Abstract

This paper describes the risk management plan implemented for a large dam project which involved raising the existing dam and construction of a new dam. Construction of this dam upgrading and enlargement project was exposed to serious risks on safety of existing dam, risk of delay, cost overrun and contractual claim. A three tiered approach in risk assessment and risk mitigation was implemented. A quantitative risk analysis on risk of piping failure of the existing dam due to foundation excavation works was conducted to aid in the decision making process for resolving the construction risk encountered. The risk management of the project has created opportunities for design optimization. The integration of risk management and value engineering in the project has resulted in cost saving of over RM 150 million. The framework of the risk management plan and process involved in risk identification, risk assessment, mitigating measure options evaluation, risk control and the issues resolved are described.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The Mengkuang dam upgrading and enlargement project in Penang state involved raising the existing dam and construction of a new dam adjacent the old dam. During construction stage several dam safety issues were encountered, particularly the risk of piping failure of the existing dam due to foundation excavation for the dam construction was serious. The operation of the existing dam had to be maintained throughout the construction period. Any interruption to the raw water supply from the existing dam would lead to serious consequence.

The variability in site geology, foundation conditions, construction materials and site conditions of project added to the risk of the project. In some cases the latent conditions were only uncovered after the site was cleared and the foundation exposed. Changes in the design during construction stage become necessary in order to suit the actual site conditions. As the project proceeds further down the time line of implementation, it becomes more complicated and costly to introduce changes in the contract. There are contractual risks which need to be addressed for managing changes of contract conditions.

A three tiered project risk management plan (PRMP) was implemented for raising the existing dam and construction of a new dam. The implementation of the PRMP besides reducing the risk exposure of the project also created opportunities for value engineering. The integration of risk management and value engineering in the project has yielded good outcome. It resulted in a saving of RM 150 Million in construction cost. The framework of the PRMP and process involved in identification, risk assessment, mitigation measure options evaluation, risk control and issues resolved are presented.

2 Importance of the Water Source Expansion Project

The Expansion of Mengkuang Dam Project with construction cost RM 607 Million was awarded by KATS (formerly KeTTHA) to China International Water & Electric Corp. (M) Sdn. Bhd. in 2012. This major water source augmentation project increases the reservoir active storage from 22 to 73.5 MCM. The water source is vital for Sg. Dua Water Treatment Plant which provides over 80% of the potable water supply of Penang state. The project is located in Pulau Pinang near Bukit Mertajam.

The original Mengkuang Dam was an earthfill dam 31 m high and about 1 km long completed in 1985. The project involved raising the existing dam by 11 m and construction of a new dam 45 m high and about 2 km long. The new dam is a zoned earthfill dam. Figure 1 shows the new dam completed in July 2015.

3 Project Risk Management Plan (PRMP)

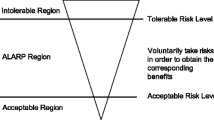

A PRMP was established to assist in the decision-making process of determining what is the acceptable level of risk and which option provides the most suitable risk reduction measure. The process of risk management involved risk identification, risk estimation, risk aversion and risk control.

A three tiered PRMP was formulated for the project. In level 1 assessment a qualitative method was used for quick evaluation of the risks. In cases which the risk rating were high, they were moved to level 2. Level 3 dealt with cases in which their probability of failure was uncertain but the consequences were very high involving loss of life, extensive damage to environment and economic losses.

3.1 Level 1 Risk Assessment

A workshop and seminar were conducted to deliberate on 50 odd risk factors identified. Various risk categories covering technical, environmental, legal, contractual and financial risks were evaluated. In the category of technical risk, risks are organized further according to their particular nature or discipline such as hydrology, hydraulic, geology, geotechnical, structure, mechanical, electrical etc. The process performed in the risk analysis as illustrated in Fig. 2 below involved the following:

-

Separating the project into its component parts and functions.

-

Identifying the construction activity that has potential risk.

-

Analysing risk of each factor, its probability of occurrence and consequences from which a risk rating was derived.

An initial risk control plan with mitigation measure was applied for risk with rating medium to high, otherwise, monitoring is sufficient. In cases which the consequence or impacts are high or the probability of occurrence was uncertain, a level 2 risk analysis was undertaken.

3.2 Level 2 Risk Assessment

13 risks factors were identified for level 2 assessment as shown in Fig. 3. Some risks impact only at the construction stage, while others impact on the safety of the dam for future operation. What risk reduction measures adopted at the construction stage will have impact on the future performance of the dam (Table 1).

3.3 Level 3 Risk Assessment

Three risks factors were identified as critical for level 3 detailed analysis as follow:

-

Risk to old dam due to construction of new dam adjacent the existing dam.

-

Risk to old dam due to construction of dam raising works.

