Abstract

Food packaging plays a vital role in food processing and preservation. The growing concern of consumers in food safety and quality has imparted a great deal of attention in understanding the interaction of food and packaging materials, particularly polymers. This chapter presents a detailed note on the prospective health effects of polymeric materials and their interaction phenomena including migration (from package to product), permeation (from environment through package) and sorption (from product to package), highlighting appropriate illustrations from recent research works to provide an in-depth understanding of the subject. Factors such as physicochemical characteristics of the food, package and additives used in the package, as well as environmental and storage factors like temperature and duration, and their implications are presented. The chapter also describes the mechanism and mathematical models involved in interaction phenomena. Finally, food simulants for testing and testing methods, along with legislations to be adopted, are also discussed.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Packaging forms an integral part of food processing and handling sector. According to Coles (2003), ‘Packaging is defined as a means of safely and cost effectively delivering products to the consumer in accordance with the marketing strategy of the organisation’. The basic functions of packaging are containment, protection, presentation, market promotion, preservation, communication and so on (Coles 2003). In general, the packaging material used can be primary, secondary, tertiary and quaternary based on the nearness level to the packaged product (Robertson 2013). Primary packaging is of prime concern as it is in direct contact with the food material. Paper, glass, metals and natural substances are used as primary packaging material since long time. Polymerization of monomers like ethylene, propylene, vinyl alcohol, etc. has made the packaging sector versatile and flexible. Addition of some external agents like additives, plasticizers and colouring agents is done to improve the property of polymers, and polymers with those external agents are called plastics. However, these external agents on contact with the food material can have negative impact on the food as well as the health of the consumer.

The packaging sector is focussed more as the processed food market is growing tremendously. Also, the need and design of packaging material change with change in consumer behaviour. Packaging materials like nanocomposite, bio-based polymers are being explored mainly because of the negative impact of polymer-based packaging material on the environment. Biopolymers are biodegradable polymeric materials that consist of covalently bonded monomeric units. Under suitable conditions, these polymers are degraded by the action of naturally occurring microorganisms leaving no toxic residues into the environment. Biopolymers can be obtained from renewable sources or petroleum products (Vieira et al. 2011; Othman 2014). And, polymer composites are composed of a continuous phase (polymer matrix) and a dispersed phase (reinforced material) (Youssef 2013). Polymer nanocomposite is a composite material in which at least one dimension of the material (usually reinforcements/ fillers) is of nanoscale size, but the final composite material can be either of micro- or macro-scale (Azeredo et al. 2011). Despite nanocomposites being able to protect the packaged food and extend its shelf life, the possibility of migration of nanosized materials into food possesses a serious threat (Song et al. 2011). Thus, the knowledge on interaction and the factors affecting these phenomena are very essential.

2 Interaction

Interaction is a major concern mainly in polymer-based packaging materials. Nearly 42% of the polymers produced are used as packaging materials, and about half of them are used for food packaging applications (Silvestre et al. 2011; Rhim et al. 2013). Polymers are preferred for food packaging applications due to their flexibility, strength, stability, low density, ease of processing, reduced cost and controlled hydrophobicity. But packing of food product in polymers can induce undesirable quality changes in packed food. For instance, degree of browning and ascorbic acid degradation of orange and grapefruit juice was found to be high when packed in polyethylene-laminated cartons than in glass (Mannheim et al. 1987). Interaction is the mass transfer phenomena involving migration (from packaging material to product), permeation (from the outside environment to food contact environment through packaging material) and sorption (adsorption/absorption of food components on the packaging material), either in combination or individually. Interaction of packaging material with the food and the environment plays a major role on quality of the product as well as integrity of the package. These effects have impact on market value, goodwill of the manufacturer, sensory attributes of products and health effect of consumers. Moreover, strict legislations are set for ‘zero tolerance’ of carcinogenic migrants (Gilbert et al. 1980), and also the compounds that migrate into food are considered as indirect food additive by FDA. Hence, knowledge on factors affecting interaction phenomena and its effect are of high importance. In this section, interaction phenomena like migration, permeation and sorption are discussed in detail.

