Abstract

Synthesis of polyesters via enzymatic polymerization is described comprehensively in up-to-dated review manner, in which the polymerization is of polycondensation type using hydrolases mainly lipase as catalyst. First, characteristics of lipase catalysis are discussed: catalyst nature for green polymer chemistry including the catalysis mechanism, immobilization of lipases, role of surfactants for lipase catalysis, and so forth. Then, the lipase-catalyzed polycondensation synthesis of polyesters is argued according to the types of polymerization reactions: via dehydration of α- and ω-oxyacids and of dicarboxylic acids, via transesterification using carboxylic acid esters, and via ring-opening addition-condensation polymerization using cyclic anhydrides or cyclic esters as a monomer component. Other polymers like polyamides, polyamines, polycarbonates, and sulfur-containing polymers were synthesized by lipase catalyst. These reaction results indicate that lipase catalysts induce various polycondensation reactions to produce a variety of new polyesters. Further, protease which catalyzes primarily the peptide bond cleavage and bond formation catalyzed also the polyester production via polycondensation.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Lipase catalyst

- Polyester synthesis

- Polycondensation

- Dehydration polymerization

- Transesterification polymerization

- Ring-opening addition-condensation polymerization

- Protease catalyst

5.1 Introduction

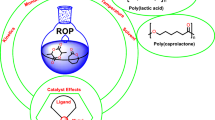

Polycondensation is an abbreviated expression of condensation polymerization. Polycondensation and ring-opening polymerization are two major reaction modes for the polyester synthesis. Both of them are catalyzed by enzymes. Synthesis of polyesters via polycondensation is described in this Chap. 5 and that via ring-opening polymerization is in the next Chap. 6. Polycondensation to produce polyesters is catalyzed by hydrolase enzymes such as lipase and protease.

Such polycondensation reactions are very extensively studied and extremely important in the polymer synthesis field, in particular by lipase catalyst, and hence have been reviewed or focused many times for more than these two decades; related publications are typically shown [1,2,3,4,5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29].

Thus, polyester synthesis using hydrolases (mainly EC 3.1.1.3) as catalyst is given in Chaps. 5 and 6, and that using acyltransferases (EC 2.3.1) as catalyst in Chap. 7.

5.2 Lipase-Catalyzed Polycondensation

Synthesis of polyesters is most often achieved by using lipase as catalyst. Depending upon the substrate structure, two reaction modes of polycondensation are typically given as Scheme 5.1. During the reaction small molecules (XOH) are eliminated. Condensation reactions are basically reversible processes, and hence, it is necessary to remove or reduce a by-product water or an alcohol from the reaction mixture for producing the product polymer effectively.

It is notable that enzyme-catalyzed polyester synthesis was first achieved via polycondensation reaction in the middle of the 1980s by using lipase as catalyst [30, 31]. The catalysis of lipase in vitro in the polycondensation to produce polyester is via the ester bond formation, whereas the hydrolysis of ester compounds in vivo is a reverse reaction, i.e., via the ester bond cleavage.

5.2.1 Lipase as Catalyst

Catalyst Functions of Lipase

Lipase (triacylglycerol lipase, EC 3.1.1.3) belongs to a hydrolase enzyme, which catalyzes the hydrolysis of fatty acid esters (ester bond cleavage) normally in an aqueous environment in living systems (in vivo). Scheme 5.2 represents a typical fundamental reaction in vivo [32]. It is stressed here again that the enzymatic reaction is reversible in principle, and hence, the polyester synthesis (ester bond formation) in vitro via polycondensation is a reverse reaction of the hydrolysis in vivo.

Generally, lipases play indispensable role to industry; hydrolyzing carboxylic ester bonds that are used in many of applications for food, detergent, pharmaceutical, and materials sciences. Here from fundamental scientific viewpoint, lipase is a typical enzyme catalyst for polycondensation synthesis of polyester, similarly to ring-opening polymerization of polyester synthesis as seen in the next chapter.

It is to be paid attention that in vitro lipase catalysis was observed in many years ago, in the 1930s [14, 33], and the catalysis became used later with much attention in organic chemistry field [34,35,36]. Lipase is by far the most well-known enzyme among others to catalyze the polyester synthesis, and hence, in this section some important aspects of lipase are described.

So far, various lipases of the different origin have been employed. For examples, industrial lipases derived from Candida cylindracea (abbreviated as lipase CC), Candida rugosa (lipase CR), Burkholderia cepacia (lipase BC), Pseudomonas fluorescens (lipase PF), and porcine pancreas (PPL) were used [37,38,39]. In addition, Aspergillus niger (lipase A), Penicillium roqueforti (lipase PR), Pseudomonas aeruginosa (lipase PA), Pseudomonas cepacia (lipase PC), Rhizopus delemer (lipase RD), Candida antarctica (lipase CA), and Rhizomucor miehei (lipase RM) were active in polyester synthesis [40, 41]. Candida antarctica lipase B (CALB) immobilized on acrylic resin is commercially called as Novozym 435.

Due to developments of X-ray crystallographic analysis technique as well as of isolation and crystallization techniques of enzymes, three-dimensional structures of enzymes were elucidated. Such structure determination of CALB was reported [42]; its 3D structure was given [43] and also referred [16]. CALB is constituted of 317 amino acid residues having a formula weight of 33,273. The active center has a catalytic triad, serine (Ser105)-histidine (His224)-aspartic acid (Asp187), containing a large hydrophobic pocket above the Ser-His-Asp triad and a medium-sized pocket below it. In the catalysis pathway, the acyl moiety of the substrate is considered to lie in the large subsite, while the leaving group/nucleophile moiety to lie in the medium pocket. The catalytic triad, Ser-His-Asp, is common to serine hydrolases like lipases and esterases.

Well-accepted catalytic mechanism involving the triad is illustrated in Fig. 5.1, where an ester RC(=O)-OR’ (substrate) is hydrolyzed when a nucleophile Nu-H is water (HO-H) and trans-esterified when Nu-H is an alcohol (R”O-H). The catalyst site is –CH2OH of Ser residue [16]. During the reaction, the imidazole group of His residue acts as a general base catalyst to pull the proton from –CH2OH and increases the nucleophilicity of the oxygen to attack the carbonyl carbon of the substrate in the stage of ES complex. At the same time, the carboxylate group of Asp residue helps the imidazole group to pull the proton, and the acyl-enzyme intermediate is formed with liberating R’O-H (acylating step). Then, in the deacylating step, also the imidazole and carboxylate groups act like a general acid/base mode to facilitate the production of RC(=O)-Nu.

Illustration of the mechanism of lipase-catalyzed hydrolysis (Nu-H = H2O) and transesterification (Nu-H = R”O-H). (Reproduced with permission from [16]. Copyright 2010 The Japan Academy)

Furthermore, lipase involves several catalysis aspects from “green chemistry” viewpoint:

-

High reaction-selective catalysis for acylation from alcohols or amines to give esters or amides.

-

High enantioselective hydrolysis and resolution of esters or amides.

-

Reactions under mild reaction conditions.

-

Reactions in aqueous solution, organic media, or other green solvents like supercritical CO2 and ionic liquids.

-

High selectivity in enantiomer formation from a racemic mixture, etc.

-

Also, lipase itself is derived from renewable resources.

-

Lipase is often used to catalyze a polymerization reaction using starting materials from renewable resources like biomasses, giving rise to useful polymers.

Lipase involves possibilities to be used as catalyst in vitro for industrial production of polyesters, polyamides, poly(ester-amide)s, etc.; it is recovered after the reaction and reused for many cycles. So, lipase is strongly hoped to be highly active as catalyst, be physically, thermally, and hydrolytically stable, and be stored for a longer time and handled conveniently. For realizing these hopes, lipase is modified or treated in various methods; one of typical methods is immobilization.

Immobilization

Lipase has been immobilized via various ways. In general, immobilization is achieved via chemical covalent binding of enzyme to the support or via physical or chemical adsorption of enzyme on the surface of the support. Lipase CR was employed for both approaches [44]. First, polyethylene glycol (PEG)-diacyl chloride (ClCO-PEG-COCl) was attached to -OH group of cellulose surface via ester bond formation and then allowed to react with the enzyme to form amide covalent bond via the reaction between –COCl and Enz-NH2 group (sample 1). Second, poly(acrylic acid) (PAA) was grafted onto the cellulose surface through –OH group and then allowed the enzyme adsorption via the interaction between –CO2H and Enz-NH2 groups (sample 2). Both surface polymer chains are compatible with aqueous and organic media. The stability of the enzymes of samples 1 and 2 toward several organic solvent was improved compared with the free enzyme. The sample 1 enzyme showed much better thermal stability than sample 2. Sample 1 showed higher catalytic activity at elevated temperatures than sample 2 and free lipase form. Both sample 1 and 2 lipases were repeatedly used for four cycles.

It is to be noted that the support substance is very important and can be one of the following many materials, for example, polyacrylic resins, ion-exchange resins, cellulose, alumina, celite, porous glass particles, silica, alumina, poly(ethylene glycol) (PEG), hollow fiber membrane, poly(vinyl alcohol) cryogels, etc. [45, 46]. A poly(ether-sulfone) (PES, Scheme 5.3) was employed as a supporting material for CALB immobilization [47]. The PES membrane (around 2 mm in thick) was prepared from 20% of the optimized mixtures of PES, PSf (polysulfone), and PEG dissolved in 80% N-methylpyrrolidone as solvent. CALB was immobilized on the PES membrane, and the immobilized CALB showed twice higher than the native enzyme in p-nitrophenol palmitate hydrolyzing catalyst, indicating an excellent support material of PES for CALB immobilization.

