Abstract

Prefabricated vertical drains (PVDs) are frequently used to decrease the drainage path of water within soft soils to accelerate the time rate of consolidation. In this paper, the settlement of PVD-reinforced silty-clay soil prepared at OMC is determined using a model box of measures 33.90 cm diameter and 60 cm high to evaluate the effectiveness of the PVD at OMC. For an increase of surcharge load, the increase in the settlement is recorded every 10 days of an interval with the help of dial gauges attached with it. Settlement of the PVD-reinforced soil bed is found to be increased compared to the unreinforced one and is more pronounced in the cases where higher surcharge loads are applied. But, the results of the settlement became closer to each other at 6 and 8 kPa of surcharge load (stress). From these testing results, it may be concluded that PDVs are effective around up to 6 kPa or it may be said that PVDs can extract water from soft soils even when the soil is compacted at OMC.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Prefabricated Vertical Drains (PVDs) are used in soft soils, over which any important civil engineering structures can be constructed, to accelerate the consolidation process of the soil and hence reduce the time required for the completion of the project areas. Application of Prefabricated Vertical Drain (PVD) is a soft soil repairing method that has been used for over 30 years replacing the conventional sand drain. If a building is built on soft soil that can be compacted, it will automatically occur on the soil compaction that will obviously disrupt the stability of structures above it. The timing of the compression that occurs may take place in a short time or tend to be very long. The use of vertical drains is what will reduce the time of compression that initially lasts a long time and then becomes much shorter. Before the 1970s, compression of the soft ground using sand drain and the horizontal sand blanket drain method was expensive and the corresponding processing time was very long. Other than that, the pores of sand mass can be clogged by soil particles that have a diameter smaller than the sand particles such that it can block the drainage of water out of the existing field or ground. In the early 1980s, the production of prefabricated vertical drains began to develop and was used as a substitute for the use of sand drains. The installation of PVD is relatively faster and cheaper than sand drain such that at the end of 1980, it began to grow and was widely used worldwide. Around the year 1987, PVD was used in conjunction with the Prefabricated Horizontal Drain (PHD) in field projects. Because of these, today in every road construction project such as airport, dam and toll road, PVD is always used to condense soft soil. Mostly, settlement criteria are a matter of concern if any civil engineering construction is to be built over soft soil deposits. This type of soil can be improved using vertical drains such as sand drains, wick drains and prefabricated vertical drains. Nowadays, PVDs are preferred compared to other types of vertical drains owing to their easy and feasible installation methods. The time required for construction also decreases while PVDs are used. Vertical drains will reduce the time of compression that initially lasts a long time.

Close horizontal spacing of about 1 to 3 m greatly accelerated consolidations of the soil deposits [13]. In many projects of soil improvement throughout the world, the well-known technique of preloading associated with vertical drains proved to be effective in accelerating consolidation of soils, thus increasing the shear strength of the soil and reducing post-construction settlement (e.g., [1, 11, 14, 15, 19, 22,23,24]). Nowadays, popular methods to speed up the consolidation of soft soil are the utilization of synthetic or polymer-based PVDs [12]. Certain operational problems, such as clogging and bending, are inherent to PVDs but they accelerate [9] the consolidation process of soft soils and help to rapidly increase its strength and stiffness. However, the soil displacement method with the compaction of granular material may be the most effective construction method [21]. If the pores of the filter materials are clogged, reduction in the discharge capacity of the PVD is observed and consequently, the consolidation process is impeded. Creep deformation of the PVD filters decreases the long-term discharge capacities of four types of prefabricated vertical drains (PVDs) confined in clay [20] that ultimately decrease the consolidation settlement of the soil. The construction rate and spacing of PVDs can significantly affect the degree of consolidation at the end of construction and the stability of the embankment [18]. A relatively simple method for calculating the degree of consolidation and the strength gain of the foundation soil during construction was evaluated based on finite element results, and those were shown to be reasonably conservative. Drain clogging and well resistance of long drains lead to reduced settlement [10] compared with that which would be expected from ideal drains, and both analytical and numerical modelling details are elucidated based on the authors’ experience and other research studies. Quality control tests for PVDs, selection of design parameters and smear effect greatly affect the design of PVDs [10]. Using a higher surcharge is a way to shorten the consolidation time of the soil. The smear zone develops around vertical drains upon withdrawal of the pipe/mandrel that leads to reduced permeability and increases compressibility [17]. In this study, no mandrel is used during preparing soil samples.

