Abstract

The soil liquefaction is a major earthquake disaster which causes tremendous damages to all infrastructure facilities. The examples during past earthquakes have shown the evidence of liquefaction-induced ground failures in fine-grained soils. Until recently, liquefaction-related studies concentrated on clean sands believing that only sands are susceptible to liquefaction. However, the earthquakes like 1976 Tangshan earthquake, the 1989 Loma Prieta earthquake, the 1999 Kocaeli earthquake, the 2010 Chile earthquake, and the 2011 Christchurch earthquake, etc., showed that sand with fines could also liquefy. The present study deals with the numerical simulations on cycling loading effects on the undrained response of silty sand. The material parameters for the numerical model are found after conducting basic experimental tests. The response of silt sand under the undrained condition of cyclic triaxial loading is analyzed using the hypoplastic constitutive model. The influence of soil parameters, i.e., void ratio/relative density and consolidation pressure level on undrained response of soil is examined from model simulations.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The hypoplastic constitutive model has been utilized for all geotechnical applications of field studies since 1985. The original version of the hypoplastic model is coined by Kolymbas (1985) and is improved in further versions. The present improved version of the hypoplastic model is more advanced over the elasto-plastic models. P.‐A. von Wolffersdorff (1996) has described the mathematical formulations involved in this model. These formulations capture the influence of mean pressure and density along various deformation paths and the soil behavior bounded by asymptotic states including the widely accepted critical state, as stated by P.‐A. von Wolffersdorff (1996).

The hypoplastic constitutive relation requires eight parameters; the standard procedure required to determine these material parameters from real experimental data have been published by P.‐A. von Wolffersdorff (1996) and Herle (1997, 2008). This model requires three input data files including model parameters, initial soil state condition and test conditions for the analysis.

2 Hypoplastic Model

It is found that hypoplastic models are more advanced to elasto-plastic models for continuum modeling of granular materials. The first version of the hypoplastic constitutive model was proposed by Kolymbas (1985). It used a single-state variable, the current Cauchy stress Ts. Later another state variable, the void ratio (e), was added. The hypoplastic constitutive equation in general form is given by

Herein, Ts represents the objective stress rate tensor as a function of the current void ratio e, the Cauchy granulate stress tensor Ts and the stretching tensor of the granular skeleton D.

It is the symmetric part of the deformation gradient \(L = \frac{{{\text{d}}v\left( {x,t} \right)}}{{{\text{d}}x}}\), v being the velocity vector of the continuum representing the grain skeleton at a point x.

The present study has focused on performing the numerical simulations on silty sand under undrained cyclic loading.

2.1 Model Parameters

The hypoplastic constitutive relation requires eight parameters: the granular stiffness hs, the critical friction angle φc, the critical void ratio ec0 at zero pressure, the minimum and maximum void ratios ed0 and ei0 at zero pressure and the constants of n, α and β.

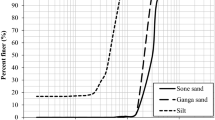

The silty sand used in this study is processed by mixing 40% quarry dust into the fine sand (herein, designated as SS40). The fine sand is collected from Cherthala, Kerala and quarry dust is procured from Blue Diamond M-sand manufacturers, Kattangal, Kerala. The details about the preparation of this combination and its basic properties are explained in Akhila et al. (2018). The model parameter is listed in Table 1.

3 Validation of the Model

The element test program has been prepared by Herle using mathematical formulations involved in hypoplastic soil model. The test program requires three input files, namely material parameters, initial state parameters and test conditions. The variation of pore water pressure with number of cycles for SS40 tested at CSR = 0.127 is shown in Fig. 1 (based on experimental test) and Fig. 2 (based on numerical simulation).

The number of cycles to reach the state of initial liquefaction is almost 55 for experimental and 60 for numerical simulations. The numerical and experimental results at other CSRs are also matching. The results of the same are shown in Fig. 3. Hence, the model simulations can be extended to find the effect of various parameters on the liquefaction susceptibility of silty sand.

4 Results and Discussion

The section discusses the numerical results obtained from the hypoplastic model. Initially, the effect of various parameters on liquefaction susceptibility of soil was studied by using hypoplastic model. The results are displayed in terms of stress paths, hysteresis loops, variation of pore water pressures and strain with no. of cycles, etc.

The parameters affecting soil liquefaction i.e., the magnitude of cyclic stress ratios, void ratio of soil and, consolidation pressures are studied with the help of element test program written using hypoplastic relations. The following sections discuss the effect of each parameter on liquefaction susceptibility.

4.1 Effect of Cyclic Stress Ratio

The silty sand in the present study is subjected to various cyclic stress ratios like 0.127, 0.152 and 0.178. The cyclic stress ratio is defined as the ratio of cyclic deviator stress to twice the applied effective consolidation pressure. The soil element having a void ratio of 0.74 is consolidated under the pressure of 100 kPa prior to applying the cyclic shear. The pore pressure variations with number of cycles, subjected to each CSR are overlapped in a single plot as shown in Fig. 4.

