Abstract

This review paper outlines the recent research works on bond properties of reinforced concrete specimens. Bond strength depends mainly on corrosion of the main bar and stirrups, type of concrete, concrete cover and corrosion rate. The environmental effects also play a dynamic role in the degradation of bond stability within reinforced rods and concrete. To integrate the bond behaviour amidst reinforced rods and concrete, several testing methods have been used and the pull-out experiment is used worldwide among them due to its simplicity. The study is gone through bond toughness amid reinforcement and concrete in different environments in different types of concretes such as high strength concretes, fibre-reinforced concretes, reinforcement corroded concretes, lightweight concrete and recycled aggregate concrete. Bond-slip behaviour is also studied for the lightweight concrete, and the graph visualizes the fact that the curve of bond-slip in lightweight concrete is comparable with the standard concrete. From the literature study, it is remarked that very few investigations have organized on the behaviour of bond in corroded reinforced steel rods. The span of cracks on the surface of concrete that occurs due to corrosion performs a prominent part in estimating the bond stability. Also, the bond toughness varies in real-time corroded structures compared with laboratory corroded techniques. Still, there is a shortage of study in those areas, and advanced tests and investigations are required.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Bond stress is a stress that acts on the outer layer of the reinforced bar and the concrete that surrounds the reinforcement. This stress resists the force which attempts to pull out the reinforced material from the concrete. The communication between the concrete and the reinforcing member is over bonding that usually permits force to transfer from the reinforcing member to the concrete. It also deals with the composite action of embedded concrete members. Three components that embrace the bond stress are chemical cohesion, friction and mechanical interlace [1]. Chemical cohesion is the bond due to chemicals that exists at the initial loading of the structure and the bond relationship fails when the load is increased. Thus, the chemical adherence, which is a resisting property, is not steady. The frictional bond of the rebars built up over the peculiarity of rebar’s surface. The interfacial zone of the rebar and concrete has a roughness where the frictional forces get rolled out. This force has an eloquent role in the tie between concrete and rods. Mechanical interlacing is the elementary component of the relationship amidst the embedded ribs and the concrete keys. When the ultimate bond is applied, the occurrence of shear cracks in the middle of concrete and ribs takes place. This cracking ends in a slip where the significant bearing stresses are caused due to interlocking forces [2]. Figure 1 shows the influence of bond components between reinforced rods and concrete, where 1-chemical cohesion, 2-mechanical interlacing and 3-friction.

The exposure of concrete to moisture, temperature cycles and marine or other dynamic environmental condition that may decrease the integrity and also limits the durability of the concrete structures [3]. Technological parameters due to ageing and environmental effects such as steel corrosion, rust, bond improvement and bond decay due to low and high temperatures, respectively, perform an indicative role over the behaviour of the bond [4]. Bond deterioration of concrete and reinforcement reduces the serviceability as well as the extreme load-carrying ability of the structure. In addition, it changes the condition of failure due to ductility to the failure due to catastrophic brittleness [5,6,7,8,9]. The corroded reinforcement has an esteemed reaction on the bending tests of concrete beams those fail in bond [10]. The corrosion of steel rods reinforced in concrete specimens for the laboratory tests is done artificially, which differs a lot from the reinforcement corrosion in concrete structures that occurs under natural condition [11].

Pull-out tests are executed for measuring the bond strength amid reinforced rods and concrete. Bond-slip curve has obtained at intervals of the application of load and the slippage of the steel rod that occurred in the test specimen. The capacity of the structure to carry new loads is unpredictable due to an unaccustomed increase or decrease in load on the structures [12]. Additive or alternate materials are practising in concrete to boost the strength of concrete and to beat the demand for raw materials that are used in concrete, respectively. Fibre-reinforced concrete (FRC) emerges as a superior alternative as it prevents the earlier bonding failure of critical regions in a structure [13], where the dangerous areas in a structure include the base of a column, a middle span in a beam and the beam-column joint. The other such alternate is concrete using recycled aggregate. Studies were done in the reuse of waste concrete expose that the concrete comprised of coarse aggregate obtained by recycling possess identical mechanical properties corresponding to nominal concrete, and the base idea for this eco-friendly practice is in the process of discovering high strength concrete [14].

