Abstract

Food waste is categorized as the largest degradable component in the waste stream. Degradation of food waste that involved aerobic bacteria is the most suitable approach to dispose of this waste. The main objective of this research is to evaluate the optimum condition of aerobic bacteria growth for food waste degradation by comparing the implementation of response surface method (RSM) and genetic algorithm. Preliminary experiment is conducted to determine the best time for aerobic bacteria growth. Then, evaluation of five factors such as temperature, time, type of nutrient, agitation rate and inoculum size is done by conducting experiments according to the experimental table that is constructed by using design expert software. Growth of aerobic bacteria can be determined by measuring the optical density (OD) of the bacteria. Aerobic bacteria at the best growth condition are mixed with the food waste for degradation process. The ability of aerobic bacteria to degrade food waste is determined by monitoring the pH, moisture content and ratio of volatile solid to total solid (VS/TS) of food waste on the first and twentieth days of degradation. The result analysis using RSM showed that the optimum condition for aerobic bacteria growth is at 37 °C and 200 rpm in commercial nutritional supplement (CNS) medium with 10% (v/v) of inoculum size for 20 h. At this optimum condition, the OD value was 2.264 while optimization using genetic algorithm generated the OD value at 2.643 where this is 14% improvement from the RSM.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

In recent years in Malaysia, environmental issues keep rising due to the increasing amount of food waste. Statistics from the Solid Waste Corporation of Malaysia (SWCorp) showed that in 2015, the food waste in Malaysia reached 15,000 tonnes daily (Komandai 2017). Degradation of food waste by using aerobic bacteria is one of the most promising approaches to manage food waste as this waste contains high organic matters which are easily biodegradable. Food waste can also be degraded under anaerobic condition but the process is slow and less efficient compared to the aerobic condition (Gill et al. 2014).

Tortora et al. (2016) stated that aerobic bacteria grow at its best at pH near neutral which is between 6.5 and 7.5. According to Haug (2018), aerobic bacteria required adequate amounts of oxygen to grow and degrade food waste. Oxygen should be well supplied during the degradation process to reduce the reaction time between food waste and aerobic bacteria. Other than that, moisture content is one of the factors that must be considered for food waste degradation. Excess amount of moisture in food waste is not good for degradation process because it can slow the process (Hamid et al. 2019). On the other hand, carbon-to-nitrogen ratio is also important in degradation process because it shows the quality of biofertilizer. Lin et al. (2019) stated that the degradation may be more effective when C/N ratio is between 30 and 40%. Other factors such as temperature, time, type of nutrients, agitation rate and inoculum size are also crucial for bacteria growth. Most of the previous studies did not focus on those five factors. Therefore, this study focused on those five affecting factors to aerobic bacteria growth for food waste degradation. Hence, the main objective of this research is to optimize the growth of aerobic bacteria for food waste degradation.

The modelling and optimization process done by (Dhanarajan et al. 2014) for production of marine bacterial lipopeptide from food waste had used artificial neural network (ANN) to model the production process, and particle swarm had been used to optimize the production output. The selected feedforward network architecture was 4-17-1 and the model training error of 0.000124 mean square error (MSE). The optimization of production output had used the particle swarm optimization produced a significant enhancement of lipopeptide production from waste by about 46% (w/v).

The modelling and optimization of anaerobic codigestion of potato waste and aquatic weed by response surface methodology and genetic algorithm by Jacob and Banerjee (2016) had produced higher methane yield around 6% improvement by the ANN-GA method when compared with the CCD-RSM method. The ANN topology for modelling had used 3-12-1 architecture and used Levenberg–Marquardt training algorithm to train the network. The MSE for ANN modelling with architecture of 3-12-1 was 0.14 while other ANN architectures produced higher modelling MSE compared to the 3-12-1 architecture. Genetic algorithm (GA) was also being used to determine the maximum biogas yield output from several ANN models which used back-propagation training, particle swarm optimization and evolutionary neural networks (Fakharudin et al. 2013).

2 Process Description of Optimization Using Response Surface Method

2.1 Materials

The sample of food waste was collected from several cafeterias at Universiti Malaysia Pahang in Gambang, Pahang. Aerobic bacteria were purchased from Universiti Malaya, Kuala Lumpur. Nutrient broth, nutrient agar and sodium chloride (NaCl) were obtained from Sigma-Aldrich. Commercial nutritional supplement (CNS) was purchased from a local grocery shop.