The area of research which remains to be explored is to investigate the deformation of prefabricated vertical drain-reinforced soils prepared at optimum moisture content.

2 Experimental Test Program and Setup

2.1 Objective of the Present Study

The aim and objective of the present study are to determine the settlement behaviour of the locally available soft soil reinforced with Prefabricated Vertical Drain prepared at Optimum Moisture Content, i.e., to find out the effectiveness of PVD in terms of the settlement of the locally available silty-clay soil prepared at OMC.

2.2 Materials and Sample Preparation

2.2.1 Materials

The materials that were used for the experimental works are silty-clay soil and a prefabricated vertical drain. The soil was collected from Ananda Nagar bypass road of Khayerpur-Agartala, Tripura, India, and the PVD was bought from Maccaferri Private Limited, India. Geotechnical properties of the soil and technical specifications of the PVD are shown in Tables 1 and 2, respectively.

2.2.2 Sample Preparation

First, the soil bed is prepared at Optimum Moisture Content of the soil and then placed in the model box in three layers. Without the insertion of any PVD, the experimental tests are conducted and completed. Later on, another set of experimental tests are conducted on the soil bed where a PVD is kept straight vertically at the middle of the box before the placement of the soils into it. A mandrel is not used to eliminate the effect of disturbance upon insertion and withdrawal of mandrel.

2.3 Model Used in the Test Programs

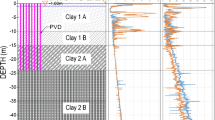

The size of the model used in this study is 60 cm high and 33.90 cm in diameter made of steel. It is shown in Fig. 1. After the preparation of the soil bed, it is covered with a sand layer of 1 cm thickness. Then, a seating plate of 15 mm thick is placed over the top surface of the sand layer. Over the seating plate, a loading beam with a groove is placed connected to a loading bar with a bearing ball through which dead loads are applied that pass uniformly onto the soil bed. Loading bar, lever arm, dial gauges and other parts of the model are shown in Fig. 1. Lever arm ratio \(\left( {l_{2} /l_{1} } \right)\) is 10, where l2 = 100 cm and l1 = 10 cm.

2.4 Methodology

In the first case, the bed of the silty-clay soil is prepared at optimum moisture content, i.e., at 22.43% and placed in the model at three stages by tamping. A sand layer of 10 mm thickness is placed. Thereafter, a seating plate of 15 mm thickness is placed over the soil bed. Now, with the help of a lever arm, vertical surcharge pressure of 2 kPa is applied over the seating plate through the loading bar. After 10 days, another vertical pressure of 2 kPa is added to the previous load, i.e., now the load is 4 kPa. In other words, the increment of pressure is 2 kPa per 10 days. In this way, a total surcharge pressure of 16 kPa is attained after long 80 days. Settlements are calculated with the help of two dial gauges placed at the opposite corner of the seating plate. The same test procedure is followed for other surcharge pressures such as 4 kPa, 6 kPa and 8 kPa leading to final surcharge pressures of 32 kPa, 48 kPa and 64 kPa, respectively, after 80 days. The test setup is shown in Fig. 1.

In the second case, a prefabricated vertical drain is held vertically in the middle of the model tank, and the soil bed prepared at optimum moisture content is place into the model in three stages. Here, no mandrel is used in this study so the disturbance around the drain due to mandrel insertion is eliminated. So, there is no question about the presence of a smear zone. The top surface of the soil bed is smoothened thereafter, and a layer of sand of thickness 1 cm is dressed over it. Then, a seating plate is placed over the soil bed, and the same test procedures are repeated as mentioned in the first case. Experimental works are kept under the observations for 80 days. Figure 2 shows the test setup.

