Abstract

Construction and demolition waste (CDW) consists of debris generated during the renovation or development of structural elements. Rapid urbanization renders it necessary to reduce the consumption of non-renewable natural resources drastically and also to limit the dumping of these materials after the expiration of their service life. In a rapidly progressing country like India, development of infrastructure produces a lot of solid waste. This derives the interest to reuse it by admixing or adding with existing soil to improve its strength properties. The concrete and brick content, which constitutes a major portion of CDW, is called as building derived material (BDM). The shear strength of soil partially replaced with BDM is a significant property that defines its suitability for several applications. However, it is not an intrinsic property and varies with several experimental factors such as relative density of soil and shearing strain at which shear tests are conducted. The present study deals with the behavior of BDM when admixed with locally available red soil tested at different strain rates (1.25 and 2 mm/min). Consolidated undrained triaxial tests are carried out at three different confining pressures (100, 150, and 200 kPa). This study further investigates the effect of the degree of compaction on the shear strength properties of soil–BDM blends. The results obtained from this study show that the addition of BDM to the soil is enhancing the resistance of the soil to deformation under axial load.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Society and economy of the nation depend directly or indirectly on the natural resources available. Due to rapid industrial and urban developments, these natural resources are depleting. Hence, there is a need to find out an alternative which serves the purpose especially engineering uses. Construction and demolition waste (CDW) is one such material which can be an alternative to natural sand and aggregates in construction activities. In India, as per 2016 statistics, 530 million tons of CDW are getting deposited every year. This is leading to the occupation of land space and disturbance in the ecological system. So, this material should be deposited properly or reused in engineering applications. CDW consists of concrete, steel, wood, tile, and glass (BMTPC 2017). Concrete and brick part of CDW is termed as building derived material (BDM). Concrete-based BDM exhibits more strength than brick-based BDM (Suluguru et al. 2017; Jayatheja et al. 2017). CDW having sizes larger than 4.75 mm possesses greater shear strength than natural gravel. CDW is also used for increasing bearing capacity of soils and its implementation reduces carbon footprint. Moreover, the cost of collection, recycling, screening, and procuring is much lesser compared to that of other building materials (Hasan et al. 2016). Resilient modulus increased when CDW is adopted in pavement sub-bases. Unconsolidated-undrained (UU) and cyclic triaxial tests are performed on cement-treated CDW. Factors like humidity, cement content, and curing time also play a part in resilient modulus (Mohammadinia et al. 2015). Finer fractions of CDW can be used in cement preparation and bind with coarser particles like gravels and cobble (Bianchini et al. 2005). Pavement filter layer as a component of permeable pavement can be laid with CDW because their hydraulic and geotechnical properties are similar to granular materials (Rahman et al. 2015). The angle of internal friction changes with porosity. Loose sands exhibit lower values like 11° in undrained case (Bjerrum and Kringstaad 1954). Axial strains and pore water pressures are proportional to the strain rate adopted during the triaxial test (Ni et al. 2012). Imposing end restraints and varying strain rates cannot predict the true material behavior of soil elements at a constitutive level (Sheng et al. 1997). When undrained tests are performed on silty sands, the material showed a contractive behavior. When the same specimen is tested with incremental confining pressures, the residual strength of the material is also varying proportionately (Sitharam et al. 2014). Void ratio increases with the addition of fines content to sand and results in a decrease of residual shear strength. Hence, residual strength is indirectly proportional to finer fraction content (0–50%) present in the soil composition (Belkhatir et al. 2011).

Geotechnical problems which deal with stability of slope, bearing capacity of foundations are dependent on shear strength of soil. Shear box and triaxial tests are conducted on soils to evaluate shear properties. There will be some errors in measuring the normal stress and peak frictional angle in direct shear apparatus. Outputs of tests are also dependent on rate of loading (strain rate); shear strength is increased by 10% when sand sample is tested at strain rate of 115%/s that of initial value (Casagrande and Shannon 1948). Maintaining constant confining pressures of 200 kPa and increasing strain rate till 1000%/s increased shear strength by 15–20% for dense saturated sands (Seed and Lundgren 1954). Tests on loose and dense sands conducted at confining pressure of 70 kPa observed that drained strength increased by 10% and undrained strength by 100%. It is observed that angle of internal friction is independent of strain rate (Whitman and Healy 1962). Schimming et al. (1966) reported that the shear strength of cohesionless materials will not increase if loading is changed from static to dynamic. Lee et al. (1969) conducted tests on loose and dense dry sand at cell pressures from 100 to 1470 kPa and strain rates up to 250%/s and noticed that the difference in shear strength value shows a change of mechanism of shear strength mobilization and failure envelope. Larger strain rates are responsible for particle crushing and change in shear strength. Yamamuro and Lade (1993) noticed there is a change of 2 and 7% when drained and undrained triaxial performed on dense sands at confining pressure of 34.0 MPa. Tatsuoka et al. (1999) and Matsushita et al. (1999) worked on Toyoura sand in triaxial compression test at strain rates ranging between 0.00000417 and 0.0021%/s. They noticed that low strain rates have no effect whereas high strain rates have a greater impact on shear strength.

