Abstract

This paper presents experimental study efforts to explore the performance and emission characteristics of an existing single-cylinder, four-stroke, water-cooled, direct injection Kirloskar diesel engine was converted into HCCI engine. From the investigation, it was stated that WPPO with diesel results increased the brake thermal efficiency by 42.12% at 413 K inlet air temperature and full load condition. Formerly NOx were decreased for all blends and later slightly increases but smoke is negligible. However, the CO and UHC emissions are first increased and then decreased for the HCCI operation. The ANN was trained, validated and tested with experimental data sets. The artificial neural network system was created to predict the performance and emission parameters of the engine. A multi-layer discernment network was utilized for non-straight mapping among input and output parameters. Six objectives—BTE, EGT, NOx, Smoke, CO and UHC were considered. The performance of the ANN model is determined also illustrations the efficiency of the model to predict the performance and emission with a determination coefficient of 0.999.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Attaining a non-pollutant environment becomes a big task in present days, the reason is that carcinogenic chemicals were accumulated continuously in air, non-degradable and degradable matters in air, sea and land disposal of toxic substance. The polluted environment is caused by the hazardous substances released from the industrial events and burning of fossil fuels.

It is stated that the use of alternative fuels such as hydrogen and alcohols and clean combustion technologies may cause to improve the quality of air. At this condition, it can be predicted nitric oxide (NO) and ultra-low smoke emissions will be produced by HCCI compared to conventional engines [1]. In petrol and diesel engines, fuel injection and spark timing initiate the start of combustion. But in the case of HCCI, the chemical kinetics purely governs the auto-ignition of the fuel/air premixed mixture. So, direct control mechanism is lacked by the HCCI combustion [2, 3]. The most efficient method for the preparation of homogeneous charge is by using external mixture formation. Maurya et al. [4] did exploration different tests regarding PFI technique for ready homogeneous mixture. Tests were performed by varying equivalence ratio (2.0–5.0) and the intake charge temperature (120–150 °C) at constant speed 1500 rpm with a specific final result to achieve the stable HCCI ignition. As stated, that at 120 °C, λ = 2.5 given improved combustion efficiency, combustion parameters and fewer NOx emissions. The results utilizing ANN are a transformative methodology which has not to use any critical numerical conditions for clarifying the non-straight and multi-dimensional frameworks. At the time of training the network, the ANN models the output data validate with predict output. Trained ANN model can predict the performance of an engine for unknown data [5, 6]. Predict the performance and emission characteristics have extensively used the ANN models of SI and CI engines [7, 8]. In this, the present investigation is as follows: ANN-based forecast instrument was utilized to process the HCCI engine performance and emission characteristics, i.e. assessed the connection between the engine input parameters and yield parameters. The experimental outcomes and prediction outcomes of the ANN predicted results are listed in this article.

2 Experimental Setup

For attaining the objective of the waste plastic pyrolysis oil-diesel-fuelled HCCI mode, tests have conducted on a single-cylinder, water-cooled, four-stroke naturally aspirated direct injection (DI) diesel engine was converted into HCCI mode. The engine specifications are shown in Table 1. To give a specific load to the engine, an electrical dynamometer was attached to the experimental setup. The fuel is introduce into the cylinder with PFI and is restrained by electronic control unit which synchronized with a crank angle sensor. To accomplish auto-ignition temperature preheats the intake charge of waste plastic pyrolysis oil biodiesel.

3 Results and Discussion

Figure 1 shows the effect of intake charge temperature on BTE of HCCI engine for selected fuel blends operation at altered loads. The BTE increases with the increase in the engine load. The lower BTE is found for the lower engine loads because of the retarded start of combustion in HCCI engine the heat losses are lower because of LTC, combustion time is less, better mixture homogeneity causes to less soot formation. The higher combustion temperatures and high HRR are affected by the advance start of combustion. Hence, the surfaces of the cylinder and piston are increased by heat loss; therefore, the net work done is decreases. Least combustion efficiency has noticed at the retardation of start of combustion because of increased emissions and lowers LTC. The maximum thermal efficiency for the WPPO-diesel-fuelled HCCI mode is stated to be 45.12% at 413 K with WPPO-5%with diesel.