Figure 4 illustrates the effect of CSR on pore pressure buildup. The soil model subjected to CSR of 0.127 develops the gradual buildup of pore pressure and the 100% pore pressure build occur at about 60 cycles of loading. However, the pore pressure buildup is very rapid in the case of soil model subjected to high CSR values and 100% pore pressure buildup occur at a low number of cycles about 18 and 6 corresponding to CSR values of 0.152 and 0.178, respectively. The liquefaction resistance curve is shown in Fig. 5.

4.2 Effect of Void Ratio

To find the effect of void ratio on undrained response under cyclic loading, the simulations were performed under various void ratios like 0.6, 0.74 and 0.9. The soil model is consolidated under an effective pressure of 100 kPa and subjected to different cyclic loadings of 0.127, 0.152 and 0.178. The pore pressure variation with number of cycles for soil model analyzed at different void ratios and subjected to each CSR is overlapped in a single plot as shown in Figs. 6, 7 and 8.

The soil model with a low void ratio of 0.6 develops the gradual buildup of pore pressure and the 100% pore pressure build occur at large cycles of loading irrespective of applied CSR values. However, the pore pressure buildup is very rapid in the case of the soil model with high void ratios and 100% pore pressure buildup occurs at a low number of cycles. It indicates that loose samples are causing a rapid buildup of pore pressure that leads to liquefaction in short duration and causes large deformations. The effect of void ratio on liquefaction resistance curves is shown in Fig. 9.

4.3 Effect of Consolidation Pressure

To study the effect of consolidation pressure on liquefaction susceptibility of silty sand, soil model is consolidated with different pressures of 100, 150 and 200 kPa. The soil model with the void ratio of 0.74 is subjected to different cyclic stress ratios of 0.127, 0.152 and 0.178 to construct the liquefaction resistance curves.

The soil model consolidated with low pressure of 100 kPa develops the gradual buildup of pore pressure and the 100% pore pressure build occur at large cycles of loading irrespective of applied CSR values. However, the pore pressure buildup is very rapid in the case of the soil model consolidated with high pressures and 100% pore pressure buildup occurs at a low number of cycles.

The pore pressure variation with a number of cycles for soil model analyzed at different consolidation pressure (100, 150 and 200 kPa) and subjected to each CSR is overlapped in a single plot as shown in Figs. 10, 11 and 12. The liquefaction resistance curve for the varying void ratio is shown in Fig. 13.

5 Summary and Conclusions

Based on the discussion of numerical results, the following conclusions can be drawn with regards to the effect of various parameters on the liquefaction susceptibility of silty sands:

-

The pore pressure buildup and strain propagations are very rapid in the case of soil model subjected to higher magnitudes of cyclic stress ratios. It is interesting to note that the strain variation is insignificant before triggering the liquefaction and becomes rapid during and after triggering of liquefaction. At high CSR values, the soil model will liquefy in short duration of less number of load cycles.

-

The pore pressure buildup and strain accumulations are very rapid in the case of the soil model with high void ratios/low relative densities. It indicates, the loose soil samples are causing a rapid buildup of pore pressure and large deformations lead to liquefaction in short duration.

-

The required cyclic stress amplitude causing initial liquefaction is decreasing with increase in the void ratio at any particular number of load cycles. It indicates that the loose soils are liquefiable at lesser amplitudes of cyclic loads.

-

The pore pressure buildup and strain accumulations are very rapid in the case of soil model consolidated with high pressures. It indicates the consolidated samples at large pressures are causing a rapid buildup of pore pressure that leads to liquefaction in short duration and large deformations.

-

The required cyclic stress amplitude causing initial liquefaction is decreasing with an increase in the consolidation pressure at any particular number of load cycles. It indicates that the soils consolidated at large pressures are liquefiable at lesser amplitudes of cyclic loads.

References

Akhila M, Rangaswamy K, Sankar N (2018) Undrained response and liquefaction resistance of sand-silt mixtures. Geotech Geol Eng 37:2729–2745

Herle I (1997) Hypoplastizit t und granulometrie einfacher Kornger ste. Ph.D. thesis, Insitut f r Boden- und Felsmechanik der Universit t Karlsruhe

Herle I (2008) On basic features of constitutive models for geomaterials. J Theor Appl Mech 38(1–2):61–80

Kolymbas D (1985) A generalized hypoelastic constitutive law. In: Proceedings of the eleventh international conference on soil mechanics and foundation engineering

Kolymbas D (1991) An outline of hypoplasticity. Arch Appl Mech 61:143–151

von Wolffersdorff P‐A (1996) A hypoplastic relation for granular materials with a predefined limit state surface. Mech Cohesive-Frictional Mater 1(3):251–271. Online wiley library

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Akhila, M., Jithesh, P.C., Rangaswamy, K., Sankar, N. (2020). Numerical Study on Cyclic Loading Effects on the Undrained Response of Silty Sand. In: Latha Gali, M., P., R.R. (eds) Geotechnical Characterization and Modelling. Lecture Notes in Civil Engineering, vol 85. Springer, Singapore. https://doi.org/10.1007/978-981-15-6086-6_86

Download citation

DOI: https://doi.org/10.1007/978-981-15-6086-6_86

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6085-9

Online ISBN: 978-981-15-6086-6

eBook Packages: EngineeringEngineering (R0)