2 Bond Degradation

Bond strength is the resisting force that exerts during the separation of concrete from the reinforcing bars. The bond strength lay on the primary reinforcement bar corrosion, lateral confinement, type of concrete and corrosion rate. When the bonding in between concrete and reinforced bar gets fail, there occurs degradation of the bond. Figure 2 gives the flow of bond components in bond degradation.

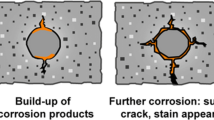

2.1 Influence of Main Reinforcement Corrosion

The major concern for the bond deterioration within reinforcing steel and concrete from past decades is by cause of the main reinforcement corrosion. To overcome the problem of reinforcement corrosion, many techniques were conducted in the laboratory by accelerating artificial corrosion. The corrosion in the main reinforcing bar is first explored in 1990 [15]. It is found that the bond strength has a confident impact found in the earlier phase of corrosion. As the level of corrosion increased, there is a gradual decrease in the durability of the bond in the middle of the concrete and the reinforcing substance. It is also ended up that the visibility of cover cracking due to corrosion exhibits no negative strike over the stability of the bond [16]. There is an origin of radial pressure created over the interface of the concrete and reinforcement rod due to products of corrosion at the initial stage, which means that the occurrence of corrosion begins. The roughness of the surface in the reinforcing bar is increased even at the stage of minor corrosion. There is a reduction in a mechanical bond component when the corrosion gets initiated, as the corrosion-induced radial pressure fights with the bursting stresses created by the action of bond interlocking [17]. In the higher level of corrosion, there is a development of longitudinal cracks as the capacity of concrete on tension is fully used up. After the concrete cover gets cracked, the radial pressure, which is induced by the corrosion, has got released up at the space amidst the concrete and the reinforced material. The area of the rib of reinforcing material got reduced due to severe corrosion, and the material gets weakened. The corrosion products are mounted over the surface of the interface, where those two effects cause a reasonable loss in strength of the bond.

2.2 Effects Concerning Stirrups

2.2.1 Stirrups Without Corrosion

The observation from literature about bond degradation is that the enormous bond tests have been conducted on specimens that are cast without stirrups. But the real-time concrete structural elements are built up with the stirrups. The comparative results of the bond test on specimens with stirrups and without stirrups show different values of bond deterioration. It is compiled that when steel gets corroded it would not create any impact on the strength of bonds when there is a presence of stirrups [18, 19]. The strength of the bond is higher in the specimens cast with stirrups than the specimens without stirrups [20, 21]. It is detected that the strength of the bond increased gradually as increases in corrosion of the specimens cast with stirrups. The occurrence of cover cracking leads to the production of passive pressure on the anchorage by the stirrups. Width of cracks can be reduced with the help of stirrups [22]. After cracking of cover, the stirrups carry the internal stress that is generated by the enlargement of products of corrosion. Thus, the stirrups help in improving the bond protection of the corroded main bar.

2.2.2 Stirrups with Corrosion

The experimental investigations reveal that the stirrups in the specimen will corrode initially, and also the rate of corrosion is higher in the stirrups when compared with the main reinforcement bars [17, 23, 24]. This difference happens because of the smaller diameter of the stirrups than the main bars and also due to the location of stirrups, which is adjacent to the exposed outer face of the specimen. The composition of chemicals in the main rod is low alloy steel, and stirrups are mild steel, which permits the creation of macro-cell corrosion in which main bars act as a cathode and the stirrups acts as an anode. In real-time structures, the stirrups are placed adjacent to the shallow of bending cracks in flexural members, which leads to the rapid corrosion of the stirrups. The relentless corrosion of the stirrups forces it in the loss of factional area of stirrups. Pull-out tests have performed on the samples that are cast with corrosion in main bars and stirrups in which the test results prove that the bond resistance is superior in samples cast by stirrups than the samples without stirrups [25]. Beam-end specimens were tested experimentally, and the numerical modelling was done in which the results confirm that the loss of bond takes place when severe corrosion starts [25, 26]. Likewise, several experimental results suggested that stirrup corrosion at the initial stage increases bond strength and bond deterioration occurs at the extreme corrosion [27, 28]. The results of the pull-out test by eccentric loading have exposed that the bond endurance is diminished at the stage of severe corrosion of the stirrups [29].