Figure 2 shows the relation between EGT and engine load for the waste plastic pyrolysis oil blend with diesel HCCI operation. As the results for all intake temperatures, the EGT directly related to the engine load. As engine load increases, EGT increases at all intake temperatures, as estimated. But, the EGT decreases with the intake temperature. As the intake temperature increases, the SOC is advanced because of the chemical kinetics and faster reaction rates. High heat transfer caused by an early SOC with little ignition time. EGT reduces caused by the increase of burned hot gases residence time in cylinder.

Figure 3 shows the difference of the NOx emissions for the different fuel blends like WPPO-5%, WPPO-10%, WPPO-15% and WPPO-20% with various load conditions in HCCI engine. From the figure, it is noticed that the NOx emissions are increased with the engine load for the WPPO fuelled with diesel HCCI engine due to high combustion temperature of the burned gases. High NOx emissions are caused by the increasing in the residence time of the burned gases which is affected by the increase intake temperature, because of the early start of combustion. High NOx emissions were observed at full load condition at 413 K WPPO biodiesel-fuelled HCCI mode.

Figure 4 represents the influence of intake charge temperature on CO Emissions of HCCI engine for selected fuel blends operation at different loads. LTC is caused by not enough oxidation temperature of the gases, which results in the creation of CO emissions in the HCCI engine. The decrement in the CO emission is found with increasing engine load due to increase in the peak cylinder temperature. The CO emission drop is because of early SOC meanwhile more CO emission is because of delay in combustion phasing. The CO emission is higher at a lower intake air temperature (353 K) and loads due to misfire, and it can be controlled at lower load conditions.

Figure 5 represents the affect of intake charge temperature on UHC of HCCI engine for selected fuel blends operation at various loads. The incomplete combustion of hydrocarbon fuel is indicated by UHC formation emissions in the HCCI engine because of a LTC. The temperature at the walls of combustion chamber is lower because of the heat losses. Superior parts of UHC emissions rise from the combustion chamber regions. From the figure, it is clear that the increasing the intake charge temperature and load conditions decrease the UHC emission because of increase equivalence ratio with the load.

From Fig. 6, it is noticed that decrease in nature of smoke emission is found for increase in the engine load and intake charge temperature. At full load, WPPO-20% and at 413 K the smoke emission is negligible because of the preparation of high degree homogeneous mixture with the increased ignition delay. The intake temperature and load cause to decrease the smoke emissions, oxidation temperature and high residence time of burned gases, smoke emission noticed to be negligible at 413 K, full load and WPPO-20%. Be that as it may, at higher load ranges as a result of non-availability of adequate air and abnormal combustion there was a noticeable white smoke emission.

3.1 Modelling with ANN

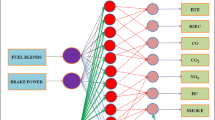

The engine performance and emission parameters have been predicted by ANN model was shown in Fig. 7. The created system engineering has a 3-8-6 configuration, with three neurons in the input layer representing intake air temperature, engine load, and EGT. Output is predicted by mapping 6 neurons BTE, EGT, NOx, smoke, CO and UHC, in output and varying neurons of hidden layer. Train of network with 44 values approximately 70% of experimental data has been used and rest of 30% data has been used to testing. The found test data are defined for getting better the performance of the system. To map input and output data, MLP was utilized and BP algorithm used to train the network. The network training is managed by this algorithm, where the network weights and leaning are computed arbitrarily at the creation of the training stage. Using the gradient descent rule, it achieves the error minimization process. The creation functions are selected by the sigmoid and linear functions for hidden and out layers. MATLAB 16 version trained and tested the developed ANN. To frame the best ANN design, it can use distinct neurons in the hidden layer; their activation and correlation coefficient are listed in Table 1. In view of the correlation coefficient esteem (R) picked the best system. It is clear from Table 1 that the R esteem is not expanded past the 18 neurons and one concealed layer arranges engineering. ANN modelling selects the network with one hidden layer and eight neurons the best. The taken network training performance, achieved with an error rate of 131.8787 and 12 epochs, and is exposed in Fig. 8. The values of correlation coefficient have been in between −1 and +1. If R value near to +1 the relationship is positive, and it is nearer to −1 the relationship is negative. Levenberg Marquardt (LM), correlation coefficient (R), Sigmoid (sig), Linear (ln), RMSE, MRE. For characterizing the system performance uses the mean relative error (MRE) and RMSE.

