Abstract

Titanium (Ti) and its alloys with zirconium (Zr) due of their biological safety, lower elastic modulus and excellent corrosion resistance are the most attractive metallic materials for medical applications. Plasma electrolytic oxidation (PEO) is an environment-friendly process with rapid deposition of anodic oxide coating on the implant surface. PEO coating can incorporate different nanoparticles (NPs) into implant surface such as ZnO that stimulates osteoblast proliferation and mineralization, possesses antibacterial ability. The aim of current research was to evaluate structural and chemical properties of TiZr-alloy with addition ZnO NPs after the PEO in Ca/P solution. The alloy of the Titanium-zirconium system was obtained from Osteoplant R&D (Dębica, Poland). ZnO nanocrystals have been synthesized through the alcoholysis and condensation reaction, known as polyol process. The pretreated samples were subjected to anodization in electrolytic bath, which contained of Ca(H2PO2)2 (0.1 Mol/L) and silver nanoparticles (40,000 mg/L). Ready samples were investigated by scanning electron microscope (SEM) which showed surface with oxide layer with large pores in different size. The process of apatite deposition is confirmed the biocompatibility properties of obtained coatings in SBF immersion test. ZnO NPs demonstrated high bacteriostatic activity and absent of cell toxicity. The obtained results showed, that PEO of TiZr alloy in Ca–P based solution with ZnO NPs is a great potential method of surface modification of implants for orthopedics and dentistry.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

8.1 Introduction

The one main way in implant design evolution is combined different methods to obtain material with bio-functionality and biocompatibility characteristics. Surface of implant plays the key role of this.

Titanium (Ti) and its alloys is the most attractive metallic materials for medical applications. Its combined such properties as advantages of high strength-to-weight ratio, excellent corrosion resistance and favorable biocompatibility. Especially in orthopedic and dental implants [1,2,3].

Alloying element such as Zr improves the corrosion resistance by forming stable oxides ZrO2 [4, 5]. These element was chosen due to their reported biological safety and β-stabilizing effect to obtain a lower elastic modulus close to bone tissue [6].

Nowadays plasma electrolytic oxidation (PEO) is most popular method to enhance surface performance of titanium alloys. PEO is a simple and environment-friendly process with rapid deposition of anodic oxide coating on the implant surface. Moreover, PEO coatings provide the increase surface hardness, roughness, porosity and excellent wear resistance.

During PEO ZnO nanoparticles (ZnONPs) could be incorporated in coating due to promising anabolic effects on bone metabolism by stimulating osteoblast proliferation and mineralization possesses, antibacterial ability [7].

PEO coatings with ZnONPs have thus attracted the interest of the biomedical community. This type of surface treatment could bind the osteogenesis ability and antibacterial effects.

The materials with anti-adhesive polymers or antibacterial agents to inhibit bacterial colonization are demanded by the orthopedic community [6].

The aim of current research was to evaluate structural and chemical properties of TiZr-alloy with addition ZnONPs to achieve both osteogenesis inducing ability and antibacterial effects after the PEO in Ca/P solution.

8.2 Materials and Methods

8.2.1 Materials

The alloy of the Titanium-zirconium system (Zr60Nb21Ti19) that was obtained from Osteoplant R&D (Dębica, Poland) we used in experiment. 6 mm diameter cylindrical samples with a height of 6 mm were prepared for experiment. All chemicals have been purchased from Sigma-Aldrich and used as received: zinc acetate dihydrate (Zn(CH3CO2)2 (H2O)2, 99%), poly(N-vinylpyrrolidone) (PVP, Mw = 40,000, K-25), sodium phosphinate monohydrate SPM (NaH2·PO2·H2O, 95%), ethylene glycol EG (C2H6O2, 90%), isopropanol (C3H8O, 90%).

Human osteoblast (HO) were obtained from collection of Sumy State University.

