Abstract

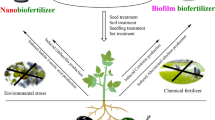

The biofertilizers are formulations containing live or latent cells of effective microbial strains cultured in the lab and packed in appropriate carriers. When applied to seeds, soil, or plant surfaces, they enhance the availability of plant nutrients and growth stimulus to target crops. Biofertilizers are known to deliver many benefits, including plant nutrition, disease resistance, and tolerance to adverse climatic conditions. During the past few decades, notable progress has been made to explore microbes' potential and for biofertilizer production to enhance agricultural productivity. All biofertilizers are known to be environment-friendly and valuable inputs for the farmers. Their application has been considered an essential component of integrated nutrient management and a potential alternative to chemical-based agriculture due to its vital role in food security and sustainable crop production. Currently, biofertilizer demand and production are gaining momentum, as there is burgeoning passion for organically grown food among the health-conscious societies. Various initiatives and affirmative regulations laid by government institutions and agencies would further be fueling the extension of the biofertilizer market worldwide. Application of these eco-friendly and cost-effective inputs would not only promote growing healthy food, but also help to maintain a sustainable environment and holistic human well-being.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

The biofertilizers are defined as the formulations containing live or latent cells of active microbial strains, which increases the availability of nutrients to crop plants. It comprises of mycorrhizal fungi, blue-green algae, and bacteria already present and available in nature (Itelima et al. 2018). When applied to seeds, plant surfaces, or soil, they accelerate the biological N-fixation, solubilization/mobilization of P, K, Zn, and many other nutrients and thus enhance the availability of plant nutrients and growth stimulus to target crops (Bhattacharjee and Dey 2014). Biofertilizers were developed with the discovery of biological nitrogen fixation (BNF). BNF is a natural source of nitrogen and plays a vital role in the sustainable production of leguminous and even non-leguminous crops. The most striking relationship that these have with plants is symbiosis, in which the partners derive benefits from each other. Plants have many connections with fungi, bacteria, and algae, the most common of which are with Mycorrhiza, Rhizobium, and Cyanophyceae (Sinha et al. 2014; Itelima et al. 2018). These are known to deliver many benefits, including plant nutrition, disease resistance, and tolerance to adverse climatic conditions.

Plants nutrients are essential for crop production and healthy food production for the world. Biofertilizers, when applied, add nutrients to the soil through the natural processes (Vessey 2003; Sinha et al. 2014). They also add plant growth-promoting substances like phytohormones and enzymes, thus increasing the productivity of crops (Barman et al. 2017; Itelima et al. 2018). As we know, India is overwhelmingly reliant on imports for meeting its fertilizer needs. Therefore, the Government of India is trying to explore innovative ideas to build self-reliance on environment-friendly fertilizers to reduce the dependence on imports. The Indian government is also encouraging the domestic fertilizer sector, primarily to promote the use of biofertilizers across the country (Gupta 2018). Biofertilizer has been considered as an alternative to chemical-based crop production due to its potential role in food safety and sustainable agriculture (Bhattacharjee and Dey 2014).

2 Microbes Used in Biofertilizers and Their Suitability for Crops and Benefits

Globally, the commercial journey of biofertilizer began with the introduction of the rhizobium “Nitragin” by Nobbe and Hiltner in 1895. Currently, many biofertilizers are available on a commercial scale (Kribacho 2010). Table 10.1 shows the classification of biofertilizers based on the different types of microorganisms used in their formulations. According to the recommended package of practices, farmers typically require to apply 120 kg of N per hectare for crops such as rice and wheat. However, the N-fertilizer use efficiency is generally below 40%, meaning that most applied fertilizer either wash out or is lost to the environment. Similarly, plants utilize P-fertilizer to the tune of only 10–15% of the phosphate applied. The balance 85–90% remain in insoluble form in the soil, which can be solubilized by applying P-solubilizing biofertilizers such as Bacillus megaterium. According to Zulaika et al. (2017), the application of biofertilizers can increase the yield by around 25–50%, while reducing the application of chemical fertilizers up to 25–50% for N and about 25% for P. Suitability of biofertilizers for crops and its benefits are given in Table 10.2.

3 Biofertilizer Formulations

Biofertilizers are also known as cultures, most commonly attributed to as particular beneficial microbial strains cultured in a lab and packed in appropriate carriers (Hari and Perumal 2010; Itelima et al. 2018). The biofertilizer preparations are commercially available as carrier-based, as well as liquid-based formulations (Swarnalakshmi et al. 2016). In general, there are 6-steps involved in making carrier-based biofertilizer formulation and its production (Fig. 10.1). These are exploration and identification of active microorganisms, isolation and choosing of beneficial target microbes, selection of suitable method and carrier, selection of best propagation method, phenotype (quality) testing, and field trials at a diverse environment to examine its effectiveness and limitations (Khosro and Yousef 2012; Youssef and Eissa 2014). The necessary steps involved in making carrier-based biofertilizer are shown in Fig. 10.1.