2.1 Migration

Migration mainly denotes diffusion of chemical compounds or polymer residues from the food contact material to the product. The process of migration can be described in four steps: diffusion of substances through polymers, desorption from the surface of polymers, sorption at polymer-food interface and desorption into the food material (Ferrara et al. 2001). According to European and American regulations, migration can be global or specific. The former denotes the overall migrants migrated from the packaging material into the food, whereas the latter denotes the specific substance migrated (Abbes et al. 2015). In general, migration not only happens during packaging but also has the possibility of occurrence during other operations like handling, processing, storage, transportation, preparation and consumption, where the food comes in direct contact with various materials (Castle 2007). Goodson et al. (2004) studied the migration of bisphenol A from the can coating by considering various parameters like type of food (soup, minced beef, evaporated milk, carrot and a food simulant (10% ethanol)), can damage, storage conditions (5 °C (chilled) and 20 °C (ambient) for 9 months and also 40 °C (accelerated) for 3 months). The study concluded that maximum amount (80–100%) of BPA migrated during processing from can coating. And, further migration did not occur in all the kinds of foods stored for the study period. However, migration of BPA (68.3 ± 9 μg kg−1) into food simulant was comparatively higher than that of other foods tested (soup, 45.7 ± 5 μg kg−1; minced beef, 53.8 ± 7.6 μg kg−1; evaporated milk, 49.8 ± 10.9 μg kg−1; carrot, 47.2 ± 5.1 μg kg−1). Moreover, damage to the can showed little/no effect on migration of BPA (Goodson et al. 2004).

Migration of compounds from packaging material in small quantities possesses effect on sensory properties of the food, whereas migration in large scale can impose health effects (Risch and Hotchkiss 1991). Effects on sensory properties include mainly colour, taints and off flavours. This can be detected by trained panellist or by the use of instruments like gas chromatography-mass spectrometry (GC-MS) and electronic nose (Tice 1996). Compounds like vinyl polymer monomer used in polyvinyl chloride (PVC) synthesis, monomers of styrene and isocyanates in polyurethane have toxic effects. The level of migration is influenced by many factors such as amount as well as type of additives and residual monomers present, nature of the food, surrounding environment and so on. Table 1 explains some of the potential migrants and their migration at given condition. Several researchers have identified the presence of migrated compounds in food product. For instance, a European survey on the migration of epoxidized soybean oil (ESBO) from PVC gaskets into baby food found that out of 248 samples, 95 samples contained ESBO in the range of 1.5–135.2 mg kg−1. Among these, 14.9% contained ESBO above 31.5 mg kg−1 of food, the level calculated on the basis of 1 mg kg−1 of body weight (tolerable daily intake recommended by Scientific Committee on Food) (Hammarling et al. 1998; Fantoni and Simoneau 2003). Similarly, Simoneau et al. (2012) conducted a study on migration of chemicals from plastic baby bottles and found that under hot-fill conditions of 2 h at 70 °C, diisobutyl phthalate and dibutyl phthalate migration levels were from 50 to 150 μg kg−1, whereas diethylhexyl phthalate migration level was from 25 to 50 μg kg−1 (Simoneau et al. 2012).

Migration can be advantageous in case of active and intelligent packaging (Brown and Williams 2003). For instance, migration of antioxidants, like carvacrol, thymol, astaxanthin, etc., from polymers was reported to enhance the shelf life of packed food products (Colín-Chávez et al. 2013; Ramos et al. 2014). Similarly, migration of antimicrobial agents from polymers was able to protect the food products from microbial contamination and deterioration (Duran et al. 2016).

In general, migration occurs due to difference in concentration of the compounds present in the polymer. Due to high concentration difference, diffusion of compounds from the polymers occurs. Fick’s law of diffusion governs the mass diffusion. It is analogous to Fourier’s law of heat transfer by conduction. Fick’s first law of diffusion states that at steady state, rate of movement of the diffusing compound through a unit cross-sectional area is proportional to the concentration gradient normal to the surface.

