Abstract

When small damage is detected in its initial stage in a real structure, it is necessary to decide if the user must repair immediately or keep on safely monitoring it. Regarding the second choice, the present paper proposes a methodology for damage severity quantification of delamination extension in composite structures based on a data-driven strategy using autoregressive modeling approach for Lamb wave propagation. A pair of features is used based on the autoregressive (AR) model coefficients and residuals and a machine learning algorithm with Mahalanobis Squared Distance for outlier detection. The damage severity quantification is proposed through an experimentally identified smoothing spline trend curve between the damage index and its severity. The application of the methodology is demonstrated in a composite plate with various progressive damage scenarios. The proposed method proved to be able to identify and predict the localization and the damage index related to its respective extension of minimal simulated damage with promising accuracy.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The use of composite materials in industrial applications has increased substantially in the last decades, due to their unique properties, such as high strength and stiffness combined with a low-density [1]. On the other hand, they have various and more complex types of damage such as matrix cracking, fiber debonding, and delamination [2]. Then, a drawback for the use of composite materials is to assure their reliability in service. In this scenario, structural health monitoring (SHM) techniques have been the focus of intensive research and development in recent years as a plausible solution, motivated by the potential of a substantial improvement in the safety of structures and economic benefits with maintenance cost reduction.

Damage identification methods can be decomposed in five levels that are related with: (1) detection, (2) localization, (3) classification, (4) quantification and (5) prognosis [3]. SHM methods based on guided waves and Lamb waves are the most widely used for damage identification [4]. They typically comprise the use of a network of piezoelectric elements (PZT) acting as both sensors and actuators to capture a baseline condition that after is related to an unknown condition to be classified. To ensure the reliability of damage identification is necessary to separate environmental and operational conditions from the structural changes associated with damages. Several works in the literature focused on damage detection and localization techniques in this context. However, a limited number of contributions have addressed the damage quantification level [5,6,7,8]. Ghrib et al. [9] presented a study of damage type classification and severity quantification in a composite structure with Support Vector Machine (SVM) using nonlinear model-based features to damage severity classification into the categories: “low,” “mid” or “severe.” Vitola Oyaga et al. [10] applied an approach for damage localization and quantification close to what will be employed in this work, using autoregressive models (AR). Nevertheless, it was based on vibration signals applied for civil structures and they did not verify a direct correlation among the index proposed and the damage size.

Thus, the primary purpose of this paper is to introduce a methodology for damage severity quantification of delamination size in composite structures based on a data-driven strategy. The paper is organized as follows: first, the proposed methodology of damage quantification is presented, where the damage identification using AR models is discussed concomitantly with the damage-sensitive features proposed. Next, the last step of the methodology of trend curve extrapolation to quantify the damage is detailed and discussed. Then, an experimental application of the methodology is demonstrated for a composite plate considering simulated damage. Finally, the results are discussed and further directions are suggested.

2 Quantification Methodology Proposed

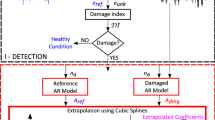

Figure 1 illustrates the methodology proposed herein for damage quantification. The methodology can be separated into two steps: (1) learning and (2) test. First, a data set from the healthy state and small damage conditions known a priori is used to identify an AR model and to construct a trend curve between damage severity and the damage index. Next, this connection represented by a smoothing spline is used into the test step to quantify the damage severity of an unknown condition in a future state based on the curve extrapolation. As the methodology requires data from undamaged and damaged conditions, it is posed in the context of supervised methods [3].

