Abstract

The expensive manufacturing process and low efficiency at high working temperature of Solar cells necessitate the need for an alternate solar energy generation system. Solar concentrated thermal electric system has proved to be a promising candidate for a reliable energy conversion system. In this study, Fresnel lens had been chosen as the concentrating medium due to its low weight and easy installation. Optimum design of the Fresnel lens setup inclusive of the ability to track during an entire solar day has been devised. Standard TEG of material bismuth telluride was considered for energy harvesting from concentrated solar irradiance, and complete cost analysis was performed, and payback period of the proposed model was found out to be considerably less compared to conventional solar panel system.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Fossil fuel is a general term for buried combustible geologic deposits of organic materials, formed from decayed plants and animals that have been converted to crude oil, coal, natural gas, or heavy oils by exposure to heat and pressure in the earth’s crust over hundreds of millions of years. The total primary energy uses of Inhdia are coal (44%), petroleum and other liquids (23%), biomass and waste (23%), natural gas (6%), nuclear (1%), hydroelectric (2%) and Other renewable (1%). About 80% of India’s electricity generation is from fossil fuels. The burning of fossil fuels by humans is the largest source of emissions of carbon dioxide, which is one of the greenhouse gases that contribute to global warming [1].

Solar Energy: Solar power is usable energy generated from the sun in the form of electric or thermal energy. Solar energy is captured in a variety of ways, solar thermal systems, solar photovoltaic (PV) and concentrating solar power (CSP) systems, and the most common of which is with photovoltaic solar panels that convert the sun’s rays into usable electricity. Even though solar energy is a renewable source, it is not a clean source, because one of the major ways of tapping solar energy is by using the PV panels which is a PN junction diode made up of single-crystal silicon or amorphous silicon. These materials are generally manufactured by various techniques like the Czochralski process, float zone process, zone refining or by cutting wafer process; out of these, Czochralski is the imminent one, and this process of producing solar PV panels is not eco-friendly, and they arrive with serious environmental issues. So, there is a need for another efficient or prominent way of tapping this solar energy which is by using the solar thermoelectric generators [2].

A solar collector is an object that is used to collect energy from the sun, which it does by absorbing solar radiation and converting it into heat or electricity. The parabolic trough reflector is one of the majorly used solar thermal energy collectors designed to capture the sun’s direct solar radiation over a large surface area and focus, or more generally “concentrate it” onto a small focal point area on the trough [3]. Even though it offers good concentrating solar energy at the TEG system, the maintenance, overall weight and the cost of this conventional trough collector is too high. So, we need a simple and lightweight collector to collect the solar radiation. To rectify this problem, a Fresnel lens collector is used. A Fresnel lens replaces the curved surface of a conventional optical lens with a series of concentric grooves. These contours act as individual refracting surfaces, bending parallel light rays to a common focal length [4]. As a result, a Fresnel lens, while physically narrow in profile, is capable of focusing light similar to a conventional optical lens but has several advantages over its thicker counterpart. One of the most common applications for a Fresnel lens is the collection of solar light, which is considered very nearly parallel (an infinite-conjugate system). Using a Fresnel lens for light collection is ideal for concentrating light onto a photovoltaic cell or to heat a surface [5]. There are two main types of Fresnel lens: imaging and non-imaging. Imaging Fresnel lenses use segments with curved cross sections and produce sharp images, while non-imaging lenses have segments with flat cross sections and do not produce sharp images. As the number of segments increases, the two types of the lens become more similar to each other [6]. The major application of this Fresnel lens is in imaging, photography, illumination, solar power, etc., Fresnel lenses can concentrate sunlight onto solar cells with a ratio of almost 500:1. This allows the active solar-cell surface to be reduced, lowering cost and allowing the use of more efficient cells that would otherwise be too expensive [7].

2 Thermoelectric Generators

It is a solid-state device that either converts heat directly into electricity or transform electrical energy into thermal power for heating or cooling. Such devices are based on thermoelectric effects involving interactions between the flow of heat and of electricity through solid bodies. A thermo-electrical generator consists of a heat source, which is kept at a high temperature and a heat sink, which is maintained at a temperature less than the heat source.

3 Background of the Work

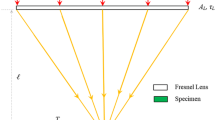

Initially a Fresnel lens of the specifications (Table 1) was chosen. The lens was purchased and framed; with the help of concrete tubes, the lens was raised from ground horizontally at a height of 200 cm (as shown in Fig. 1) with respect to its focal length.

Optical pyranometer along with a beaker (containing water) was used in order to know the variation of focal point with respect to time, and Fig. 2 was obtained. The figure shows that the focal point moves along a path following a semicircle of radius 200 cm. Thus by experiment, it was found that solar tracking was essential for efficient solar energy utilisation. However, says that conventional solar tracking consumes power and might be economically inefficient [8]. Thus, an efficient Fresnel lens system had been developed in this paper which is more economical and simple compared to the previous systems [9].

