Abstract

In this paper, the application of artificial intelligent techniques on condition monitoring and diagnosis of power transformer has been reported. Enormous technological innovations have been reported by researchers to quantify the health assessment methodologies for in-service power transformers such as Artificial Neural Network, Fuzzy logic, Clustering techniques, and Expert systems for precise diagnostics and prognostics tasks. Albeit, numerous reports, and studies, prediction of accurate health status of an in-service power apparatus like transformer is still a challenge. An effort has been made in this paper to compile the outcome of various research tools with practical in-service data to get an overall status of existing technological breakthroughs in the emerging field of condition monitoring of transformer for the benefit of utilities and researchers. The prospective of condition monitoring and diagnosis technologies of a power transformer can be emulated for asset management and prevent catastrophic failures of power transformers.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Transformers are the most important and expansive equipment of power system. The size of power transformer ranges between a hundred KVA to hundred MVA, involves plenty of money as replacement costs in event of a catastrophic failures. [1]. The power transformer is usually reliable throughout its service with operational life varying between 30 and 40 years. Practically, the transformer life can be extended up to 50 years with good conditioning monitoring and maintenance practices [1]. Failures of these power transformers majorly affect the social life of utility and also dangerously affect the power system results in loss of revenue. The health index is a mathematical tool that combines all the information such as results of operating observation, field test, site, and laboratory test which provide a single quantitative index that represents overall health index [2]. Initially, the transformer works satisfactory, but as the transformer aged, some fault occurred due to internal degradation. Mostly failure happened by a severe condition like short circuit, lightning stroke, switching transient or incipient fault. When a transformer is installed it is sufficient to bear unusual conditions. After some time, the transformer age, their insulation strength degrades so it cannot withstand these unusual conditions [3]. To reduce or prevent these types of failures and maintain the transformer to work satisfactory several studies have to be done and many techniques developed in recent years. These techniques measure the various technical parameter such as breakdown voltage (BDV), dissipation actor (DF), partial discharge (PD) thermal imaging, tap changer test, bushing test, recovery voltage test, interfacial tension (IFT), moisture content in oil, acidity, dissolved gas analysis (DGA), furan analysis, paper insulation, winding temperature, sweep frequency response analysis (SFRA), also it includes economical parameter such as percent of economic life (%EL) and ageing acceleration factor (F_AA) [2, 3]. Traditionally such tests are conducted on a routine basis to evaluate the health of transformers. Several authors have reported fuzzy clustering based expert systems for health assessment of transformers [4]. The main advantage of condition-based management is that maintenance is only done when it is necessary rather than maintenance done at regular time intervals. There is a lot of testing method and monitoring techniques which are used by the utility. This paper reviews all those techniques and gives an idea about how to calculate the health index of power transformer by emerging techniques.

2 Failures and Problems of Power Transformer

Failures of transformer may arise due to different operational conditions. Generally, transformer failures are classified into three categories.

-

1.

Electrically

-

2.

Mechanically

-

3.

Thermally.

The reason for failure may be external or internal. In view of the main tank failure, bushing failure, tap changer, or in transformer accessories can also occur. Table 1 shows typical failures in transformer [1] and various failure mechanisms have been summarized in [5].

The failure rate of the transformer can understand by bathtub curve which is shown in Fig. 1. According to the bathtub curve, the lifetime of power transformer can be divided into three stages. Correspondingly there are three stages of failure of power transformer. The first stage denotes infant stage which is not more than one year. The second stage denotes the normal stage. In both stages the failure rate is constant. The third stage denotes wear out stage. In this stage failure rate is increased due to wear and tear.

A survey report shows the main cause of failure of power transformer (51% in a 5-year period) due to the following problem [6].

-

Transformer internal dielectric strength weakening due to moisture contents, oil contamination, and ageing of oil.

-

Winding short circuit or damage to the winding by decompression.

-

Bushing problem due to loss of internal dielectric strength.