2.1 Damage-Sensitive Index Using AR Models

An AR model in healthy condition using a time-series measured using a set of PZTs can be described by [11]:

where \(x_{ij}(k)\) is the output signal in i position caused by an excitation signalFootnote 1 applied in j spot in a sample time k, the healthy polynomial of the AR model is \(A_{h_{ij}}(q) = 1+a_1q^{-1}+\cdots +a_{n_a}q^{-n_a}\), where \(q^{-1}\) is a lag operator, i. e., \(a_1q^{-1}x_{ij}(k) = a_1x_{ij}(k-1)\), and \(e_{h_{ij}}(k)\) is the reference error prediction assumed to be a white noise. The order \(n_a\) can be found using Bayesian information criterion (BIC) and the parameters of the polynomial \(A_{h_{ij}}(q)\) are identified using a simple least squares method with a focus in a one-step-ahead prediction [11,12,13]. Equation 1 can be used for monitoring an unknown situation signal \(y_{ij}(k)\) in the path \(i-j\) through:

If the new error \(\varepsilon _{ij}(k)\) has the same distribution (white noise) of the reference error, the system is in the healthy condition [14, 15]. On another hand, if the error varies, probably it is induced by damage or environmental/operation variations. So, a new model must be identified:

where \(A_{d_{ij}}(q) = 1+a_{d_1q}^{-1}+\cdots +a_{d_{n_a}}q^{-n_a}\) is the new polynomial in unknown condition. Important to note that it is assumed the same model order because there is an assumption of a small variation between the two states. Two features can be well applied to describe a damage detection procedure. First, to compute the ratio of variance of the error obtained:

and second using the parameters given by:

The Mahalanobis Squared Distance \(\mathcal D^2\) is applied as the damage index for statistical outlier detection using a test matrix \(\mathbf Z \) in a multivariate data set, including the two features presented previously [3]:

where \(\mu \) is the mean vector and \(\sum _{}\) is the covariance matrix assuming a training matrix formed by the indices in a defined baseline condition \(\mathbf X = \left[ \mathbf X_1 \quad \mathbf X_2\right] \).

To perform the detection is required the establishment of a threshold value to separate the damaged and healthy states. The strategy presented by Figueiredo et al. [16] is used in this study, where the threshold for outliers detection is defined by the most significant value of the \(\mathcal D^2(\mathbf Z )\) considering all signals corresponding to the safe condition.

2.2 Trend Curve Extrapolation

To establish a direct ratio among the damage index and its severity, it is proposed a trend curve fitting by a smoothing spline, where the data from undamaged and damaged states of the learning steps are used to define the curve, that can be extrapolated in order to predict the damage index and its respective severity in the next test step.

The damage severity (s) examined in this work corresponds to the area covered by simulated damage and can be measured for each state. As for each damage condition, it is considered a population of computed damage indices; then, its statistical model is used to relate to its particular severity. The statistical distribution of the damage indices is unknown a priori. Then, the kernel smoothing technique is used to estimate their probability density function (PDF) to obtain the mode of a set of damage index values in each damaged condition [17].

Suppose observed n pairs of damage index and severity (\(\mathcal D^2_i, s_i\)), \(i=1...,n\), relating to the general smoothing spline regression [18]

where \(\xi _i\) is an independent random error. A smoothing spline estimate \(f_p\) for f is defined as the minimizer of the penalized criterion [18].

where \(\delta \) is a positive known as smoothing parameter. As long as the smoothing spline curve is estimated on the learning step of the methodology, it can be applied to predict an unknown damage size on the test step in a future state.

3 Experimental Application

Figure 2(a) illustrates a carbon-epoxy laminated with layup containing 10 plies unidirectionally oriented along \(0^{\circ }\) with four PZTs SMART Layers from Accelent Technologies, with 6.35 mm in diameter and 0.25 mm in thickness. A pitch-catch configuration is employed where the PZT 1 is used as an actuator. A five-cycle tone burst signal with 35 V of amplitude and center frequency of 250 kHz is applied. The outputs used are measured in PZT 2, PZT 3 and PZT 4 with a sampling frequency of 5 MHz and timespan of 200 \(\upmu \)s. All signal generation and the acquisition was performed using the setup schematically described in Fig. 2(b), composed by a NI USB 6353 from National Instrument, a power amplifier EL 1225 from Mide QuickPack and an oscilloscope DSO7034B from Keysight, both controlled by Labview.