Enzymes are generally limited to hydrophilic reaction media, because they usually are not soluble and active in hydrophobic media. However, chemical modification of enzymes using an amphiphilic synthetic polymer like poly(ethylene glycol) (PEG) made various enzymes soluble and active in highly hydrophobic organic solvents. The activated polymers can be attached to enzymes in aqueous buffer solutions, and once enzymes are modified, they become soluble and active in various organic solvents such as benzene, toluene, and chlorinated hydrocarbons and exhibit high enzymatic activities in these organic solvents. Modified hydrolytic enzymes catalyzed the reverse reaction of hydrolysis in organic solvents; the modified lipase catalyzed various ester synthesis reactions. Such lipase also catalyzed ester exchange between an ester and an alcohol, between an ester and a carboxylic acid, and between two esters in organic solvents. When the two substrates for ester exchange were liquid, the reaction could take place without organic solvents. The modified lipase catalyzed an ester exchange reaction between trilaurin and triolein when dissolved in these substrates. The modified enzyme was extremely thermostable in its substrates [48,49,50,51,52].

Moreover, the lipase from Burkholderia cepacia adsorbed on macroporous resin NKA was investigated by combined strategies of bioimprinting and interfacial activation to enhance its catalytic performance. The activity of the derived lipase was 20–47% enhancement over the free lipase powder. The derived lipase exhibited a thermal stability over a wide range of temperature (from 30 to 70 °C) and a strong tolerance to organic solvents such as methanol, ethanol, and acetone [53]. PMMA nanoparticles obtained by miniemulsion polymerization proved to be a good support for the CALB enzyme immobilization, particularly in terms of hydrolysis catalyst activity [54].

Encapsulation is another effective way of immobilization [55]: Lipase PC was spontaneously complexed by simply mixing with nanogels of cholesterol-bearing pullulan (CHP). The enzyme increased catalytic activity after complexation, in several times more by kcat values, and the thermal stability of the lipase also increased upon complexation. It is stated as a new type of nano-encapsulation of enzyme inside a hydrogel matrix [55]. In relation to encapsulation, a vesicle (self-assembled capsule) can hold enzymes or drug components inside and act as a “nanoreactor” or “nanofactory” [56, 57]. Self-assembled nanofactories formulate with polymeric vesicles with an intrinsically permeable membrane. The vesicles, glyco-polymer liposomes (CAPsomes), are composed of carbohydrate-b-poly(propylene glycol) and show molecular-weight-depended permeability. This property enables CAPsomes to act as biocatalyst nanoreactors, protecting encapsulated enzymes from degradation while acting on low-molecular-weight substrates. In tumor-bearing mice, combined treatment with enzyme-loaded CAPsomes and doxorubicin prodrug inhibits tumor growth in these mice without any observable toxicity. The results demonstrated in vivo therapeutic efficacy of CAPsomes as nanofactories for enzyme prodrug cancer therapy [56].

Lipases were immobilized onto a photo-cross-linked polymer network, showing the activity recovery 76% and 41% for entrapment and adsorption methods, respectively. Both immobilized enzymes were very stable, retaining more than 60% of their activity. In the ring-opening polymerization of ϵ-caprolactone, polymerization rates were clearly affected as monomer conversions of 58% and 49%, and the highest molecular weights (M n) obtained were 7890 and 5600 for entrapment and adsorption methods, respectively [58]. Nanofibrous membranes containing reactive carboxyl groups were fabricated from poly(acrylonitrile-co-maleic acid) by the electrospinning process. The morphology and fiber diameter were 100 to 600 nm. Lipase CR was covalently immobilized onto the membrane surface. The properties of the immobilized lipases on the nanofibrous and hollow fiber membranes were as follows. Compared with the hollow fiber membrane, the enzyme loading and the activity retention of the immobilized lipase on the nanofibrous membrane increased from 2.36 to 21.2 mg/g and from 34 to 38%, respectively [59].

CALB was complexed with iron oxide nanoparticles followed by interfacial assembly at the surface of an oil-in-water emulsion to lead to a hierarchical assembly immobilization, which brought about increasing the catalytic efficiency compared with the native enzyme and Novozym 435 and about enhanced thermal and pH stability. Very specific aspect is that the iron-containing lipase can be magnetically recovered across five times [60]. In addition, immobilization employing magnetic microparticles is reported, where lipase RM was adsorbed onto hydrophobic surfaces of magnetic microparticles, and then, the surface amino acids of lipase can be tailored on the previously modified hydrophilic surface of the particles to suit biomolecule conjugation, as seen in Fig. 5.2 [61].

Image of the immobilization of lipase onto hydrophobic magnetic particles. (Reproduced with permission from [61]. Copyright 2013 American Chemical Society)

Lipase CR was immobilized via physical adsorption onto an ethylene−vinyl alcohol polymer (EVAL) functionalized with acyl chlorides. To alter the hydrophobicity, three long aliphatic fatty acid chlorides (C8, C12, C18) were employed, EVAL-OH group was esterified, and the obtained EVAL functionalization degrees were ranged from 5% to 65%. The enzyme−polymer affinity increased with both the length of the alkyl chain and the matrix hydrophobicity. The esterified polymers showed a tendency to give segregated hydrophilic and hydrophobic domains. Desorption experiments showed that lipase CR may be adsorbed in a closed form on the polymer hydrophilic domains and in an open, active structure on the hydrophobic ones, an image of which is shown in Fig. 5.3. The best results were found for the EVAL-C18 13% matrix that showed hyperactivation with both the soluble and insoluble substrate. This supported biocatalyst retained its activity for repetitive cycles [62].

Image of hydrophobicity influence on lipase catalyst activity. (Reproduced with permission from [62]. Copyright 2012 American Chemical Society)

A recent paper reported a lipase immobilization for catalysis using graphene oxide (GO) supports, which opens the lipase lid and maintains it in an open conformation in order to expose its active site [63]. The study belongs to immobilization via physical adsorption of enzyme on the surface of the support, and the lipase from Alcaligenes sp. (QLM) was used, which is an extracellular enzyme. The morphologies of bare GO sheets and GO sheets containing surface-bound QLM (GO+QLM) were visualized using AFM. The height profile corresponding to bare GO sheets (Fig. 5.4a) features a stable plateau near 1 nm (Fig. 5.4d). Upon putative lipase immobilization (Fig. 5.4c), a rougher surface topography emerges alongside a height profile plateau at 2–3 nm (Fig. 5.4e), confirming that protein has been successfully deposited. These dramatic changes in the height profile probably correspond to the formation of a sandwich-like structure between two GO+QLM monolayers. Each GO+QLM sheet should be dotted with protein adsorbates on both sides, enabling the cohesion of multilayered complexes bridged by lipase molecules. Figure 5.4 e shows a molecular model for how QLM’s binding to single GO sheets proceeds. Increasing hydrophobic surface of graphene increased lipase activity due to opening of the helical lid present on lipase, which was examined by the hydrolysis experiment of canola oil and p-nitrophenyl palmitate. The molecular mechanism of lid opening revealed in molecular dynamics simulations showed the role of hydrophobic interactions at the interface. The open and active form of lipase can be achieved and tuned with an optimized activity through chemical reduction of GO. This research looks a very good step toward designing nanomaterials as a platform for enhancing enzyme immobilization/activity. These tailor-made graphene-based nanosupports for effective immobilization may be a big challenge to control biophysicochemical interactions at the nano−bio interface. From the polymerization viewpoint, it is of interest to examine the catalytic activity of the present lipase for a polymerization reaction.

Binding of lipase to graphenes. AFM images of (a) bare GO and (b) lipase-bound GO. (c) Illustration of lipase adsorption onto GO obtained from molecular modeling. (d, e) Height profiles of representative cross sections taken from (a) and (b), respectively. The GO surface became rough upon lipase binding, and the corresponding height profile exhibits a doubling or tripling of sample thickness. (f) Far-UV CD spectra for lipase bound to different hydrophobic surfaces. A general decrease in ellipticity at 208 nm was observed, implying a decrease in α-helical content upon adsorption. (Reproduced with permission from [63]. Copyright 2016 American Chemical Society)

Protein Engineering

Enzyme is modified by protein engineering, in order to alter the catalytic activity toward an increased number of substrate to yield a new polymeric product or to change the nature of active site of the catalyst. A reference example in polymer synthesis area is a study of using a mutated enzyme of endoglucanase II, in which cellulose-binding domain was delated [64]. The mutated enzyme catalyzed the enzymatic polymerization of β-cellobiosyl fluoride to produce highly crystalline artificial cellulose with lacking the hydrolytic activity, in contrast to the artificial cellulose obtained by the un-mutated enzyme [65].