2.2 Preparation for Aerobic Bacteria Growth

Aerobic bacteria were cultured on nutrient agar medium. Nutrient agar was prepared by dissolving 23 g of nutrient agar medium in 1000 ml distilled water. Then, the agar on agar plate was cooled and toughened in the refrigerator overnight. Saline solution was prepared by dissolving NaCl distilled water to produce NaCl solution with 0.85% concentration. NaCl is able to enhance bacteria growth and prevent cell damage. 0.5 g of aerobic bacteria was mixed with 10 ml of NaCl (Zhang et al. 2019). 0.1 ml of bacteria samples was spread evenly on the surface of agar by using triangle shape cell spreader. Aerobic bacteria were spread from the first quadrant until quadrant number 4 of agar before incubating it at 37 °C for 24 h. Aerobic bacteria on the agar were streaked by using inoculation loop and transferred to nutrient broth in conical flask. Then, the samples of bacteria in nutrient broth were incubated at 37 °C and 100 rpm for 24 h (Smarajit and Kenney 2018).

2.3 Preliminary Experiment

Preliminary experiment was conducted in order to determine the best time for aerobic bacteria growth. Nutrient broth was used as a growth medium of bacteria. Then, all samples were incubated at 37 °C and 100 rpm in stackable incubator shaker (Smarajit and Kenney 2018). Every two hours, Varian Spectrophotometer was used to determine optical density for each sample.

2.4 Experimental Set-up for Response Surface Method (RSM)

There were five selected factors that were studied in this research in order to optimize the OD value of aerobic bacteria sample. The factors were temperature, time, type of nutrient, agitation rate and inoculum size. Tables 1 and 2 show the design factors and levels were coded as −1 (low level) and +1 (high level) where low level indicates the lowest range of the factors and high level indicates the highest range of the factors. 16 runs of experiments were conducted in this study (Dzulkefli and Zainol 2018). The responses (optical density) of the experimental design were analyzed by using ANOVA based on the p-value with 95% of confidence level.

2.5 Sample Analysis

The bacteria concentration in suspension was determined in terms of optical density by using Varian Spectrophotometer. Each sample was inserted into cuvette before locating it in sample holder. The wavelength of the spectrophotometer was set to 600 nm in order to get the absorbance from the samples. The optical density was expressed in absorbance unit (ABS) which is a dimensionless unit.

3 Genetic Algorithm Optimization Methodology

3.1 Process Optimization Using Artificial Intelligence Techniques

The model had used basic architecture of five input nodes for all five factors and one output node for the optical density. Only the output node used linear activation function while the hidden node used hyperbolic tangent activation function. Levenberg–Marquardt (LM) training algorithm was used to train the ANN model starting from the smallest number (2 hidden nodes) and will be increased until a significant ANN model can be generated through the training process. Only LM training algorithm was used because of the fast convergence and less epoch compared to other algorithm, and only this model was used for the optimization process. The training process will be stopped when the training error reaches 0.01. The implementation of the ANN modelling had used the ENCOG 3.3.0 (Heaton 2018) Java library with NetBeans 8.0.2 which was used to the development of IDE.

The data set was divided into 80:20 percent ratio—with 12 random samples of the data set were used as training and 4 samples were used as testing set. The data set was normalized between −1 to 1 which followed the hyperbolic activation function range. The network performance will be measured using mean square error (MSE), and one model was selected to be optimized using the GA search. The generated ANN model architecture was 5-4-1 with 4 hidden nodes. The model training MSE was 1.0881 × 10−5, and testing MSE was 0.1920. The model overall MSE was 0.0480.

3.2 Genetic Algorithm Optimization Process

The optimization of the neural network output was implemented using Jenetics 3.6.0 (Wilhelmstötter 2018) a Java library for genetic algorithm, evolutionary algorithm and genetic programming. A preliminary run was conducted to find the optimal parameter for crossover and mutation operators. The final value for the crossover probability was set to 0.1, and mutation probability was set to a small value of 0.01 based on the preliminary run which produced higher OD. The population size was set to 30 chromosomes with 100 generations for all the runs. The optimization run was also set to 10 runs, and the best (lowest) was selected as the optimized value. In this process, the generated model was used as the fitness function and the boundary followed the normalized range of −1 to 1.

4 Results and Discussion

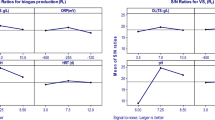

4.1 Optimization by Response Surface Method

The criteria set-up to select optimum processing condition was given in Table 3. The suggested optimum condition is given in Table 4 and can be applied in the aerobic bacteria growth to be used for food waste degradation.

4.2 Optimization by Genetic Algorithm

The optimization results using the heuristic search of genetic algorithm are shown in Table 5. The neural network model was used as the fitness function for the genetic algorithm, and it searched for the maximum neural network output. The highest run was by run number 8 with the OD of 1.2578, and the lowest output was by run number 10 with OD of 1.2238. Overall the OD optimization by GA has shown stable output with OD around 1.2.

