Abstract

Leather tanneries sludge is categorized under hazardous waste owing to its properties comprising of organic content, chloride, heavy metals, and pathogenic occurrence. The main objective of the present study was to assess the sustainable vermiconversion of tannery sludge in its raw state employing Eisenia fetida over eight-week trial. No mortality with positive growth of 10–30% was attained in all the reactors. Total carbon, pH, and C:N ratio decreased from initial in the range of 12–23.5, 3–17, and 31–55%, respectively, in the final products. Electrical conductivity, salinity, and total nitrogen showed a substantial increase from initial in all trials. A significant decrease of 75–99.5% was attained in the pathogenic load of both total and fecal coliforms from initial in all the reactors. The vermicomposting process has the potential to stabilize and convert hazardous industrial tannery sludge into quality organic manure of agronomic importance without any adverse effect on the earthworms.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The leather processing industries or tanning industries are among the top ten foreign exchange earners of the country [1]. Nevertheless, tanning industry is one of the most polluting industries operating mostly in low- and middle-income countries creating heavily polluted industrial zones. India, a developing country, is the second largest producer of heavy leather in the world with production of 700,000 tons of wet salted hides and skin [2]. There are about 42,000 units consisting of around 75% small-sized, 20% medium-sized, and 5% large-sized units clustered mostly (88%) in states like Uttar Pradesh (UP), West Bengal (WB), and Tamil Nadu (TN) [3]. Moreover, the predominant tanning method followed worldwide involves the use of chromium salts (Cr III) as a tanning agent. Unfortunately, only a fraction (30–50%) of chromium salts is utilized in the tanning process and the rest is discharged along with the wastewater [4, 5]. Additionally, tanneries generate a huge amount of wastewater in the tune of 1200–1300 m3/day as well as about 500 kg/tonne raw hide of tannery sludge produced during tannery wastewater treatment in common effluent treatment plants (CETPs) [4, 6]. Tannery wastes, both wastewater and sludge, produced are categorized as hazardous waste owing to their characteristics especially high organic and heavy metals (Cr III) content [5, 7, 8]. Further, these wastes are discharged and/or dumped untreated or partially treated into flowing surface water or on lands causing irreparable damage to ecosystems with increased health risks. The tannery sludge exhibits variation in constituents present but normally possesses high water content, oil, grease, lime, chromium (Cr), residuary sulfide, chloride, organic and inorganic contaminants as well as pathogens mostly of fecal origin [6, 7, 9,10,11].

Numerous potential solutions of tannery sludge treatment, viz. pyrolysis, solidification, incineration, anaerobic digestion, or use as inert material in bricks, have been adopted [4, 5, 7, 12]. However, gaseous emissions, operational difficulties, toxic residue releases, high use of chemicals, and high operation costs limit their application. Consequently, scientific interest has been drawn on the environmentally safe treatment of the tannery sludge such as composting and vermicomposting processes. Composting is the thermophilic biological decomposition process where microorganisms act on the organic matter in aerobic conditions to convert it into simpler forms [8, 9], while vermicomposting is a mesophilic waste bio-oxidation and stabilization process where earthworms and microorganisms jointly process wastes under aerobic condition to produce chemically stable and nutrient-rich biofertilizer (vermicompost) [6]. However, vermicomposting is a better option as it results in a homogeneous product (vermicompost) with better quality in terms of desirable aesthetics, reduced levels of pathogenic microorganisms, and more available plant nutrients [6, 8, 9]. Moreover, the time required for complete stabilization and sanitization of waste is less. The aim of the present study is to evaluate the possibility and feasibility of employing vermicomposting technique for treatment and management of tannery sludge for its end use for agronomic purposes. In this context, the primary clarified tannery sludge obtained from CETP is mixed with partially dried cow dung in varying proportion, viz. 0:100, 10:90, 25:75, 40:60, and 50:50, on wet weight basis in order to make it palatable to earthworm Eisenia fetida. Also, various physicochemical and microbiological parameters and biomass gain were taken as indicators of the suitability of the feed mixtures for earthworms. The main objective of the present study was to assess the sustainable vermiconversion of primary clarified tannery sludge and the role of E. fetida in pathogen reduction over eight-week trial.