Carrier-based preparations are primed with powdered charcoal or lignite (106 CFU/g) with 3–6 months’ shelf-life and are commonly available in the market (Swarnalakshmi et al. 2016). However, vermiculite, press mud, farmyard manure, peat soil, and soil mixture can also be used as carrier materials. The use of lignite is sometimes found to have harmful effects on the workers involved in biofertilizer production. Contamination of cultures is often caused by high moisture. It may either compete with biofertilizers or cause antagonistic interaction. Sometimes retail traders and shopkeepers do not prefer to sell biofertilizers because of short shelf-life, limited demand by farmers, and non-existence of storage facilities (Mazid and Khan 2014). The carrier-based formulation is available in various forms such as powder, slurry, and granules. The powder form is usually used as seed coating before planting. The smaller the particle size of powder, the better the inoculants will adhere to the seeds. Standard size varies from 0.075 to 0.25 mm. The amount of inoculants required or used is around 200–300 g ha−1. The powder-type inoculants suspended in liquid or slurry are directly applied to the furrow, or the seeds are dipped just before sowing. The granular form is used directly to the furrow together with seeds. Size ranges are from 0.35 to 1.18 mm. The granular form is better than powder inoculants for rhizobia under stressful planting conditions, but costlier owing to more required quantity (Trimurtulu and Rao 2014).

Liquid biofertilizers (LBFs) are aqueous, oil, or polymer-based liquid formulations or suspensions carrying desired microorganisms and their nutrients along with cell protectants and additives that promote the formation of resting spores or cysts for extended shelf-life and tolerance to adverse conditions after application to seed or soil (Brahmaprakash and Sahu 2012). They are neither the water suspension of carrier-based biofertilizers nor the usual broth culture obtained by fermentation. LBFs consist of beneficial microbial cultures suspended in liquid medium rich in cell protectors and nutrients. The cell protectors and additives improve the inoculant quality by stabilizing the product, preventing osmolysis, giving better binding to seed, enhancing the microbe's survival during storage, and protecting the inoculum after exposure to extreme environmental conditions upon inoculation into seed or soil (Sahu and Brahmaprakash 2016). LBFs are now considered a great alternative to conventional carrier-based biofertilizers in current agriculture. Carrier-based biofertilizers are susceptible to high temperatures and UV rays, and most importantly, the population density of the microbes reduces gradually to almost nil by the end of 6 months from its time of production (Mahdi et al. 2010). Liquid-based preparations are coming up with a high microbial mass (109 CFU/mL), with longer shelf-life of 12–24 months and additionally, they can be applied in drip irrigation and as a component of organic farming (Swarnalakshmi et al. 2016; Vyas and Shelat 2019). LBFs can help to boost crop yields, rescue soil health, and sustainable food production as they offer several advantages. Advantages of LBFs over carrier-based biofertilizers are as follows:

-

Negligible contamination during the production process

-

Comparatively longer shelf-life (12–24 months)

-

The higher microbial load of the desired microorganism (109 Cells/ml) which can be maintained during storage

-

Easy to identify the biofertilizer by the typical fermented smell

-

Cost-saving on preparation (pulverization, sterilization, and packing) and transportation of carrier material

-

Easy to follow and maintain the quality control standards

-

Higher survival on seed and soil

-

Farmers friendly as it is easy to apply in the field

-

Low dosage compared to carrier-based biofertilizers

-

Tolerant to high temperatures and ultra-violet radiations

-

Compatible with modern agriculture machinery for its application

-

They allow alternative applying methods such as fertigation and spray application to soil

4 Biofertilizer Application

Currently, both solid-carrier based and liquid-suspension based biofertilizers widely used by the farmer. Liquid inoculants can be based on broth cultures, mineral or organic soils, or on oil-in-water suspensions. In the case of solid carriers, powder, granules, or beads are the ideal forms utilized. The application of both the carrier and liquid-based biofertilizers is discussed below.