2.3 Effect Concerning Concrete Cover

Failure in the cover of concrete where the steel rod is without corrosion influences the bond stability amid the reinforcement and concrete. The technique of deterioration either occurs by splitting cover or crushed concrete keys. In steel bars with corrosion, there exists a confident outcome over the large cover of concrete after the initiation of crack. The experimental tests result that when the cover of concrete in a specimen is larger, then the specimen possesses high bond strength [15, 30], which happens even at the severe corrosion stage. This varying bond strength occurs by virtue of two reasons, which is when the cover of concrete is larger, and then, the time taken to initiate the corrosion of concrete is larger. This action permits the products of corrosion to get into microscopic openings of concrete and postpone the degradation of the bond. The other noticeable thing is that the confinement exists even after the cracking of cover; this is by cause of tensile capacity of concrete not loosening suddenly after the cracking, where the shear stress and tensile stress are retained through the fine cracks.

2.4 Effect Concerning Type of Concrete

The action of the bond in the middle of the reinforcing rod and concrete gets varied as the type of concrete varies. The type of concrete influence here is the addition or replacement of other materials in concrete. The action of bond in concrete strengthened with fibre and concrete fabricated with recycled aggregate are taken in the study.

2.4.1 Fibre-Reinforced Concrete

Fibres are added as the additional material in the concrete, which intensifies the resilience of the concrete. The use of fibre in the concrete will keep up the relationship within the concrete and reinforced member, and it further helps in reducing or preventing the cracking that occurs in the area of provided concrete cover. The fibres, namely polypropylene fibre, steel fibre, nylon fibre and polyvinyl alcohol fibre were studied. Those study results prove that apart from the type of fibre used, the fibre-reinforced concrete delays the cracking of concrete cover, and provides higher strength in the bond when correlated with the typical concrete [31,32,33,34]. When the fibre is added in concrete, the experimental assessment outcomes prove that the stability of the bond is no more altered even when the corrosion stratum of steel reached from 10 to 15% [35].

2.4.2 Recycled Aggregate Concrete

Due to the demand for raw materials, the replacement of material is done where the aggregates are supplanted by artificial recycled aggregate. The experimental test outcomes illustrate that there is no great discrepancy in deterioration of bond due to corrosion in both concrete with usual aggregates and with recycled aggregates. In unconfined experimental samples, the toughness of bond initially gets increased and then shortened, whereas the bond disintegration is restricted in the test specimens with stirrups. The test on beams cast using coarse aggregates after recycling ended with the reduction of the bond as the rate of supplantation of recycled coarse aggregate gets intensified [36]. The other experimental results revealed that the tenacity of the bond gets raised as there is an upsurge in the percentage of replacement of recycled aggregate and also showed off the delayed cracking of concrete cover [37]. Since controversial results were obtained, advanced studies are mandatory for the clarification.

2.5 Effect Concerning the Rate of Corrosion

Accelerated corrosion techniques were done because of the shorter duration of the period of corrosion, and the level of corrosion could be controllable. There is a major discrepancy in the deterioration of bond amidst the stimulated corrosion and normal corrosion. On comparing the current densities of corrosion adopted in field condition and laboratory condition, it is seen that the density of current for corrosion in field condition fluctuate through 0.1 and 1 µA/cm2 [22]. In contrast, the current density of corrosion in laboratory conditions is a thousand times higher. When the rate of corrosion is larger, then there occurs different oxidation when comparing natural corrosion and accelerated corrosion, and the expansion volume of corrosion products resulted from corrosion will vary. When the corrosion takes place in a faster manner, there will be an only fewer moment for the compounds of corrosion to get into the finite orifice of the concrete or the cracks. Thus, the bond deterioration varies concerning the time taken for the corrosion.

Ayop and Cairns [38] have conducted an accelerated test with two different densities of current such as 80 and 400 µA/cm2 that are noted in the act of ‘slow’ and ‘fast’ densities of current. The after effect from the experiment exposed that the crack width is more comprehensive, and the bond strength is lower during the fast current when compared with slow current, and the resistance of bond decreases as the corrosion rate gets increased. The capacity to carry the load is lower, and the reduction in the bond is higher in the accelerated corrosion while comparing with typical corrosion [39]. It is found that there is severe bond deterioration in the reinforced concrete beams that are corroded using the galvanostatic method in comparison with the ordinary corrosive ambience [40]. Pull-out experiments were handled on the original concrete samples that are obtained from the demolition of a bridge in Norway, and its service life is calculated as 29 years and the outcomes display that the ability of the bond is not distressed until the corrosion level reaches up to 10% [41]. It is crucial to broaden the awareness over the degradation of bond in steel–concrete structures that are under the natural corrosive experiment, so it is vital to conduct bond tests of the structures under the natural corrosive environment.

