Abstract

Three-layer nanostructured films FexNi100–x/Cu/FexNi100–x (x ≅ 50, dFeNi = 40 нм; dCu = 5 нм) consisting of Fe0,5Ni0,5 alloy layers separated by Cu layer were obtained by layers-by-layers vacuum condensation at the pressure of 10−4 Pa. Magnetic hysteresis loops of three-layer films were obtained using a vibration magnetometer. Magnetic hysteresis loops obtained in transverse geometry have an almost rectangular shape with sharp magnetization reversal. The magnetization reversal of the films completely changes in the magnetic field range with induction of −25 to 25 mT for freshly condensed films and −30 to 30 mT for thermostabilized films. The rectangular hysteresis contour is typical for single-layer films of ferromagnetic metals and alloys based on them and indicates the presence of an axis of easy magnetization in the sample plane. Magnetization in the direction perpendicular to the film plane shows the effect of a strong demagnetizing field. After thermal stabilization of the films, the dependence does not change significantly, except for an increase in the residual magnetization and coercive force (more pronounced hysteresis).

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

32.1 Introduction

Currently, an intensive study of the physical properties of new film materials is being carried out in connection with their wide practical use as functional elements of instrument structures [1,2,3,4,5,6,7,8] and protective coatings [9,10,11,12,13,14,15,16,17,18]. The study of magnetically inhomogeneous film materials (multilayer structures, granular films, composites, etc.) made it possible at the end of the twentieth century to discover a number of important magnetoresistive effects—giant magnetoresistance (GMS), tunneling magnetoresistance (TMS), colossal magnetoresistance, etc. [19,20,21,22,23].

Multilayer film systems based on permalloy (Py) and copper, in which spin-dependent electron scattering is realized, are widely used as effective magnetic field sensors, digital magnetoresistive memory devices, automotive electronics, biomedical technologies, etc. But despite this, there is a need for further search and experimental study of film structures that would satisfy additional requirements (minimum dimensions, high sensitivity, high reproduction samples, etc.). Also important is the task of predicting the behavior of the electrical and magnetoresistive properties of multilayer systems with a change in the thickness of the metal layers, structure, temperature, and external magnetic field. The solution to such problems is possible only under the condition of using an integrated approach to the study of the physical properties of film systems.

The purpose of this work is a comprehensive study of the magnetic structure and magnetic parameters of magnetic three-layer films based on permalloy and copper.

32.2 Experiment Details

Investigated samples with a thickness of 5–100 nm were obtained by evaporation and condensation in the vacuum chamber of VUP-5 M (at the pressure of 10−4 Pa). The films were condensed onto a glass substrate with pre-applied copper contacts with a substrate of chromium at room temperature. The rate of precipitation of the alloy was ω = 0.5–1 nm/s. Three-layer films consisting of Fe0,5Ni0,5 alloy layers separated by Cu layer were obtained by layers-by-layers condensation. The construction of the lining holder allowed to receive two film samples in one cycle with a different thickness of the copper layer and with similar thicknesses of the alloy layers. For measuring their electrical resistance, the geometric dimensions of the films were set by windows in the nichrome foil mechanical masks, which made with high accuracy.

The percentage composition of the film was determined by x-ray microanalysis with an energy dispersive spectrometer (EDS).

32.3 Results and Discussion

To establish the relationship between the magnetoresistance of three-layer films with a change in their magnetic structure, a study was made of the domain structure of the films Fe0,5Ni0,5/Cu/Fe0,5Ni0,5/S with simultaneous measurement of the magnetoresistance of the films. To observe the domain structure of the films, the magneto-optical Kerr effect was used, which consists of rotating the plane of polarized light reflected from the surface of a magnetized ferromagnet by a certain angle φ of the plane of polarization. Due to the differences in the angles of rotation of the plane of polarization of light by neighboring domains (depending on the orientation of their magnetic fields), after passing the reflected light through the analyzer, a light contrast is observed between areas with different magnetization. This light contrast is insignificant, since the light reflected from the film surface is not plane-polarized, but polarized elliptically. In Fig. 32.1 shows the loop of magnetoresistive hysteresis and its connection with the domain structure of the upper layer of a freshly condensed three-layer FexNi100-x/Cu/FexNi100-x/S (x ≅ 50, dF = 40 nm; dN = 5 nm) with giant magnetoresistance. The magnitude of the isotropic magnetoresistance for freshly condensed films is 0.5–1%, depending on the thickness of the layers. Small values of isotropic magnetoresistance are caused by small sizes of crystallites, high defectiveness of layers, and shunting of the effect with a relatively thick nonmagnetic interlayer [24, 25].