Based on existing literature, it is seen that recycled CDW is used for engineering applications, although the mechanical and chemical recycling processes incur additional costs. However, limited information is available on the procurement and use of virgin BDM is an additive for soils. Hence, this study aims to use virgin BDM as an additive for the red soil to enhance its resistance to deformation under axial loads. The shear strength of soil partially replaced with BDM is a significant property that defines its suitability for several applications. However, it is not an intrinsic property and varies with several experimental factors such as relative density of soil and shearing strain at which shear tests are conducted. The present study deals with the behavior of BDM when admixed with locally available red soil tested at different strain rates. The materials and methods are explained below.

2 Materials

The tests are carried out on locally available red soil collected from the vicinity of Hyderabad Campus of BITS-Pilani. CDW is generated in the campus as it is undergoing renovation. The guidelines proposed by ASTM practice for sampling are followed during sampling and adequate precautions are taken to ensure that each sample contains a representation of each particle size. Collected CDW is broken down into particles of sizes less than 10 mm. A major portion of this CDW consists of concrete and brick and their fragmentation leads to BDM. BDM particles having a size between 75 and 10 mm are used in this study.

3 Experimental Investigations

3.1 Grain Size Analysis

Grain size analysis is performed for both red soil and BDM according to IS: 2720—4. The properties of red soil used are presented in Table 1. The percentage of BDM is varied from 5 to 30% by weight. Laboratory tests are conducted according to IS specifications to investigate the compatibility of BDM with soil. The Atterberg limit tests are also carried out on particle sizes of BDM less than 425 μm and it is observed that BDM is non-plastic in nature. The low plasticity index value of red soil indicates that the soil less plastic and also does not possess significant swelling properties.

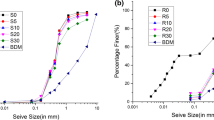

The value of the coefficient of uniformity (Cu) is less than 5 and the value of the coefficient of curvature (Cc) is 0.11, respectively. Figure 1 shows that the red soil is gap graded. Shape parameter and size parameter give an idea that particles in red soil are uniformly sized. The soil is classified as silty sand according to the unified system of soil classification.

The Cu and Cc of BDM are found to be 18.4 and 0.87, respectively. The gravel (>4.75 mm), sand (0.075–4.75 mm), and silt and clay (<0.075 mm)-sized particles present in BDM are found to be 38.2%, 61.6%, and 0.2%, respectively.

3.2 Compaction

Optimum moisture content (OMC) and maximum dry density (MDD) are determined by standard compaction test according to IS: 2720—7. In the first stage, red soil samples are prepared by mixing the soil with de-aired water and their MDD–OMC is evaluated. In the second stage, BDM is added to red soil, 10% and 20% by mass, respectively, and standard compaction test is performed on the soil–BDM blends. It is observed that red soil exhibits maximum density at 16.5 kN/m3 on addition of an optimum moisture content of 12.5%. Variation of OMC with corresponding percentages of BDM replaced is shown in Figs. 2 and 3. It is observed that as the % of BDM is increased, MDD is also varying proportionally till the optimum content is reached and then it decreases. Moisture acts as a lubricant within soil particles which is helpful for particles to slide among each other. Less moisture cannot make the particles to slide over each other due to adhesive density, and more moisture makes the specimen weak as the entire voids are occupied by the water.

3.3 Shear Strength

Consolidated undrained shear strength tests are carried out in a computerized AIMIL triaxial testing system apparatus according to IS: 2720—11 and 12. Figure 4 shows the triaxial test setup. It consists of a universal cell where a sample of diameter 38 and 76 mm height is tested. The resistance offered by the soil sample against loading is recorded by a load cell of 1-ton capacity. 1 LVDT is placed on the platform of the cell to monitor the displacements. The load cell and LVDT are connected to a data acquisition system (Daq). The AIMIL digital indicator displays changes in load, displacement, and pore water pressures. Cell/confining pressures and back pressures are supplied on to the sample through pipes. These pressures can be altered in AIMIL Constant Pressure System. It is a hydraulically operated system which consists of oil–water interface. Cell and back pressures are varied incrementally until the sample is fully saturated. After the saturation factor reaches a value of 0.8, the sample is sheared at strain rates of 1.25 and 2.0 mm/min under constant cell pressure. During the shearing process, drainage is not allowed. A constant relative density of 40% is maintained throughout the study. To evaluate the material behavior under load and to know the effects of strain on soil specimen, two different strain rates are adopted in this study. At each strain rate for each type of soli–BDM blend, three separate confining pressures of 100, 150, and 200 kPa are applied. The test program is summarized in Table 2. In Table 2, R denotes red soil.