To simulate the damage reversibly, an industrial adhesive putty was inserted on the plate surface [19]. The additional mass introduced by the putty simulates local changes in the damping of the plate, which is an effect similar to the delamination in composites according to Lee et al. [19]. The damage severity of all states on the learning and test steps are presented in Table 1.

The experiments were conducted inside a temperature chamber SM-8 from Thermotron with a controlled temperature of \(30\,^{\circ }\text {C}\) and placed in a free-free boundary condition in order to eliminate the effects from environmental and operational variability.

Therefore, in total, the structure was submitted to 12 conditions and, for each one, the experiments were performed 100 times to have enough data for statistical analysis. The signals used in the learning and test steps of the methodology were collected in different days and state conditions. The first condition corresponds to the healthy state (H30) used as a baseline condition. The next seven conditions correspond to the progressive damaged states (D1 to D7), used on the learning step to create the trend curve. Finally, the last four conditions correspond to the conditions of damage in future states of severity progression used on the test step (DF1 to DF4).

Figure 3 shows the consequence of the introduction of the progressive damage on the first arrival mode measured by PZT 2. An increase in the area covered by the damage is observed to be proportional to a reduction of the response signal amplitude. This phenomena is due to the nature of damage introduced, which adds local damping in the transducer path causing a higher attenuation of the wave [19]. Figure 4 presents the response signal acquired on all PZTs considering the baseline and a damaged condition D7, where it can be observed a more pronounced difference on the PZT 2 than on the others, as the damage is situated in a path along this transducer.

Based on the BIC method, the model order was chosen as \(n_a=20\) for all PZTs. Figure 5 shows the response signals measured by the PZTs, the predicted signals with the estimated AR models and the residues. The residues are used as one of the features to interrogate the structure condition. As observed on the signals, the amplitude of residues is slightly more evident on the arrival modes. Then, the effectiveness of the damage detection is more dependent on the damage sensitivity from these modes.

Figure 6 shows the state-space of the two features, where it is observed a separation between the cluster states (points) for the healthy condition from the damaged one.

The proposed machine learning algorithm, based on the MSD for outlier detection, calculates the distance of the points from the test matrix to the centroid of the ellipse formed by the points from train matrix, which in this case corresponds to the features measured for the baseline condition. Figure 7 shows the damage index \(\mathcal D^2\) calculated using the machine learning algorithm. It was employed 70% of the data from the damage features assuming the baseline condition. As can be noted in Fig. 7, the damage index manifested more accentuated for PZT 2 than PZTs 3 and 4, as the damage is positioned in the path between the transducers PZT 1 to PZT 2. The classification of the structural condition was performed based on the statistical model of PDF estimated for each condition, estimated using the kernel smoothing technique with cross-validation method to choose the smoothing parameter [17].

Damage index \(\mathcal D^2\) computed for all performed tests (learning and test steps) and the three PZTs.

represents the index considering healthy condition (H30),

represents the index considering healthy condition (H30),

represents the index for progressive damage conditions used on the learning test (D1 to D7) and

represents the index for progressive damage conditions used on the learning test (D1 to D7) and

represents the index for the damaged conditions used on the test step (DU1 to DU4) and (

represents the index for the damaged conditions used on the test step (DU1 to DU4) and (

) is the threshold line considered for the outliers detection.

) is the threshold line considered for the outliers detection.

Based on a direct ratio among the mode of the statistical model estimated of the population of \(\mathcal D^2\) index in each condition and the respective damage severity, a trend curve was fitted using a smoothing spline function to obtain a direct relationship between the two variables. Figure 8 shows the trend curve obtained using the smoothing fitted spline function and the boxplot of the population of damage index in each condition. The trend curve was obtained using only the pairs of data from the learning step (H30 and D1 to D7) of the mode for damage index in each condition and its particular severity. The extrapolation of the trend curve was performed until a damage severity of 8000 mm\(^2\).