Mathematically,

Steady state flux along x:

where:

-

C p is the concentration of migrating compound present in the polymer.

-

D is diffusion coefficient.

Negative sign indicates that the diffusion process occurs in the direction opposite to that of concentration gradient (Bhunia et al. 2013; Abbes et al. 2015). Practically, diffusion coefficient is considered to be constant, and in polymers, diffusion coefficient depends on concentration of the compounds, temperature, glass transition temperature, polymer morphology, melting temperature and molecular mass of the migrant (Ferrara et al. 2001).

In general, the food and package interaction occurs in unsteady state condition (Bhunia et al. 2013). Fick’s second law is based on unsteady state of diffusion. Mathematically, change in concentration C p with respect to time can be written as:

Considering diffusion coefficient to be constant, (2) becomes:

Similar to diffusion coefficient, partition coefficient (k p) plays a vital role in polymer-food interface:

where:

-

C S denotes the concentration of migrating compound present in the food.

Partition coefficient values vary with the polarity of the food material that is in contact with the polymer. For fatty foods, k p is very low (≤1), whereas for pure water, k p is very high (≫1000) (Piringer 2007). For practical applications, similar to diffusion coefficient, partition coefficient is also considered to be constant. Partition coefficient also depends on the temperature of the food and polymer. Further, temperature also influences diffusion process. Arrhenius-type equation governs the systems that are influenced by temperature (Ferrara et al. 2001). It gives the relationship between temperature and migrant. The equation is as follows (Hernandez and Giacin 1998):

where:

-

D 0 is a constant (pre-exponential factor).

-

E d represents activation energy for diffusion.

-

R represents universal gas constant.

-

T represents absolute temperature.

2.2 Permeation

Permeation involves movement of volatile and aroma components, gases, moisture and other low molecular weight substances from the outside environment into food through the packaging material or vice versa. In general, permeation involves three steps: adsorption of the permeant on the polymer surface, diffusion through the polymer and desorption of the permeant from the polymer surface. It mainly causes unbalanced flavour profile, leading to change in sensory properties of the food product. Further, packing of food products with packaging material of effective barrier properties can extend the shelf life of the product stored. For instance, aluminium foil has better barrier properties that can protect the foods packed in them for longer time than other polymers (Lamberti and Escher 2007). Willige et al. (2002) studied the relationship between flavour absorption and oxygen permeability of low-density polyethylene (LDPE), polypropylene (PP), polycarbonate (PC) and polyethylene terephthalate (PET). The study found that flavour absorption had linear positive effect on oxygen permeability of LDPE and PP. It was because of change in network of polymeric material due to swelling after flavour absorption. In case of PC, flavour absorption had linear negative effect on oxygen permeability, due to blockage of microcavities. Moreover, PET did not have any significant effect on oxygen permeability due to flavour absorption (Van Willige et al. 2002).

Similarly, moisture and gas permeation also plays a major role in selection of packaging material for a particular food product. For instance, carbonated beverage packaging requires an efficient gas barrier packaging material. Further, gas permeation is of high importance in modified and controlled atmospheric packaging. In case of fresh fruits and vegetables packing, due to product’s respiration and metabolism, the oxygen percentage present inside the pack decreases, leading to anaerobic decomposition. This can be prevented by using permeable membrane. The permeability rate varies with gas composition, temperature and relative humidity. For polymers, oxygen permeates four times slower than that of carbon dioxide (Del-Valle et al. 2003). Also, the permeability of gases increases with increase in temperature. Galić and Ciković (2001) reported the permeability of gases at temperatures from 20 to 60 °C. Further, to investigate the effect of gas permeability with respect to relative humidity of ambient and water activity of polymer, the polymers were subjected to simulants (15% (v/v) ethanol and 3% (v/v) acetic acid solution) prior to analysis. The results found that the permeability of polymers treated with simulants showed higher permeability than that of dry polymers. Zhang et al. (2001) investigated the effect of oxygen and water vapour permeability of ethylene vinyl alcohol (EVOH) copolymers with respect to relative humidity and found that beyond 75% RH, the permeabilities of the film increased.