3 Pull-Out Test

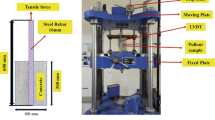

There are various methods for measuring the stability of the bond within concrete and reinforcing material. Among them, the pull-out experiment is a technique which is used among worldwide [2, 42,43,44,45,46,47,48,49].The pull-out test can also be done by mounting reinforcing rods near the outer surface [50,51,52,53,54,55]. In the pull-out mechanism, a steel rod or any other reinforcing material is embedded in the block of concrete, which may be cube[56, 57] or rectangular [18] or cylindrical [58] specimen. While the load is imposed, the rod pulls out from the sample with the controlled load. LVDT is used to measure the displacement in the rod. From the experiment, the load at which the rod slips out from the specimen is taken as tenacity of the bond amidst reinforced material and concrete. This test results also help in obtaining bond-slip relativity. The strength of binding is predicted by using Eq. 1 when the applied load and embedded length are known [56].

where

- T:

-

Bond stability (MPa).

- P:

-

Maximum enforced load (N).

- d:

-

Circumference of the embedded bar (mm).

- L:

-

Embedded segment’s length (mm).

The samples for the pull-out experiment can be cast under the recommendations of RILEM [52, 59,60,61,62] or ASTM [63, 64]. Different testing methods are used for testing of which universal testing machine is commonly used [65, 66]. The loading may be eccentric loading or focus point loading or two-point loading. The occurrence of slippage of the rod from the specimen is deliberated by linear variable differential transducer (LVDT) [50, 67,68,69], and it can also be monitored and by acoustic emission [42, 70,71,72]. The simplest schematic portrayal of the pull-out experiment for a cubical specimen using INSTRON which is a machine used to perform tensile tests is presented in Fig. 3.

The conditions of failure that occur during the pull-out experiment of the samples are of three types [56]. (i) Pull-out failure—this mode of failure occurs when the bar reaches its peak load value, and the rod gets split out from the specimen. (ii) Splitting failure—when the bar reaches its maximum, the bar pulls out with cracks parallel to the appliance of force in the front face of the specimen. (iii) Yielding of the rod—this occurs when the load carried by the samples stretches higher than the load needed for the yielding. Yielding of the rod is literally not technical failure. In many cases, when the yielding gets visible, the test would be stopped to prevent the fracture of the embedded bar.

4 Bond-Slip Relationship

Bond-slip curves are mainly comprised of two parts; they are ascending and descending curves [10, 73, 74]. At the initial stage, the binding property within reinforced rod and concrete is due to chemical adhesiveness, and when load gets increased, adhesion undergoes failure; hence, mechanical interacting plays an integral role in bonding mechanism. There is a formation of minute cracks in diagonal direction that occurs at the apex of the rib of rods due to the elongation stresses closer to the apex of rib induced by the bearing stresses at the front face of the rib surface [10, 20, 73, 75,76,77,78]. These cracks are called bond cracks, which permit the slip of bar along the direction of application of load, which results in a bond-slip curve in a softer and nonlinear way. Splitting of the specimen occurs over the whole concrete cover when the installation of the rod in concrete is with low confinement [67]. At the maximum load, there will be a plateau over the bond-slip curve, and a linear line is endured in a decreased manner corresponding to maximum frictional strength of bond at a slip. The value of slip is almost nearer to clear distance that occurs between the legs of the reinforced bars [79].

Thus,

-

Unconfined concrete fails by splitting of the concrete specimen,

-

Confined concrete fails by pulling out of the steel rod in which failure occurs due to splitting happens in the concrete sample,

-

Well-confined concrete fails purely by pulling out of the rod, which is embedded in the specimen [80].

Figure 4 depicts the affiliation amidst bond stress and slip in well-confined concrete, where

- A:

-

Initial bond due to chemical adhesion.

- B:

-

Failure of chemical adhesion.

- C:

-

Visibility of splitting crack.

- D:

-

Initiation of slip.