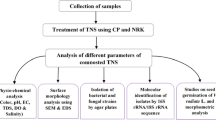

2 Materials and Methods

2.1 Tannery Sludge

Primary clarified tannery sludge (PCTS) was obtained as and when required from a CETP based on activated sludge process (ASP) at Banthar, Kanpur, Uttar Pradesh, India. Prior to experimentation, PCTS was characterized for various physicochemical and microbiological parameters.

2.2 Bulking Agent

In the present study, cow dung (CD) was used as a bulking agent to take care of high water content in tannery sludge before vermiconversion. Raw CD was necessitated to partially air-dry in sun for one week for expunging obnoxious gases and heat to prevent earthworm mortality. Prior to use as a bulking material, the partially dried CD was also characterized for various physicochemical and microbiological parameters.

2.3 Eisenia fetida (Earthworms)

Epigeic earthworm species E. fetida was used in the present study. The earthworm culture was procured from Regional Agricultural University (RAU), Pusa, Bihar, India. The earthworms were cultured and developed in small-scale plastic reactors in the laboratory feeding on the partially dried CD. Mature (clitellated) earthworms from the laboratory stock culture were subsequently used for the purpose of this study.

2.4 Experimental Methodology

2.4.1 Physicochemical and Microbiological Analysis of Tannery Sludge, Bulking Agent, and Vermicompost

The PCTS partially dried CD as bulking agent and vermicompost were characterized for various physicochemical and microbiological parameters according to the procedures mentioned in the Standard Methods for Examination of Water and Wastewater and Test Methods for the Examination of Composting and Compost [13, 14]. The samples were analyzed for various physicochemical parameters like pH, electrical conductivity (EC), salinity (SAL), moisture content (MC), total solids (TS), volatile solids (VS), fixed solids (FS), total carbon (C) and total nitrogen (N) and microbiological parameters like total coliforms (TC) and fecal coliforms (FC). The pH, EC, and SAL were determined by preparing a suspension of the sample using distilled water in the ratio of 1:10 (w/v) and then stirred at 230 rpm for 30 min. The MC and TS contents were determined by drying the samples at 70 ± 2 °C for 24–72 h using hot air oven. The VS and FS content were determined by muffling the known weight of samples in a muffle furnace at 550 ± 5 °C for 2 h. Further, the samples were dried in oven at 60 ± 2 °C for 24–72 h and then ground using mortar and pestle for homogeneity and sieved through 0.2 mm sieve prior to estimation of C and N using elemental CHNS Analyzer. The microbiological parameters like TC and FC were performed by the most probable number (MPN) test mentioned in the USDA and USCC [13], and APHA et al., [14]. Most of the analyses were performed immediately after collection and/or preparation of the samples. The values reported for the parameters are the mean of the triplicate on dry weight basis.

2.4.2 Experimental Design for Vermicomposting of Tannery Sludge

Vermicomposting of tannery sludge was performed in PVC-made reactors under controlled environmental conditions. The circular reactors (diameter: 180 mm and depth: 100 mm), with 0.025 m2 of exposed top surface area, were covered using perforated lids to provide proper air ventilation and restrict the movement of earthworms out of the reactors. The reactors were filled with a mixture of tannery sludge and cow dung in varying proportion, viz. 0:100 (T0), 10:90 (T1), 25:75 (T3), 40:60 (T4), and 50:50 (T5) on wet weight basis in triplicates along with control. The total weight of each reactor was 1 kg, and the reactors were kept inside the wooden vermichamber. Before the introduction of earthworms, aerobic preprocessing of the reaction mixture was performed for 13 days [15]. Earthworm (E. fetida) was introduced into each of the reactors at a stocking density of 1.5 kg/m2. All replicates were fed in a single batch with enough feeding material for the entire eight-week duration of vermicomposting. The moisture level was maintained throughout the study at 60–70% by periodic sprinkling of tap water. All the reactors were manually examined for survival and growth of earthworms at the end of the vermicomposting process. The gain in biomass of earthworms was estimated on the basis of total weight gain and the number of earthworms present in the reactor. The values were determined as the live weight of earthworms upon hand sorting from the reactors. The vermicompost was analyzed for various physicochemical and microbiological parameters.