-

Risk of piping at left abatement of new dam adjacent Weng Lee Quarry.

The selection of mitigating option can become difficult for cases which probability of failure is low but the consequences is very high involving loss of life, extensive damage to environment and economic losses. In cases which the decision making process involved several parties a long lead time was required to resolve the issues concerned.

3.4 Purpose of Level 3 Risk Assessment

A quantitative risk assessment was conducted to determine whether the do-nothing option is acceptable and if not whether lowering the reservoir water level would reduce the probability of breaching of the dam to an acceptable level and how it compares with the option of soil improvement works or option of controlling the construction activities near existing dam.

4 Risk of Piping Failure of Existing Dam

The existing dam was filled almost to its full supply level EL 43 m at the time of construction of the project. During excavation for the foundation preparation works at the left abutment of the old dam, concentrated leak was observed at an excavated trench about 100 m away from the existing dam. The leaks were discharging from a porous layer of highly weathered granite as shown in Fig. 4. The leakage through the existing dam abutment is hydraulically connected to the existing reservoir. This observation has prompted the need to assess critically the safety of existing dam due to piping erosion.

4.1 Piping Risk Analysis

The risk analysis is focus on the risk of piping failure of existing dam during construction. The analysis was not aimed at assessing the overall probability of failure of the existing dam under all possible causative events.

Piping phenomenon involves complex initiation and development processes which are not easily quantifiable. Piping analysis using analytical method was faced with uncertainty on hydraulic gradient, extend of porous materials and erodibility of soils. A probabilistic analysis was conducted to assist in the decision making process in addressing the issue on the safety of existing dam due to construction works. The event tree techniques was adopted to represent initiation, continuation, progression and breach phase based on method proposed by Foster et al. (2002).

Given that concentrated leak had been observed at a layer of porous highly weathered granite near the existing dam, the probability of piping erosion was estimated assuming leakage conduits of various sizes were present within the porous layer of granite. The hydraulic shear stresses were computed to assess whether initiation of internal erosion is likely. The published soil erosion rate index of various types of soils were used as guide to judge the progression of piping.

4.2 Postulated Breach Mechanism and Event Tree Construction

Internal erosion failure mechanism might result through progressive internal erosion of porous layer of granite until the reservoir is breached at which point rapid erosion of the abutment soils is likely to cause instability to the embankment of the existing dam.

If internal erosion and piping failure modes were to initiate, it would be difficult to detect during rainy days and night times. The failure modes could be well developed and in progress by the time it is detected. Once the abutment is breached to the reservoir, rapid enlargement and complete loss of the reservoir filled with 22 MCM of water could occur. Also even if detection were made, there are uncertainties on the evacuation efficiency. Figure 5 shows the Event Tree constructed based on the postulated failure mechanism.

In the event trees, the aggregate conditional probability of dam failure along each failure path is calculated. The issue of piping was complex and judgement couple with analytical method were required as a guide for this type of risk analysis.

4.3 Consequences Assessment

Consequences include loss of life, economic loss, environmental and social damages. The inundation maps prepared from the dam break simulations were used to estimate the population at risks and the properties in the flood plain. The consequence due to the dam failure would be catastrophic.

The RMP adopted the principle that the risk should be as low as reasonably practicable and the maximum level of societal risk for life safety should be less than 10-3/year for loss of one life that was not explicitly foreseen and identified in advance of the failure. A higher risk is considered unacceptable which was in line with the overseas guidelines, e.g. Canadian Dam Association (2007) and ANCOLD (2003).

4.4 Risk Reduction Measures – Options Evaluation

Options evaluated include: Option 1 – Do-nothing, Option 2 -lowering reservoir water level, Option 3 - Construction control and Option 4 - Structural measure using soil improvement works.

Option 2 – lowering existing reservoir water level from elevation 43 m to 34 m was recommended for the lease contractual impact and minimum cost involved.

However, option 2 involved reduction of water stored in the reservoir from 22 MCM to 10 MCM which impact on the security of water supply system of Penang State. The potential risk was not acceptable to Penang government unless an alternative water source as back-up could be provided. Beris Dam water source from Kedah state was identified as a suitable back up source. However charges on raw water release from Beris Dam was imposed by Kedah government. The issue was resolved through a process of negotiation amongst Federal Ministry (KeTTHA), Penang and Kedah State government.

5 Integration of Risk Management and Value Engineering

In the process of implementing the RMP, opportunities were created for saving construction cost, reducing construction risk and better project delivery. The risk management was integrated with value engineering in an interactive manner in achieving project requirements.

The potential impacts of changes in design on cost, work program, contractual, legal and environmental etc. were evaluated. An interactive process was developed to address issues that arise due to design changes.