CU triaxial tests are conducted, and strain hardening behavior is observed. When the material is loaded, resistance is exhibited by the sample and also the confining pressure surrounded to it. In the second stage, the soil specimen possesses resistance depending upon density at which it is arranged. Stress–strain curve will be in linearly elastic zone. In the third stage, soil specimen approaches yield point and beyond that it goes into perfectly plastic zone. Particle reorientation occurs during axial loading which makes void space to be filled which is also a reason for the non-elastic behavior. Figure 5a, b represents the stress–strain plots for red soil mixed with 0%, 10%, and 20% BDM at strain rates of 1.25 mm/min and 2 mm/min, respectively.

It can be observed from Fig. 5a, b that R0 and R20 exhibit more strength when sheared at confining pressure of 200 kPa. Although R0 achieves peak value at a smaller strain of 5%, R20 reaches a peak value at an axial strain 20%. In samples which are tested at 1.25 mm/min, it is found that for all mixtures except for R0 sheared at 100 and 200 kPa, deviatoric stress is proportionately increasing with axial strain till it reaches the peak value and remains constant at residual level. In both cases where strain rates varied, it is found that addition of BDM made sample harder and also peak stress value is increased with an increase in the percentage of BDM. In all cases, peak stress value is obtained at axial strain which is ranged between 7 and 13%. Addition of BDM to red soil increases its porosity which has drainage characteristics suitable for backfill applications. For samples loaded at a strain rate of 1.25 mm/min, particles in soil specimen have not given an immediate response to load as it has sufficient time to get crushed and rearrangement. For samples loaded at a strain rate of 2.00 mm/min, time for particles in the soil to get rearranged is less and response is quick although there is only a little difference in peak stress values.

Figure 6 shows Mohr’s envelope and angle of internal friction and cohesion intercept for soil mixed with different percentages of BDM at varying strain rates. The results presented in Table 3 indicate that shear stress of soil sample has increased with increase in strain rate. Higher strain rates and higher percentages of BDM lead to particle reorientation and crushing which leads to a decrease in values of shear parameters. Cohesion and angle of internal friction are increasing in all combinations except in case of R20. Further investigation is required in order to assess the soil–BDM blend behavior and to determine an optimum value which possesses maximum shear strength.

4 Conclusions

Based on consolidated undrained triaxial test results, the present study highlights the effect of strain rates on the angle of internal friction and cohesion of soil and soil mixed with different percentages of BDM. It is observed that behavior of soil is highly dependent on confining pressures and soil stiffness is influenced by strain rate.

-

The yield stress increases with the addition of BDM to existing red soil. At higher strain rate, the soil reaches plastic state quickly.

-

Compaction and shear strength studies indicate that 17–23% is the optimum content of BDM to be replaced.

-

Increase in confining pressure and strain rate increases the shear strength of soil–BDM blend. Therefore, the shear parameters obtained from triaxial test are susceptible to changes in strain rate at which they are performed.

-

The strain at which the peak shear strength occurs reveals an unpatterned variation with a corresponding variation in strain rate. The peak shear strength also varies with strain rate for specific normal stress.

-

Based on the present study, it is recommended to mention the test condition at which the shear strength test is carried pot, along with the obtained shear strength parameters.

References

Belkhatir M, Missoum H, Arab A, Della N, Schanz T (2011) Undrained shear strength of sand-silt mixture: effect of intergranular void ratio and other parameters. KSCE J Civil Eng 15(8):1335–1342. https://doi.org/10.1007/s12205-011-1051-x

Bianchini G, Marrocchino E, Tassinari R, Vaccaro C (2005) Recycling of construction and demolition waste materials: A chemical-mineralogical appraisal. Waste Manage 25(2): 149–159. https://doi.org/10.1016/j.wasman.2004.09.005

Bjerrum L, Kringstaad SOK (1954) The shear strength of a fine sand. Geotechnique: 29–35. Retrieved from https://www.issmge.org/uploads/publications/1/40/1961_01_0005.pdf