- E:

-

Occurrence of transverse cracks.

- F:

-

Shear action of concrete between ribs completed.

For example, Figs. 5 and 6 have plotted for the diameter of the bar to the highest load and the slip at that maximal load for lightweight aggregate concrete for two varying mixes, respectively, where the value of slip observed for all mixes lies between 0.8 and 2.15 mm [67].

5 Conclusion

This paper gave an overall view about the reasons for degradation of bond and the pull-out analysis through which the stability of the bond is determined and also covered the basic concept of bond-slip relationship with an example of lightweight aggregate concrete. It is noticed that the corrosion of the main reinforcement rod pointed to boost up in toughness of bond at the initial stage, and later as the degree of corrosion enlarges, the toughness of bond gets decreased. The grade of corrosion of reinforcement rod varied within usual corrosive situation and stimulated corrosion technique, where the rate of corrosion is slow under a natural corrosive environment. The study revealed the law of raise in the diameter of bars had reduced bond strength and the shallow temperature would have a antipathetic strike on the bond relationship amid the concrete and reinforced rod. The exposure environment of the concrete specimen or concrete structure has more considerable sway on the stability of the bond.

It is also observed that the tenacity of the bond amidst the reinforced rod and concrete is related to the transverse pressure over the specimen, and also the cover density of concrete had a proficient impact over the bond strength. The stability in binding differs in the samples, which were cast with stirrups and without stirrups. It also proved that the width of the crack is lesser in samples cast with stirrups when compared with the samples without stirrups. It is finalized that the stirrups with corrosion at the initiative phase upsurges the tenacity of bond. The stirrups get corroded easily, as it is placed near the surface of bending cracks in flexural members and the diameter of the stirrups is lower than the main reinforcement bar, which is also the reason for quick corrosion of stirrups.

The type of concrete used also hold a considerable outcome on the bond stability of the specimen. As discussed, the reinforced concrete with fibre and recycled aggregate delays in the cracking of the concrete. Studies show that the simplest and common method used for regulating bond capacity is the pull-out experiment, where the usual equipment used for measuring the slip of bar is a linear variable differential transducer (LVDT). For real-time corroded samples, there is deficient in investigation over the strength of the bond. As the rate of corrosion varies in real-time structures and laboratory specimens, it will be helpful if more investigations have done in real-time corroded structures.

References

Tepfers R (1979) Cracking of concrete cover along anchored deformed reinforcing bars. Mag Concr Res 31(106):3–12

Hollý I, Bilčík J, Keseli O, Gažovičová N (2016) Bond of GFRP reinforcement with concrete. Key Eng Mater 691:356–365

Benzarti K, Chataigner S, Quiertant M, Marty C, Aubagnac C (2011) Accelerated ageing behaviour of the adhesive bond between concrete specimens and CFRP overlays. Constr Build Mater 25(2):523–538

Bilcik J, Holly I (2013) Effect of reinforcement corrosion on bond behaviour. Procedia Eng 65:248–253

Ahmad S (2003) Reinforcement corrosion in concrete structures, its monitoring and service life prediction––a review. Cement Concr Compos 25(4–5):459–471

Lachemi M, Al-Bayati N, Sahmaran M, Anil O (2014) The effect of corrosion on shear behavior of reinforced self-consolidating concrete beams. Eng Struct 79:1–12

Kallias AN, Rafiq MI (2010) Finite element investigation of the structural response of corroded RC beams. Eng Struct 32(9):2984–2994

Khan I, François R, Castel A (2012) Structural performance of a 26-year-old corroded reinforced concrete beam. Eur J Environ Civ Eng 16(3–4):440–449

Recupero A, Spinella N, Tondolo F (2018) Failure analysis of corroded RC beams subjected to shear-flexural actions. Eng Fail Anal 93:26–37

Bhargava K, Ghosh A, Mori Y, Ramanujam S (2006) A proposed model for corrosion-induced bond degradation in reinforced concrete. In: Structures congress 2006: 17th analysis and computation specialty conference, pp 1–15

Tahershamsi M, Fernandez I, Lundgren K, Zandi K (2017) Investigating correlations between crack width, corrosion level and anchorage capacity. Struct Infrastruct Eng 13(10):1294–1307

Toutanji HA, Gomez W (1997) Durability characteristics of concrete beams externally bonded with FRP composite sheets. Cement Concr Compos 19(4):351–358