A survey conducted by CIGRE group on power transformers failures. On the basis of the survey, they conclude that 41% of failures happened due to on-load tap changer, and 19% happened due to windings. Figure 2 shows that the percentage failure of power transformer distribution with on-load taps changers.

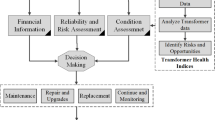

3 Monitoring and Diagnostic Method

Generally, the term “monitoring” means supervising activities in progress which means to ensure they are on course and on schedule in meeting the objectives and performance target. The term “diagnostics” means to assess the health with the help of an expert system and suggest taking some action if anything is not in good condition. There are so many tools that evaluate the health of transformers [1,2,3,4]. They can be divided into two types, one is traditional and another is nontraditional. Former has been widespread use for many years and later still in the research stage. Monitoring and diagnosis of a transformer play a critical role in deciding the financial aspects and risk assessment of an industry. A proper condition monitoring and an appropriate preventive or corrective timely action enable sound maintenance of the transformer. This also ensures proper health monitoring and enables the long life of the transformer. Condition monitoring of the transformer may also avoid premature ageing of the transformer and avoids catastrophic failures.

4 Diagnostic Method

4.1 Oil Testing

The transformer oil is the most important parameter to evaluate the health of power transformer. Thermal fault as well as electrical fault is the main cause of degradation of oil. Recently, various oils based on esters and mixed oils are laid due emphasis by the researchers [7,8,9].

-

1.

Dissolved gas analysis

Dissolved Gas Analysis (DGA) is among the most important technique for the determination of incipient faults on oil-filled transformers. Due to thermal and electrical stresses the hydro-carbon chains breakdown causing the formation of gases [10]. Various DGA methods like Gas Chromatography and Photo Acoustic Spectroscopy extract information about the concentrations of various dissolved gases. Then DGA techniques like Key Gas Method, Ratio Methods, or Graphical Methods are used to analyze these data to predict nature of incipient fault developing in the transformer. The major fault gases are H2, C2H2, C2H4, C2H6, and CH4. Table 2 shows the key gases generated by a particular fault.

To determining the health index of transformer DGAF is calculated as follows which is based on IEEE and IEC standards.

where i denote dissolved gases, Si is the score value based on the volume of dissolved gases, and wi is the weighing factor of each gas.

-

2.

Oil insulating quality

Oil is the most important characteristic of the life of transformer. Insulation of oil greatly affects the life of transformer. There are so many ways that reduced the insulation level of transformer oil. That’s why many tools and tests are used to determine the insulation quality of oil [11]. There are so many tests perform for transformer oil. The tests, method/standard, and effects which are usually performed are listed in Table 3.

From the observation of testing of transformer oil by the various methods, one single parameter is defined called oil quality factor which is further used to calculate the health index of transformer.

When paper ages, a number of furan compounds are present in the transformer oil. The availability of these furan compounds is directly related to the paper insulation strength through its degree of polymerization (DOP) [4]. Transformer oil samples must be tested for furan analysis when one of the conditions follows [1, 8]:

-

Transformer overheating

-

Transformer overloading

-

Level of carbon monoxide (co) or carbon dioxide (co2) is very high

-

Reduction in interfacial tension with a constant acidic number

-

Change in color of oil

-

Increase in moisture content.

Furan compounds are produced in transformer oil as cellulose material. These cellulose materials are used in solid or paper insulation. Measurement of furan compounds of oil also used for measurement of degree of polymerization of the paper insulation [6,7,8]. Ranges and paper degradation are listed in Table 4.

4.2 Hot Spot Temperature and Load Index

The life of the transformer estimated by the manufacture, real age, weather condition is taken into account to determine the health condition. As the transformer load current flow in the winding heat is dissipated so the winding temperature is also used to estimate the expected life of the transformer [9].

Another parameter related to winding temperature, i.e., load history also considers evaluating the health index which is very useful. Instead from average load, the peak load should be considered in certain time periods [9]. As the winding temperature increases, mostly paper insulation degraded. So, for the protection of paper insulation, it must be recognizing accurately where the hot spot occurring. The main work to estimate the health indices adding with this concept is described in the following methodology [4, 9].