Permeability of a substance is a quantitative representation of permeant passing through a polymer, and it depends on two main factors: diffusion factors and permeant solubility (Siracusa 2012; Abbes et al. 2015). Mathematically,

Permeability coefficient,

where D and S represent the diffusion coefficient and solubility coefficient, respectively.

Similar to diffusion process, permeation is also influenced by temperature. Hence, Arrhenius-type equation can be used to represent the relationship (Siracusa 2012). Mathematically:

Here, P 0 represents a constant (pre-exponential factor), and E p represents activation energy for permeation.

2.3 Sorption

Sorption can be adsorption and absorption. Adsorption involves transfer of mass from the food to the surface of the packaging material, resulting in increased concentration of components at the interface (Arvanitoyannis and Kotsanopoulos 2014). In absorption, initially, adsorption takes place, followed by permeation of components into the polymer matrix. In general, sorption of fat and flavour is a major area of concern. As sorption of fat has the possibility to enhance the migration of food components into package as well as chemical compounds from package into food (Lebossé et al. 1997).

Sorption of aromatic components present in food by polymers can result in degradation of quality. This phenomenon of loss in quality of food product by absorption of flavour from food by polymer or vice versa is known as ‘scalping’ (Sajilata et al. 2007). Scalping of flavour is a major problem to be addressed in beverage industry. Nevertheless, the mere presence of volatile flavours does not lead to scalping. For scalping to occur, a thermodynamically favourable condition must exist (Gnanasekharan and Floros 1997). But the major concern of flavour sorption is that loss in very small amount of flavour has significant effect on quality of the stored food product depending on the component sorbed (Gnanasekharan and Floros 1997). A study on packing of orange juice in glass bottles and polyethylene-laminated cardboard packages found that after 24 weeks of storage at 4 °C, up to 50% of d-limonene and little aldehydes and alcohols were absorbed into polyethylene-laminated cardboard packages. But, this had little/no effect on the sensory properties of the orange juice (Pieper et al. 1992).

At times, sorption can result in swelling of the packaging material, leading to increased migration and permeation. Further, it can reduce the mechanical properties of the polymer (Helmroth et al. 2002; Piringer 2007). For instance, the absorption of limonene on LDPE increased the oxygen permeability of the polymer and that was proportional to the concentration of limonene (Sadler and Braddock 1990; Lebossé et al. 1997).

Flavour absorption depends on characteristics of polymer (polarity, crystallinity, chain stiffness), flavour compounds (concentration, chemical composition, polarity) and environmental and external factors like temperature, relative humidity, duration of storage and composition of food matrix (Caner 2011). For liquid foods, the sorption is mainly affected by partition coefficient of flavour components, whereas for solid foods, the sorption is affected by solubility and vapour pressure of components in the polymer (Kwapong and Hotchkiss 1987; Lebossé et al. 1997).

Similar to migration, sorption is also a diffusion process. Hence, Fick’s law governs sorption as well (Gnanasekharan and Floros 1997). Further, sorption process is also influenced by temperature. In general, sorption and temperature are positively related. Exceptionally, sorption and temperature are negatively correlated in few cases. For instance, sorption of vinyl chloride by dry casein particles was found to reduce with increasing temperature (Biran et al. 1979). In sorption process, the quantity of volatile component sorbed by the polymer can be measured by the parameter ‘solubility’. Solubility ‘S’ can be given by the following equation (Siracusa, 2012):

Here,

-

S o denotes pre-exponential factor.

-

H s represents the heat of sorption.

In other words, solubility coefficient is the amount of volatile component sorbed by a polymer of unit mass under unit partial pressure (Caner 2011).

Mathematically:

where M is the total amount of vapour absorbed; p and v are pressure and volume of the polymer, respectively.