On the test step, the damaged conditions DF1 to DF4 were used to validate the trend curve extrapolation. The extrapolated curve is very close to the damage index distribution in all conditions. The trend curve can be used for the inverse problem and to obtain the damage severity using the mode of damage index. Table 2 presents the damage severity obtained using the trend curve and mode of damage index distribution compared with the measured one, for each condition, where it can be noticed a sufficient similarity presenting a low percentage error, mainly for the extrapolated damaged states in a possible future state before the occurrence. In this work, the damage quantification was performed only assuming the damage positioned in the path between the transducers PZT 1 and PZT 2 that corresponds the position where the small initial damage to be monitored is detected. However, each path of the PZT network has its trend curve, and it can be created on the learning step of the methodology.

4 Final Remarks

The methodology presented in this paper, based on the use of AR models for damage quantification in composite structures, can predict the size and location of simulated damage with adequate precision. The set of features proposed was a combination of residuals and coefficients used along with a machine learning algorithm based on the Mahalanobis Squared Distance. This methodology was also able to extract information about the damage severity in a future state. The proposed methodology to obtain the relation between the damage index and its severity using smoothing spline fitting was validated in the test step by estimating the damage size, that presented a small percentage error. Additional research of the methodology is being carried about the influence of environmental/operational variability, that represents the central shortcoming to be overcome.

Notes

- 1.

The input signal assumed here is a burst signal and it is not used to create the predictions models.

References

Ghrib, M., Berthe, L., Mechbal, N., Rébillat, M., Guskov, M., Ecault, R., Bedreddine, N.: Generation of controlled delaminations in composites using symmetrical laser shock configuration. Compos. Struct. 171, 286–297 (2017)

Talreja, R., Singh, C.V.: Damage and Failure of Composite Materials. Cambridge University Press, Cambridge (2012)

Nobari, A.S., Ferri Aliabadi, M.H.: Vibration-Based Techniques for Damage Detection and Localization in Engineering Structures. World Scientific (Europe) (2018). https://doi.org/10.1142/q0145

Su, Z., Ye, L.: Identification of Damage Using Lamb Waves: From Fundamentals to Applications, vol. 48. Springer, Heidelberg (2009)

Rebillat, M., Mechbal, N.: Damage localization in composite plates using canonical polyadic decomposition of lamb wave difference signals tensor. IFAC-PapersOnLine 51(24), 668–673 (2018). https://doi.org/10.1016/j.ifacol.2018.09.647

Shiki, S.B., da Silva, S., Todd, M.D.: On the application of discrete-time volterra series for the damage detection problem in initially nonlinear systems. Struct. Health Monit. 16(1), 62–78 (2017). https://doi.org/10.1177/1475921716662142

Memmolo, V., Pasquino, N., Ricci, F.: Experimental characterization of a damage detection and localization system for composite structures. Measurement 129, 381–388 (2018). https://doi.org/10.1016/j.measurement.2018.07.032. http://www.sciencedirect.com/science/article/pii/S0263224118306274. ISSN 0263-2241

Mallouli, M., Ben Souf, M.A., Bareille, O., Ichchou, M.N., Fakhfakh, T., Haddar, M.: Damage detection on composite beam under transverse impact using the wave finite element method. Appl. Acoust. 147, 23–31 (2019). https://doi.org/10.1016/j.apacoust.2018.03.022. http://www.sciencedirect.com/science/article/pii/S0003682X17305741. ISSN 0003-682X. Special Issue on Design and Modelling of Mechanical Systems Conference, CMSM 2017

Ghrib, M., Rébillat, M., des Roches, G.V., Mechbal, N.: Automatic damage type classification and severity quantification using signal based and nonlinear model based damage sensitive features. J. Process Control (2018). https://doi.org/10.1016/j.jprocont.2018.08.002. http://www.sciencedirect.com/science/article/pii/S0959152418301975. ISSN 0959-1524

Vitola Oyaga, J., Burgos, D.A.T., Vejar, M.A., Montero, F.P.: Structural damage detection and classification based on machine learning algorithms. In: Proceedings of the 8th European Workshop on Structural Health Monitoring (2016)

Kitagawa, G.: Introduction to Time Series Modeling. Chapman and Hall/CRC, Boca Raton (2010)