4.1 Application of Carrier-Based Biofertilizers

4.1.1 Seed Treatment or Seed Inoculation

Seed treatment is the crucial practice used for various types of bio-inoculants, in which the inoculant is mixed with water to take the form of slurry and then mixed with seeds (Narayanasamy et al. 2012). The seed treatment can be done with more than one type of bio-inoculant. It is an effective and economical method. The carrier-based biofertilizer seed treatment process is shown in Fig. 10.2. Inoculants of Rhizobium, Azotobacter, Azospirillum, and phosphate solubilizing bacteria are generally applied through seed treatment. In general, 150–200 g of inoculant is enough to treat seed for an acre of land. For the purpose of making stickers, mainly adhesive, like sugar (gur), gum, rice-gruel water, sucrose solutions are used. The total quantity of water to be taken should be just sufficient to moisten the seeds, and 10% solution of jaggery or sugar is to be prepared. Boil the solution and let the solution be cooled completely. Biofertilizers are mixed thoroughly in the cooled solution, and the slurry thus prepared is poured on seeds and shaken continuously so that a uniform layer of biofertilizer is coated onto each seed. After coating, the inoculated seeds are shade-dried for 20–30 min and to be sown immediately. For acidic and alkaline soils, it is always advisable to use 1 kg of slacked lime or gypsum powder, respectively, for coating the wet biofertilizer treated seeds. Precautions must be taken carefully to avoid direct exposure of the inoculant packet and the inoculated seeds to sunlight, contact with chemical fertilizers, and pesticides. Application and doses of carrier-based biofertilizers for various crops are shown in Table 10.3.

4.1.2 Soil Application or Main Field Application

The second technique is direct soil application by the broadcasting of biofertilizer on plantation or during sowing or before sowing. It is mostly practiced for plantation crops, fruit crops, sugarcane, and other crops where the localized application is required. Generally, for one acre, depending upon the total plant density, 2–4 kg of the recommended biofertilizer is mixed with 50–100 kg of compost or FYM, and the mixture is kept overnight with adequate moisture for conditioning. Then, the mixture is applied in the rows or during the leveling of soil or sowing. In the case of standing crops, it is to be applied to soil near the roots.

4.1.3 Root/Seedling/Sett/Tuber Inoculation

This method is mainly used for transplanted crops, seed-setts of sugarcane, cut pieces of potato, the base of banana suckers, and forest nurseries. In the case of seedlings, the seedlings required for one acre should be inoculated using 2–2.5 kg of recommended biofertilizers. The inoculant has to be mixed with just sufficient quantity of water (10–15 l), and the root portion of the seedlings has to be dipped in the mixture for a minimum 30 min before transplantation. It has been found well-suited for crops like tomato, onion, cole crops, and flowers. For transplanted rice in low land, a sufficient size bed should be made in the field, and it is filled with 3–4 inches of water. Recommended biofertilizers (5 kg/ha) are to be mixed thoroughly in this water, and roots of seedlings are dipped in this bed for 8–10 h and then transplanted. For sett treatment, the ratio of biofertilizer to water is approximately 1:50. Culture suspension is prepared by mixing 1 kg of biofertilizer in 40–50 l of water, and cut pieces of planting material are kept immersed in the suspension for 30 min. Then, the cut pieces are shade-dried before planting.

4.2 Application of Liquid-Based Biofertilizers

Application of LBFs in the field is easy and very simple. Like carrier-based biofertilizers, they are also applied through seed and soil, root/seedling treatment on the plantation, at sowing or before sowing, but the dosages of LBFs are usually 10 times lesser than that of former. In addition to the above-mentioned methods of application, alternative application methods, such as fertigation, in-furrow, foliar sprays, and direct spraying to the soil, can also be employed (Campo et al. 2010; Fukami et al. 2016; Moretti et al. 2018). They are also compatible with modern agricultural machinery and can be applied using hand sprayers, power sprayers, fertigation tanks, and drip irrigation. A bottle containing a 200 ml culture of Azotobacter/Azospirillum is sufficient for one acre area of cereal crops like rice, wheat, oat, barley, maize, and sorghum; pulses like chickpea, pea, groundnut, soybean, beans, lentil, alfalfa, berseem clover, green gram, black gram, cowpea, and pigeon pea; oilseeds like mustard, sesame, linseeds, sunflower, castor, etc. Some of the most important LBFs and their application method and the ideal amount required for various agricultural crops and agroforestry/fruit/trees are given in Table 10.4.

5 Biofertilizers: Global and Indian Scenario

The expanding use of biofertilizers is showing its potential for sustainable farming. The growing concern about food safety is expected to drive more interest in the industrial production of biofertilizers globally as well in the Indian scenario.

5.1 Biofertilizers: Global Scenario

The global biofertilizer market size was at US $787.8 million in the year 2016. That stood at US $1.34 billion during the year 2018. It is projected to witness a compound annual growth rate (CAGR) of 14.08% during 2018–2025, thereby reaching US$3.3 billion by the end of 2025 (TechSci 2019). The worldwide biofertilizers market growth can be attributed to the rising adoption of cutting-edge technologies by farmers to increase soil fertility and inclusive crop productivity and sustainable farming (Itelima et al. 2018). Besides this, a growing passion for organically produced food is driving force for biofertilizers demand over chemical fertilizers across the world (Santos et al. 2012; Itelima et al. 2018). As a result, vast quantities of cultivated produce to cater to the demand from the growing population are subsequently stimulating the use of biofertilizers on a large scale. Various initiatives and affirmative regulations and action policies laid by government organizations would further be fueling the extension of the worldwide biofertilizer market.