5.1 Opportunities Created by Lowering Reservoir Water Level for Value Engineering

The risk management plan created opportunities for value engineering of the project which led to significant saving in construction cost about RM 150 Million. The important cases of value engineering are described below.

Harvesting of Clay Core Materials at the Ridge between Left and Right Valley

After the water level of the existing reservoir was lowered by 11 m the ridge separating the left valley (new reservoir) and right valley (existing reservoir) which contain earthfill materials suitable for clay core of the dam can be harvested for the project. Import of clay materials from external sources which cost about RM 40 Million was omitted.

Construction of a Deep Channel to Connect the Left and Right Valley Reservoirs

After the reservoir water level of existing dam was lowered to EL 34 m, construction of a balancing channel with invert EL 24 m was made possible to connect the two reservoirs. This allowed the draw-off tower and access bridge, strengthening works of existing draw-off culvert which cost about RM 12 Million to be omitted.

Change to the Design for Raising Existing Dam

The original design of dam raising works involved construction of a deep concrete cutoff wall as shown in Fig. 6. Risk of slope instability of existing dam is serious. After the draw-off tower and access bridge were omitted, revision of design for raising existing dam on upstream and downstream side was made possible as shown in Fig. 7. Construction of a plastic concrete cut-off wall at downstream shoulder of existing dam which cost about RM 15 million was omitted.

Change of Filter Materials

The project required approximately 2.5 Mcu.m of filter materials. The contractor opted to use river sand for the filter zone. By mid-2013 there was a shortage of river sand which hampered the progress of construction work. The filter material was changed to crushed rocks. A laboratory test proposed by Khor (1989, 1992) was set up for testing the acceptability of the crushed rocks filters. The risk of shortage of filter materials was resolved after the contractor opened a quarry and set up a rock crushing and filter processing plant.

5.2 Contractual Implications Related to Design Changes

The contractor submitted claim for cost on the basis of changed conditions to the contract. The contractual claim was small compared with the saving in cost. The contractual risk related to changes in design during construction was mitigated through consultation and open discussions with the contractor. Throughout the process of revision of design the inputs of the contractor was obtained. Thanks to the cooperation of the contractor, the contractual risk was reduced to a minimum level. The benefits brought about by the design changes were significant including saving in cost and time of construction, long term safety of the dam and a better project delivery.

6 Conclusions

-

1.

Construction of large scale dam upgrading and enlargement project is exposed to risks that can lead to delay and cost overrun.

-

2.

Risk assessment can provide basis for decision making in selection of mitigation measures require to reduce risk to an acceptable level.

-

3.

A three tiered risk management plan is a practical approach to deal with a wide range of risk factors with different likelihood of occurrence and severity of consequence which require different level, extent, rigor and cost of risk assessment.

-

4.

Integration of risk management with value engineering has resulted in significant saving in the construction cost and improved the project delivery.

References

Canadian Dam Association: Dam safety guidelines 2007, 2013th edn. CDA, Canada (2007)

Australian National Committee on Large Dams: Guidelines on Risk Assessment. ANCOLD, Australia (2003)

Foster, M.A., Fell, R., Davidson, R., Wan, C.F.: Estimation of the Probabilities of Failure of Embankment Dams by Internal Erosion and Piping Using Event Tree Methods. ANCOLD, Australia (2002)

Wan, C.F., Fell, R.: Investigation of rate of erosion of soils in embankment dams. J. Geotech. Geoenviron. Eng. ASCE 130(4), 373–380 (2004)

Fell, R., et. al.: A unified method for estimating probabilities of failure of embankment dams by internal erosion and piping. UNICIV, Australia (2008)

Khor, C.H., Woo, H.K.: An Investigation of Crushed Rock as Filters for A Dam Embankment. ASCE Geotechnical Division, USA (1989)

Khor, C.H.: Crushed rock filters and leakage control in embankment dams. J. Instit. Eng. Malays. (IEM), Bil. 50 (1992)

Acknowledgments

The authors acknowledge the project team members of Bahagian Bekalan Air, Angkasa Consulting Services Sdn. Bhd. and China International Water & Electric Corp. (M) Sdn. Bhd. who contributed directly or indirectly to the development and execution of the project risk management plan.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Khor, C.H., Shamsuddin, A.H. (2020). Risk Management for the Mengkuang Dam Upgrading and Enlargement Project. In: Mohd Sidek, L., Salih, G., Boosroh, M. (eds) ICDSME 2019. ICDSME 2019. Water Resources Development and Management. Springer, Singapore. https://doi.org/10.1007/978-981-15-1971-0_15

Download citation

DOI: https://doi.org/10.1007/978-981-15-1971-0_15

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-1970-3

Online ISBN: 978-981-15-1971-0

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)