Staphylococcus aureus B 918, obtained from National collection of microorganism (D. K. Zabolotny Institute of Microbiology and Virology) were used in experiment. All bacteriological media were purchase from HiMedia (India), Alamar blue—from Invitrogen. For the cell culture study all media and reagents were purchased from Gibco®, USA.

8.2.2 Synthesis of ZnO Nanocrystals

ZnO nanocrystals have been synthesized through the alcoholysis and condensation reaction, known as polyol process, of Zn(CH3CO2)2 (H2O)2 (2.2 g) in EG (10 ml) at 160 °C, similar to work. After heating up the solution in a round-bottom flask fitted with a reflux condenser for 4 h under magnetic stirring, the precipitation of ZnO nanocrystals has occurred. The nanocrystals have been recovered by the centrifugation at 4000 rpm for 5 min and washed twice with isopropanol.

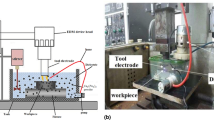

8.2.3 Plasma Electrolytic Oxidation

Before starting PEO, the samples were cleaned and degreased. All samples were rinsed with distilled water and ultrasonically cleaned in a deionised water and 2-propanol for 5 min each. The pretreated samples were subjected to anodization in electrolytic bath, which contained of Ca(H2PO2)2 (0.1 Mol/L) and ZnONPs (40,000 mg/L). The anodic oxidation was performed under a constant current of 0.1 A cm−2 and up to final voltage of either 350 V for 5 min. The anodised specimens were rinsed with distilled water and in a deionised water/2-propanol mixture for 5 min.

The process was performed in a water-cooled electrolysis cell with a titaniummesh cathode and magnetic stirrer. The Zr60Nb21Ti19 alloy served as the anode. A DC power supply (PWR 800H, Kikusui, Japan) was used throughout these treatments.

8.2.4 SEM

To analyzed surface morphology and chemical compound all samples were covered with gold and observed in a scanning electron microscope with EDX (JEOL JSM 5410). Before SEM all samples after PEO and SBF test were covered with gold.

8.2.5 Contact Angle Measurement

Contact angle (CA) measurements experiments were made using a video-based optical contact angle measuring instrument (OCA 15 EC, Data Physics, San Jose, CA city, state, USA) and SCA 20 software for OCA and PCA. The CA data was recorded for ultra-pure water, for at least three parallel samples.

8.2.6 SBF

Bioactivity investigations were performed in a protein-free SBF with an ions concentration simulating that of human blood plasma. The SBF was prepared by dissolving reagent-grade NaCl, NaHCO3, KCl, K2PO4_3H2O, MgCl2_6 H2O, CaCl2, and Na2SO4 in distilled water, which was adjusted to a pH of 7.40 using tris (hydroxymethyl) aminomethane and 1 M HCl at 37 °C. This solution has the following ionic composition: 142.0 mmol/L Na+, 5.0 mmol/L K+, 1.5 mmol/L Mg2+, 2.5 mmol/L Ca2+, 147.8 mmol/L Cl−, 4.2 mmol/L HCO3−, 1.0 mmol/L HPO42−, 0.5 mmol/L SO42−.

After the PEO process, samples were immersed in the SBP for a total of 4 weeks, with daily replacement of the solution. After each 7 days, samples were taken out of solution, then washed with distilled water and dried. The dehydrated samples were covered with gold (The Cressington Sputter Coater 108 auto). And analyzed by observations in a scanning electron microscope (Hitachi S-3400 N).

8.2.7 In Vitro Experiment

8.2.7.1 Bacteria Adhesion Test

S. aureus, strain B 918 was used to describe the adhesive properties of the Zr60Nb21Ti19 disks. Gram positive bacteria grown on nutrient agar at 37 °C for 24 h was suspended in a saline solution (0.9%, w/v NaCl) and re-suspended to a final density of 1 × 108 colony forming units (CFUs)/mL (8 log CFU) in nutrient broth using McFarland standards. The adhesion possibilities was measured by horizontally incubation with 2.0 ml of the bacterial suspension in static conditions in a 24-well plate at 37 °C for 2, 4, 6 and 24 h. Then samples were removed from broth. The washing were conducted tree times with 2.0 ml sterile physiological saline to remove freely-adherent bacteria.