The value in Table 4 was in normalized value and to get the actual value which can be compared with the response surface optimization the process of denormalized had been applied to the result. The best result which was the run number 8 had been denormalized and the actual value is shown in Table 6. For factors 1, 2, 3, the values were denormalized to the nearest condition but for factors 4 and 5, the values were denormalized using actual numbers. Table 7 shows the comparison of optimum conditions from RSM and GA for maximum OD value. The condition for temperature, reaction time and type of nutrient were the same from both optimization models. However, GA suggested a lower value of agitation at only 26 rpm compared to 200 rpm suggested by RSM. In terms of OD value, optimization using GA model yielded a value of 2.643, which is an improvement of 14% compared to the value yielded using RSM.

5 Conclusions

The optimization of OD using genetic algorithm yielded a value of 2.643 compared to 2.264 from RSM. This shows 14% improvement in OD value compared to RSM. The application of machine learning by using ANN and heuristic search of GA had produced improved OD.

References

Dhanarajan, G., Mandal, M., & Sen, R. (2014). A combined artificial neural network modeling–particle swarm optimization strategy for improved production of marine bacterial lipopeptide from food waste. Biochemical Engineering Journal, 84, 59–65. https://doi.org/10.1016/J.BEJ.2014.01.002.

Dzulkefli, N. A., & Zainol, N. (2018). Data on modeling mycelium growth in Pleurotus sp. cultivation by using agricultural wastes via two level factorial analysis. Data in Brief, 20, 1710–1720. https://doi.org/10.1016/j.dib.2018.09.008.

Fakharudin, A. S., Sulaiman, M. N., Salihon, J., & Zainol, N. (2013). Implementing artificial neural networks and genetic algorithms to solve modeling and optimization of biogas production. In Proceedings of the 4th International Conference on Computing and Informatics, ICOCI 2013 (pp. 121–126), Sarawak, Malaysia. Universiti Utara Malaysia, August 28–30, 2013.

Gill, S. S., Jana, A., & Shrivastav, A. (2014). Aerobic bacterial degradation of kitchen waste: A review. Journal of Microbiology, Biotechnology and Food Sciences, 3(6), 477–483.

Hamid, B., Jehangir, A., Baba, Z. A., & Fatima, S. (2019). Isolation and characterization of cold active bacterial species from municipal solid waste landfill site. Research Journal of Environmental Sciences, 13, 1–9.

Haug, R. (2018). The practical handbook of compost engineering eBook. New York: Routledge. https://doi.org/10.1201/9780203736234.

Heaton, J. (2018). Encog machine learning framework. Retrieved May 15, 2018, from https://github.com/encog/encog-java-core.

Jacob, S., & Banerjee, R. (2016). Modeling and optimization of anaerobic codigestion of potato waste and aquatic weed by response surface methodology and artificial neural network coupled genetic algorithm. Bioresource Technology, 214, 386–395. https://doi.org/10.1016/J.BIORTECH.2016.04.068.

Komandai, N. (2017). Free Malaysia Today Corporation. Retrieved from Free Malaysia Today Web site: http://www.freemalaysiatoday.com/category/opinion/2017/08/29/food-wastage-management-crucial-for-a-better-environment/.

Lin, L., Xu, F., Ge, X., & Li, Y. (2019). Biological treatment of organic materials for energy and nutrients production—Anaerobic digestion and composting. In Advances in Bioenergy (Vol. 4, pp. 121–181). https://doi.org/10.1016/bs.aibe.2019.04.002.

Smarajit, C., & Kenney, L. J. (2018). A new role of OmpR in acid and osmotic stress in Salmonella and E. coli. Frontiers in Microbiology, 9, 2656. https://doi.org/10.3389/fmicb.2018.02656.

Tortora, G., Funke, B., & Case, C. (2016). Microbiology: An Introduction (12th ed.). San Fransisco: Pearson Benjamin Cummings.

Wilhelmstötter, F. (2018). Jenetics. Retrieved May 15, 2018, from http://jenetics.io/.

Zhang, F., Wang, X., Lu, W., Li, F., & Ma, C. (2019). Improved quality of corn silage when combining cellulose-decomposing bacteria and lactobacillus buchneri during silage fermentation. BioMed Research International, 1–11. https://doi.org/10.1155/2019/4361358.

Acknowledgements

The authors wish to acknowledge the Universiti Malaysia Pahang for funding the project under grant RDU1803119 and RDU1703295.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Zainol, N., Fakharudin, A.S., Zulaidi, N.I.S. (2020). Model Optimization Using Artificial Intelligence Algorithms for Biological Food Waste Degradation. In: Yaser, A. (eds) Advances in Waste Processing Technology. Springer, Singapore. https://doi.org/10.1007/978-981-15-4821-5_11

Download citation

DOI: https://doi.org/10.1007/978-981-15-4821-5_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-4820-8

Online ISBN: 978-981-15-4821-5

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)