Mansour FR, Bakar SA, Ibrahim IS, Marsono AK, Marabi B (2015) Flexural performance of a precast concrete slab with steel fiber concrete topping. Constr Build Mater 75:112–120

Ajdukiewicz A, Kliszczewicz A (2002) Influence of recycled aggregates on mechanical properties of HS/HPC. Cement Concr Compos 24(2):269–279

Al-Sulaimani G, Kaleemullah M, Basunbul I (1990) Influence of corrosion and cracking on bond behavior and strength of reinforced concrete members. Struct J 87(2):220–231

Altowaiji WA, Darwin D, Donahey RC (1986) Bond of reinforcement to revibrated concrete 83(6)

Tastani S, Pantazopoulou SJ (2007) Behavior of corroded bar anchorages. ACI Struct J 104(6):756

Fang C, Lundgren K, Chen L, Zhu C (2004) Corrosion influence on bond in reinforced concrete. Cem Concr Res 34(11):2159–2167

Fischer C (2010) Experimental investigations on the effect of corrosion on bond of deformed bars. In: Proceedings of the 8th fib Ph.D. symposium, Kgs, Lyngby, Denmark

Zandi Hanjari K, Coronelli D, Lundgren K (2011) Bond capacity of severely corroded bars with corroded stirrups. Mag Concr Res 63(12):953–968

Rodriguez J, Ortega L, Casal J (1994) Corrosion of reinforcing bars and service life of reinforced concrete structures: corrosion and bond deterioration. In: International conference on concrete across borders, vol 2, Odense, Denmark, pp 315–326

Lin H, Zhao Y (2016) Effects of confinements on the bond strength between concrete and corroded steel bars. Constr Build Mater 118:127–138

Fu C, Jin N, Ye H, Jin X, Dai W (2017) Corrosion characteristics of a 4-year naturally corroded reinforced concrete beam with load-induced transverse cracks. Corros Sci 117:11–23

Otsuki N, Miyazato S-i, Diola NB, Suzuki H (2000) Influences of bending crack and water-cement ratio on chloride-induced corrosion of main reinforcing bars and stirrups. Mater J 97(4):454–464

Tondolo F (2015) Bond behaviour with reinforcement corrosion. Constr Build Mater 93:926–932

Coronelli D, Hanjari KZ, Lundgren K (2012) Severely corroded RC with cover cracking. J Struct Eng 139(2):221–232

Zhou H, Liang X, Zhang X, Lu J, Xing F, Mei L (2017) Variation and degradation of steel and concrete bond performance with corroded stirrups. Constr Build Mater 138:56–68

Zhou H, Lu J, Xv X, Dong B, Xing F (2015) Effects of stirrup corrosion on bond–slip performance of reinforcing steel in concrete: an experimental study. Constr Build Mater 93:257–266

Lin H, Zhao Y, Yang J-Q, Feng P, Ozbolt J, Ye H (2019) Effects of the corrosion of main bar and stirrups on the bond behavior of reinforcing steel bar. Constr Build Mater 225:13–28

Amleh L, Mirza M, Ahwazi B (2000) Bond deterioration of reinforcing steel in concrete due to corrosion, vol 3

Farhan NA, Sheikh MN, Hadi MN (2018) Experimental investigation on the effect of corrosion on the bond between reinforcing steel bars and fibre reinforced geopolymer concrete. Structures 14:251–261

Haddad RH, Ashteyate AM (2001) Role of synthetic fibers in delaying steel corrosion cracks and improving bond with concrete. Can J Civ Eng 28(5):787–793

Xinhua C, Shilang X, Shiping Y, Zhen H (2012) Experimental research on bond behaviors of corroded rebar and ultra high toughness cementitious composites (UHTCC). J Chin Soc Corros Prot 32(3):228–234

Berrocal CG, Fernandez I, Lundgren K, Löfgren I (2017) Corrosion-induced cracking and bond behaviour of corroded reinforcement bars in SFRC. Compos B Eng 113:123–137

Hou L, Liu H, Xu S, Zhuang N, Chen D (2017) Effect of corrosion on bond behaviors of rebar embedded in ultra-high toughness cementitious composite. Constr Build Mater 138:141–150