3 Results and Discussion

3.1 Physicochemical and Microbiological Characterization of Tannery Sludge and Cow Dung

The properties of tannery sludge usually show a wide variation owing to the type of the raw material processed, i.e., hides/skins sourced from various animals and the type of the target finished leather product. In addition to these two major factors, other secondary factors, viz. type of tanning process, tanning agent, process water requirement, and type of the tanning unit whether small-, medium-, or large-sized unit, affect the properties of tannery sludge. Depending on these factors, each tanning unit utilizes a wide range of raw materials including active tanning agent, salts, and other chemicals affecting the properties of tannery sludge. In the present study, the PCTS as collected from the CETPs was observed to be dark gray in color and alkaline in nature with more than 90% water content and significant presence of both total and fecal coliforms. The physicochemical and microbiological characteristics of the PCTS are reported in Table 1.

3.2 Physicochemical and Microbiological Changes During Vermicomposting of Tannery Sludge

During vermicomposting of tannery sludge mixed in varying proportion with cow dung, significant changes in physicochemical and microbiological parameters of the vermicomposted material were observed. It is evident from the present study that tannery sludge in its raw state is harmful to E. fetida earthworms. However, treatment (T5) containing 50% of the tannery sludge on wet weight basis is acceptable to earthworms and the vermicompost produced showed a significant difference for all physicochemical and microbiological parameters. The changes in different physicochemical and microbiological parameters during vermicomposting employing E. fetida have been discussed in detail in the subsequent sections.

3.2.1 pH

A slight decrease in pH of vermicomposted material relative to the initial substrate mixture is attained in all treatments. The maximum reduction of around 17% was in reactors T1, while reactors T5 showed the lowest reduction in pH of about 3%. The decrease in pH (3–17%) is positively correlated with the increasing concentration of tannery sludge (0–50%) as shown in Fig. 1. The decreasing trend in pH during vermicomposting is similar to the findings of other researchers [16,17,18]. The percentage decrease in pH of the final vermicompost is in the order of T2 > T1 > T3 > T4 > T5. The formation of organic acids and ultimately CO2 by microbial action due to the decomposition and mineralization of organic matter content (fulvic and humic acids) is responsible for the decrease in pH.

3.2.2 Electrical Conductivity (EC) and Salinity (SAL)

Similar to several other studies on the vermicomposting process, a significant increase in EC of the vermicompost was observed in all treatments as compared to the initial substrate [1, 6, 16,17,18]. The initial characteristics of the substrate showed highest EC in T5 (1.682 mS/cm), and it decreased with a decrease in tannery sludge content in the order of T5 > T4 > T3 > T2 > T1. However, the increase in EC from initial was in the range of 21–42% for vermicompost in all the treatments. The EC of the vermicompost from different reactors is analyzed after every 10 days as depicted in Fig. 2. The increase is related to the release of different ions or mineral salts in available forms like ammonium, phosphate, and potassium during organic matter stabilization [16,17,18]. The maximum percentage increase was in treatment T1 (42%), and it decreased with increasing sludge content, suggesting that EC is negatively correlated to the sludge content.

The EC also reflects the salinity of the vermicompost material, and similar trend of salinity with respect to EC is observed in all treatments. A marked increase in the range of 15–44% from initial values was observed in all treatments. Salinity is directly related to the content of total dissolved solids in the substrate, and it increases with the decomposition and release of mineral ions from the substrate, while EC considers only the conductive entities. The increase in salinity with respect to all the treatments during 60 days vermicomposting trials is shown in Fig. 3.

3.2.3 Volatile Solids (VS) and Fixed Solids (FS)

A significant decrease in the VS content and a proportional increase in the FS content indicate decomposition and mineralization of substrate material. The percentage loss in the VS content of the vermicompost was in the range of 19.5–25%. The maximum loss was observed in T5 treatment in the order of T5 > T2 > T4 > T3 > T1. Further, the proportional percentage increase in the content of FS was attained in the range of 21–37% in all trials.

