Abstract

The use of an earth–air heat exchanger (EAHE) system to heat/cool the air is a passive way to meet the ventilation and thermal comfort of a building. The system uses geothermal energy by burying different combinations of pipe networks to certain depths below the building. Due to different geographical and climatic conditions, the influencing factors and applicability of EAHE systems need to be studied. In this paper, the influencing factors of the EAHE system are explored in depth by consistent theoretical analyses and scale model experiments. The experimental results show that the most reasonable pipe depth for this project is 4 m. The use of longer pipes, smaller diameters, and lower air velocities can effectively improve the thermal performance of the EAHE system.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

1.1 A Subsection Sample

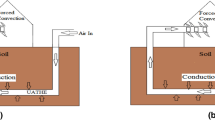

Earth–air heat exchanger system, as a renewable energy utilization method, makes reasonable use of the geothermal energy. Due to the time delay characteristics and attenuation of soil temperature wave, it provides a good temperature difference for the heat transfer between soil and the outside air. In winter, the soil releases heat into the buried pipes to heat the air. In summer, the soil absorbs heat from the buried pipes to cool the air. EAHE system is one of the important ways to save energy in HVAC [1]. For decades, EAHEs have been used in combination with solar chimneys or air conditioning (AC) systems. The EAHE system is probably the fastest growing alternative renewable energy in the world. With the increasing demand for energy savings, the markets in Europe, Germany and other places have developed rapidly in recent years [2].

In recent years, the complex heat transfer process of a EAHE system has been investigated by changing the burial depth, pipe diameter, pipe length, inlet air velocity, inlet air temperature, running time, and other parameters [3]. Bisoniya et al. [4] found that at lower air velocities, there is a higher temperature drop of EAHE systems regardless of the season. Barakat et al. [5] studied the application of EAHE in the inlet of a gas turbine. The results of the study show that a low inlet air velocity, deep burial, longer tube, and smaller diameter increase the power output. Serageldin et al. [6] conducted an experiment to determine the soil temperature distribution in Egypt. The result shows that as the pipe diameter is increased, the convection heat transfer decreases. Niu et al. [7] predicted the cooling capacity of an EAHE by considering the heat and mass transfer between the air and tube. The results indicate that as the tube diameter increases, the outlet temperature decreases. Benhammou et al. [8] studied the performance of an EAHE in the Algerian Sahara during July. The results indicate that as the pipe diameter is increased, the coefficient of performance (COP) decreases. Gan et al. [9] conducted a thermal model to study the performance of EAHE. The thermal and moisture interaction between the heat exchanger atmosphere and soil has a significant effect on the rate of heat transfer.

In this paper, the soil temperature distribution is analyzed to calculate the original temperature distribution of shallow soil in Xi’an, China. The heat transfer mechanism between the buried pipe and the air is analyzed. By nondimensional analysis of the heat transfer differential equations, the similarity criterion numbers of EAHE system are obtained. An scale experimental model is created to investigate the influence of the pipe length, diameter, burial depth, and inlet air velocity on the thermal performance of the EAHE system.

2 Methodology

2.1 Model

Due to the limitations of computer and computational simulations, engineering models are widely used to study the complex fluid dynamics characteristics for large-scale problems. In practice, many different scale model experiments have been applied. In consideration of the experimental conditions and engineering experiences, the model size (L × W × H: 1.5 × 0.3 × 0.3 m) is decided to be 1/20 of the real size. The model box is made of the 6 mm thick plexiglass board (acrylic board) (see Fig. 1) with a 30 mm layer of insulation cotton on the outside and a removable cover on the top. The center of the two XY surfaces of the model has circular holes for the installation of polyvinyl chloride (PVC) pipes. One end of the pipe is connected to a hose and a fan. The model box is filled with soil for experiments.

-

(1)

Similarity of air flow

In the three criterion numbers, Euler number (Eu), Froude number (Fr), and Reynolds number (Re) that determine the dynamic similarity, Eu number is generally considered as the passive criterion number. When the similarity criteria Re and Fr of the model are equal to the prototype, the dynamic similarity can be satisfied. In this experiment, gravity of the air can be ignored because the air flow is sent by the fan. Therefore, Re is selected to be the similarity number, and when the Re number is large enough, the flow enters the self-similarity zone, and the flow resistance is independent of the Re number and is related to only the relative roughness. In this experiment, v = 0.37 m/s can be obtained when ρ = 1.205 kg/m3, μ = 17.9 × 10−6 Pa s, and the maximum pipe diameter is 40 mm. Therefore, dynamic similarity can only be achieved if the air velocity in the experiment is guaranteed to be larger than 0.37 m/s [10].

