Abstract

The high vibration, temperature, and pressure issues cause the failure of the rotating electrical equipments. The failures become considerable when these equipments are used in industries and in smart grid. The more common failures are because of high vibrations, and sometimes, it may lead to complete shutdown of the system. The condition monitoring system must be reliable and detects the future fault conditions of the electrical equipment. The condition monitoring (CM) system is reliable and predictive when machine learning and data analytics are implemented. There are various machine learning techniques that help to detect the fault in minimum time using the historical data of the equipment and data analytics. It also helps to avoid the permanent failure of the electrical rotating equipment. Therefore, this paper focuses on health monitoring and remaining useful life (RUL) estimation of the electrical equipment connected to the grid using principal component analysis (PCA). PCA is an unsupervised machine learning technique that is proposed in this paper for case study of high-speed wind turbine bearing.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The sensors’ data from different locations of the grid are collected. These data are stored and used in analytical machine learning-based algorithms for making the system smart and reliable. The system becomes reliable and smart when appropriate information from the collected datasets are extracted. The system is made automatic for its operation, decision making, and controlling the analytical procedure. A smart grid network is integrated with different equipment, feeders, and substations. Hence, there are variety of data coming from each location of the grid. These collected data are used to predict future states, load demands, weather conditions, fault in the equipment. These data are also helpful in forecasting future states.

The rotating parts of the electrical equipment of the grid generally degrade due to high vibration, temperature, and pressure. To avoid or reduce this degradation rate of these equipments, CM is implemented. In industrial smart grid equipment, the maintenance is done in three ways are as follows.

-

(i)

Reactive Maintenance- This type of maintenance is done during the post-fault condition.

-

(ii)

Preventive Maintenance- The maintenance is done in a regular interval of time like once in a week, month, or year

-

(iii)

Predictive Maintenance- In this type of maintenance, the future coming fault is predicted and maintenance is done during the pre-fault condition. Predictive maintenance is more advantageous than the other two types of maintenance because it avoids the occurrence of faults, increases the lifetime of the equipment, and it is cost-effective too.

The recent developments and facilities in data collection, data analysis, cloud storage, data computation, and the Internet of Things (IoT) are helpful to move the smart grid performance towards the industry 4.0 revolution. Data collection is the first step for data-driven maintenance in predictive maintenance. The collected data are further used in different predictive algorithms using statistics and machine learning techniques. The digital transformation makes the grids smarter and more reliable [1, 2].

For CM of the industrial equipment, vibration-based CM is commonly implemented. The era of acoustic emission (AE) has taken attention for the researchers and industries towards AE for the diagnosis of the equipment because of the advancements in machine learnings and data science. The analysis of data of the equipment is done in time and frequency domain for AE based techniques. The authors in [3] have explained the AE based approach for bearing fault diagnosis. The three methodologies were demonstrated in the previous research work for the fault diagnosis. These methodologies are given as follows.

-

(i)

Frequency reduction technique based on heterodyne: This is used to reduce the frequency of the AE signal from a range of MegaHertz to a fewer range to Hertz.

-

(ii)

Synchronous time sampling

-

(iii)

Spectral frequency-domain analysis: This is used to find the condition indicators for the fault diagnosis.

The above-proposed techniques are useful in the diagnosis of all four types bearing faults. These bearing faults are as follows [4, 5].

-

(i)

Inner race fault,

-

(ii)

Outer race fault,

-

(iii)

Faults in the ball, and

-

(iv)

Faults in the cage.

The mathematical expressions and equations have been explained in [4, 5]. In the time-domain analysis, kurtosis, peak-to-peak value, crest factor, mean value, standard deviation are important indicators for feature extraction of the dataset and in frequency-domain analysis, spectral kurtosis is a better indicator for extracting information from the vibration signal [6, 7]. Fault detection is crucial than the fault diagnosis in predictive maintenance. So, the important step is to detect the fault in minimum time so that fault can be diagnosed [8].

Machine learning is the method of learning and extracting information from historical data. Machine learning techniques are classified into two groups.