3.2.4 Total Carbon (C) and Total Nitrogen (N) Content

Significant reduction in C of vermicompost in all treatments was obtained in comparison with the initial substrate content (Fig. 4). The loss in C content during vermicomposting was in the range of 12–23.5%. The maximum loss was observed in treatment T2, and it followed in a particular order of T2 > T1 > T3 > T4 > T5. Further, a proportional increase in N content was observed in all the reactors from the initial values (Fig. 4). The increase in N was in the range of 16–42% in the order of T2 > T3 > T4 > T5 > T1. The observed results in the present study are supported by other researchers focusing on the vermicomposting of municipal and industrial wastes [1, 6, 16,17,18]. The decrease in C content and a proportional increase in N content are due to microbial metabolism involved in decomposition and mineralization of organic matter content, leading to the formation of CO2 and ammonium, nitrate and nitrites as well as earthworm N excrements [16].

The decrease in C with a simultaneous increase in N content leads to an overall decrease in C:N ratio of the vermicomposted material. The percentage decrease in C:N ratio of the vermicompost obtained from all the reactors was in the range of 31–55% and in the order of T2 > T3 > T4 > T5 > T1. The decreasing trend of C:N ratio during vermicomposting is in agreement with the studies of other researchers [1, 6, 16,17,18]. Further, the C:N ratio below 25 shows an advanced degree of stabilization and acceptable maturity [16]. Moreover, the C:N ratio in the final vermicompost is in the range of 17.4–22.6 in the order of T1 < T2 < T3 < T4 < T5.

3.2.5 Microbiological Parameters

The microbiological parameters in terms of total and fecal coliforms content in the vermicompost are assessed in order to determine the role of earthworms in pathogen reduction during vermicomposting. It is evident from the present study that vermicomposting caused a significant reduction in the pathogenic load of the initial substrate. Significant reduction of around 75–99.5% in the pathogenic content of both total and fecal coliforms was obtained in all trials. The reduction of pathogens during vermicomposting can be attributed to various earthworm actions like intestinal enzymatic action, secretion of coelomic fluids having antimicrobial properties, and grazing actions [16].

3.3 Growth and Fecundity of Earthworm E. fetid During Vermicomposting of Tannery Sludge

No mortality was observed in any reactor during the entire 60-day vermicomposting of tannery sludge as aerobic preprocessing of 13 days was done prior to vermicomposting. Contrary to the findings of Vig et al. [6], the final biomass gain in earthworms was found to increase by around 10–30% as compared to the initial biomass in all trials. Further, the biomass gain was proportional to the increasing sludge concentration but up to a certain limit of 25% tannery sludge, beyond which the percentage increase was lesser as shown in Fig. 5.

4 Conclusions

It is evident from the present study that tannery sludge (100%) is toxic to earthworms and therefore it is mixed with other organic waste, i.e., cow dung, to enhance the nutrient contents. The obtained results showed that vermicompost produced by E. fetida possesses higher electrical conductivity and nitrogen content with lower C:N ratio. Also, there was a significant reduction in carbon content, suggesting that vermicomposting is effective in the transformation of the organic content of toxic tannery sludge. The decrease in pH with a simultaneous increase in electrical conductivity and salinity contribute to the point that decomposition and mineralization have occurred during 60 days vermicomposting of primary clarified tannery sludge in its crude form employing E. fetida. Further, an effective reduction in the pathogenic content of both total and fecal coliforms was obtained during 8-week vermicomposting process in all trials. Therefore, it is successfully shown in the present study that vermicomposting process is effective in both transformation and pathogen reduction, thereby converting a toxic hazardous industrial sludge into a valuable product of agronomic importance.