5.2 Biofertilizers: Indian Scenario

In India, a systematic study on biofertilizers was started by NV Joshi in 1920 (Barman et al. 2017). Rhizobium was isolated from various cultivated legumes, and the first commercial production of Rhizobium biofertilizer in India began in 1956, and by the late 1960s, when soybean was introduced, large scale production began (Panda 2011; Bhattacharjee and Dey 2014; Barman et al. 2017). The use of mycorrhizae as biofertilizer is a recent development. The use of microbial strains in biofertilizers re-establishes the natural nutrient cycle, maintains the optimal nutrients level, increases organic carbon contents and fertility of the soil (Sinha et al. 2014; Shelat et al. 2017). The production of biofertilizer in India during 2010–11 was 37997.6 metric tons. However, during 2014–15, the total biofertilizer production reached 80696.5 metric tons (Table 10.5).

It was also noticed that the maximum utilization capacity of biofertilizer is in the south zone at 49.5% and west zone at 29.5%, while the North East Zone recorded the lowest capacity production at <1% during 2014–2015 (NCOF 2015). Zone wise carrier-based biofertilizer production in India is given in Table 10.5. Based on crop area in India, the requirement of biofertilizers is estimated at around 5,50,000 metric tons (Pindi and Satyanarayana 2012). However, the total production of biofertilizers in the country is much less than the need. This signalizes the inevitability of an increase in biofertilizer production (Barman et al. 2017).

The state-wise contribution in the production of carrier-based biofertilizer in India during 2014–15 (Fig. 10.3) indicates that Karnataka ranks first in the production of carrier-based formulation, followed by Tamil Nadu and Maharashtra. However, Gujarat is leading in the production of liquid-based biofertilizers, followed by Maharashtra (Fig. 10.4). Approximately 225 biofertilizer production units have been installed with a production capacity of around 98,000 million tons/annum.

Recently, under the NAIP-ICAR project, Anand Agricultural University, Gujarat has developed a liquid biofertilizer formulation, a safe and eco-friendly substitute for chemical fertilizers. They fix atmospheric N and solubilize insoluble P and make it available to the crops. It is sold to farmers under the brand name “Anubhav liquid Biofertilizers.” It is produced from native bacterial cultures, viz. Azospirillum lipoferum, Azotobacter chroococcum, and Bacillus coagulans. Anand Agricultural University has licensed the LBF technology to commercialize under the Public-Private Partnership to Business Planning and Development Unit, Gujarat. Anand Agricultural University has provided around 50,000 l LBFs to the Gujarat government. It is mostly used in cotton, potato, turmeric, rose, banana, and papaya and showed better yield and quality of these crops (Vyas and Shelat 2019).

The Indian government has taken several initiatives to harness the potential of microbes by introducing as biofertilizers along with chemical fertilizers to the farmers (Barman et al. 2017). In 2006, the Government of India had enforced BIS certification to assess the quality control of biofertilizers such as Rhizobium, Azotobacter, Azospirillum, and PSB under the ambit of Fertilizer (control) Order (1985) during 2006. Still, very few manufacturers opt for quality standards (Swarnalakshmi et al. 2016). Central and state governments are promoting the biofertilizer production and use both at the farmer and the investor level through (1) farm level extension and promotion programs, (2) financial support to investors for setting units, (3) subsidies on sales, and (4) direct production in public and cooperative sector, and through universities and research institutions (Mazid and Khan 2014). Presently, the Government is helping to improve productivity of biofertilizer industries in India. The Government of India is also promoting the use of biofertilizers across the country. Much financial support has been provided to establishment of biofertilizers production unit as back ended subsidy, at 25% of total financial outlay up to a maximum of Rs. 40 lakh. National Bank for Agriculture & Rural Development (NABARD) also awards a national productivity award to the efficient biofertilizer production unit in India (Borkar 2015; Barman et al. 2017).

6 Biofertilizers: Microbial and Biotechnological Approaches

Today, microbial techniques and biotech-tools are assisting in solving many challenges, especially in the unexplored potential of microbes. The integration of the microbial and biotechnological approaches in the field of biofertilizers can help in improving microbe's efficiencies, and making better use of natural resources. It will also help to increase agriculture production and reduce the use of chemical fertilizers, pesticides, and insecticides on crops.

6.1 Bacterial Biofertilizers

Most of the bacteria added in biofertilizers have a close association with crop roots and the ability to fix atmospheric N. Many symbiotic and free-living bacteria are involved in biological nitrogen fixation (Table 10.1). The annual biological N-fixation is assessed to be nearly 175 million tons, of which almost 79 % is considered by terrestrial N-fixation (Ali et al. 1998). Soil bacteria drive the majority of plant growth-promoting activities. For example, biological N-fixation performed by Rhizobium, Azotobacter, Azospirillum, Acetobacter, Klebsiella, etc.; P-solubilization is performed explicitly by Bacillus megaterium and Pseudomonas striata; while K and Zn solubilization is mostly by Bacillus species. Some of the soil microbes, such as Azotobacter, Pseudomonas, are capable of producing growth hormones, while some of them are involved in antibiotic production like Pseudomonas and Bacillus, etc.