The error found during the learning method is the RMSE and is defined as:

The MRE, which expressions the mean ratio between the experimental values and the error is defined as:

where n is the quantity of the points in the data collection and E and P are experimental output and anticipated output sets (Fig. 9).

4 Conclusion

Maximum thermal efficiency for the WPPO-5% blended with diesel HCCI operation observed as 42.12% at 413 K inlet temperature. The NOx emissions were reduced for all blends and later slightly increased. For the HCCI mode, smoke emission was observed below 0.1% that is almost negligible. The evolved ANN tool can expect the performance characteristics BTE and EGT with the ±5 error. Moreover, ANN of the emission characteristics together with NOx, smoke, CO and UHC within ±5 error. The ANN model can also be utilized for the HCCI engine restraint and testing. Future research, the analysis can be carried out by implementing fuzzy logic-GA-FAHP (Fuzzy Analytical hierarchy process) to get more accurate results.

References

Turkcan, A., Ozsezen, A.N., Canakci, M.: Effects of second injection timing on combustion characteristics of a two stage direct injection gasoline—alcohol HCCI engine (2013)

Saxena, S., Schneider, S., Aceves, S., Dibble, R.: Wet ethanol in HCCI engines with exhaust heat recovery to improve the energy balance of ethanol fuels (2012)

Zhen, X., Wang, Y.: Numerical analysis of knock during HCCI in a high compression ratio methanol engine based on LES with detailed chemical kinetics (2015)

Murugan, S., Ramaswamy, M.C., Nagarajan, G.: Assessment of pyrolysis oil as an energy source for diesel engines. Fuel Process Technol. 90, 67–74 (2009)

Maurya, Rakesh Kumar, Agarwal, Avinash Kumar: Experimental study of combustion and emission characteristics of ethanol fuelled port injected homogeneous charge compression ignition (HCCI) combustion engine. Appl. Energy 88(4), 1169–1180 (2011)

Özener, Orkun, Yüksek, Levent, Özkan, Muammer: Artificial neural network approach to predicting engine-out emissions and performance parameters of a turbo charged diesel engine. Therm. Sci. 17(1), 153–166 (2013)

Oğuz, Hidayet, Sarıtas, Ismail, Baydan, Hakan Emre: Prediction of diesel engine performance using biofuels with artificial neural network. Expert Syst. Appl. 37(9), 6579–6586 (2010)

Kiani, M., Kiani, D., et al.: Application of artificial neural networks for the prediction of performance and exhaust emissions in SI engine using ethanol-gasoline blends. Energy 35(1), 65–69 (2010)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Jyothu Naik, R., Thirupathi Reddy, K. (2020). Prediction of the WPPO Biodiesel-Fuelled HCCI Engine Using Artificial Neural Networks. In: Reddy, A., Marla, D., Simic, M., Favorskaya, M., Satapathy, S. (eds) Intelligent Manufacturing and Energy Sustainability. Smart Innovation, Systems and Technologies, vol 169. Springer, Singapore. https://doi.org/10.1007/978-981-15-1616-0_60

Download citation

DOI: https://doi.org/10.1007/978-981-15-1616-0_60

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-1615-3

Online ISBN: 978-981-15-1616-0

eBook Packages: EngineeringEngineering (R0)