-

The winding temperature or hot spot temperature is determined by thermal imaging camera or software based on the finite element method.

-

Subsequently, spotting the hot spot winding visually and calculating the circulating current in the winding. These values are ranged between optimal loads to full load.

-

An equation is proposed relating the hot spot and load index with the help of the above two steps. Therefore, ageing acceleration factor of insulation system relate to the transformer health condition.

The severity of overheating from the thermal imaging camera can be categorized as shown in Table 5.

4.3 Economic Analysis

It is also very helpful in assessing the health condition of power transformer. Basically, it includes the capital cost, running cost, depreciation factor, or interest rate to help assessing the condition of the transformer [2].

Economic analysis is done with the help of bathtub curve. At the time of starting or initial time period transformer faults are more so it needs more inspection but this time period is not more than one year. This time period is called infant time period. After this time period transformer working normally and faults occur less than infant period. The third and last time period is wear and tear stage in which faults occur more than other two-time periods. The fault rate is equal in both infant and normal time periods whereas in wear and tear stage fault rate is higher. From the bathtub curve, we decide the failure rate as follows [6, 8]:

-

1.

Modeling of failure rate of power transformer

-

2.

Modeling of outage probability distribution of power transformer

-

3.

Modeling of annual cost disturbance

-

4.

Modeling of annual operational cost.

Once failure rate decided, Model the economic lifetime of power transformer annually by modeling equivalent annual cost which also includes the investment cost. In wear and tear time period maintenance costs should be increased due to more failure rate to maintain the transformer work satisfactory [2]. So, for the evaluation of economic life, operating and maintenance costs are taken into account to calculate the minimum annual cost (AC) of the transformer.

where n is the no. of year which is studied. Present worth (PW) includes initial purchase cost (PC) and salvage Value (SV). The present worth is usually decreased [2].

Operating cost (OC) include the interruption cost, cost of maintenance, diagnostic test cost, and cost of labor. The operating cost (OC) is usually increased [2]. The year in which the annual cost occurring its lowest value is the economic life of the transformer. Then, percent of economic life is defined as given below.

5 Health Index of Transformer

The conventional transformer health assessment needs information such as deterioration of insulation system, load characteristics, winding temperature, and many other factors to evaluate the life of transformer. Final health index is calculated as follows:

where ‘n’ is the number of input parameters.

K is the coefficient of multiplication.

HIF is the number from the evaluation of each testing parameter.

The health index value obtained from equation no (5) is categorized into five divisions from 0 (zero represent the poorest value) to 1(one represents very good value).

6 Different AI Techniques

This paper also reviews the different AI techniques which determine the health assessment of power transformer. There are following AI techniques which usually used by the utility.

-

1.

Artificial neural network (ANN)

-

2.

Fuzzy Logic

-

3.

Adaptive neuro-fuzzy inference system (ANFIS).

6.1 Artificial Neural Network Technique

ANN is an AI technique that is motivated by human behavior of brain. An ANN is an information processing paradigm that is inspired by the biological nervous system such as the human brain’s information processing mechanism. ANN is an efficient method that assess the health condition of the power transformer by observing the relationship between inputs (transformer parameter which affects the health condition) and output (HI). ANN consists of three layers, i.e., input layer, hidden layer, and output layer. ANN models are shown in Figs. 3 and 4 as in [10]:

6.2 Artificial Neural Network Technique

Fuzzy logic is a superset of Boolean logic that handles the concept of partial truth, which is a truth value between “completely truth” and “completely false”. Fuzzy logic is multivalued. It deals with degree of membership function and degree of truth. Fuzzy logic uses the continuum of logical values between 0 denotes completely false and 1 which denotes completely truth [11]. The membership function of fuzzy logic is shown in Fig. 5.

6.3 Adaptive Neuro-Fuzzy Inference System

Adaptive neuro-fuzzy inference system is a kind of Artificial Neural Network that combines both neural network and fuzzy logic principal. The ANFIS is a very strong technique that helps in predicting test score and simulating the complex nonlinear system. This model has five layers as follows in [4, 6].