4 Proposed Fresnel Lens System

-

(a)

Initial conditions: The Fresnel lens specification (Table 1) was kept constant. Lead Telluride was chosen as the TEG module due to its high melting point and cost effectiveness.

-

(b)

Boundary Conditions: The latitude of the place where the solar system must be considered for inclination about north-south direction, i.e. the latitude of Coimbatore is 11.01° N, so the lens must be tilted about 15 + 11.01 = 26.01° during summer and 11.01 − 15 = −3.99° during winter [10].

The Target material was considered to be placed in line with the optic centre of the Fresnel lens.

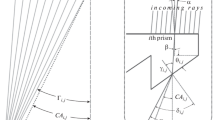

Model 1: In order to do away with the traditional power consuming solar tracking setup, initially two lens system was considered as shown in Fig. 2.

The above model was designed with consideration that the concentrated spot would lie always in a specified area (common area of the two semicircles) throughout the solar day. The design was imported into Trace pro software, and the inclination was varied in order to obtain efficient concentration of solar power in the common area throughout the day. The lens was considered to be inclined at 15° to the horizontal as shown in Fig. 2. Model 2: Another type of setup such as the three-lens setup was proposed as shown in Fig. 3.

The model was analysed in Trace pro software, and the optic centre distance between the left and right was changed with respect to change in inclination of lenses, and the amount of radiation incident on the target with respect to radiation incident on the lens was noted, and the inclination and distance between the lenses at optimal point were recorded. 20 target materials each of 4 * 4 cm2 was arranged in a line about 200 cm from each lens. Thus, the final proposed model is shown in Fig. 3.

The optic centre distance was set finally as 300 cm. The left and right Fresnel lens were inclined at about 10° towards right and left, respectively.

5 Results and Discussion

Model 1: Considering the inclination angle and the optic centre distances between the lenses, simulation results stated that the system concentrates effectively during before and after noon, however, the system does not concentrate during the noon (hours of peak intensity) due to the significant gap between the lens. Hence, the system has proved to be inefficient during the significant noon time, thereby this model was rejected.

Model 2: The amount of radiation incident at target material with respect to radiation incident at Fresnel lens during AM period was found out by setting light source in respective manner (Fig. 4). Similar method was used during noon and PM (Fig. 5).

The following calculation was done in order to obtain payback period of the proposed design similar to the calculation done in the work [8]:

Heat input at target:

Total cost of the setup was Rs. 22,000

The payback period in the proposed system is considerably less than that of conventional solar system. Hence, the proposed three lens concentrated system can be considered as a candidate for an efficient solar thermal system.

6 Conclusion

The critical parameters of a Fresnel concentrated system were identified, and suitable decisions and values were chosen for them. An efficient tracking concentrated system was designed using Trace pro software, and necessary calculations were done to obtain the payback period which was found to be less than the conventional concentrated system stating that the concentrated system designed is efficient.

References

Kibria A et al Fossil fuel share in the energy mix and economic growth

Kasaeian A et al (2018) A review on parabolic trough/fresnel based photovoltaic thermal systems. Renew Sustain Energy Rev 91:193–204 (Department of Renewable Energies)

Xu Y, Wang L, Zhang X et al (2008) Experimental study on solar cell arrays of trough concentrating solar system, Pantoa Ti Hsueh Pao. Chin J Semicond 29:2421–2426

Kumar V, Shrivastava RL, Untawale SP (2015) Fresnel lens: a promising alternative of reflectors in concentrated solar power. Renew Sustain Energy Rev 44:376–390

Zheng H, Feng C, Su Y et al (2014) Design and experimental analysis of a cylindrical compound Fresnel solar concentrator. Sol Energy 107(9):26–37

Li P, Cai L, Zhai P et al (2010) Design of concentration solar thermoelectric generator. J Electron Mater 39:1522–1530. https://doi.org/10.1007/s11664-010-1279-0

Khan F, Baek SH, Kim JH (2014) Intensity dependency of photovoltaic cell parameters under high illumination conditions: an analysis. Appl Energy 133(6):356–362

Zhai H, Dai Y, Wu J (2007) Investigation of concentrating solar photovoltaic/thermal system performance based on Fresnel lens. J Eng Thermophys 28(5):725–728

Seme S, Srpčič G, Kavšek D et al (2017) Dual-axis photovoltaic tracking system. Design and experimental investigation. Energy 139

MaMiller DC, Kurtz SR (2011) Durability of Fresnel lenses: a review specific to the concentrating photovoltaic application. Sol Energy Mater Sol Cells 95

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Babu, S., Sriram, R., Gopikrishnan, S., Praveen, A. (2021). Solar Energy Simulation of Fresnel Lens Concentrated System for Thermal Electric Generator. In: Prabu, T., Viswanathan, P., Agrawal, A., Banerjee, J. (eds) Fluid Mechanics and Fluid Power. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-0698-4_91

Download citation

DOI: https://doi.org/10.1007/978-981-16-0698-4_91

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-0697-7

Online ISBN: 978-981-16-0698-4

eBook Packages: EngineeringEngineering (R0)