3 Factors Affecting Interaction Phenomena

The extent of the abovementioned interaction phenomena and their impact on the quality of the food material as well as the integrity of the package depends on various factors like characteristics of food material, nature of the packaging material and the additive used, as well as on the storage and handling environment of the package.

3.1 Nature of the Food Material

The effect of interaction varies with the nature of food material, and hence, in most of the studies involving migration and permeation, various food-simulating agents like water, oil, acetic acid, ethanol and hexane (Arvanitoyannis and Kotsanopoulos 2014) are used. A study on migration of nanosilver into various food simulants for a period of 15 days at 50 °C revealed that highest migration of nanosilver was found in hexane, followed by 4% acetic acid (v/v) and ultrapure water. The migration into 95% ethanol (v/v) was found to be the least (Huang et al. 2011). The composition of food matrix also shows significant effect on the absorption of volatiles into packaging material. For instance, Van Willige et al. (2000) studied the effect of various food matrices on the absorption of flavour compounds like limonene, decanal, linalool and ethyl 2-methyl butyrate into linear low-density polyethylene (LLDPE) and proved that composition of food matrix influences the absorption of volatiles. The composition containing fat/oil had major effect on flavour interaction, followed by proteins and polysaccharides and then by disaccharides (van Willige et al. 2000). The interaction of packaging and product also depends on the pH of the food. A study on effect of pH on the migration of toxic metals like lead, cobalt, nickel and zinc from ceramic food packaging materials showed that the migration rate increased with decrease in pH value (Dong et al. 2014)

Further, the nature and concentration of volatile materials present in food also has considerable impact on the interaction. The higher the concentration of the migrating/penetrating/diffusing material, the higher will be the rate of interaction. Also, the presence of similar flavour compounds also influences the interaction (especially sorption) of particular compound because of reduced availability of free site in the polymer. For instance, the degree at which limonene is sorbed into the polymer has comparatively reduced when it is present in the blend of flavoured compounds than individual presence (Halek and Luttmann 1991; Caner 2011). At times, the compatibility of the food material with the polymer also plays a significant role on interaction. For example, when acidic foods come in contact with metal containers, the erosion and, hence, leaching of metals from the container into the food material are accelerated (Castle 2007). Thus, the selection of the packaging material used for packing a product should be based on the nature of the food material. Apart from the factors discussed above, factors like molecular weight of the interacting molecule, its carbon chain length, structure, functional group and polarity also play important roles in determining the rate and extent of interaction (Caner 2011).

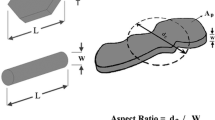

3.2 Nature of the Packaging Material

Similar to the characteristics of food packed, the nature of the packaging material also has considerable impact on the interaction. The packaging material used can be impermeable, permeable or porous. In case of impermeable materials like glass and metals, the migration occurs only at the surface of the material, whereas in case of permeable materials like plastics and rubbers, the migration occurs both on surface and from the inner side of the material. But these materials offer some amount of resistance. Porous materials including paper and boards facilitate rapid migration (Castle 2007). The rate of interaction between polymers and the food material depends on factors like molecular weight, density, additive present, crystallinity, glass transition temperature and so on. An experiment on migration of carbon black found that the migration rates in LDPE and polystyrene (PS) decreased by a factor of 10 (approx.), when the molecular weights were doubled (Bott et al. 2014). In case of PP, the migration rate increases with decrease in degree of crystallinity (Alin and Hakkarainen 2010). And highly crystalline polymers like HDPE and PP show comparatively lesser absorptivity than that of other polymers like LDPE and surlyn (Charara et al. 1992). Besides, the polymers with lower glass transition temperatures show higher permeability as well as high diffusion coefficients. The affinity of the polymer toward the interacting molecule also influences interaction. For instance, packing of non-polar materials like oils and fats in polyolefins is not advisable because of its lipophilic nature (Caner 2011). Similarly, the rate of sorption also decreases with increase in density of the polymer.