3 Result and Discussions

3.1 Effect of Time Period on Settlement

Various soil beds are prepared at OMC, and vertical pressures (i.e., 2, 4, 6 and 8 kPa) are applied on this bare soil, i.e., no PVDs are installed in these soil beds. Changes in the settlement reading are recorded every 5 days, and loading is changed every 10 days. In each case (vertical pressure), it is observed that gradual settlement occurs with time up to 40 days and beyond this period the settlement becomes almost constant. Up to 40 days, settlements of the soil are observed as 9.0, 10.50, 11.60 and 12.60 mm for 2, 4, 6 and 8 kPa vertical pressures, respectively, and no significant change in settlements are observed between 40 and 80 days. In other words, when no PVD is installed into the soil and vertical pressure 2, 4, 6 or 8 kPa is imposed, the time periods between 35 and 40 days turn out to be crucial periods (after which the settlement tends to be almost constant) for each vertical pressure. The difference in the settlement between 8 kPa and 2 kPa vertical pressures is only 3.60 mm between 40 and 80 days. Here, the expulsion of water takes place in the vertical direction only and this causes maximum pore water to remain onto the soil mass, so the settlement of the soil mass also gets decreased. But when PVDs are incorporated into the soil, the travelling distance of pore water gets decreased, i.e., pore water travels in both horizontal and vertical directions. Maximum pore water reaches the PVD and it drains off the water on the top surface. These phenomena expedite the consolidation settlement of the PVD-reinforced soil. Hence, crucial time periods put up different trends and change to 40 to 45, 45 to 50, 50 to 55 and 55 to 60 days for 2, 4, 6 and 8 kPa vertical pressures and the corresponding vertical settlement results are 18.80, 23.30, 28.20 and 30 mm, respectively. The time period versus settlement graph is shown in Fig. 2.

3.2 Effect of Vertical Loading on Settlement

In the first case, no PVD is used with the soil bed. When vertical loading of 2 kPa is applied, a rapid settlement of the soil bed is observed up to 40 days with 9 mm settlement, but beyond this period it tends to be almost constant. The same trend is observed at other vertical pressures such as 4, 6 and 8 kPa with 10.50, 11.60 and 12.60 mm settlements, respectively, up to 40 days. In other words, with an increase in vertical loading, settlement increases at a small rate. An increase in vertical pressure could not increase significant settlement since no PVD is embedded into the soil mass. In the second case, when PVD is installed in the soil, settlement results are found to increase comparatively if surcharge loading is increased from 2 kPa to 6 kPa, i.e., an increase in vertical pressure increases settlement drastically as can be seen from Fig. 3 and the results are shown in the previous section. After a few days, settlements at all vertical pressures become almost constant due to likely clogging of the PVD. However, the settlement results became almost closer to each other for the cases of loading of 6 kPa and 8 kPa. Expulsion of most of the moisture contents is completed within 50 to 55 days or the clogging of the PVD occurs, and/or these may be the reasons for these graphs becoming closer. So, it may be concluded that even though we increase vertical pressure settlement of the soil will not increase beyond 8 kPa vertical pressure.

4 Conclusions

From the testing results obtained from laboratory works, it may be concluded that with the use of prefabricated vertical drain (PVD), settlement of silty-clay soils increases very rapidly even though the soil is prepared at optimum moisture content. The higher the load (stress), the greater is the settlement value. Time versus settlement curves of the PVD-reinforced soil became closer to each other at the imposing load (stress) of 6 kPa and 8 kPa. So, it may be concluded that a significant amount of settlement may not be expected beyond 8 kPa of surcharge load (stress). That implies that PVD is much effective up to 8 kPa even at OMC of the silty-clay soil (used in this study), and its effectiveness diminishes gradually beyond this loading range. These results of settlement may be used as a reference in the studies that use different water content of the soil. Because, generally, settlements of soft soils are determined at water content closer to their liquid limit. Therefore, this research may be a useful reference to the academicians/researchers who work on PVD-reinforced soft soils.

References

Almeida MSS, Santa Maria PEL, Martins ISM, Spotti AP, Coelho LBM (2000) Consolidation of a very soft clay with vertical drains. Géotechnique 50(6):633–643

ASTM (2012) Standard Test Methods for Identification of Fibers in Textiles. ASTM D276-12. West Conshohocken, PA: ASTM

ASTM (2014) Standard Test Method for Determining the (In-plane) Flow Rate per Unit Width and Hydraulic Transmissivity of a Geosynthetic Using a Constant Head. ASTM D4716/D4716M-14. West Conshohocken, PA: ASTM

ASTM (2015) Standard Test Method for Trapezoid Tearing Strength of Geotextiles. ASTM D4533/D4533M-15. West Conshohocken, PA: ASTM