-

(i)

Supervised type machine learning: In this machine learning technique, both pre-fault and post-fault data are needed to make the prediction algorithm.

-

(ii)

Unsupervised type machine learning: In this learning technique, if the fault data is not available, then it can be useful to detect the fault condition but it cannot classify the fault that occurred.

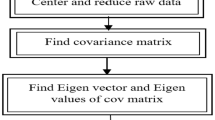

The most common supervised machine learning techniques are regression and classification-based machine learnings. Clustering and PCA are commonly used unsupervised machine learning techniques [9,10,11,12,13,14,15]. PCA is also a data reduction technique, which is used to reduce the high dimensional dataset into a low dimensional dataset. The number of principal components (PCs) is less than or equal to the number of attributes available in the dataset. Among the principal components, the first principal component (PC1) is given the highest priority because it covers the highest variance percentage of the dataset and goes on decreasing for PC2, PC3, … where PC2 and PC3 are the second and third principal components, respectively. The most important properties of principal components are that they are independent and orthogonal to each other [16,17,18,19,20]. The authors in [18, 21] have explained the PCA technique in detail and they have used this unsupervised machine learning technique for early fault detection algorithms for equipment based on vibration sensor data. The author in [18] has observed that clustering is a better tool for the fast fault detection of the equipment. The author in [21] has observed that along with the PCA technique, frequency-domain analysis is a better method for fault detection. Thus, the fast fourier transform (FFT) technique is implemented to detect the fault as the frequency and amplitude of faulty vibration signal will be different from the normal trend. It is not recommended to use this FFT technique for fault detection in minimum time. It is recommended to diagnose the fault after detection. During unbalance fault condition of bearing, the FFT signal of the vibration signal has a peak value at a frequency double of its original frequency. It does not show the health degradation. Therefore, the detection system should be pro-active and must detect the fault in minimal possible time.

This paper mainly focuses on the health condition monitoring of smart grid equipment like rotating electrical machines and high-speed wind turbine bearings. The frequency-domain analysis for feature extraction of the datasets using spectral kurtosis is discussed. In this paper, the PCA technique is used to monitor the health status of the high-speed wind turbine bearing and for RUL estimation. The exponential degradation model is chosen for RUL estimation which is explained in Sect. 2. The computation procedure starts from collection of data and then pre-processing of data, post-processing, PCA algorithm, RUL estimation are carried out in Sect. 3 and the results obtained from PCA algorithm are discussed briefly in Sect. 4. The work done in this paper is concluded in Sect. 5 with some scopes for future work.

2 PCA and RUL Estimation

PCA is used to reduce the dimension of the dataset. Before applying PCA to the dataset, the data is standardized to remove the noise and smoothen the dataset. The first principal component is used as the health indicator and also helpful in estimating RUL of the equipment. For estimating RUL, a model is developed based upon the statistical properties of condition indicator values. The degradation model gives the probability distribution of the RUL of the selected equipment. There are various types of RUL models discussed in the literature and also implemented in industries. Some of them are exponential degradation model, linear degradation model, hash similarity model, residual similarity model, reliability survival model. The most commonly used model is the degradation model which is of two types linear degradation model and exponential degradation model.

The objective function of the linear degradation model is as given in Eq. (1) [11]

where ϕ is the model intercept, which is constant. One can initialize ϕ as the nominal value of the degradation variable using Phi. θ(t) is the model slope and is modeled as a random variable with a normal distribution with mean Theta and variance ThetaVariance. ε(t) is the model additive noise and is modeled as a normal distribution with zero mean and variance NoiseVariance.

Exponential degradation model is defined as Eq. (2) [11].

where h(t) is the health indicator as a function of time, \(\emptyset\) is the intercept term considered as a constant. \(\theta\) and \(\beta\) are random parameters determining the slope of the model, where \(\theta\) is lognormal-distributed and \(\beta \;\).is gaussian-distributed. At each time step t, the distribution of \(\theta\) and \(\beta\) is updated to the posterior based on the latest observation of h(t). \(\epsilon\) is a gaussian white noise yielding to \(N\left( {0,{\sigma^2}} \right)\). The \(- \frac{\sigma^2}{2}\) term in the exponential is to make the expectation of h(t) satisfy the Eq. (3) [11].