6.2 Mycorrhizal Biofertilizers

Mycorrhiza is a symbiotic relationship between the fungus and green plants. The fungus colonizes with the host plant roots. It may be either intracellularly (arbuscular mycorrhizal fungi) or extracellular (ectomycorrhizal fungi). The fungus is dependent for food on plant, basically for glucose and fructose, which are translocated from leaves to roots and then on to fungus (Maillet et al. 2011). In return, the plant gets the benefit of fungal mycelium’s high absorptive capacity for nutrients (especially phosphorus) and water uptake due to the large surface area of hyphae. Fungal hyphae cover the plant roots, hence protecting desiccation. Most of the higher plants form mycorrhizal associations, except the members of Brassicaceae and Chenopodiaceae. The most common type association is arbuscular mycorrhiza, which is found in 70% plant species. Mycorrhizal associations are divided into two broad categories. First is ectomycorrhiza, in which fungal hyphae do not penetrate the cell wall. Second is endomycorrhiza, in which fungal hyphae penetrate the cell wall, and invaginates the cell membrane. Endomycorrhiza is further sub-divided into arbuscular, ericoid, and orchid mycorrhiza. Another category called arbutoid mycorrhiza is also known as ecto-endo mycorrhiza.

6.3 Mechanism and Mode of Actions of Bacterial and Mycorrhizal Biofertilizers

The biofertilizer mode of action depends on the groups or types of microbes they contain. Plant growth-promoting rhizobacteria (PGPR) improves plant growth and resistance to abiotic stresses through several mechanisms. These mechanisms of action are: (1) the synthesis of plant nutrients or phytohormones as growth promoter, (2) mobilization of soil nutrients to plant, (3) plant protection under stress conditions, and countering its injurious effects, (4) defense against plant pathogens, combating the plant diseases or death (Paula et al. 2015). The mechanisms of PGPR are shown in Fig. 10.5.

Among the PGPR species, Azospirillum is capable of secreting gibberellins and auxins. Some plant-associated bacteria help in phytohormone synthesis. For example, lodgepole pine, when inoculated with Paenibacillus polymyxa, increases Indole-3-Acetic Acid (IAA) in plant roots. Rhizobium and Bacillus were cited for synthesizing IAA in different cultures, pH, and temperature in agro-waste material as a carrier.

Nitrogen-fixing microbes, especially Rhizobium and Azospirillum species and blue-green algae fix the atmospheric N and convert it to ammonium (NH4+) or nitrate (NO3−) ions in the soil and root nodules of legume crops, in that way making it available and usable to crop plants (Choudhury and Kennedy 2004).

Phosphorus exists in the soil typically as insoluble phosphate form, which cannot be readily absorbed by crops (Gupta 2004). Phosphate solubilizers in biofertilizers, especially Bacillus, Pseudomonas, and Aspergillus, solubilize insoluble phosphate to orthophosphate. This solubilized phosphate can then be easily used by crop plants (Chang and Yang 2009). Potassium solubilizing bacteria (KSB) solubilize K-bearing insoluble silicate minerals by producing organic acids. KSB also help in metal ions removal, thereby making them accessible to crops (Itelima et al. 2018). Zinc and sulfur solubilizers (Thiobacillus) and manganese solubilizer (Penicillium citrinum) are also recognized for commercial operations (Borkar 2015). PGPR and Pseudomonas in biofertilizers produce hormones and anti-metabolites, which promotes root growth, decomposing the organic matter. They also help in the soil mineralization process, in that way increasing the availability of plant nutrients and increasing crop yield.

Abiotic stress in plants is the primary cause of crop loss worldwide (Wang et al. 2003). Pseudomonas strains in biofertilizers were found to enhance asparagus seedling growth and seed germination under water-stress conditions (Liddycoat et al. 2009). Pseudomonas fluorescens MSP-393 strains act as a PGPR for many crops grown in the saline soils of coastal ecosystems (Paul and Nair 2008). Pseudomonas putida Rs-198 supports cotton seedling growth under salt stress. It also increases germination and protects against salt stress through growing absorption for Mg2+, K+, Ca2+, reducing Na+ uptake, and production of endogenous indole acetic acid (Yao et al. 2010). Strains of Paenibacillus alcaligenes, Bacillus polymyxa, and Mycobacterium phlei produce calcisol and improved maize growth and nutrient uptake under high-temperature conditions as well as under salinity (El-Akhal et al. 2013).