7 Discussion on Various Research Tools

Many researchers are evaluating the health index of transformer with different methodologies or used different kinds of tools to analyze their results to compare with conventional methods. A few of results of researcher is shown below to get an overall status of existing technological breakthrough in this field for benefit of utilities and researcher. Results of health index evaluation using industry standard and health index evaluation using ANN and ANFIS models are given in Tables 6 and Table 7 respectively.

8 Conclusion

A review of the application of AI techniques on condition monitoring and diagnosis of power transformer has been reported. In the health assessment part, the actual age, environmental conditions of transformer location, and life expected by manufacturer are taken into account to determining the health index. The winding temperature is also used to estimate the life of the machine. The load history of the transformer could be very useful for the health index. Another group of practical data that has been considered for the health evaluation is the leakage reactance, state of bushing, electrical resistance, ground isolation, focusing on oil leaks, and the level and color of oil. The physical and dielectric properties of oil are the most common variables mentioned by industry. Some other group of data reported includes the economical parameter to monitor the life of power transformer.

References

Baldonado M, Chang C-CK, Gravano L, Paepcke A (1997) The stanford digital library metadata architecture. Int J Digit Libr 01:108–121

Bruce KB, Cardelli L, Pierce BC (1997) Comparing object encodings. In: Abadi M, Ito T (eds), theoretical aspects of computer software. Lecture notes in electrical engineering, vol 1281. Springer, Berlin Heidelberg New York, pp 415–438

Van Leeuwen J (ed) (1995) Electrical engineering today. Recent trends and developments, lecture notes in electrical engineering, vol 1000. Springer, Berlin Heidelberg New York

Mohan Rao U, Sood YR, Jarial RK (2015) Subtractive clustering fuzzy expert system for engineering applications. Procedia Comput Sci Elsevier Sci 48:77–83

Mohan Rao U, Sood YR, Jarial RK (2017) Physiometric and FTIR analysis of cellulose insulation in blend of mineral and synthetic ester oils for transformers. IET Sci Meas Tech 11(3):297–304

Giovanis E (2010) Application of adaptive network-based fuzzy inference system (ANFIS) with genetic algorithms in crisis periods prediction. SSRN Electron J

Mohan Rao U, Sood YR, Jarial RK (2016) Oxidation stability enhancement of a blend of mineral and synthetic ester oils, IEEE Electr Insul Mag 32(2):43–47

Hamdi A, Fofana I, Djillali M (2017) Stability of mineral oil and oil–ester mixtures under thermal aging and electrical discharges. IET Gener Trans Distrib 11(9):2384–2392

Mohan Rao U, Sood YR, Jarial RK (2016) Performance analysis of alternate liquid dielectrics for power transformers. IEEE Trans Dielectr Electr Insul 23(4):2475–2484

Khan S, Equbal M, Islam T (2015) A comprehensive comparative study of DGA based transformer fault diagnosis using fuzzy logic and ANFIS models. IEEE Trans Dielectr Electr Insul 22(1):590–596

Fernández F, Ortiz A, Delgado A, Fernández T, Santisteban A, Cavallini A (2017) Transformer health indices calculation considering hot-spot temperature and load index. IEEE Electr Insul Mag 33(2):35–43

Acknowledgements

The authors are thankful to TIFAC CORE on Power Transformer Diagnostics at NIT Hamirpur, India for providing in-service data and technical support for carrying out experimentation for field tests.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Bhushan, U.P., Jarial, R.K., Jadoun, V.K., Agarwal, A. (2021). On Condition Monitoring Aspects of in-Service Power Transformers Using Computational Techniques. In: Pandey, V.C., Pandey, P.M., Garg, S.K. (eds) Advances in Electromechanical Technologies. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-5463-6_31

Download citation

DOI: https://doi.org/10.1007/978-981-15-5463-6_31

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-5462-9

Online ISBN: 978-981-15-5463-6

eBook Packages: EngineeringEngineering (R0)