Surfactant (Detergent)

As seen above, the catalytic activity of lipase is sensitive to hydrophobic/hydrophilic nature of the enzyme surface. Accordingly, in the presence of various surfactants, enzyme was subjected to immobilization procedure [66]. Lipase CR and CALA as well as CALB (lipase isoforms A and B from lipase CA) were adsorbed on monoaminoethyl-N-aminoethyl (MANAE)-agarose beads as support in the presence of detergent Triton-X 100 to have individual lipase molecules. Then, one fraction was washed to eliminate the detergent, and both preparations were treated with glutaraldehyde for covalent cross-linking. The presence of detergent during the cross-linking of the lipases to the support permitted an increase in the activity (in some instances, even by a tenfold factor). The activity increase was speculated as that the lipase active center of the serine residue is more exposed to the medium by the detergent (with opening the lid), which makes the substrate easier to access to the active center. Hydrophobic area of detergent tends to help for lid opening, causing the higher activity [60]. Other surfactants are, for example, Span 85 (sorbitan trioleate) and propylene glycol stearate [67].

The influences of detergent using 17 kinds including nonionic, anionic, cationic, and zwitterionic detergents were investigated on the enzymatic activity and thermal stability of Thermomyces lanuginosus lipase (lipase Tl) [67]. For all detergents, low concentrations enhanced the activity of lipase Tl toward p-nitrophenyl butyrate hydrolysis by more than an order of magnitude. It was concluded that lipase-detergent interactions occur at many independent levels and are governed by a combination of general and structurally specific interactions.

5.2.2 Polycondensation of Oxyacids or Their Esters

A general reaction mode of oxyacids is shown as reaction (1) (X = H) in Scheme 5.1. In this section, we describe their reactions as two parts with dividing them into α-oxyacids and ω-oxyacids.

α-Oxyacids or Their Esters

The smallest molecule of α-oxyacid, glycolic acid (R = R’ = H, Scheme 5.4), was polymerized via lipase-catalyzed polycondensation with dehydration in an organic solvent to produce oligo(glycolic acid). Lipase from Aspergillus niger gave the best result for the polycondensation of glycolic acid among the unmodified enzymes used. PEG-modified lipase gave relatively high yields. By using ethyl glycolate (R = H, R’ = C2H5) as monomer, PEG-modified lipase catalyzed the polycondensation in 1,4-dioxane effectively to give the pentamer of poly(glycolic acid) with transesterification [51].

In the lipase-catalyzed polycondensation of lactic acid (R = CH3, R’ = H, Scheme 5.4), porcine pancreatic lipase (PPL) showed better conversions of lactic acid monomer and higher molecular weight poly(lactic acid) (PLA) than those with Lipozyme IM20. The highest molecular weight achieved was 1423 at 80% conversion by PPL. Blends of enzymatically prepared PLA with polystyrene yielded very good films in terms of tensile strength, elongation, and optical properties [68].

From the viewpoint of green polymer chemistry, PLA is derived from lactic acid, lactate, or its cyclic dimer of lactide as monomers, which are very promising alternate starting biobased and biodegradable materials in place of petro-based materials for practical polymer production (Fig. 5.5). In the production of PLA, impurities in lactic acid or lactide much affect the various properties of resulting PLA; these effects are discussed from a variety of analytical and characterization methods [69]. It might be possible, however, that if PLA is produced via enzymatic process, impurity problems may be much mitigated, because enzymatic catalysis is very high in substrate selectivity, i.e., impurities would less bother the synthesis reaction. It is to be added here that lactic acid was used extensively as an important starting biobased material for the production of various functional polymers [70, 71].

PLA synthesis processes. (Reproduced with permission from [69]. Copyright 2011 American Chemical Society)

Novel enzymatic oligomerizations of alkyl lactates (RLa) were disclosed, employing lipase [72] and protease [73], respectively, as catalyst. These studies revealed new information on the mechanism for enantioselection aspects. Polycondensation of alkyl D-lactates (RDLa, α-oxyacid ester) involving transesterification catalyzed by lipase (Novozym 435) at 50 °C produced oligo(D-lactic acid)s (oligoDLA) up to 82% yields with n = 2–7 (Scheme 5.5). Primary alkyl lactates of R = Et-, Pr-, and Bu- showed a higher reactivity than longer alkyl lactates like R = Pe-, Hx-, Hp-, and Oc-, and a secondary alkyl lactate of sBuDLa showed a reduced reactivity. These results suggested that there is an appropriate hydrophobic nature as well as stereochemistry of acyl group in monomer substrate for the enzyme to enable the enzyme catalysis. L-Lactates did not show oligomerization reactivity, i.e., enantioselection for D-isomers is very severe [72].

Michaelis-Menten Eq. (5.1) and for simplicity a pseudo-first-order rate Eq. (5.2) were applied for the reaction analysis:

where E, S, and P denote enzyme, substrate, and product, respectively. Plots of integrated form of Eq. (5.2) gave k values (× 104 s−1): MeDLa (3.7), EtDLa (4.4), PrDLa (3.7), and BuDLa (3.4).

The inhibition function of EtLLa toward the oligomerization of EtDLa was found “competitive.” As a model reaction, the following hydrolysis experiments of BuDLa and BuLLa were conducted in THF (Scheme 5.6) [72]. Interestingly, in contrast to the oligomerization, Novozym 435 induced the hydrolysis of both BuDLa and BuLLa substrates. The rough values (× 104 L mol−1 s−1) are k = 2.1 for BuDLa and k = 0.92 for BuLLa at 50 °C; the D-isomer proceeded about 2.3 times faster than the L-isomer.

The above observations suggest the mechanistic aspects of lipase (Novozym 435) catalysis as follows: Enantioselection is operated by deacylation step as shown in Fig. 5.6 [72], where only the dimer formation is shown for simplicity. First, the monomer (substrate) is to be activated by the enzyme with forming (R)-acyl-enzyme intermediate in step (a) (enzyme-activated monomer: EM) (“acylation of lipase”). Onto the activated carbonyl carbon of EM, OH group of the D-lactate nucleophilically attacks to form an ester bond with liberating lipase enzyme, giving rise to D,D-dimer in step (b) (“deacylation of lipase”). If, in place of the D-lactate monomer, OH group of D,D-dimer attacks EM, D,D,D-trimer will be formed, and the repetition of this type of reaction ends up with the formation of higher D-oligomers. Since the L-lactate was not consumed, the reaction of EM with OH group of L-lactate does not occur; reaction of step (c) does not take place. On the other hand, hydrolysis of D-lactate also needs activation to form EM. Then, EM reacts with water to give D-lactic acid shown in step (d).

Lipase-catalyzed oligomerization pathways of D-lactates (A) and L-lactates (B): acyl-enzyme intermediate formation steps (a and e), subsequent dimer formation steps (b, c, f, and g), and hydrolysis steps (d and h). ○ denotes that the step takes place, whereas × denotes that the step does not take place. (In steps b, c, d, f, g, and h, the leaving group of lipase is omitted). (Reproduced with permission from [72]. Copyright 2010 American Chemical Society)

On the other hand, alkyl L-lactate monomers (B) were not consumed in the oligomerization. Whereas, in the hydrolysis, alkyl L-lactates were hydrolyzed to give L-lactic acid in step (h). This is a clear indication that step (e) actually took place to produce (S)-acyl-enzyme intermediate EM. However, neither OH group of D-lactate nor OH group of L-lactate was allowed to attack EM to give L,D-dimer via step (f) or L,L-dimer via step (g).

Hydrolysis steps (d) and (h) (both deacylations) are nonselective due to no chirality in water molecule, whereas esterification steps (b), (c), (f), and (g) (all deacylations) are enantioselective. The above results demonstrate that “the enantioselection is governed by the deacylation step”; among four steps, only step (b) is allowed to give D,D-dimer. However, the EM formation, both steps (a) and (e), is possible from all alkyl D- and L-lactate monomers. This “enantioselection mechanism” is a clear-cut new finding.

More generally, Fig. 5.7 shows a reaction mechanism of lipase (Novozym 435)-catalyzed oligomerization of alkyl lactates (RLa). The acylation step of RLa takes place regardless of D- or L-isomer, and therefore, their hydrolysis is catalyzed by the lipase. In the oligomerization, however, the reaction of (R)-acyl-enzyme intermediate (EM) is possible only with OH group of D-lactate or D-oligoLA and not with L-lactate or L-oligoLA. (S)-Acyl-enzyme intermediate, on the other hand, does not react with OH group of D-, L-lactates or D-, L-oligoLA. Namely, the deacylation step governs the enantioselection in the oligomerization.

General illustrative mechanism of lipase-catalyzed oligomerization of alkyl lactates. (Reproduced with permission from [72]. Copyright 2010 American Chemical Society)

These behaviors of lipase catalysis are to be compared with those of protease catalysis, where the enantioselection of the latter is much loose than the former [73]. This situation is mentioned in the Sect. 5.3.

The above D-selective reaction of alkyl lactates by lipase catalysis was applied for optical resolution of D, L-isomers [74]. Typically, a mixture containing 90.4% of n-butyl L-lactate (BuLLa) and 9.6% of D-lactates (BuDLa) was incubated with an immobilized lipase, and then, the purity of BuLLa was increased to 98.6%, indicating that the lipase catalysis provides with a good method for enantio-purification.

ω-Oxyacids or Their Esters

Polycondensation of an ω-oxyacid (m ≥ 1 in Scheme 5.7) was reported first in 1985, describing a poly(ethylene glycol)-modified (PEG) lipase-catalyzed dehydration polycondensation of 10-hydroxydecanoic acid (m = 8), a hydrophobic monomer, in a benzene solution [31]. The resulted polyester structure is considered linear; degree of polymerization (DP) was not high. In this polymerization, modification of the lipase with PEG (mol. wt. 5000) was very important and made the reaction proceed in a hydrophobic medium.