References

Nunes, R.R., Bontempi, R.M., Mendonça, G., Galetti, G., Rezende, M.O.: Vermicomposting as an advanced biological treatment for industrial waste from the leather industry. J. Environ. Sci. Health, Part B 51(5), 271–277 (2016)

Gupta, A.K., Sinha, S.: Phytoextraction capacity of the Chenopodiumalbum L: grown on soil amended with tannery sludge. Biores. Technol. 98, 442–446 (2007)

Gupta, S., Sharma, M., Singh, U.N.: Tannery clusters in India and waste management practices in tannery intensive states–inventory and status. J. Environ. Sci. Toxicol. Food Technol 8, 2319–2399 (2014)

Montañés, M.T., Sánchez-Tovar, R., Roux, M.S.: The effectiveness of the stabilization/solidification process on the leachability and toxicity of the tannery sludge chromium. J. Environ. Manage. 143, 71–79 (2014)

Kavouras, P., Pantazopoulou, E., Varitis, S., Vourlias, G., Chrissafis, K., Dimitrakopulos, G.P., Mitrakas, M., Zouboulis, A.I., Karakostas, Th, Xenidis, A.: Incineration of tannery sludge under oxic and anoxic conditions: study of chromium speciation. J. Haz. Mater. 283, 672–679 (2015)

Vig, A.P., Singh, J., Wani, S.H., Singh, D.S.: Vermicomposting of tannery sludge mixed with cattle dung into valuable manure using earthworm Eisenia fetida (Savigny). Biores. Technol. 102(17), 7941–7945 (2011)

Basegio, T., Berutti, F., Bernardes, A., Bergmann, C.P.: Environmental and technical aspects of the utilization of tannery sludge as a raw material for clay products. J. Eur. Ceram. Soc. 22, 2251–2259 (2002)

Haroun, M., Idris, A., Omar, S.R.S.: Physico-chemical characterization of compost of the industrial tannery sludge. J. Eng. Sci. Technol. 2(1), 81–94 (2007)

Haroun, M., Idris, A., Omar, S.: Analysis of heavy metals during composting of the tannery sludge using physicochemical and spectroscopic techniques. J. Hazard. Mater. 165(1–3), 111–119 (2009)

Contreras-Ramos, S.M., Alvarez-Bernal, D., Trujillo-Tapia, N., Dendooven, L.: Composting of tannery effluent with cow manure and wheat straw. Biores. Technol. 94(2), 223–228 (2004)

Kilic, E., Font, J., Puig, R., Çolak, S., Çelik, D.: Chromium recovery from tannery sludge with saponin and oxidative remediation. J. Hazard. Mater. 185, 456–462 (2011)

Yılmaz, O., Kantarli, I.C., Yuksel, M., Saglam, M., Yanik, J.: Conversion of leather wastes to useful products. Resour. Conserv. Recycl. 49, 436–448 (2007)

U.S.D.A., U.S.C.C.: Test Methods for the Examination of Composting and Compost. United States Department of Agriculture, United States Composting Council, Washington, DC (2002)

A.P.H.A., A.W.W.A., W.E.F.: Standard Methods for the Examination of Water and Wastewater, vol. 22 (2012)

Swati, A., Hait, S.: Four-pronged pre-processing approaches for maximum utilization of raw tannery sludge by earthworms. In: International Conference on Water, Environment, Energy and Society (ICWEES-2016) (2016)

Hait, S., Tare, V.: Optimizing vermistabilization of waste activated sludge using vermicompost as bulking material. Waste Manag. 31(3), 502–511 (2011)

Hait, S., Tare, V.: Vermistabilization of primary sewage sludge. Biores. Technol. 102(3), 2812–2820 (2011)

Hait, S., Tare, V.: Transformation and availability of nutrients and heavy metals during integrated composting-vermicomposting of sewage sludges. Ecotox. Environ. Saf. 79, 214–224 (2012)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Choudhary, R.K., Swati, A., Hait, S. (2019). Vermicomposting of Primary Clarified Tannery Sludge Employing Eisenia fetida. In: Rathinasamy, M., Chandramouli, S., Phanindra, K., Mahesh, U. (eds) Water Resources and Environmental Engineering II. Springer, Singapore. https://doi.org/10.1007/978-981-13-2038-5_13

Download citation

DOI: https://doi.org/10.1007/978-981-13-2038-5_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-2037-8

Online ISBN: 978-981-13-2038-5

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)