In this paper, the exponential degradation model is used as a health indicator. The selection of threshold value is very important in degradation model which is generally done based on the historical data of the equipment or sometimes the last value of the health indicator is itself chosen as threshold value.

3 Computational Procedure

The algorithm starts with the collection of data on wind turbine bearing. The parameters in rotating equipment which can indicate the health status of the equipment are vibration, temperature, lubrication, pressure, etc. Out of these parameters, vibration is an important parameter to be used as an indicator of health status. So, in this paper, vibration data has been selected for early fault detection and estimation of RUL.

3.1 Collection of Data

The full datasets analyzed in this paper are available in the data repository, http://data-acoustics.com/measurements/bearing-faults/bearing-3/, which have been collected from a 2 MW wind turbine high-speed shaft driven by a 20-tooth pinion gear [22]. A vibration signal had been measured each day of 6 s and this had been done for the next 50 consecutive days. In this dataset, there is fault data of inner race fault occurred in the bearing which caused failure. The collected data set is imported in the first step of the algorithm which contains the vibration sensor data and tachometer data. The information can be extracted from the data signals when it is analyzed both in time and frequency domains. The vibration signal in time domain is shown in Fig. 1. The vibration measurements are in acceleration unit (g = m/s2) and time is in seconds.

In Fig. 1, the vibration signal is showing an increasing trend of the signal impulsiveness. Therefore, kurtosis, peak-to-peak value, crest factors would be good indicators for the prognostic features of this dataset in the time-domain analysis. In the frequency domain, spectral kurtosis is a good technique for the prognosis of this case study.

3.2 Data Pre-processing and Features Extraction

The features extracted from time-domain analysis and frequency-domain analysis are (i) time-domain features: mean, standard deviation, skewness, kurtosis, peak-to-peak, RMS, Crest Factor, shape factor, impulse factor, margin factor, energy, etc. (ii) frequency-domain (Spectral Kurtosis) features: spectral kurtosis mean, standard deviation, skewness, kurtosis, etc. These are helpful in the prognosis of the bearing of wind turbines.

3.3 Data Post-processing

The signals being selected for prediction generally contain noise which can affect the prediction result and also the RUL value would not be accurate. To avoid this problem, a casual moving mean filter can be used with a lag window of some steps (4, 5, or 6). With this filter, it is meant that no future value is used in the filtering. The removal or filtering of noise from the features and signals is also called as smoothening. One selected feature, for example, spectral kurtosis means is shown in Fig. 2 before smoothing and after smoothing. After ranking the features in increasing order, the features with a score larger than 0.3 are selected for the further steps of the algorithm which are mean, standard deviation, kurtosis, and skewness. After the selection of features, the next step is to normalize the dataset into a common scale. For this, a dimensional reduction technique is used which is PCA. The number of principal components can be less than or equal to the number of variables. The highest data variance is covered by the first principal component and the value goes decreasing as the numbering of the component is increased. The two principal components have been selected and the dataset has been scattered in the space formed by the first two components as shown in Fig. 3a.

In Fig. 3a, the bar chart is showing the time of measurement of the data. The first principal component is very important as it indicates the health of the equipment showing the direction of movement of the data as shown in Fig. 3b. Therefore, PC1 is used as a health indicator.

Figure 4 is showing the percentage of data variance covered by each principal component individually and cumulatively. It can be observed from Fig. 4 that the first two principal components are covering approximately 65% and 22% of the total data variance individually, respectively. When first two principal components are considered cumulatively, they will cover approximately 87% of the data variance. Here, first two principal components will be used for further procedure of data analysis and fault detecting alarm system.

3.4 RUL Estimation

The confidence interval boundary in the exponential degradation model is taken 95%. Due to a lack of historical data, the last health indicator value is chosen as the threshold value means the threshold value will be updated as the health indicator is updated. The model gives a probability density function of the health indicator (RUL) which shows the probability of the fault to occur. The 50 days duration has been scaled into a small scale of 10 units.