It is to be noted that the dehydration polycondensation occurred in water solvent catalyzed by lipases PA, CC, PC, and PF; in water the lipase-catalyzed dehydration reaction of ω-oxyacids (m = 9, 13 in Scheme 5.7) at 35–75 °C for 24 h gave the corresponding polyesters with M n ~1000 in 5–69% yields. Normally, this type of dehydration reaction is in equilibrium with the starting side and the product side, and hence, the water solvent makes the reaction proceeding disfavor because of the water product, due to the “law of mass action.” Yet, lipase catalysis enabled the reaction forward; this concept dehydration in water is considered as a new finding in organic chemistry [75, 76].

Dehydration polycondensation of an oxyacid, ricinoleic acid (a main component from castor oil), was catalyzed by lipase at 35 °C in an organic solvent to give a polyester with M n ~1000 in good yields (R = H, Scheme 5.8) [77]. Methyl ricinoleate was polymerized via transesterification with immobilized lipase PC catalyst in bulk in the presence of molecular sieves at 80 °C for 7 days. Polyricinoleate was of high mol. wt. M w ~ 105, a viscous liquid at room temperature with a glass transition temperature (T g) of −74.8 °C, and was biodegraded by activated sludge. Polyricinoleate was readily cured using a dicumyl peroxide at 170 °C for 30 min to produce a chloroform-insoluble cross-linked polyricinoleate. Its M w value was very high ~105 (R = CH3, Scheme 5.8) [78].

Regioselective oligocondensation of cholic acid (an oxyacid) by lipase CA catalyst was achieved. A mixture of cholic acid, 11-methacryloylaminoundecanoic acid, and the lipase produced a radically polymerizable oligo(cholic acid ester) baring methacryloyl end group. This new monomer was radically polymerized to give a corresponding comb polymer having several cholic acid ester units as side chains [79].

Hydrophobic oxyacids were efficiently condensation-polymerized by lipase CA as catalyst. In the polymerization of 16-hydroxyhexadecanoic acid (m = 14, Scheme 5.7), 12-hydroxydodecanoic acid (m = 10), or 10-hydroxydecanoic acid (m = 8) under vacuum at a higher temperature (90 °C) in bulk for 24 h, the DP value of the product polymer was beyond 100, whereas the polyester with lower molecular weight (DP ~ 63) was formed from 6-hydroxyhexanoic acid (m = 4) under the similar reaction conditions [80]. Immobilized Humicola insolens (HiC)- and Novozym 435 (N435)-catalyzed homopolymerizations of ω-hydroxyalkanoic acids (ωHA) were investigated. ωHAs examined were hexanoic acid (m = 4), 10-hydroxydecanoic acid (m = 8), 12-hydroxydodecanoic acid (m = 10), and 16-hydroxyhexadecanoic acid (m = 14) (Scheme 5.7) [81]. HiC’s activity for ωHA substrates with 12 and 16 carbons was high C16 > C12, but not C10-ωHA and C6-ωHA were polymerized. In contrast, N435’s activity for ωHA substrates was C16 = C12 > C10, but not C6-ωHA was polymerized. HiC-AO (Amberzyme oxirane resin)- and N435-catalyzed C16-ωHA homopolymerization at 70 °C for 8 h gave polyesters with M n values ~ 4.0 × 104 and ~ 2.6 × 104, respectively, which are quite high. These results show that the catalytic activity of these lipases is very sensitive to the length of the substrate monomer; hydrophobic nature of the monomer is operative.

The lipase CC-catalyzed polycondensation of 11-hydroxyundecanoic acid (m = 9, Scheme 5.7) in hexane produced a polyester, the molecular weight of which was up to 3.5 × 104. A time-conversion course study of the polymerization process revealed that oligomers were formed relatively rapidly and that these oligomers then condensed to generate higher molecular weight polyesters [82]. Novozym 435 was also an efficient catalyst for the dehydration polycondensation of an oxyacid, cis-9,10-epoxy-18-hydroxyoctadecanoic acid, carried out in toluene in the presence of molecular sieves at 75 °C for 68 h to give the polyester with the highest M w 2.0 × 104 (M w/M n = 2.2). It is noticeable that the epoxy functional group was not affected by the enzyme catalysis [83].

The transesterification polycondensation of methyl 6-hydroxyhexanoate, an ω-oxyacid ester, with lipase catalyst in hexane at 70 °C for more than 50 days gave the polyester with DP value up to 100 (Scheme 5.9, see also reaction (1) in Scheme 5.1). PPL-catalyzed polymerization of methyl 5-hydroxypentanoate produced the polyester with DP value of 29 [39].

Various hydroxyesters, ethyl esters of 3- and 4-hydroxybutyric acids, 5- and 6-hydroxyhexanoic acids, 5-hydroxylauric acid, and 15-hydroxypentadecanoic acid, were polymerized by lipase PS catalyst via transesterification to give the corresponding polyesters with molecular weight of several thousands [84]. Novozym 435 induced a regioselective polycondensation of isopropyl aleuriteate, where the only primary alcohol was reacted at 90 °C in a toluene/2,4-dimethyl-3-pentanol mixed solvent, giving rise to the polymer of M n 5600 in 43% yields (Scheme 5.10) [85].

With using a chemo-enzymatic method, new polyesters having rotaxanes in the side chain were prepared. Terminal-functionalized polymers like macromonomers and telechelics are important and often used as prepolymers for synthesis of functional polymers. The lipase CA-catalyzed polycondensation of 12-hydroxydodecanoic acid in the presence of 11-methacryloylaminoundecanoic acid produced a methacrylamide-group-containing polyester macromonomer, in which a β-cyclodextrin is contained in the side chain [86]. 12-Hydroxydodecanoic acid and methyl 12-hydroxystearate (both from seed oil) were copolymerized in polycondensation manner catalyzed by Novozym 435 in toluene in the presence of molecular sieves at 90 °C. During the reaction water as well as methanol liberated. After several days, the copolymer was obtained in good yields, having M w ~1.0 × 105 showing elasticity and biodegradability [87].

An optically active oligoester was obtained by enantioselective polycondensation of racemic 10-hydroxyundecanoic acid, a secondary alcohol, by lipase CR catalyst. The resulting oligomer (mol. weight ~1000) was enriched in the (S) enantiomer with 60% enantio-excess (ee), and the residual monomer was recovered with 33% ee favoring (R) enantiomer. It was speculated that the enantioselection is caused at the deacylating step, the attack of substrate OH group onto the acyl carbon of acylated enzyme (see also Fig. 5.1 for reference) [88]. Lipase PPL catalyzed transesterification polycondensation of racemic ε-substituted-ε-hydroxy ester monomers (HOCHR(CH2)4COOR’: R = Me, Et, Ph; R’ = Me, CH2CCl3) to produce optically active oligomers (degree of polymerization DP < 6); enantioselection occurred. With increasing bulkiness of the substituent, in the order Me < Et < Ph, the enzymatic reaction becomes slower, yet the enantioselectivity becomes higher. Copolycondensation between the monomer 1, R = H, R‘ = Me, and three monomers 2, R = H, R‘ = Me; 3, R = H, R‘ = Et; and 4, R = H, R‘ = Ph, gave copolyesters with DP values 8.7, 7.0, and 5.4, respectively. Optically active copolymers were obtained, being higher in molecular weight than the analogous homopolymers [89].

Iterative tandem catalysis (ITC), a method of synthesizing chiral polyesters via the transesterification polycondensation of racemic monomers, was investigated. The reaction uses racemic oxyacid ester monomers (AB type monomers) having a secondary hydroxy group and a methyl ester moiety (Scheme 5.11). The concurrent actions of an enantioselective acylation catalyst (Novozym 435) and a racemization catalyst (Ru(Shvo)) brought about the high conversion of the racemic monomers to enantio-enriched D-polymers. Monomers used were typically methyl 6-hydroxyheptanoate (Me-6HH), methyl 7-hydroxyoctanoate (Me-7HO), methyl 8-hydroxynonanoate (Me-8HN), and methyl 13-hydroxytetradecanoate (Me-13HT). Using isopropyl esters under the selected reaction conditions, the polymerization produced chiral polymers with monomer conversion (up to 99%), high enantiomeric excess (ee, up to 92%), and molecular weight (up to 16.3 × 103) [90], (see also 5.2.3 for DKR method).

A chemo-enzymatic method was applied to prepare an oleic acid (a vegetable oil)-based polyester: First, oleic acid (C-18 mono-ene acid) was epoxidized by Novozym 435 catalyst with H2O2 oxidant, and then the intermolecular ring-opening addition between the epoxide group and CO2H group thermally took place to produce the poly(oleic acid)-based polyester. It was further cross-linked by a diisocyanate compound to give a biodegradable tough material of polyester [91].

5.2.3 Polycondensation of Dicarboxylic Acids or Their Esters with Alcohols

Via Dehydration

This type of lipase-catalyzed polycondensation of reaction (2) (X = H, Scheme 5.1) was reported first in 1984 on the dehydration reaction between a dicarboxylic acid and a diol to produce polyester oligomers (Scheme 5.12). Lipase from Aspergillus niger catalyzed the synthesis of oligoesters from various dicarboxylic acids and diols. For example, the product oligoesters synthesized from 1,13-tridecanedioic acid (p = 11) and 1,3-propanediol (q = 3) contained pentamer and heptamer as dominant components, both end groups being hydroxy [30]. Dehydration polycondensation of adipic acid and 1,4-butanediol in diisopropyl ether gave a polyester with a degree of polymerization (DP) of 20 (p = q = 4) [92]. Higher molecular weight polyesters were enzymatically obtained by polycondensation of sebacic acid (p = 8) and 1,4-butanediol (q = 4) under vacuum. In the lipase MM-catalyzed polymerization in hydrophobic solvents of high boiling point such as diphenyl ether, the molecular weight of polyesters from various combinations of diacids and glycols reached the value higher than 4 × 104 [93,94,95].