-

(2)

Similarity of heat transfer

The heat transfer of air in buried pipeline includes the convective heat transfer between the inner wall of buried pipe and air, and the conduction heat transfer of soil around the pipeline. The main factor affecting the outlet air temperature is the heat storage of soil. Therefore, we pay more attention to the similarity of soil heat conduction. The heat conduction differential equation is:

Among it, \(R^{2} /a\Gamma = 1/{\text{Fo}}\) and the similarity number of the heat conduction between the buried pipe and the soil is the Fourier number (Fo), where \({\text{Fo}} = a\tau /\delta^{2}\) and \(\delta\). presents the soil penetration depth. To ensure that the model heat transfer and the real heat transfer are similar, the Fourier numbers should be the same:

Then, the following scale can be obtained:

-

(3)

Similar scales

Air temperature is the main objective of this experiment. Therefore, the temperature difference scale (\(C_{{{\vartriangle }{\text{T}}}}\)) and the temperature scale (CT) should be satisfied first. If the selected specific heat Cp, thermal conductivity λ, and thermal diffusivity α of the material are equal, the measured temperature of the model can directly represent the temperature value of the corresponding point in the real scenario. Therefore, the temperature scale CT and the temperature difference scale \(C_{{{\vartriangle }{\text{T}}}}\) are both 1. We can obtain the following equations:

2.2 Experimental Processes

The experiment was conducted in an unheated room in winter. During the experiment, the indoor temperature was 7.8–9.8 °C, the corridor temperature was 5.3–5.6 °C, and the outdoor temperature was −2–1 °C. For the experimental conditions in summer, the heat pipe was used to heat the temperature of the surrounding air, which was sent to the pipe after reaching the requirement temperature. For winter conditions, the inlet air is taken directly from the corridor. Experimental parameters are shown in Table 1.

In this experiment, the soil temperature was adjusted to simulate the real soil characteristics at different depths, and the soil used was taken from 4 m underground of Xi’an city. The heat conductivity coefficient of the soil is greatly affected by the temperature and moisture content, which were controlled in the experiment. Four equidistant heating cables were arranged in the experiment box, which were connected with the thermostat to adjust the heating temperature of soil. In the direction of X-axis, four k-type thermocouples were equidistant installed on both sides of the pipe and connected to the data acquisition instrument to ensure the uniformity of the soil temperature. The layout of thermocouples is shown in Fig. 2. The soil moisture in model box is monitored by a soil moisture meter to ensure the same soil moisture as the actual soil.

The soil and air temperatures in the pipe were measured by the k-type thermocouples with an accuracy of 0.5 °C. The air velocity, inlet and outlet air temperatures were measured by a checked hot wire anemometer (TESTO 425).

3 Results

3.1 Soil Temperature

According to the relevant data [10], the average annual temperature of the Xi’an ground surface is td = 15.7 °C, and the wave amplitude of the ground surface temperature is Ad = 14.8 °C. The parameters of the soil thermal properties are found in the literature [11]. The soil density is ρ = 1857 kg/m3, the soil moisture content is φ = 20%, the soil specific heat capacity is c = 1.61 kJ/(kg k), the thermal conductivity is λ = 1.186 W/(m k), and the thermal diffusivity is α = 0.00143 m2/h. MATLAB software was used to calculate the soil temperature at different depths in Xi’an city. The calculation results are presented in Fig. 3.

Figure 3 shows that the amplitude of the soil temperature wave is the greatest at the surface, and the amplitude gradually decreases with increasing depth. The underground soil temperature of 4 m is gradually close to the average surface temperature of xi’an. Below 8 m underground, the soil temperature basically unchanged. Besides, the peak value of the soil temperature is delayed as the depth increased. Therefore, the heat transfer conditions with depths of 2, 4, 5, 6, and 8 m were studied in July (summer) and January (winter).

3.2 Buried Depth

The soil temperature in the model box was controlled to simulate the different buried depths of pipes in reality (see Table 2). When inlet air temperature was 42/5.6 °C (summer/winter), air velocity was 4/2 m/s (summer/winter), the outlet air temperatures were measured. The results are presented in Fig. 4.

As can be seen from Fig. 4, with the increase of buried pipe depth, the air outlet temperature decreases (summer) or increases (winter) obviously, thus providing better cooling or heating capacity. Under 4 m, the original soil temperature fluctuation is not obvious; therefore, the outlet air temperature tends to be stable. It can be concluded that when the burial depth is below 4 m, the heat transfer of the EAHE is improved, but it does not increase with the buried depth. Therefore, combined with the economic and practical construction considerations, the burial depth of the pipe in the EAHE system in Xi’an should not exceed 4 m.

3.3 Pipe Length

In this experiment, the air temperatures along the pipe length (0, 0.3, 0.6, 0.9, 1.2, and 1.5 m) with different pipe diameter (20, 30, and 40 mm) were measured. The inlet air velocity and temperature are the same as in the previous case. The results are shown in Fig. 5.