4 Results and Discussion

The spectral kurtosis in the frequency domain of the taken dataset has been shown in Fig. 5 plotted as a function of frequency (Hz) and time (day). The bar chart in Fig. 5 shows the severity of the fault indicating ‘0’ as no-fault and ‘1’ as faulty condition.

From Fig. 5, it can be observed that the spectral kurtosis value is high near 10 kHz frequency, and it is increasing day by day as the machine health status is degrading. Various statistical features of the spectral kurtosis which are commonly used as good indicators of the bearing degradation are a mean and standard deviation. The Probability Density Function (PDF) shown in Fig. 6 is of day 9 of the 50 days data.

In this paper, an unsupervised machine learning technique, PCA, is used for fault detection of rotating electrical equipment and high-speed wind turbine bearing is taken as case study. A very important part of predictive maintenance and automatic system is condition and data visualization. As the first principal component indicates the health status of the equipment, the score values are helpful in indicating the boundary for the normal and fault region and also show the degradation direction, therefore, it is easier to visualize the health condition of the equipment directly on the monitoring system screen. Hence, an alarm system and visualization can be found using the PCA technique for the early fault detection of equipment as shown in Fig. 7. Data points lying in the green region shows the normal operation of the equipment; if the data points move in the orange range, then there is something wrong with the equipment and the system automatically give alarm, and if the data points are lying in the red region, the monitoring system would give warning that the equipment is not in normal operating condition and some problem has occurred in the equipment.

The PCA technique is also helpful in estimating the uptime gained by doing maintenance of the equipment upon first alarm or first warning, which helps the maintenance team in forecasting and scheduling the maintenance of the equipment.

5 Conclusion and Scopes for Future Work

The previous condition monitoring method is not reliable. In these methods, the maintenance of the equipment is done on pre-scheduled date in a fixed interval or during the post fault. The proposed technique of CM for the equipment using machine learning algorithms and data analytics is more reliable which detects the future faults and supports to avoid the electrical equipment shutdown. The maintenance schedule can be forecasted before the occurrence of the equipment fault. It saves the maintenance cost by avoiding unnecessary maintenance. The proposed technique in this paper is applicable in other smart grid electrical equipment which is one of the future scopes of this paperwork. The proposed method of this paper differs in all applications in the selection of appropriate predictors for the algorithm. The time domain and frequency-domain analysis give important information about features of dataset. These features are useful in machine learning-based algorithm for the prediction of future states. Hence, the involvement of machine learning and data analytics in the CM of smart grid equipment makes the grid compatible with the digital transformation of the system. This digital transformation helps the grid to move towards the revolution of industry 4.0.

The first step in predictive maintenance of equipment is the fault detection. The maintenance can be scheduled after the detection of the fault. There are a few suggestions which can be scoped for future work:

-

(i)

The proposed technique of fault detection is based on the vibration sensor data. This can also be done using other parameters like temperature, pressure, lubrication. These parameters are also very important indicators of the health status of the smart grid electrical equipment.

-

(ii)

The proposed algorithm can be implemented in the smart grid online condition monitoring system. Also, the output of the algorithm can be used as health condition monitoring of the electrical equipment.

-

(iii)

A supervised machine learning-based algorithm can be useful for the classification of faults.

-

(iv)

Time-domain analysis can also be integrated with frequency-domain analysis for electrical equipment fault detection.

References

Wan J, Tang S, Li D, Wang S, Liu C, Abbas H, Vasilakos AV (2017) A manufacturing big data solution for active preventive maintenance. IEEE Trans Indus Inf 13(4):2039–2047

Kumar S, Kumar KA, Kumar S, Bharti OP, Varshney L, Saket RK, Vishwakarma DN (2019) Probabilistic evaluation and design aspects for reliability enhancement of induction motor. Int J Reliab Saf 13(4):267–290

Van Hecke B, He D, Qu Y (2014) On the use of spectral averaging of acoustic emission signals for bearing fault diagnostics. J Vibr Acoust 136(6):061009

Van Hecke B, Qu Y, He D (2015) Bearing fault diagnosis based on a new acoustic emission sensor technique. Proc Inst Mech Eng Part O J Risk Reliab 229(2):105–118