Lipase CA efficiently catalyzed the polycondensation of dicarboxylic acids and glycols without solvent under mild reaction conditions at 60 °C. Methylene chain length of the monomers greatly affected the polymer yield and molecular weight. The polymer with molecular weight higher than 1 × 104 was obtained by the reaction under vacuum [96]. In the polymerization between dicarboxylic acids and glycols, effects of various combination of the monomers (p = 2, 4, 6, 8, and 12 and q = 2, 3, 4, 5, 6, 8, 10, and 12 in Scheme 5.12) as well as several lipase catalysts were examined. The best results were observed in terms of yields and M n values for the reaction of sebacic acid (p = 8) and 1,5-pentanediol with lipase CA catalyst at 60 °C for 48 h, giving rise to the product polyester in 86% yields with M n 14,000. In order for the reaction to proceed, it was necessary for the monomers to have appropriate hydrophobicity (e.g., p, q > 4). These syntheses afforded a variety of biodegradable aliphatic polyesters via nontoxic enzyme catalysis under mild reaction conditions, and hence, it was addressed to provide a good example of “Green Polymer Chemistry” [97].

Catalytic activity of lipases, immobilized Humicola insolens (HiC) and Novozym 435 (N435), was studied on the dehydration polycondensation of α,ω-n-alkane diols and α,ω-n-alkane diacids with varying chain length (Scheme 5.12). HiC on Amberzyme oxirane (AO) resin (i.e., HiC-AO) activity for the polymerization of sebacic acid (p = 8) with the diols (q = 3, 4, 5, 6, and 8) was C8 > C6, where C3, C4, and C5 diols were not polymerized. N435’s relative activity for diol substrates was C8 > C6 > C5 > C4 > C3. HiC-AO activity for the polymerizations of 1,8-octanediol with the diacids with 6-, 8-, 9-, 10-, and 13-carbon chain lengths was C13 > C10, where HiC showed little activity for C6, C8, and C9 diacid polymerizations. N435 displayed similar activity for all these diacid chain lengths. Thus, N435 has a broader substrate promiscuity than HiC-AO. HiC-AO- and N435-catalyzed copolymerization of 1,8-octanediol/C13-diacid at 8 h gave polymers with M n of 11.0 × 103 and 9.6 × 103, respectively [81].

Reaction pathway of Novozym 435-catalyzed dehydration polycondensation between adipic acid (A, p = 4) and 1,4-butanediol (B, q = 4) (see Scheme 5.13) was studied. The polyester chain formation involves a step-growth mechanism utilizing a key synthon, the simplest adduct of 1,4-butanediol and adipic acid, 6-carboxy-11-hydroxy-7-oxaundecanoic acid (1), termed as BA. In the solvent-free reaction, enzyme-catalyzed esterification of BA with 1,4-butanediol forms BAB (2), and stepwise addition of AB gives B(AB)2, B(AB)3, etc. These reactions to give the oligomers with both B-terminals at the early stage are due to the hard solubility of the acid monomer. The polymerization pathway involves a key-adduct 1, which becomes acylated by the enzyme catalysis. Propagation of the polymer chain proceeds via reaction with a hydroxy-terminated species, releasing the enzyme site, i.e., propagation via stepwise fashion [92, 98].

Effects of substrates and solvent on the ester-chain formation, polydispersity, and end-group structure were examined. Diphenyl ether shows a high boiling point with hydrophobic nature, and hence, it is a preferred solvent for the polycondensation of adipic acid (p = 4) and 1,8-octanediol (q = 8), giving M n of 2,85 × 104 (48 h, 70 °C). Monomers having longer alkylene chain length of diacids (sebacic and adipic acids) and diols (1,8-octanediol and 1,6-hexanediol) showed a higher reactivity than the reactions of shorter chain derivatives, indicating that lipase catalysis is generally more effective for a hydrophobic substrate [99].

As to the reaction solvent, the enzymatic reaction takes place even in ionic liquids [100]; in an ionic liquid, lipase was active and transesterification polycondensation between diethyl adipate or diethyl sebacate and 1,4-butanediol occurred to give the product polyester [101].

“Dehydration reaction in water solvent” was achieved for the first time in organic chemistry field, which was also mentioned above [75, 76]. Dehydration reaction is generally achieved in nonaqueous media, because the product water of the dehydration is in equilibrium with starting materials and the solvent water disfavors the dehydration to proceed in an aqueous medium due to the “law of mass action.” Nevertheless, lipase catalysis enabled a dehydration polycondensation between several α,ω-dicarboxylic acids and glycols in water at 45 °C, to afford a polyester in good yields. Lipase CA and other lipases were active for these dehydration polycondensations (Scheme 5.12). In the polymerization of a dicarboxylic acid and a glycol, the polymerization behavior was greatly depending on the methylene chain length of the monomers. For example, from sebacic acid and 1,8-octanediol (p = q = 8, in H2O solvent), the polyester with M n = 1700 in 43% yields at 45 °C for 24 h by lipase CA catalyst was obtained, whereas no polymer formation was observed from sebacic acid and 1,6-hexanediol, suggesting that the combination of the monomers with appropriate hydrophobicity is important for the polymer production by dehydration. This finding of dehydration in water is a new aspect and attracted organic chemists with much interests (see also the above 5.2.2) [75, 76].

CALB was covalently immobilized onto epoxy-activated macroporous poly(methyl methacrylate) Amberzyme beads with a poly(glycidyl methacrylate) outer region. In bulk Amberzyme-CALB-catalyzed polycondensation between glycerol (0.1 equiv), 1,8-octanediol (0.4 equiv), and adipic acid (0.5 equiv) at 90 °C for 24 h gave higher molecular weight polyester of M w ~ 4.0 × 104 [102].

For obtaining information on commercialization of the environmentally friendly synthetic process, the scale-up experiments of the Novozym 435-catalyzed polyester synthesis from adipic acid and glycerol (a triol) were performed on a 500 g scale. The reaction was carried out in a heated, solvent-free system, and the influence of various reaction conditions (i.e., temperature 60–90 °C, reduced pressure, enzyme concentration, reactants ratio, stirrer type, stirring rate, and reaction time) on the substrate conversion and molecular weight of the product was investigated. Conversions were higher than 90%, and molecular weights were in the desired M n range of 2000–3000. High hydroxyl functionality of the product polymer is expected to cause new function. And, a scale-up to 200 kg polyester yields was also examined [103, 104].

Dehydration polycondensation of adipic acid and 1,8-octanediol in the presence of L-malic acid (L-MA) in organic media was achieved with Novozym 435 catalyst. The molecular weight reached to a maximum of 17,400 at 80 °C in isooctane at an L-MA feed ratio in the diacids of 40 mol %. The M w increased from 3200 to 16,600 when the reaction time was extended from 6 to 48 h at 70 °C. The hydrophilicity, thermal stability, and crystallizability of the copolymer were also investigated [105]. As green polymerization cycle, the preparation of partially renewable aliphatic polyesters based on 1,8-octanediol and biobased long-chain diacids, namely, 1,12-dodecanedioic and 1,14-tetradecanedioic acid, was performed. It involved CALB-catalyzed prepolymerization combined with low-temperature post-polymerization, in the melt or solid state [106].

The direct dehydration polycondensation between adipic acid and sorbitol, a polyol sugar component, with Novozym 435 catalyst in bulk was performed at 90 °C for 48 h. The product poly(sorbityl adipate) was water-soluble. The M n and M w values were ~1.1 × 104 and ~1.7 × 104, respectively. In the polymer, sorbitol was esterified at primary alcohol group of 1- and 6-positions with high regioselectivity (~85%). In place of sorbitol, glycerol was employed; however, the M n and M w values were lower, 2500 and 3700, respectively. To obtain a water-insoluble sorbitol copolyester, adipic acid, 1,8-octanediol, and sorbitol (molar ratio 50:35:15) were terpolymerized at 90 °C for 42 h (reaction (A), Scheme 5.14). The methanol-insoluble part (80%) had M w of 1.17 × 105. Another terpolymerization of adipic acid, 1,8-octanediol, and glycerol (molar ratio 50:40:10) was performed in bulk at 70 °C, to give a polyester (reaction (B), Scheme 5.14). The product polymer showed the monomer ratio in the 50:41:9, respectively, and the values for M w and M w/M n of 7,56 × 104 and 3.1, respectively. The product contained 90% methanol-insoluble parts, showing few cross-links. The selectivity at glycerol primary alcohol sites was only 66%; therefore, the product was highly branched; 27% of glycerol units were for branched sites. Physical properties of the resulting polyesters containing sorbitol or glycerol were characterized in detail [107, 108].