Yang H, Lan W, Qin Y, Wang J (2016) Evaluation of bond performance between deformed bars and recycled aggregate concrete after high temperatures exposure. Constr Build Mater 112:885–891

Fernandez I, Etxeberria M, Marí AR (2016) Ultimate bond strength assessment of uncorroded and corroded reinforced recycled aggregate concretes. Constr Build Mater 111:543–555

Ayop SS, Cairns JJ (2015) The influence of impressed current on residual bond strength of corroded structure. Appl Mech Mater 773–774:984–989

Sæther I, Antonsen A, Vennesland Ø (2007) Effect of impressed anodic current density applied to accelerated corrosion laboratory results. In: International RILEM workshop on integral service life modeling of concrete structures, pp 307–314

Yuan Y, Ji Y, Shah SP (2007) Comparison of two accelerated corrosion techniques for concrete structures. ACI Struct J 104(3):344

Horrigmoe G, Saether I, Antonsen R, Arntsen B (2007) Laboratory investigations of steel bar corrosion in concrete: sustainable bridges background document SB3, p 10

Abouhussien AA, Hassan AA (2017) Acoustic emission monitoring for bond integrity evaluation of reinforced concrete under pull-out tests. Adv Struct Eng 20(9):1390–1405

Barbosa MTG, Sánchez Filho S (2013) Investigation of bond stress in pull out specimens with high strength concrete. J Res Eng Civ Struct Eng 13(3):55–64

Ihekwaba N, Hope B, Hansson C (1996) Pull-out and bond degradation of steel rebars in ECE concrete. Cem Concr Res 26(2):267–282

Maranan GB, Manalo AC, Karunasena W, Benmokrane B (2015) Pullout behaviour of GFRP bars with anchor head in geopolymer concrete. Compos Struct 132:1113–1121

Chang X, Yue G, Lin H, Tang C (2010) Modeling the pullout behavior of fiber reinforced polymer bars from concrete. Constr Build Mater 24(4):431–437

Chourasia A, Singhal S, Chourasia A (2019) Pull-out behaviour of headed bars embedded in concrete. 8th International Engineering Symposium - IES 2019 , Kumamoto, Japan

Chu S, Kwan A (2018) A new method for pull out test of reinforcing bars in plain and fibre reinforced concrete. Eng Struct 164:82–91

Cunha VM, Barros JA, Sena-Cruz JM (2009) Pullout behavior of steel fibers in self-compacting concrete. J Mater Civ Eng 22(1):1–9

De Lorenzis L, Rizzo A, La Tegola A (2002) A modified pull-out test for bond of near-surface mounted FRP rods in concrete. Compos B Eng 33(8):589–603

Kalupahana W, Ibell T, Darby A (2013) Bond characteristics of near surface mounted CFRP bars. Constr Build Mater 43:58–68

Kotynia R (2012) Bond between FRP and concrete in reinforced concrete beams strengthened with near surface mounted and externally bonded reinforcement. Constr Build Mater 32:41–54

Soliman SM, El-Salakawy E, Benmokrane B (2010) Bond performance of near-surface-mounted FRP bars. J Compos Constr 15(1):103–111

Yu B, Kodur V (2014) Effect of high temperature on bond strength of near-surface mounted FRP reinforcement. Compos Struct 110:88–97

Zhang H, He L, Li G (2015) Bond failure performances between near-surface mounted FRP bars and concrete for flexural strengthening concrete structures. Eng Fail Anal 56:39–50

Mansoor YA, Zhang ZQ (2013) The reinforcement bond strength behavior under different corrosion condition. Res J Appl Sci Eng Technol 5:2346–2353

Ali A, Iqbal S, Holschemacher K, Bier TA (2016) Effect of fibers on bond performance of lightweight reinforced concrete. Periodica Polytech Civ Eng 60(1):97

Németh OI, Lublóy É, Farkas G (2014) Bond of reinforcement in polymer concrete. Periodica Polytech Civ Eng 58(2):137–141

Achillides Z, Pilakoutas K (2004) Bond behavior of fiber reinforced polymer bars under direct pullout conditions. J Compos Constr 8(2):173–181

Silva Filho L, Vale Silva B, Dal Bosco V, Gomes L, Barbosa M, Lorrain M (2012) Analysis of the influence of rebar geometry variations on bonding strength in the pull-out test. Bond Concr 978-88-907078-1-0:63–68