ZhAng X, Kang J, Bechhoefer E, Zhao J (2014) A new feature extraction method for gear fault diagnosis and prognosis. Eksploatacja i Niezawodność 16(2):295–300

Saidi L, Ali JB, Bechhoefer E, Benbouzid M (2017) Wind turbine high-speed shaft bearings health prognosis through a spectral Kurtosis-derived indices and SVR. Appl Acoust 120:1–8

Ali JB, Saidi L, Harrath S, Bechhoefer E, Benbouzid M (2018) Online automatic diagnosis of wind turbine bearings progressive degradations under real experimental conditions based on unsupervised machine learning. Appl Acoust 132:167–181

Kumar S, Mukherjee D, Guchhait PK, Banerjee R, Srivastava AK, Vishwakarma DN, Saket RK (2019) A comprehensive review of condition based prognostic maintenance (CBPM) for induction motor. IEEE Access. 3(7):90690–90704

Nair PS, Rao KR, Nair MS (2019) A machine learning approach for fast mode decision in HEVC intra prediction based on statistical features. J Intell Fuzzy Syst 36(3):2095–2106

O’Dwyer H, Csadi S, Bates E, Boland FM (2019) A study in machine learning applications for sound source localization with regards to distance. In Audio engineering society convention 146

Henri G, Lu N (2019) A supervised machine learning approach to control energy storage devices. IEEE Trans Smart Grid

Wang Y, Silva-Saravia HD, Pulgar-Painemal HA (2019) Actuator placement for enhanced grid dynamic performance: a machine learning approach. IEEE Trans Power Syst

Cui M, Wang J, Yue M (2019) Machine learning based anomaly detection for load forecasting under cyberattacks. IEEE Trans Smart Grid

Shahsavari A, Farajollahi M, Stewart E, Cortez E, Mohsenian-Rad H (2019) Situational awareness in distribution grid using micro-PMU data: a machine learning approach. IEEE Trans Smart Grid

Arendt D, Saldanha E, Wesslen R, Volkova S, Dou W (2019) Towards rapid interactive machine learning: evaluating tradeoffs of classification without representation. In Proceedings of the 24th international conference on intelligent user interfaces, pp 591–602

Wold S (2012) Cross-validatory estimation of the number of components in factor and principal components models. Technometrics

Li W, Shi T, Liao G, Yang S (2003) Feature extraction and classification of gear faults using principal component analysis. J Qual Main Eng

Amruthnath N, Gupta T (2018) A research study on unsupervised machine learning algorithms for early fault detection in predictive maintenance. In: 5th ınternational conference on ındustrial engineering and applications (ICIEA), pp 355–361

Wang Y, Ma X, Qian P (2018) Wind turbine fault detection and identification through PCA-based optimal variable selection. IEEE Trans Sustain Energy 9(4):1627–1635

Yellapu VS, Vajpayee V, Tiwari AP (2019) Online fault detection and ısolation in advanced heavy water reactor using multiscale principal component analysis. IEEE Trans Nucl Sci 66(7):1790–1803

Bachir A, Hafaifa A, Guemana M, Hadroug N (2018) Application of principal component analysis approach in gas turbine defect diagnosis. In: Iin ınternational conference on applied smart systems (ICASS), pp. 1–6

High speed bearing data | Acoustics and Vibration Database, http://data-acoustics.com/measurements/bearing-faults/bearing-3/

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sarita, K., Kumar, S., Saket, R.K. (2021). Fault Detection of Smart Grid Equipment Using Machine Learning and Data Analytics. In: Reddy, M.J.B., Mohanta, D.K., Kumar, D., Ghosh, D. (eds) Advances in Smart Grid Automation and Industry 4.0. Lecture Notes in Electrical Engineering, vol 693. Springer, Singapore. https://doi.org/10.1007/978-981-15-7675-1_4

Download citation

DOI: https://doi.org/10.1007/978-981-15-7675-1_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-7674-4

Online ISBN: 978-981-15-7675-1

eBook Packages: EnergyEnergy (R0)