Some PGPR synthesizes antibiotic substances to inhibit the growth of plant pathogens. For example, Pseudomonas sp. produces antibiotics to inhibit Gaeumannomyces graminis var. tritici, a necrotrophic soilborne pathogen, the causal organism of take-all of wheat (Mazzola et al. 1995). Bacillus cereus UW85 was identified as a biocontrol agent of alfalfa damping-off caused by Pythium spp (Silo-Suh et al. 1994). Kumar et al. (2010) found that Sinorhizobium fredii KCC5 and Pseudomonas fluorescens LPK2 produce chitinase and β-glucanases that inhibit fungal growth and control the fusarium wilt caused by Fusarium udum. The siderophores of Pseudomonas have been found to control the Fusarium oxysporum, the causal organism of wilt disease in potato (Schippers et al. 1987). Pseudomonas and Bacillus species produce siderophores that inhibit fungal pathogens in maize crops (Pal et al. 2001).

PGPRs are accepted worldwide as bio-agents for agricultural sustainability, and alternatives to chemical agents. Apart from acting as a plant growth promoter, they are providing tolerance against pathogens by producing various metabolites (Backman and Sikora 2008). Bacillus subtilis GBO can induce defense-related pathways. Bacillus subtillis N11, along with digested compost and farmyard manure was found to control Fusarium infestation in the banana root. Generally, they are exploited in dealing with spotted wilt viruses in tomato, pepper, cucumber mosaic, and banana bunchy top disease. In some circumstances, it is witnessed that mycorrhizae and bacterial species can also provide resistance against fungus and inhibit the progress of root pathogens such as Pythium and Rhizoctonia solani spp. (Itelima et al. 2018).

7 Producers of Biofertilizers

In India, Rhizobium based biofertilizer production was started in 1934 by M. R. Madhok (Yadav and Raychaudhary 2004). However, the commercial Rhizobium culture production was started in 1956 at the IARI, New Delhi and ACRI, Coimbatore in the mid-sixties, Tamil, Nadu. Nitragin inoculant shipped from the USA in 1964, along with soybean. It was a significant event in the biofertilizer history of India. That fortified Rhizobium success and Nitragin inoculant replaced locally produced rhizobium inoculants for soybean. A letter on this was extended to other pulses and legume oilseeds.

In the years 1965–1990, around 30 biofertilizer production and research units were set up to meet the country’s demand. The 1990s saw a histrionic growth in the industry by the addition of new biofertilizers such as Azotobacter, Azospirillum, PSBs (Essays 2018). The current positive trend has significantly changed the biofertilizer industry in India. Currently, Agro Industries Corporation (AIC) is the largest producer of biofertilizers, followed by the State Agriculture Department. National Biofertilizer Development Centre, State Agriculture Universities also contribute significantly (Pindi and Satyanarayana 2012). Tamil Nadu, Madhya Pradesh, Utter Pradesh, Gujarat, and Maharashtra are the leading states in biofertilizer's production capacity.

Globally, Novozymes (Denmark), Madras Fertilizers Ltd. (India), Gujarat State Fertilizers and Chemicals Ltd. (India), National Fertilizers Ltd. (India), Rizobacter Argentina S.A. (Argentina), T. Stanes and Company Ltd. (India), Camson Bio Technologies Ltd.(India), Rashtriya Chemicals and Fertilizers Ltd. (India), Lallemand Inc. (Canada), Nutramax Laboratories, Inc. (the USA), Biomax (Singapore), Symborg (Spain), Ajay Bio-Tech (India) Ltd. (India) and Agri Life (India), and CBF China Bio-Fertilizer AG (Germany) are critical players in control of global biofertilizers marketplace.

8 Future Prospective

Uncontrolled chemical fertilizer use has led to excess nutrient buildup in soils, which sometimes causes soil sickness. As we know, the availability of plant nutrients depends primarily on soil-based microbes. Several microbes are involved in N-fixing, P, and K solubilization and mobilization. Apart from these, many of them play a vital role in the cycling of Ca, Fe, Mn, Zn, S, and Mo. The use of biofertilizers leads to enhanced soil biological processes such as nutrient cycling and minerals transformation and soil fertility. Its application also stimulates the plant growth, and provides resistance to plants under abiotic and biotic stresses. Biofertilizers are eco-friendly and profitable technology for the farming communities. Hence, future crop production strategy should be a combined use of chemical, organic, and biofertilizer, rather than sole chemical fertilizers. Progress of the biofertilizer industry cuts the demand for chemical fertilizer and helps in moving towards eco-friendly agriculture and farmer's prosperity and food safety.