Yalciner H, Marar K (2017) Experimental study on the bond strength of different geometries of corroded and uncorroded reinforcement bars. J Mater Civ Eng 29(7):05017002

Weiße D, Holschemacher K (2003) Some aspects about the bond of reinforcement in ultra high strength concrete. Leipzig annual civil engineering report (LACER), no 8, pp 251–263

Hassan M, Benmokrane B, ElSafty A, Fam A (2016) Bond durability of basalt-fiber-reinforced-polymer (BFRP) bars embedded in concrete in aggressive environments. Compos B Eng 106:262–272

Ali A, Iqbal S, Holschemacher K, Bier TA (2017) Bond of reinforcement with normal-weight fiber reinforced concrete. Periodica Polytech Civ Eng 61(1):128–134

Krstulovic-Opara N, Watson KA, LaFave JM (1994) Effect of increased tensile strength and toughness on reinforcing-bar bond behavior. Cement Concr Compos 16(2):129–141

Sydenstricker TH, Mochnaz S, Amico SC (2003) Pull-out and other evaluations in sisal-reinforced polyester biocomposites. Polym Testing 22(4):375–380

Al-Shannag MJ, Charif A (2017) Bond behavior of steel bars embedded in concretes made with natural lightweight aggregates. J King Saud Univ Eng Sci 29(4):365–372

Kotynia R, Szczech D, Kaszubska M (2017) Bond behavior of GRFP bars to concrete in beam test. Procedia Eng 193:401–408

Wu Y-Z, Lv H-L, Zhou S-C, Fang Z-N (2016) Degradation model of bond performance between deteriorated concrete and corroded deformed steel bars. Constr Build Mater 119:89–95

Di B, Wang J, Li H, Zheng J, Zheng Y, Song G (2019) Investigation of bonding behavior of FRP and steel bars in self-compacting concrete structures using acoustic emission method. Sensors 19(1):159

Gallego A, Benavent-Climent A, Suarez E (2015) Concrete-galvanized steel pull-out bond assessed by acoustic emission. J Mater Civ Eng 28(2):04015109

Wang L, Yi J, Xia H, Fan L (2016) Experimental study of a pull-out test of corroded steel and concrete using the acoustic emission monitoring method. Constr Build Mater 122:163–170

Firmo JP, Correia JR, França P (2012) Fire behaviour of reinforced concrete beams strengthened with CFRP laminates: protection systems with insulation of the anchorage zones. Compos B Eng 43(3):1545–1556

Gudonis E, Kacianauskas R, Gribniak V, Weber A, Jakubovskis R, Kaklauskas G (2014) Mechanical properties of the bond between GFRP reinforcing bars and concrete. Mech Compos Mater 50(4):457–466

Cairns J, Du Y, Law D (2006) Residual bond strength of corroded plain round bars. Mag Concr Res 58(4):221–231

Harajli M (2010) Bond behavior in steel fiber-reinforced concrete zones under static and cyclic loading: experimental evaluations and analytical modeling. J Mater Civ Eng 22(7):674–686

Haskett M, Oehlers DJ, Ali MM (2008) Local and global bond characteristics of steel reinforcing bars. Eng Struct 30(2):376–383

Hassan A, Hossain K, Lachemi M (2010) Bond strength of deformed bars in large reinforced concrete members cast with industrial self-consolidating concrete mixture. Constr Build Mater 24(4):520–530

Lundgren K (1999) Three-dimensional modelling of bond in reinforced concrete theoretical model, experiments and applications. Chalmers Univer Technol 91-7197-853-4:1-50

Magnusson J (2000) Bond and anchorage of ribbed bars in high-strength concrete. Chalmers Univer Technol 9171978798

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Editor(s) (if applicable) and The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Navaneethan, K.S., Kiruthika Nandhini, B., Anandakumar, S., Jayakrishna, K.P. (2021). Pull-Out and Bond Degradation of Rebars in Reinforced Concrete Structures. In: Mohan, S., Shankar, S., Rajeshkumar, G. (eds) Materials, Design, and Manufacturing for Sustainable Environment. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-9809-8_22

Download citation

DOI: https://doi.org/10.1007/978-981-15-9809-8_22

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9808-1

Online ISBN: 978-981-15-9809-8

eBook Packages: EngineeringEngineering (R0)