Figueiredo, E., Figueiras, J., Park, G., Farrar, C.R., Worden, K.: Influence of the autoregressive model order on damage detection. Comput.-Aided Civil Infrastruct. Eng. 26(3), 225–238 (2010). https://doi.org/10.1111/j.1467-8667.2010.00685.x

Nardi, D., Lampani, L., Pasquali, M., Gaudenzi, P.: Detection of low-velocity impact-induced delaminations in composite laminates using auto-regressive models. Compos. Struct. 151, 108–113 (2016). https://doi.org/10.1016/j.compstruct.2016.02.005. http://www.sciencedirect.com/science/article/pii/S0263822316300253. ISSN 0263-8223. Smart composites and composite structures In honour of the 70th anniversary of Professor Carlos Alberto Mota Soares

da Silva, S., Lopes Jr., V., Dias Jr., M.: Structural health monitoring in smart structures through time series analysis. Struct. Health Monit. 7(3), 231–244 (2008). https://doi.org/10.1177/1475921708090561. http://shm.sagepub.com/content/7/3/231.abstract

Farrar, C.R., Worden, K., Todd, M.D., Park, G., Nichols, J., Adams, D.E., Bement, M.T., Farinholt, K.: Nonlinear system identification for damage detection. Technical report, Los Alamos National Laboratory (LANL), Los Alamos, NM (2007)

Figueiredo, E., Park, G., Figueiras, J., Farrar, C., Worden, K.: Structural health monitoring algorithm comparisons using standard data sets. Technical report, Los Alamos National Lab.(LANL), Los Alamos, NM (United States) (2009)

Bowman, A.W., Azzalini, A.: Applied Smoothing Techniques for Data Analysis: The Kernel Approach with S-Plus Illustrations, vol. 18. OUP, Oxford (1997)

Brien, C.M.: Smoothing splines: methods and applications by Yuedong Wang. Int. Stat. Rev. 80(3), 475–476 (2012). https://doi.org/10.1111/j.1751-5823.2012.00196_6.x

Lee, J.-S., Park, G., Kim, C.-G., Farrar, C.R.: Use of relative baseline features of guided waves for in situ structural health monitoring. Journal of Intelligent Material Systems and Structures 22(2), 175–189 (2011). https://doi.org/10.1177/1045389X10395643

Acknowledgements

The authors are thankful for the financial support provided from São Paulo Research Foundation (FAPESP) grant numbers 2017/15512-8 and 2018/15671-1, and the Brazilian National Council for Scientific and Technological Development (CNPq) grant number 307520/2016-1.

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Paixão, J.A.S., da Silva, S., Figueiredo, E. (2020). Damage Quantification in Composite Structures Using Autoregressive Models. In: Wahab, M. (eds) Proceedings of the 13th International Conference on Damage Assessment of Structures. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-8331-1_63

Download citation

DOI: https://doi.org/10.1007/978-981-13-8331-1_63

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-8330-4

Online ISBN: 978-981-13-8331-1

eBook Packages: EngineeringEngineering (R0)

) and progressive damage states.

) and progressive damage states.

represents the last state of damage D7 and

represents the last state of damage D7 and

represents the progressive damage stages from D1 to D7.

represents the progressive damage stages from D1 to D7.

) and the last state of damage D7 (

) and the last state of damage D7 (

) in the learning step.

) in the learning step.

) compared with predicted signal using the AR reference model (

) compared with predicted signal using the AR reference model (

) and residuals in mV (

) and residuals in mV (

) for PZTs 2, 3 and 4 assuming the baseline condition.

) for PZTs 2, 3 and 4 assuming the baseline condition.

is the data set in the healthy condition,

is the data set in the healthy condition,

is the data set for progressive damage conditions used on the learning step and

is the data set for progressive damage conditions used on the learning step and

is the data set for the damaged conditions used on the test step.

is the data set for the damaged conditions used on the test step.

) and test step (

) and test step (

). The threshold line is represented by the dashed line (

). The threshold line is represented by the dashed line (

).

).