References

Ali M, Mishra JP, Ahlawat IP, Kumar R, Chauhan YS (1998) Effective management of legumes for maximizing biological nitrogen fixation and other benefits. In: Kumar Rao JV, Johansen C, Rego TJ (eds) Residual effects of legume in rice-wheat cropping systems of Indo-Gangetic plain. ICRISAT, Andhra Pradesh, pp 107–128

Backman PA, Sikora RA (2008) An emerging tool for biological control. Biol Control 46(1):1–3

Barman M, Paul S, Choudhury AG, Roy P, Sen J (2017) Biofertilizer as prospective input for sustainable agriculture in India. Int J Curr Microbiol Appl Sci 6:1177–1186

Bhattacharjee R, Dey U (2014) Biofertilizer a way towards organic agriculture: a review. Afr J Microbiol Res 8(24):2332–2343

Borkar SG (2015) Microbes as biofertilizers and their production technology. Wood Head Publishing, New Delhi, pp 7–153

Brahmaprakash GP, Sahu PK (2012) Biofertilizers for sustainability. J Indian Inst Sci 92(1):37–62

Campo RJ, Araujo RS, Mostasso FL, Hungria M (2010) In-furrow inoculation of soybeans as alternative for fungicides and micronutrients seed treatment and inoculation. Rev Bras Ciênc Solo 34:1103–1112

Chang CH, Yang SS (2009) Thermotolerant phosphate solubilizing microbes for multifunctional biofertilizer preparation. Bioresour Technol 100:1648–1658

Choudhury MA, Kennedy IR (2004) Prospects and potentials for the system of biological nitrogen fixation in sustainable rice production. Biol Fertil Soils 39:219–227

El-Akhal MR, Rincón A, Coba de la Peña T, Lucas MM, El Mourabit N, Barrijal S, Pueyo JJ (2013) Effects of salt stress and rhizobial inoculation on growth and nitrogen fixation of three peanut cultivars. Plant Biol 15(2):415–421

Essays UK (2018) Biofertilizer industry in India. https://www.ukessays.com/essays/biology/bio-fertilizer-industry-in-india-biology-essay.php?vref=1. Accessed 18 Feb 2020

Fukami J, Nogueira MA, Araujo RS, Hungria M (2016) Accessing inoculation methods of maize and wheat with Azospirillum brasilense. AMB Express 6:1–13

Gupta AK (2004) Complete technology book on biofertilizer and organic farming. National Institute of Industrial Research Press, Mumbai, pp 242–253

Gupta U (2018) No relief in sight for fertilizer prices. https://www.dailypioneer.com/2018/columnists/no-relief-in-sight-for-fertiliser-rices.html. Accessed 1 Jan 2020

Hari M, Perumal K (2010) Booklet on biofertilizer (phospho bacteria). Shri A.M.M. Murugappa Chettiar Research Centre (MCRC), Chennai, pp 1–6

Itelima JU, Bang WJ, Onyimba IA, Oj E (2018) A review: biofertilizer; a key player in enhancing soil fertility and crop productivity. J Microbiol Biotechnol Rep 2:22–28

Khosro M, Yousef S (2012) Bacterial biofertilizers for sustainable crop production-a review. APRN J Agric Biol Sci 7(5):237–308

Kribacho (2010) Fertilizer ratios. Krishak and Bharati Cooperative Ltd. J Sci 5:7–12

Kumar H, Bajpai VK, Dubey RC, Maheshwari DK, Kang SC (2010) Wilt disease management, enhancement of growth, and yield of Cajanus cajan var Manak by bacterial combinations amended with chemical fertilizer. Crop Prot 29(6):591–598

Liddycoat SM, Greenberg BM, Wolyn DJ (2009) The effect of plant growth-promoting rhizobacteria on asparagus seedlings and germinating seeds subjected to water stress under greenhouse conditions. Can J Microbiol 55(4):388–394

Mahdi SS, Hassan GI, Samoon SA, Rather HA, Dar SA and Zehra B (2010) Bio-fertilizers in organic agriculture. J Phytol 2(10):42–54

Maillet F, Poinsot V, André O, Puech PV, Haouy A, Gueunier M, Cromer L, Giraudet D, Niebel A, Martinez EA (2011) Fungal lipochito oligosaccharide symbiotic signals in Arbuscular mycorrhiza. Nature 469(7328):58–63

Mazid M, Khan TA (2014) Future of biofertilizers in Indian agriculture: an overview. Int J Agric Food Res 3(3):10–23

Mazzola M, Fujimoto DK, Thomashow LS (1995) Variation in sensitivity of Gaeumannomyces graminis to antibiotics produced by fluorescent Pseudomonas species and effect on biological control of take-all of wheat. Appl Environ Microbiol 61:2554–2559

Moretti LG, Lazarini E, Bossolani JW, Parente TL, Caioni S, Araujo RS, Hungria M (2018) Can additional inoculations increase soybean nodulation and grain yield? Agron J 110:715–721

Narayanasamy G, Arora BR, Biswas DR, Khanna SS (2012) Fertilizers, manures, and biofertilizers. In: Goswami NN et al (eds) Fundamentals of soil science. Indian Society of Soil Science, New Delhi, pp 579–621

NCOF (2015) National Centre of Organic Farming, DAC, Indian Fertilizer Scenario 2015, Department of Fertilizers, Ministry of Chemicals and Fertilizers, Government of India