Casagrande A, Shannon WL (1948) Strength of soils under dynamic loads. Proc ASCE 74(4):591–608

Hasan U, Chegenizadeh A, Budihardjo MA, Nikraz H (2016) Experimental evaluation of construction waste and ground granulated blast furnace slag as alternative soil stabilisers. Geotech Geol Eng 34(6):1707–1722. https://doi.org/10.1007/s10706-016-9983-z

Jayatheja M, Suluguru AK, Anand A, Guharay A, Kar A, James N (2017) Performance of sand partially replaced with building derived materials under static loading conditions. In: International conference for geotechniques for infrastructure, Thiruvananthapuram, Kerala

Lee KL, Seed HB, Dunlop P (1969) Effect of transient loading on the strength of sand. In: Proceedings of 7th international conference on soil mechanics and foundation engineering, vol 1. Sociedad Mexicana de Mecanica de Suelos, Mexico City, pp 239–247

Matsushita M, Tatsuoka F, Koseki J, Cazacliu B, Di Benedetto H, Yasin SJM (1999) Time effects on the pre-peak deformation properties of sand. Proc. 2nd International Conf. on Pre-failure Deformation Characteristics of Geomaterials, IS Torino, Jamiolkowski et al. eds, Balkema, vol 1, pp 681–689

Mohammadinia A, Arulrajah A, Sanjayan J, Disfani MM, Bo MW, Darmawan S (2015) Laboratory evaluation of the use of cement-treated construction and demolition materials in pavement base and subbase applications. J Mater Civil Eng 27(6). https://doi.org/10.1061/(ASCE)MT.1943-5533.0001148

Ni J, Indraratna B, Geng XY, Rujikiatkamjorn C (2012) The effect of the strain rate on soft soil behavior under cyclic loading. In: ANZ proceedings, pp 1340–1345. Retrieved from http://ro.uow.edu.au/engpapers/4464

Rahman MA, Imteaz MA, Arulrajah A, Piratheepan J, Disfani MM (2015) Recycled construction and demolition materials in permeable pavement systems: geotechnical and hydraulic characteristics. J Clean Prod 90. https://doi.org/10.1016/j.jclepro.2014.11.042

Schimming BB, Haas AM, Saxe HC (1966) Study of dynamic and static failure envelopes. J Soil Mech Found Div 92(SM2):105–124

Seed HB, Lundgren R (1954) Investigation of the effect of transient loadings on the strength and deformation characteristics of saturated sands. Proc ASTM 54:1288–1306

Sheng D, Westerberg B, Mattsson H, Axelsson K (1997) Effects of end restraint and strain rate in triaxial tests. Comput Geotech 21(3):163–182. https://doi.org/10.1016/S0266-352X(97)00021-9

Sitharam TG, Govinda Raju L, Murthy BRS (2014) Cyclic and monotonic undrained shear response of silty sand from bhuj region in india. ISET J Earthq Technol 41(4): 249–260. Retrieved from http://home.iitk.ac.in/~vinaykg/Iset450.pdf

Suluguru AK, Jayatheja M, Kar A, GuhaRay A, Surana SR, James N (2017) Experimental studies on the microstructural, physical and chemical characteristics of building derived materials to assess their suitability in ground improvement. Constr Build Mater 156. https://doi.org/10.1016/j.conbuildmat.2017.09.058

Tatsuoka F et al (1999) Time-dependent deformation characteristics of stiff geomaterials in engineering practice. In: Jamiolkowski M, Lancellotta R (eds) Proceedings of 2nd international conference on pre-failure deformation characteristics of geomaterials, vol 2, Balkema, Rotterdam, The Netherlands, pp 1161–1262

Whitman RV, Healy KA (1962) Shear strength of sands during rapid loading. J Soil Mech Found Div 88(SM2):99–132

Yamamuro JA, Lade PV (1993) Effects of strain rate on instability of granular soils. Geotech Test J 16(3):304–313

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Jayatheja, M., GuhaRay, A., Kar, A. (2020). Effect of Strain Rate on Shear Strength of Red Soil Partially Replaced with Building Derived Materials. In: Latha Gali, M., P., R.R. (eds) Geotechnical Characterization and Modelling. Lecture Notes in Civil Engineering, vol 85. Springer, Singapore. https://doi.org/10.1007/978-981-15-6086-6_45

Download citation

DOI: https://doi.org/10.1007/978-981-15-6086-6_45

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6085-9

Online ISBN: 978-981-15-6086-6

eBook Packages: EngineeringEngineering (R0)