Lipase CA catalyzed the bulk dehydration polycondensation of the monomers, adipic acid (A2), 1,8-octanediol (B2), and glycerol (B′B2) and gave hyperbranched polyesters at 70 °C for 42 h. With monomer feed molar ratio A2: B2: B′B2 = 1.0:0.8:0.2, linear copolyesters were formed during the first 18 h, and extending the reaction time to 42 h gave hyperbranched copolymers with dendritic glycerol units. The regioselectivity for esterification at the primary glycerol positions ranged from 77 to 82%. Variation of glycerol in the monomer feed gave copolymers with degree of branching from 9 to 58% [109]. A similar dehydration polycondensation to produce terpolymers was conducted by using monomers, adipic acid (A2), 1,8-octanediol (B2), and trimethyrolpropane (B3) with lipase CA catalyst in bulk at 70 °C for 42 h. As an example, with a feed ratio (A2:B2:B3 = 1:0.5:0.5), a hyperbranched copolyester with 53% B3/A2 units was obtained in 80% yields having M w 14,100 (M w/M n = 5.3) [110]. CALB (N435)-catalyzed one-pot copolymerization of linoleic acid (LA), glycerol (G), and 1,18-cis-9-octanedecenedioic acid (oleic diacid, OD) yielded cross-linkable unsaturated polyesters. The reaction efficiently formed poly(OD-co-G-co-LA). For comonomer feed ratio OD:G:LA = 1:1:0.67, M n reached ~ 9500 in 8 h, trisubstituted G-units increased to 64%, and monomer was well consumed. By varying the feed ratio of LA, polymeric triglyceride-type structures were formed with controlling chain length and trisubstituted G-unit content [111]. “Sweet polyesters” were prepared from natural sugar polyols. The polyols used were C4-carbon, erythritol, C5-carbon, xylitol and ribitol, and C6-carbon, mannitol, glucitol, and galactitol. The terpolymerization was performed with Novozym 435 catalyst in bulk for the combination of a polyol, adipic acid, and 1,8-octanediol under vacuum at 90 °C. The M w value of the product polyol-polyester ranged from 1.1 × 104 (D-galactitol) to 7.3 × 104 (D-mannitol), having a branching structure. Primary alcohol groups are more reactive than the secondary ones [112].

Cutinase (EC 3.1.1.74) catalyzed a dehydration polycondensation. A glycol like 1,4-butanediol, 1,6-hexanediol, 1,8-octanediol, and 1,4-cyclohexanedimethanol (1,4-CHDM) and a diacid like adipic acid, succinic acid, suberic acid, and sebacic acid were combined for the polycondensation at 70 °C for 48 h under vacuum. In all reactions the monomers were consumed quantitatively. With fixing the adipic acid component, polyesters from 1,4-butanediol, 1,6-hexanediol, and 1,8- octanediol showed M n values of 2700, 7000, and 12000, respectively. With fixing the 1,4-CHDM component, polyesters from succinic acid, adipic acid, suberic acid, and sebacic acid possessed M n values of 900, 4000, 5000, and 19000, respectively. There was a tendency for both glycols and diacids that the higher the hydrophobicity, the higher the molecular weight of the product polyester [113]. ω-Carboxy fatty acid monomers, 1,18-cis-9-octadecenedioic, 1,22-cis-9-docosenedioic, and 1,18-cis-9,10-epoxy-octadecanedioic acids, were synthesized from oleic, erucic, and epoxy stearic acids by whole-cell biotransformations catalyzed by C. tropicalis ATCC20962. The polycondensation of the ω-carboxy fatty acid monomers and diol monomers to polyesters was carried out with using Novozym 435 catalyst, giving rise to corresponding polyesters with unsaturated and epoxidized repeat units and M w values ranging from 25000 to 57000 [114].

CALB catalyzed the synthesis of aliphatic polyesters (PEs) in the following way: from diols (1,4-butanediol and 1,8-octanediol) and diacids or their derivatives (diethyl succinate, sebacic acid, 1,12-dodecanedioic acid, and 1,14-tetradecanedioic acid), in order to produce poly(butylene succinate) (PE 4.4), poly(octylene sebacate) (PE 8.10), poly(octylene dodecanate) (PE 8.12), and poly(octylene tetradecanate) (PE 8.14). The two-stage procedures were suggested, both sustainable and in accordance with the principles of “green” polymerization. The first comprised an enzymatic prepolymerization under vacuum in diphenyl ether solvent, whereas a low-temperature post-polymerization step [solid state polymerization (SSP)] followed in order to upgrade the PEs quality. In the first synthesized prepolymers, the M n attained was from 3700 to 8000 with yields reaching even 97%. Next, SSP of PE 4.4 and PE 8.12 took place under vacuum or flowing nitrogen and lasted 10–48 h, at temperatures close to the prepolymer melting point (4 °C ~ 14 °C). The solid state finishing led to increase in the molecular weight, and it also contributed to improvement of the physical characteristics and the thermal properties [115].

With the CALB-catalyzed synthesis, linear ester oligomers and cyclic ester oligomers from succinic acid in combination with a di-anhydro hexitol (DAH) in toluene were produced. The conversion was highest for isomannide and decreases in the order isomannide (B) > isosorbide (A), isoidide (C) (Scheme 5.15). The maximum conversions under optimized conditions were in ~ 90% yields for linear oligomers [116].

Some polyester thermosets based on photocurable prepolymers composed of itaconic acid (IA) and various polyols were developed by using CALB catalyst at 90 °C or by thermal dehydration reaction at 145 °C. The reaction components were IA, a dicarboxylic acid like succinic acid and adipic acid, and a polyol like 1,4-cyclohexanedimethanol, a PEG-diol, and sorbitol. Dimethyl itaconate was an ideal monomer for enzymatic polymerization, as demonstrated by the synthesis of linear poly(1,4-cyclohexanedimethanol itaconate), poly(PEG itaconate), and poly(3-methyl-1,5-pentanediol itaconate-co-3-methyl-1,5-pentanediol adipate). Photolysis of the polyesters gave cured polyesters, whose physical properties were examined for proving the usefulness as future biomaterials [117].

By using oleic diacid having a reactive double bond and glycerol, the synthesis and structure of poly(oleic diacid-co-glycerol) were compared in the cases of catalysts, Novozym 435 (N435) and dibutyl tin oxide (DBTO). With employing N435 catalyst and an oleic diacid-to-glycerol molar ratio of 1.0:1.0, the M n values were 6000 at 6 h and 9100 at 24 h with low branching degree (% of glycerol 13%–16%). With N435 catalyst, resulting polyesters were not cross-linked. In contrast, with DBTO catalyst, an oleic diacid-to-glycerol molar ratio of 1.0:1.0 polyester M n of 1700 was obtained at 6 h, and, thereafter, a gel was formed due to cross-linking. Thus, N435’s catalyst ability to deter cross-linking due to steric hindrance enabled to give soluble and hyperbranched copolyesters [118].

Direct production of highly branched polyesters was achieved via a one-pot, enzyme-catalyzed dehydration bulk polymerization. Biobased feed components in the form of glycerol, pentaerythritol, azelaic acid, and tall oil fatty acid (TOFA) were polymerized using CALB as catalyst, and the potential for the enzymatic synthesis of alkyds was investigated. Biobased unsaturated branched polyesters (UBPs) were synthesized in a one-pot process from TOFA, glycerol, and azelaic acid as a renewable alternative to the phthalic acid or anhydride normally applied for alkyd synthesis. The UBPs were prepared at 90 °C directly from the mono- and difunctional carboxylic acids (Scheme 5.16) [119]. Pentaerythritol was also used as the alcohol component for the similar reactions to give various UBPs with more highly branched structure. The post-polymerization cross-linking of these UBPs showed their potential as binders in alkyds.

Biobased aromatic-aliphatic oligoesters were synthesized via CALB-catalyzed dehydration polycondensation reaction of aromatic dicarboxylic acids with linear diols with varying chain length. The acids used were terephthalic acid, isophthalic acid, and phthalic acid, and the glycols were HO(CH2)mOH (m = 2, 4, 6, 8, 10, and 12). The dehydration polycondensations of the acid with the glycol were very unreactive; conversions were very low [120].

As an additional type, the reaction of a linear polyanhydride, such as poly(azelaic anhydride), and a glycol, such as 1,8-octanediol, was induced with lipase CA catalyst at 30–60 °C in bulk or in toluene involving the dehydration-insertion to give a polyester with molecular weight of several thousands (Scheme 5.17). It is to be noted that this type of reaction is of dehydration polycondensation, yet this is a kind of transesterification polycondensation type as well [121].

Via Transesterification

Polycondensation normally needs activation of carboxylic acid group for better reaction results. The activation is achieved ordinarily by esterification of the acid group as shown in Scheme 5.18. In the early studies, alkyl or haloalkyl esters and later vinyl esters have been developed.

A lipase-catalyzed high enantioselective polymerization was reported in 1989; the reaction of bis(2,2,2-trichloroethyl) trans-3,4-epoxyadipate with 1,4-butanediol in anhydrous diethyl ether using porcine pancreas lipase (PPL) catalyst gave a highly optically active polyester. The feed molar ratio of the racemic diester to the diol was adjusted to 2:1, resulting in producing the (−)-polymer to show enantiomeric purity >96%. The molecular weight was estimated as 5300. From the unchanged (+)-monomer, enantiomeric purity was higher than 95% [122].