Pal KK, Tilak KV, Saxena AK (2001) Suppression of maize root diseases caused by Macrophomina phaseolina, Fusarium moniliforme, and Fusarium graminearum by plant growth-promoting rhizobacteria. Microbiol Res 156:209–223

Panda H (2011) Manufacture of biofertilizer and organic farming. Asia Pacific Business Press Inc., New Delhi, pp 103–121

Paul D, Nair S (2008) Stress adaptations in plant growth-promoting rhizobacterium (PGPR) with increasing salinity in coastal agricultural soils. J Basic Microbiol 48:378–384

Paula GF, Esther M, Raúl R (2015) Role of bacterial biofertilizers in agriculture and forestry. AIMS Bioeng 2(3):183–205

Pindi PK, Satyanarayana SDV (2012) Liquid microbial Consortium- a potential tool for sustainable soil health. J Biofert Biopestic 3(4):124

Sahu PK, Brahmaprakash GP (2016) Formulations of biofertilizers – approaches and advances. In: Singh D, Singh H, Prabha R (eds) Microbial inoculants in sustainable agricultural productivity. Springer, New Delhi, pp 179–198

Santos VB, Araujo SF, Leite LF, Nunes LA, Melo JW (2012) Soil microbial biomass & organic matter fraction during the transition from conventional to organic farming systems. Geodderma 170:227–231

Schippers B, Bakker AW, Bakker PAHM (1987) Interactions of deleterious and beneficial rhizosphere microorganisms and the effect of cropping practices. Annu Rev Phytopathol 25:339–358

Shelat HN, Vyas RV, Jhala YK (2017) Biofertilizers and PGPR for evergreen agriculture. In: Verma DK, Srivastav PP (eds) Microorganisms in sustainable agriculture, food, and the environment. CRC Press, New York

Silo-Suh LA, Lethbridge BJ, Raffel SJ (1994) Biological activities of two fungistatic antibiotics produced by Bacillus cereus UW85. Appl Environ Microbiol 60:2023–2030

Sinha RK, Valani D, Chauhan K (2014) Embarking on a second green revolution for sustainable agriculture by vermiculture biotechnology using earthworms. Int J Agric Health Saf 1:50–64

Swarnalakshmi K, Yadav V, Senthilkumar M, Dhar DW (2016) Biofertilizers for higher pulse production in India: scope, Accessibility, and challenges. Ind J Agronomy 61:S173–S181

TechSci (2019) Biofertilizers Market Size and Analysis, Global Industry. https://www.grandviewresearch.com/industry-analysis/biofertilizers-industry. Accessed 18 Feb 2020

Trimurtulu N, Rao DLN (2014) Liquid microbial inoculants and their efficacy on field crops. ANGRAU/Agricultural Research Station, Amaravathi, p 54

Vessey JK (2003) Plant growth-promoting Rhizobacteria as bio-fertilizers. J Plant Soil 225(43):571–586

Vyas RV, Shelat HN (2019) Technology for liquid biofertilizers commercialized. https://icar.org.in/node/307. Accessed 18 Feb 2020

Wang W, Vinocur B, Altman A (2003) Plant responses to drought, salinity, and extreme temperatures: towards genetic engineering for stress tolerance. Planta 218:1–14

Yadav AK, Raychaudhary S (2004) Biofertilizers as agro-inputs-past, present, and future perspectives. In: Biotechnology in sustainable and organic farming-scope and potential. Shree Publishers and Distributors, New Delhi, pp 1–17

Yao L, Wu Z, Zheng Y (2010) Growth promotion and protection against salt stress by Pseudomonas putida Rs-198 on cotton. Eur J Soil Biol 46:49–54

Youssef MMA, Eissa MFM (2014) Biofertilizers and their role in the management of plant-parasitic nematodes: a review. Biotechnol Pharm Resour 5(1):1–6

Zulaika E, Solikhah F, Alami N, Kuswytasari N, Shovitri M (2017) The viability of Azotobacter consortium in auxin production. AIP Conf Proc 1854:020041. https://doi.org/10.1063/1.4985432

Acknowledgment

The authors are grateful to Centre for Environment Sciences and Climate Resilient Agriculture (CESCRA), ICAR-Indian Agricultural Research Institute (IARI), New Delhi, and Indian Council of Agricultural Research for providing the facilities and financial support, to undertake the investigations. There are no conflicts of interest.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Renjith, P.S., Sheetal, K.R., Kumar, S., Choudhary, J., Prasad, S. (2020). Microbial and Biotechnological Approaches in the Production of Biofertilizer. In: Singh, A., Srivastava, S., Rathore, D., Pant, D. (eds) Environmental Microbiology and Biotechnology. Springer, Singapore. https://doi.org/10.1007/978-981-15-6021-7_10

Download citation

DOI: https://doi.org/10.1007/978-981-15-6021-7_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-6020-0

Online ISBN: 978-981-15-6021-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)