In this case, the film was first magnetized to saturation in a magnetic field directed along the axis of easy magnetization. When the magnetic field decreases to zero, the ferromagnetic layers of the film remain single-domain and their magnetization does not change. The magnetoresistance is also practically unchanged. At the first moment of growth of the field directed opposite to the field in which the film was magnetized, the ferromagnetic layers remained single-domain and the magnetoresistance did not change significantly. Then, when the magnetic field becomes sufficiently strong (about 0.8 mT), the magnetization vectors rotate at the edges and throughout the upper layer. As a result, small domains are formed in the form of strips. The domains that were formed are favorably oriented relative to the direction of the external magnetic field. With increasing magnetic field induction, they increase their size. Then, even with a small increase in the magnetic field, a sharp increase in the advantageously oriented domains continues at the expense of the neighboring ones. With a further increase in the magnetic field, a “breakdown” occurs—a rapid magnetization reversal of the central regions. The electrical resistance at the same time reaches a maximum value. It is obvious that the magnetic moments in the lower and upper layers of permalloy are oriented antiparallel (antiparallel configuration). One of the reasons for the delay in the magnetization reversal of the lower layer may be internal stress due to the adhesion of the layer to the substrate, which leads to an increase in the coercive force. With a further increase in the magnetic field induction (over 1 mT), a sharp decrease in the electrical resistance of a three-layer film is observed due to the magnetization reversal of the lower layer and orientation of the magnetizations in the FexNi100–x layers in parallel (parallel configuration). We believe that in these three-layer structures, the upper and lower magnetic layers are re-magnetized at slightly different values of the magnetic field induction. Although it is possible when the process of magnetization reversal in symmetric three-layer structures occurs synchronously—the upper and lower magnetic layers switch simultaneously at the same induction value of an external magnetic field. It should be noted that these values are close because a sharp peak is recorded on the magnetoresistive loop.

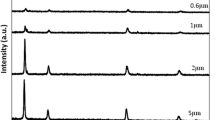

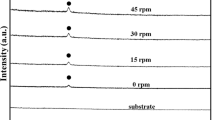

To determine the magnetic state of the systems, magnetic studies were performed using an LDJ-9500 vibration magnetometer (magnetic hysteresis loops were determined). Figure 32.2 shows for illustration the typical dependences of the normalized magnetization on the induction of an applied external magnetic field in transverse and perpendicular measurement geometries for Fe80Ni20/Cu/Fe80Ni20 films in a freshly condensed state and after heat treatment at a temperature of 700 K. For unannealed and annealed at 700 K three-layer films with dF = 25–40 nm, dN = 5–15 nm, and cNi < 70 at.% magnetic hysteresis loops, obtained in transverse geometry, have an almost rectangular shape with sharp magnetization reversal (Fig. 32.2a, c). The magnetization reversal of films completely changes in the range of a magnetic field with an induction of −25 to 25 mT for freshly condensed films and −30 to 30 mT for thermostabilized films. The rectangular hysteresis contour is typical for single-layer films of ferromagnetic metals and alloys based on them and indicates the presence of an axis of easy magnetization in the sample plane. The magnetization in the direction perpendicular to the film plane shows the influence of a strong demagnetizing field (Fig. 32.2d). After thermal stabilization of the films, the dependence does not change significantly, except for an increase in the residual magnetization and coercive force (more pronounced hysteresis).

Dependence of the normalized magnetization on the applied external magnetic field in transverse (a, c) and perpendicular (b, d) measurement geometries for films Fe0,5Ni0,5/Cu/Fe0,5Ni0,5/S (dPy = 40 nm, dCu = 10 nm) in a freshly condensed state (a, b) and after heat treatment at a temperature of 700 K (c, d)

32.4 Conclusion

The maximum value of isotropic magnetoresistance at the room temperature is 1% for as-deposited Fe0.5Ni0.5/Cu/Fe0.5Ni0.5/S thin films with dF = 25 nm and dN = 5 nm. We consider that in these three-layer structures, the upper and lower magnetic layers are re-magnetized at slightly different values of the magnetic field induction. Small values of isotropic magnetoresistance are caused by small sizes of crystallites, high defectiveness of layers, and shunting of the effect with a relatively thick nonmagnetic interlayer. The rectangular hysteresis contour is typical for investigated thin films of ferromagnetic metals and alloys based on them and indicates the presence of an axis of easy magnetization in the sample plane.