1,4-Butanediol (BD) and diethyl sebacate (DES) were copolymerized with bicyclic acetalized D-glucose derivatives (Glux) by polycondensation both in the melt at high temperature and in solution at mild temperature mediated by CALB (Fig. 5.8). Two series of random copolyesters (PBxGluxySeb and PBSebxGluxy) were prepared differing in which d-glucose derivative (Glux diol or Glux diester) was used as comonomer. Both methods were found to be effective for polymerization although significant higher molecular weights were achieved by melt polycondensation. The thermal properties of the copolyesters were largely dependent on composition and also on the functionality of the replacing Glux unit [123].

Illustration of the synthesis processes. (Reproduced with permission from [123]. Copyright 2015 American Chemical Society)

Cutinase belongs also to a hydrolase enzyme like lipase. Cutinase 1 from Thermobifida cellulosilytica (The_cut1) was found as an efficient biocatalyst in polycondensation reactions. Under thin film conditions, the covalently immobilized enzyme catalyzes the synthesis of oligoesters of dimethyl adipate with different polyols leading to higher M w (~1900) and M n (~1000), if compared to lipase B from Candida antarctica (CALB) or cutinase from Humicola insolens (HiC). Computational analysis disclosed the structural features that make The_cut1 readily accessible to substrates and optimally suited for covalent immobilization. As lipases and other cutinase enzymes, The_cut1 presents hydrophobic superficial regions around the active site. These observations and molecular dynamics simulations may allow to study a systematic comparison of functional differences between cutinases and lipases [124].

Microwave energy (MWe) effects on the lipase-catalyzed transesterification polymerization were studied. The reaction examined is the polymer synthesis from dimethyl succinate (DMS) and 1,4-butanediol (BD) to give the corresponding polyester in bulk or in solution. In terms of monomer conversion, MWe effects were not well observed: Results showed that MWe enabled the biocatalyzed synthesis of polyesters and prepolymers in a similar way to that reported using conventional heating with an oil bath [125].

Polycondensation with CALB catalyst for the synthesis of polyester prodrugs of ketoprofen was studied, giving rise to the linear polyesters with pendant ketoprofen groups based on ketoprofen glycerol ester, poly(ethylene glycol), and divinyl sebacate. The polyester had M w reaching to 7000 and could be a promising prodrug with extended pharmacological effects by delayed release of ketoprofen [126, 127].

An important phenomenon of the ring-chain equilibrium of the product was observed in the polycondensation between dimethyl succinate and 1,6-hexanediol catalyzed by lipase CA in toluene at 60 °C, reaching the ring-chain (cyclic-linear structure) equilibrium of the product polymer (Scheme 5.19) [128]. Adsorption of methanol by molecular sieves or eliminating methanol by nitrogen bubbling shifted to the thermodynamic equilibrium. Polyesters with the molecular weight about several thousands were produced from α,ω-alkylene dicarboxylic acid dialkyl esters, and regardless of the monomer structure, cyclic oligomers were formed. In the polymerization of dimethyl terephthalate and diethylene glycol catalyzed by lipase CA in toluene for producing a terephthalate polymer, the distribution of the macrocyclic species obeyed the Jacobson-Stockmayer theory, in terms of ring-chain equilibrium [129].

In the lipase-catalyzed polycondensation of dimethyl terephthalate and diethylene glycol, a cyclic dimer was selectively formed. The cyclic dimer formed (%) in the products was examined on reaction temperature, reaction time, and extent of reaction (p): at 50 °C, 4 h, 0.30 p, 2%; 8 h, 0.62 p, 24%; and 24 h, 0.99 p, 64%, and at 80 °C, 4 h, 0.95 p, 88%; 8 h, 0.98 p, 80%; and 24 h, 0.99 p, 99%. So, at 80 °C the cyclic dimer was almost quantitatively formed. It was considered that among several factors the selective cyclic dimer formation is ascribed to a driving force of a π-π stacking of the aromatic rings together with a relative flexibility of the diol segment and also of the nature of the enzyme catalytic site [130].

For the preparation of copolyesters, from dimethyl succinate and 1,4-butanediol by CALB-catalyzed transesterification polycondensation, cyclic(butylene succinate) oligomers c(BS)n were first produced. They are a mixture of dimer, trimer, and tetramers as the main components, whereas higher size cycles, c(BS)n, as well as the monomer were present in much smaller amount. Then, the ring-opening copolymerization of c(BS)n and ε-caprolactone (CL) with CALB catalyst gave the copolyester, coP(BSxCLy), with different unit composition [131]. By using chemo-enzymatic method, α,ω-dicarboxylic acid dimethyl esters having unsaturated C18, C20, C26 alkylene chains were epoxidized via chemo-enzymatical oxidation with hydrogen peroxide/methyl acetate with lipase CA catalyst. Polycondensations of these dimethyl esters with a diol by the lipase catalysis gave the linear unsaturated and epoxidized polyesters with molecular weight of 1950–3300 and melting point of 47–75 °C from a 1,3-propanediol substrate and with molecular weight of 7900–11,600 and melting point of 55–74 °C from a 1,4-butanediol substrate [132]. Novozym 435-catalyzed synthesis of poly(butylene succinate) (PBS) via polycondensation was achieved using a monophasic reaction mixture of dimethyl succinate and 1,4-butanediol in bulk and in solution. Diphenyl ether was a preferred solvent to give a higher molecular weight PBS; at 60, 70, 80, and 90 °C after 24 h, M n values of PBS were 2000, 4000, 8000, and 7000, respectively. The reaction at 95 °C after 21 h gave PBS with M n value of 38,000 [133].

In an ionic liquid, a green solvent, such as 1-butyl-3-methylimidazolium tetrafluoroborate ([bmim][BF4]), a similar polycondensation between diethyl adipate or diethyl sebacate and 1,4-butanediol gave the polyester having M n up to 1500 in good yields. Since the ionic liquid is nonvolatile, ethanol was removed under vacuum during the reaction. Lipase CA-catalyzed polycondensation of dimethyl adipate or dimethyl sebacate with 1,4-butanediol was performed in an ionic liquid such as [bmim][BF4], [bmim][PF6], and [bmim][(CF3SO2)2N] at 70 °C for 24 h to give a higher molecular weight polyester, M n reaching several thousands. Using ionic liquids as solvent involves the wide range of tunability of solvent hydrophilicity and monomer solubility [101, 134].

In a supercritical fluoroform solvent, polycondensation of bis(2,2,2-trichloroethyl) adipate with 1,4-butanediol using PPL catalyst took place, giving rise to the polymer with molecular weight of several thousands [135].

As to the structure of the alkoxy component (XO- group in Scheme 5.18), transesterifications by lipase catalyst are affected and often very slow because of the reversible nature of the reaction. To shift the equilibrium toward the product polymer more effectively, activation of esters was conducted by using a halogenated alcohol (XOH) like 2-chloroethanol, 2,2,2-trifluoroethanol, and 2,2,2-trichloroethanol. Compared with methanol or ethanol, they increased the electrophilicity of the acyl carbonyl and avoided significant alcoholysis of the products by decreasing the nucleophilicity of the leaving alkoxy group. Lipase PF-catalyzed reaction of bis(2-chloroethyl) succinate and 1,4-butanediol carried out at 37 °C gave the polyester with the highest M n of 1570 [136]. Polycondensation of bis(2,2,2-trichloroethyl) glutarate and 1,4-butanediol proceeded with PPL catalyst at room temperature in diethyl ether to produce the polyesters with molecular weight of 8200 [137]. In the PPL-catalyzed polymerization of bis(2,2,2-trifluoroethyl) glutarate with 1,4-butanediol in 1,2-dimethoxybenzene, a periodical vacuum method for removing 2,2,2-trifluoroethanol from the reaction mixture increased the molecular weight to ~ 40,000 [138]. Also, the vacuum technique was effective to shift the reaction equilibrium, thus increasing the molecular weight. The lipase-catalyzed polycondensation between bis(2,2,2-trifluoroethyl) sebacate and aliphatic diols was performed at 37 °C. The elimination of the product 2,2,2-trifluoroethanol was critical for obtaining the higher molecular weight polyesters; the polyester from 1,4-butanediol reached the highest M w of 46,400 [94].

Dynamic kinetic resolution (DKR) method was newly developed to synthesize an optically active polyester from a racemic monomer via polycondensation [139]. A mixture of racemic secondary diol, α,α’-dimethyl-1,4-benzenedimethanol, was enzymatically copolymerized with dimethyl adipate (Scheme 5.20). Because of the enantioselectivity of lipase CA, only the hydroxy groups at the (R) center preferentially reacted to form the ester bond with liberation of methanol. The reactivity ratio was estimated as (R)/(S) = ∼1 × 106. In situ racemization from the (S) to the (R) configuration by Ru catalysis allowed the polymerization to high conversion, that is, the enzymatic polymerization and the metal-catalyzed racemization occurred concurrently. The DKR polymerization was carried out for 4 days; during the reaction, molecular weight increased to 3000–4000, and the optical rotation of the reaction mixture increased from – 0.6° to 128°. In the final stage, all product polymers will be end-capped with (R) stereocenters (chain stoppers) (see also [90] and Scheme 5.11).

