical static rock typing for carbonate reservoirs based on mercury injection capillary pressure curves using principal component analysis. J. Pet. Sci. Eng. 181, 106175 (2019). https://doi.org/10.1016/j.petrol.2019.06.039

Zhiqiang, M., Jinfu, L.: Method and models for productivity prediction of hydrocarbon reservoirs. Acta Petrolei Sinica 21(5), 58–61 (2000)

Linsong, C., Chunlan, L., Zhaoxin, L., et al.: The productivity study of branch a horizontal well with multiple branched wells. Acta Petrolei Sinica 16(2), 49–55 (1995)

Yuanqian, C., Erpeng, G., Zixuan, P., et al.: Derivation of productivity formulas for horizontal wells in anisotropic fault-block reservoirs. Acta Petrolei Sinica 38(12), 1420–1424 (2017)

Acknowledgments

The study is supported by the National Major Science and Technology Projects of China (Number 2017ZX05032004).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Li, Cy., Pi, J., Zhang, Y., Qi, Cx., Zhai, Gf. (2021). Steady-State Productivity Equation for Partially Perforated Vertical Wells in Multi-layer Heterogeneous Oil Reservoir. In: Lin, J. (eds) Proceedings of the International Field Exploration and Development Conference 2020. IFEDC 2020. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0761-5_190

Download citation

DOI: https://doi.org/10.1007/978-981-16-0761-5_190

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0762-2

Online ISBN: 978-981-16-0761-5

eBook Packages: EngineeringEngineering (R0)