References

M.A. Corrêa, R. Dutra, T.L. Marcondes, T.J.A. Mori, F. Bohn, R.L. Sommer, Mater. Sci. Eng., B 211, 115 (2016)

Yuan-Tsung Chen, Jiun-Yi Tseng, S.H. Lin, T.S. Sheu, J. Magn. Magn. Mater. 360, 87 (2014)

A.M. Chornous, Yu.O. Shkurdoda, V.B. Loboda, Yu.M. Shabelnyk, V.O. Kravchenko, Eur. Phys. J. Plus 132, 58 (2017)

Yu.O. Shkurdoda, A.M. Chornous, V.B. Loboda, Yu.M. Shabelnyk, V.O. Kravchenko, L.V. Dekhtyaruk, J. Nano- Electron. Phys. 8(2), 02056 (2016)

L.V. Odnodvorets, I.Yu. Protsenko, O.P. Tkach, Yu.M. Shabelnyk, N.I. Shumakova, J. Nano- Electron. Phys. 9(2), 02021 (2017)

V.B. Loboda, I.E. Protsenko, Kristall und Technik 16(4), 489 (1981)

Yu.O. Shkurdoda, V.B. Loboda, L.V. Dekhtyaruk, Metallofiz. Nov. Tekhnol. 30(3), 295 (2008)

J. Li, Q. Zhan, S. Zhang, J. Wei, J. Wang, M. Pan, Y. Xie, H. Yang, Z. Zhou, S. Xie, B. Wang, R.-W. Li, Sci. Rep. 7, 2837 (2017)

A.D. Pogrebnjak, O.V. Sobol, V.M. Beresnev, P.V. Turbin, G.V. Kirik, N.A. Makhmudov, M.V. Il’yashenko, A.P. Shypylenko, M.V. Kaverin, MYu. Tashmetov, A.V. Pshyk, Ceram. Eng. Sci. Proc. 31(7), 127 (2010)

V.I. Lavrentiev, A.D. Pogrebnjak, Surf. Coat. Tech. 99(1–2), 24 (1998)

A.D. Pogrebnjak, D.I. Proskurovski, Phys. Status Solidi 145(1), 9 (1994)

A.D. Pogrebnjak, ShM Ruzimov, Phys. Lett. 120(5), 259 (1987)

A.D. Pogrebnjak, A.A. Bagdasaryan, A. Pshyk, K. Dyadyura, Phys. Usp. 60(6), 586 (2017)

A.D. Pogrebnjak, Ivashchenko, P.L. Skrynskyy, O.V. Bondar, P. Konarski, K. Załęski, S. Jurga, E. Coy, Composite. Part B. Eng. 142, 85 (2018)

A.A. Goncharov, V.V. Petuhov, D.N. Terpij, P.I. Ignatenko, V.A. Stupak, Neorg. Mater. 41(7), 799 (2005)

A.A. Goncharov, FMM 3, 325 (2011)

A.I. Bazhin, A.A. Goncharov, A.D. Pogrebnyak, V.A. Stupak, S.A. Goncharova, Phys. Metal. Metallography 117(6), 594 (2016)

A.D. Pogrebnjak, A.A. Goncharov, Metallofiz. Nov. Tekhnol. 38(9), 1145 (2016)

P. Fert, A. Grüunberg, F. Barthelemy, W.Zinn Petro, J. Magn. Magn. Mater. 140, 1 (1995)

M.N. Baibich, J.M. Broto, A. Fert, F. Nguyen Van Dau, F. Petro, P. Etienne, G. Creuzet, A. Friederich, J. Chazelas, Phys. Rev. Lett. 61, 2472 (1988)

E.Y. Tsymbal, D.G. Pettifor, in Solid State Physics, vol. 56, ed by H. Ehrenreich, F. Spaepen (Academic, San Diego, CA, 2001), p. 113

O.I. Tovstolytkin, M.O. Borovyi, V.V. Kurylyuk, Yu.A. Kunytskyi, Fizychni Osnovy Spintroniky (TOV Nilan LTD, 2014)

Ia.M. Lytvynenko, I.M. Pazukha, V.V. Bibyk, Vacuum 116, 31 (2015)

A.G. Basov, S.I. Vorobiov, Yu.O. Shkurdoda, L.V. Dekhtyaruk, J. Nano- Electron. Phys. 2, 69 (2010)

S.S.P. Parkin, K.P. Roche, T. Suzuki, Jpn. J. Appl. Phys. 31(9A), L1246 (1992)

Acknowledgements

The work has been performed under the financial support of the Ministry of Education and Science of Ukraine (state registration numbers 0119U100777 and 0117U003925).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Loboda, V.B. et al. (2020). Magneto-Optical and Magnetic Properties of Three-Layer Films Based on Permalloy and Copper. In: Pogrebnjak, A., Bondar, O. (eds) Microstructure and Properties of Micro- and Nanoscale Materials, Films, and Coatings (NAP 2019). Springer Proceedings in Physics, vol 240. Springer, Singapore. https://doi.org/10.1007/978-981-15-1742-6_32

Download citation

DOI: https://doi.org/10.1007/978-981-15-1742-6_32

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-1741-9

Online ISBN: 978-981-15-1742-6

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)