The amount adherent bacteria on surface of TiZr alloy were received after sonication disk in sterile tubes with 1.0 ml of sterile saline solution for 1 min by using an ultrasonic-bath (B3500S-MT, Bransone Ultrasonics Co., Shanghai, China). 10-μl aliquots saline solution from sonicated tubes were inoculation using streak plate technique cultivating onto the solid media for 24 h. Following this, we conducted determining the colony count at each term of incubation. The wells containing disks and tested samples in growth medium without bacterial inoculate were used as a control. All experiments were conducted in triplicate.

8.2.7.2 Cell Culture

Human osteoblast cells were grown in standard conditions: 5% a humidified CO2, 37 °C air temperature and medium renewal for every 2–3 days in tissue culture flasks. Dulbecco’s Modified Eagle Medium/Nutrient Mixture F-12 (DMEM/F-12) with L-glutamine used, containing 100 units/ml penicillin, 100 µg/ml streptomycin, 2.5 µg/ml amphotericin B, 10% Fetal Bovine Serum and 1.0 ng/ml bFGF. After removing medium osteoblasts were seeded on each samples and positive control wells at a cell density of 2 × 104 cells per well.

Alamar blue (Invitrogen) were added in an amount equal to 10% of the volume to each well. The plates were incubated for 4 h at 37 °C, in the dark. The absorbance of medium was measured using a Multiskan FC (Thermo Fisher Scientific) plate reader at wavelengths of 570 nm and 600 nm. The cells were quantified at different time intervals: 1 day, 3 days and 7 days. All experiments were repeated 3 times. The percentage of Alamar blue reduction was performed as Equation according to the manufacturer’s protocol.

Cells on the surfaces of TiZr alloy samples at day 7 were fixed with 2.5% glutaric aldehyde and subjected to osmium coating for 1 h, then washed three times in 0.1 M cacodylic buffer. The alloy samples were then dehydrated in increasing ethanol concentrations and covered with gold and observed in the SEM (JEOL JSM 5410).

8.3 Results

8.3.1 SEM, EDX and Contact Angle

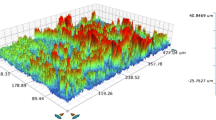

After PEO TiZr surface represents by irregular shaped grooves and round pores (Fig. 8.1b). Longitudinal size of grooves sized from 23 ± 4.3 μm to 105 ± 15.7 μm. Pores size ranges from 1.3 ± 0.5 μm to 11.4 ± 3.8 μm. Thus, PEO in complex ZnONPs solution provides formation of mesoporous structures that should be favorable for cell adhesion. Submicron pores can be detected inside the large grooves and completely covers their bottom and lateral walls.

EDX proved formation of oxide layer contained both alloy elements Ti and Zr as well as ions from PEO solution (Fig. 8.1c). Mass concentration of Ca, P and Zn corresponds to 9.92, 17.2 and 24.88 mass%. High concentration of Zn could be toxic for cells that need to clarify in cell culture experiment.

Contact angle of TiZr surface after PEO was 58.2 ± 17.6° that significantly low compare the non-treated surface (78.9 ± 6.9°). Hydrophilic surface should provide favorable environment for protein adsorption in first minutes after implantation.

8.3.2 SBF Test

SBF immersion test shown calcium-phosphate deposition from second week of experiment (Fig. 8.2a). In three weeks after immersion whole surface covered by Ca–P substrate (Fig. 8.2b) and we can detect cracks development in four weeks that probably due to Ca–P overload on TiZr surface (Fig. 8.2c). Ca and P adsorption proved high biocompatibility of newly obtained surface. Additionally, high affinity to Ca and P should be advantages after implantation and will facilitate apatite formation on implant surface.