As can be seen from Fig. 5, the outlet air temperature decreases (summer) or increases (winter) gradually along the pipeline length. This is because with the increase of pipeline length, the heat transfer area between air and buried pipeline also increases, making the heat transfer between air and buried pipeline more sufficient. It also can be seen from Fig. 5 that, when the diameter of 20, 30, and 40 mm, respectively, the total temperature increase of 1.5 m pipeline in winter are 8.3, 7.6, and 5.5 °C. While in summer, the total temperature drops of the 1.5 m pipe are 13.0, 9.5, and 5.6 °C, respectively. The temperature rise (winter)/drop (summer) of the pipe with a 20 mm diameter is the highest

3.4 Inlet Air Velocity

Figure 6 shows that the outlet air temperature gradually decreases (winter)/increases (summer) with increasing inlet air velocity. The heat transfer principle shows that as the increases of air velocity, the heat transfer coefficient increases. However, the air flow rate also increases, resulting in the insufficient heat transfer between the air flow and the inner wall of the pipe. The influence of air flow rate is far more than that of the heat transfer coefficient. Therefore, under this experimental condition the heat exchange effect between the air flow and the buried pipe decreases with the increase of the air velocity. In addition, it can be seen from Fig. 6, the outlet air temperature increases (summer)/decreases (winter) with the increase of pipe diameter. For example, when the air velocity is 2 m/s and the pipe diameters are 15, 20, 25, 30, and 40 mm, the air temperature rises are 8.7, 8.2, 7.9, 7.4, and 5 °C, respectively, in winter. The air temperature drops are 23.3, 20.1, 17.4, 15.6, and 11.1 °C in summer for corresponding pipe diameters of 15, 20, 25, 30, and 40 mm. Cause the heat exchange area between the pipe and air decreases, as the pipe diameter increases, the heat exchange effect between the air flow and the buried pipe also decreases. Therefore, from the experimental results, it can be seen that within a reasonable range, the use of longer pipes, smaller diameters, lower air velocities, and appropriate burial depths can effectively improve the thermal performance of an EAHE system.

4 Conclusion

The use of an EAHE to heat/cool the air is a passive way to meet the ventilation and thermal comfort of a building. Due to different geographical and climatic conditions, the influencing factors and applicability of EAHE systems need to be studied.

In this paper, the influence of burial depth, pipe length, diameter, and inlet air velocity on the heat transfer performance of an EAHE system is investigated using a scaled experiment. The key similarity numbers Fo and Re are proposed through the dimensionless analysis of heat conduction equations. The results show that the heat transfer effect decreases with the increasing inlet air velocity and pipe diameter, and increases with increasing pipe length. The effect of the burial depth on the heat transfer is not obvious below 4 m. Therefore, from the perspective of economic and construction practicability, the burial depth used in this project is 4 m.

References

Sharma, A., et al.: An intense review on the latest advancements of earth air heat exchangers. Renew. Sustain. Energy Rev. 89 (2018)

Uddin, S., et al.: Performance evaluation and life cycle analysis of earth to air heat exchanger in a developing country. Energy Build. 128, 254–261 (2016)

Yang, D., et al.: Evaluation of the thermal performance of an earth-to-air heat exchanger (EAHE) in a harmonic thermal environment. Energy Convers. Manag. 109, 184–194 (2016)

Bisoniya, T.S., Kumar, A., Baredar, P.: Cooling potential evaluation of earth-air heat exchanger system for summer season. Int. J. Eng. Tech. Res. (IJETR) 2, 309–316 (2014)

Barakat, S., et al.: Enhancement of gas turbine power output using earth to air heat exchanger (EAHE) cooling system. Energy Convers. Manag. 111, 137–146 (2016)

Serageldin, A.A., et al.: Earth-air heat exchanger thermal performance in Egyptian conditions: experimental results, mathematical model, and computational fluid dynamics simulation. Energy Convers. Manag. 122, 25–38 (2016)

Niu, F., et al.: Heat and mass transfer performance analysis and cooling capacity prediction of earth to air heat exchanger. Appl. Energy 137, 211–221 (2015)

Benhammou, M., et al.: Parametric study on thermal performance of earth-to-air heat exchanger used for cooling of buildings. Renew. Sustain. Energy Rev. 44, 348–355 (2015)

Gan, G.: Simulation of dynamic interactions of the earth–air heat exchanger with soil and atmosphere for preheating of ventilation air. Appl. Energy 158, 118–132 (2015)

Yan, L.Q.: Calculation and application of tunnel wind cooling. China Building Industry Press, Beijing (1982)

Huang, R.: Environmental Soil Science, pp. 1–45. Higher Education Press, Beijing (1987)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Zhao, Y., Tao, P., Hao, G., Ji, C., Liu, L. (2020). Parametric Study of an Earth–Air Heat Exchanger System for Heating and Cooling a Memorial. In: Wang, Z., Zhu, Y., Wang, F., Wang, P., Shen, C., Liu, J. (eds) Proceedings of the 11th International Symposium on Heating, Ventilation and Air Conditioning (ISHVAC 2019). ISHVAC 2019. Environmental Science and Engineering(). Springer, Singapore. https://doi.org/10.1007/978-981-13-9528-4_43

Download citation

DOI: https://doi.org/10.1007/978-981-13-9528-4_43

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-9527-7

Online ISBN: 978-981-13-9528-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)