ASTM (2017) Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method. ASTM D 4595-17. West Conshohocken, PA: ASTM

ASTM. Standard Test Methods for Water Permeability of Geotextiles by Permittivity. ASTM D4491/D4491M-17. West Conshohocken, PA: ASTM (2017)

ASTM. Standard Test Methods for Width of Textile Fabric. ASTM D3774-18. West Conshohocken, PA: ASTM (2018)

ASTM. Standard Test Method for Measuring the Nominal Thickness of Geosynthetics. ASTM D5199-12(19). West Conshohocken, PA: ASTM (2019)

Basu D, Madhav MR (2000) Effect of prefabricated vertical drain clogging on the rate of consolidation: A numerical study. Geosynthetics International 7(3):189–215

Chu J, Bo MW, Choa V (2004) Practical considerations for using vertical drains in soil improvement projects. Geotext Geomembr 22(1–2):101–117

Chu J, Bo MW, Choa V (2006) Improvement of ultra-soft soil using prefabricated vertical drains. Geotext Geomembr 24:339–348

Deng YB, Liu GB, Indraratna B, Rujikiatkamjorn C, Xie KH (2016) Model test and theoretical analysis for soft soil foundations improved by prefabricated vertical drains. Int J Geomech 17(1):1-12 04016045. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000711

Holtz RD (1987) Preloading with prefabricated vertical strip drains. Geotextiles Geomembranes 6:109–131

Holtz RD, Jamiolkowski M, Lancellotta R, Pedroni S (1991) Prefabricated Vertical Drains: Design and Performance. Heinemann-CIRIA, London

Indraratna B, Redana IW (2000) Numerical modeling of vertical drains with smear and well resistance installed in soft clay. Can Geotech J 37(1):133–145

Indraratna B, Sathananthan I, Rujikiatkamjorn C, Balasubramaniam AS (2005) Analytical and numerical modelling of soft soil stabilized by prefabricated vertical drains incorporating vacuum preloading. Int J Geomech 5(2):114–124

Joseph A, Chandrakaran S, Sankar N, Jose BT (2015) Laboratory evaluation of extent of smear zone due to columnar intrusion for cochin marine clays. In Proceedings: 50th Indian Geotechnical Conf. New Delhi, India: Indian Geotechnical Society

Li AL, Rowe RK (2001) Combined effects of reinforcement and prefabricated vertical drains on embankment performance. Can Geotech J 38(6):1266–1282

Maugeri M, Amenta G, Castelli F, Motta E (1994) Analysis and performance of an embankment on soft soil. International Proceedings of 13th ICSMFE, New Delhi, India, pp 747–750

Miura N, Chai JC (2000) Discharge capacity of prefabricated vertical drains confined in clay. Geosynthetics International 7(2):119–135

Rangeard D, Phan PT, Martinez J, Lambert S (2016) Mechanical behavior of fine-grained soil reinforced by sand columns: An experimental laboratory study. Geotech Test J 39(4):648–657. https://doi.org/10.1520/GTJ20150152

Rowe RK, MacLean MD, Barsvary AK (1984) The observed behaviour of a geotextile-reinforced embankment constructed on peat. Can Geotech J 21:289–304

Saowapakpiboon J, Bergado DT, Youwai S, Chai JC, Wanthong P, Voottipruex P (2010) Measured and predicted performance of prefabricated vertical drains (PVDs) with and without vacuum preloading. Geotext Geomembr 28:1–11

Shen SL, Chai JC, Hong ZS, Cai FX (2005) Analysis of field performance of embankments on soft clay deposit with and without PVD-improvement. Geotext Geomembr 23:463–485

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Saha, A., Reang, R.B., Pal, S.K. (2021). Settlement Analysis of Locally Available Soft Soil Reinforced with Prefabricated Vertical Drain. In: Sitharam, T.G., Parthasarathy, C.R., Kolathayar, S. (eds) Ground Improvement Techniques. Lecture Notes in Civil Engineering, vol 118. Springer, Singapore. https://doi.org/10.1007/978-981-15-9988-0_14

Download citation

DOI: https://doi.org/10.1007/978-981-15-9988-0_14

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9987-3

Online ISBN: 978-981-15-9988-0

eBook Packages: EngineeringEngineering (R0)