As mentioned above, polycondensation is, in principle, a reversible reaction. However, an irreversible polyester-formation process was disclosed; for this process, a divinyl ester was employed for the first time in 1994 as the activated acid forms in the enzyme-catalyzed polyester synthesis. A vinyl ester proceeds much faster than an alkyl ester or a haloalkyl ester to form the desired product in higher yields, where the product of vinyl alcohol tautomerizes to acetaldehyde. Thus, the lipase PF-catalyzed polycondensation of divinyl adipate and 1,4-butanediol was performed at 45 °C in diisopropyl ether for 48 h to afford a polyester with M n of 6.7 × 103 with liberating acetaldehyde (reaction (A), Scheme 5.21). While, the use of adipic acid or diethyl adipate did not produce the polymeric materials under the similar reaction conditions. As a diol, ethylene glycol, 1,6-hexanediol, and 1,10-decanediol were also reacted to give the corresponding polyester with molecular weight of several thousands [140]. The similar polycondensation of divinyl adipate and 1,4-butanediol with lipase PC catalyst produced the polyester with M n of 2.1 × 104 [141]. With varying the molar ratio of the divinyl ester and the glycol, a macromonomer having the glycol, the dicarboxylic acids, or the acid-alcohol end structure are expected to be produced.

Novozym 435-catalyzed transesterification polymerization from divinyl adipate and unprotected glycerol produced poly(glycerol adipate) (PGA) with molar mass (12 × 103), having a pendant hydroxyl group which imparts a hydrophilic character to this water-insoluble polymer (reaction (B), Scheme 5.21). Using the lipase as catalyst suppressed cross-linking at the pendant glyceryl hydroxyl through steric hindrance at the active site, thus producing polymers with low degrees of branching (5–30%) because of the regioselective reaction, and removes the need for any pre- or post-polymerization protection/deprotection reactions. Due to the ability of the synthetic route to produce a controlled structure, the generated PGA may emerge as a useful biodegradable polymer platform for various applications [142] (see also Scheme 5.15). It was argued that during the lipase-catalyzed polymerization of divinyl esters and glycols, there was a competition between the enzymatic transesterification and hydrolysis of the vinyl end group, and hence, the polymer growth might be disturbed with this side reaction [143].

A batch-stirred reactor was developed to minimize temperature and mass-transfer effects. Using the reactor, the polycondensation became very fast; within 1 h at 60 °C, poly(1,4-butylene adipate) with the molecular weight of 2.3 × 104 was obtained [144]. The CALB-catalyzed polycondensation produced aliphatic polyesters having pendant azide groups. The grafting reaction to the N3-functional polyester was carried out quantitatively at room temperature using copper-catalyzed azide-alkyne cycloaddition (CuAAC, “click” reaction) with monoalkyne-functional poly(ethylene oxide) (alkyne-PEO, M n = 750). Both enzymatic polycondensation and “click” reaction were performed in sequential one-pot reaction. The graft copolymer was surface-active and self-assembled in water [145].

A combinatorial approach was applied for biocatalytic production of polyesters. A library of polyesters was synthesized in 96 deep-well plates from a combination of divinyl esters and glycols with lipases of different origin. In the screening experiments, lipase CA was the most active biocatalyst for the polyester production. As an acyl acceptor, 2,2,2-trifluoroethyl esters and vinyl esters were examined, and it was stated that the former produced the polymer of higher molecular weight [146].

Supercritical carbon dioxide (scCO2) was shown to be a good solvent for the lipase-catalyzed polycondensation of divinyl adipate and 1,4-butanediol. Quantitative consumption of both monomers was achieved to give the polyester with M n of 3.9 × 103 [147] (see also [135] for supercritical fluids).

Aromatic diacid divinyl esters produced aromatic polyesters via lipase CA-catalyzed polycodensation. Divinyl esters of isophthalic acid, terephthalic acid, and p-phenylene diacetic acid were polymerized with various glycols to give aromatic polyesters with the highest M n of 7200 [148]. Enzymatic polycondensation of divinyl esters with aromatic diols also afforded the aromatic polyesters [149]. Biobased aromatic-aliphatic oligoesters were synthesized via CALB-catalyzed transesterification polycondensations of aromatic dicarboxylic acid methyl esters with linear diols with varying chain length. The acids used were terephthalic acid, isophthalic acid, and phthalic acid, and the glycols were HO(CH2)mOH (m = 2, 4, 6, 8, 10, and 12). In contrast to the dehydration polycondensation, the transesterification gave better results; the highest conversions of dimethyl isophthalate with 1,4-butanediol and 1,10-decanediol (m = 4 and 10) were 88 and 87%, respectively, M w being ~ 1500 [120].

Novozym 435-catalyzed polycondensation of ketone-containing diesters and diacids combined with di(ethylene glycol) gave biodegradable and amorphous polyketoesters with M n values of up to 10.1 × 103. By including ketone groups in the repeat unit, facile post-polymerization modifications were possible by reaction with oxyamine-tethered ligands through the formation of an oxime linkage. Upon reaction with molecules containing oxyamines, these polymers can easily have a diverse set of side chains appended without co-reagents or catalysts. The chemoselective oxime-forming coupling strategy is compatible with physiological conditions and can be done in the presence of a wide range of functional groups and biomolecules such as proteins and nucleic acids [150].

Silicone-containing polyesters were produced with lipase catalyst to give the polymers between 74 and 95% yields via polytransesterification. A lipase from C. rugosa was only successful in performing esterifications using carboxy-modified silicones that possessed alkyl chains greater than three methylene units between the carbonyl and the dimethylsiloxy groups [151].

Renewable green monomers were polymerized by using CALB as the biocatalyst. Commercially available succinate, itaconate, and 1,4-butanediol were enzymatically copolymerized in solution via a two-stage method. The chemical structures of the obtained products, poly(butylene succinate) (PBS) and poly(butylene succinate-co-itaconate) (PBSI) having reactive vinylene group, were confirmed. Values of M n reached to ~6500 in 90% yields [152]. Diesters and diols were converted into aliphatic polyesters and polycarbonates by lipase Candida sp. 99–125 catalysis, with β-cyclodextrin acting as supporting architecture without using organic solvents. The polytransesterification was a much greener process, being solvent-free and metal residues-free. The lipase showed a high catalytic activity for bulk polymerization of diesters and diols with various numbers of methylene groups in their chains. β-Cyclodextrin encircled the linear polymer chain and maintained the chain in a proper configuration to avoid its coagulation. Lipase initiated the polymerization and β-cyclodextrin threaded onto the polymer chain to control the structure for producing high molecular weight polyesters up to 62,100 obtained at 70 °C. The corresponding polyesters showed an excellent thermal stability till 350 °C [153].

The enzymatic synthesis of poly(ethylene glutarate) (PEG) was achieved from diethyl glutarate and ethylene glycol diacetate without solvent (reaction (A), Scheme 5.22). The reactions were catalyzed by CALB at 40 °C, for 18 h in water bath with mechanical stirring or 1 h in ultrasonic bath followed by 6 h in vacuum. The application of ultrasound intensified the polyesterification reaction with reducing the reaction time from 24 h to 7 h. The highest degree of polymerization (DP) was 31 with a monomer conversion of 97%. The ultrasound treatment demonstrated to be an effective green approach to intensify the polyesterification enhancement and brought about a high DP [154]. Ultrasound-assisted CALB-catalyzed synthesis of poly(ethylene glutarate) (PEG) (reaction (A)), poly(ethylene malonate) (PEM), and poly(ethylene phthalate) (PEP) was conducted in solvent-free conditions. The synthesis of these polyesters was based on the ester-ester exchange reaction between ethylene glycol diacetate and diethyl glutarate, dibenzyl malonate, as well as di-n-octyl phthalate to produce PEG, PEM, and PEP, respectively. The effect of ultrasound indicated to improve the synthesis of all polyesters. Ultrasound, as a green solvent-free technology, showed high potentiality to strengthen the polyester synthesis [155].

It is interesting to note that the transesterification frequently occurs not only between monomers (reaction (A)) but also between polymers during the polymerization; in fact, from a mixture of two homo-polyesters, a copolyester was obtained by lipase catalysis (reaction (B), Scheme 5.22). For example, a mixture of poly(ε-caprolactone) and poly(1,4-butylene sebacate) (M w = 1.1 × 104) was subjected to react at 90 °C in toluene for 48 h by lipase CA catalyst to give a copolyester with M w = 3.0 × 104 [156].

In the enzymatic transesterification synthesis, various reaction parameters were examined for preparing fully biobased poly(3-hydroxybutyrate-co-butylene succinate) (poly(HB-co-BS)) copolyesters. In CALB-catalyzed reactions, copolyesters were produced in solution, via a one-step or a two-step process from 1,4-butanediol, diethyl succinate, and the synthesized telechelic hydroxylated poly(3-hydroxybutyrate) oligomers (PHB-diol) (Fig. 5.9). The influences of the ester/hydroxyl functionality ratio, catalyst amount, PHB-diol oligomer chain length, hydroxybutyrate (HB) and butylene succinate (BS) contents, and the nature of the solvent were investigated. The two-step process allowed the synthesis of copolyesters of M n (up to 18,000), compared with the one-step process (M n ∼ 8000). The highest M n was obtained with diphenyl ether as solvent, compared with dibenzyl ether or anisole. During the two-step process, the transesterification rate between the HB and BS segments was influenced by the factors of the catalyst amount, molar mass of the PHB-diol oligomer, the solvent, and the HB/BS ratio. Tendencies toward block or random macromolecular architectures were also observed. Immobilized CALB-catalyzed copolyesters were thermally stable up to 200 °C. The crystalline structure of the poly(HB-co-BS) copolyesters depended on the HB/BS ratio and the average sequence length of the segments. The crystalline content, T m and T c decreased with increasing HB content and the randomness of the copolymer structure [157].