8.3.3 Cell Culture

HO cell adhesion on TiZr PEO-treated surface was significant lower (p ≤ 0.01) compared with pure non-treated TiZr alloy (40.6 ± 7.4% vs. 54.3 ± 3.2%) on day 1 after cell seeding. But next time-point shown progressive cell proliferation on day 3 and 7 compare the slightly cell number decreasing on day 3 (non-treated control). On the last day of culturing osteoblast cell number was significantly higher on PEO-treated surface (Fig. 8.3a). Despite the high Zn concentration after PEO, surface shown no cell toxicity and stimulation of osteoblast proliferation during the 7 day culturing.

8.3.4 Bacteria Adhesion Test

Bacteriological investigation confirmed S. aureus adhesion and proliferation during the 24-h experiment (Fig. 8.3b). After 2 hincubation PEO treated surface had the same concentration of bacteria compare the control (polished untreated ZrNb implant). But after 4 h of experiment the microorganism level left stable. While the bacteria concentration of untreated surface shown the significant proliferation during all time point up to 8 Log 10 CFU in 24 h. Present of ZnONPs could negative influence on adhesion process of S. aureus or may deter the multiplication bacterial cells on the implant surface.

8.4 Conclusions

Plasma electrolytic oxidation of TiZr alloy in Ca–P based solution with ZnONPs provides formation of mesoporous oxide layer that support osteoblast cell adhesion and proliferation. Additionally, obtained surface decrease bacteria adhesion in first hours after co-cultivation. New surface should be promising for medical implant production.

References

Y. Bai, Y. Deng, Y. Zheng, Y. Li, R. Zhang, Y. Lv, Q. Zhao, S. Wei et al., Mater. Sci. Eng. 59, 565–576 (2016)

P. Kubasiewicz-Ross, M. Dominiak, T. Gedrange, U.U. Botzenhart, Adv. Clin. Exp. Med. 26(3), 533–537 (2017)

I. Gnilitskyi, M. Pogorielov, R. Viter, A.M. Ferraria, A.P. Carapeto, O. Oleshko et al., Nanomed. Nanotechnol. Biol. Med. 21, 102036 (2019)

C. Nune, R.D.K. Misraa, S.J. Li, Y.L. Hao, R. Yang, Dent. Mater. 33(2), 152–165 (2016)

L. White, Y. Koo, S. Neralla, J. Sankar, Y. Yun, Mater. Sci. Eng. B Solid. State. Mater. Adv. Technol. 208, 39–46 (2016)

A. Mohandas, A.G. Krishnan, R. Biswas, D. Menon, M.B. Nair, Mater. Sci. Eng. C Mater. Biol. Appl. 75, 115–124 (2017)

K. Huo, X. Zhang, H. Wang, L. Zhao, X. Liu, P.K. Chu, Biomaterials 34, 3467–3478 (2013). https://doi.org/10.1016/j.biomaterials.2013.01.071

Acknowledgements

This research supported by H2020 Marie Skłodowska-Curie Actions Grant NanoSurf 777926 and Ukraine MES Grant “Biological effectiveness of Plasma Electrolytic Oxidation and sol-gel deposition for development of functional implant surface” (#0119U100823).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Oleshko, O. et al. (2020). Plasma Electrolytic Oxidation of TiZr Alloy in ZnONPs-Contained Solution: Structural and Biological Assessment. In: Pogrebnjak, A., Pogorielov, M., Viter, R. (eds) Nanomaterials in Biomedical Application and Biosensors (NAP-2019). Springer Proceedings in Physics, vol 244. Springer, Singapore. https://doi.org/10.1007/978-981-15-3996-1_8

Download citation

DOI: https://doi.org/10.1007/978-981-15-3996-1_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-3995-4

Online ISBN: 978-981-15-3996-1

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)