Other than the polymer itself, the nature of additives like colourants, plasticizers, stabilizers, fillers, blowing agents, antioxidants, antimicrobials, slip compounds and printing ink also migrates into the food material, and their characteristics impact the rate of migration (Guart et al. 2011).

3.3 Environmental and Storage Factors

The environment in which the product along with the package is placed has a major impact on the interaction phenomena. As discussed in previous sections, the interaction is influenced due to temperature, and thus according to Arrhenius-type equations with increase in temperature, the rate of interaction increases. Owing to increase in temperature, free volume, mobility of the interacting material present in the food as well as the polymer, degree of swelling of the polymer increases, whereas degree of crystallinity decreases, and also relaxation of polymer chain occurs (Caner 2011). A study was conducted on the effect of temperature during processing and temperature and time of storage on bisphenol A migration from can containing organosol and epoxy coatings to a fatty food simulant (sunflower oil) and tuna in oil. The study found that maximum migration level of BPA from organosol can coating into fatty food simulant (403.6 ± 52.9 μg/kg) and tuna in oil (27.4 ± 11.3 μg/kg) occurred at heat processed cans stored 25 °C for a period of 160 days. The rate of migration gradually decreased with increase in storage time for heat processed cans. Also, non-heat processed cans (186.1 ± 32.2 μg/kg) showed slower migration rate than that of heat processed cans (403.6 ± 52.9 μg/kg) stored at same temperature (25 °C) and time (160 days) (Munguia-Lopez et al. 2005). Similarly, a study on migration of nanosilver into different food-simulating solutions (water, hexane, 95% ethanol (v/v) and 4% acetic acid (v/v)) found that irrespective of the simulating solution adopted, the amount of nanosilver migration increased gradually with time and temperature (Huang et al. 2011).

Another important factor to be considered is relative humidity. The effect of humidity on the interaction varies with the polymer used. For instance, absorption of water in polymers like EVOH increases the permeability, whereas in case of polymers like PET and nylon, it decreases oxygen permeability. However, in a few cases like polyolefins, humidity has no significant effect on the permeability of the polymer (Linssen et al. 2003). A study on the effect of relative humidity on the release of antimicrobial agent (carvacrol) from EVOH coating on PP films found that diffusion coefficient increased with increase in humidity (Cerisuelo et al. 2012).

Sometimes, effects of interaction phenomena are inter-dependent. For instance, LDPE and PP showed increased oxygen permeability by 21% and 130%, respectively, after 8 h of exposure to flavours, whereas in the case of PC, the oxygen permeability decreased by 11% after 21 days of exposure. In case of PET, no significant effect was observed. Thus, the study proved that flavour absorption had effect on oxygen permeability of some polymers (Van Willige et al. 2002).

4 Effects of Interaction

In general, interaction phenomena result in mass transfer of any of the component either from the packaging material to food or vice versa. It also occurs between the outside environment and food through packaging material. Hence, there occurs a change in composition of the food material, the packaging material and the environment. However, change in environment is negligible, and it is not considered. This section deals about the effects of interaction phenomena with the packaging material as well as the product and the health effects due to consumption of interacted food.

4.1 On Polymers

The main effect of interaction on the polymeric material leads to change in structure and nature of the polymeric material. This may occur in one or many of the following ways:

-

Migration of residual monomers or oligomers into the food material

-

Migration of additives into the food material

-

Swelling of polymeric material due to absorption of components

-

Alteration in polymeric network due to absorption of components

-

Change in permeability behaviour of polymeric material

-

Development of voids due to migration

-

Filling of microcavities or void spaces in the polymer by the sorbed components

-

Relaxation of polymer linkages

-

Change in crystallinity of the polymeric material due to migration

-

Shift in glass transition temperature of the polymeric material due to migration

4.2 On Product

Change in sensory properties of the food material is one of the main problems associated with the interaction. Sensory changes may occur due to direct absorption of volatile compounds into the polymeric material or through indirect changes which occurred due to chemical reactions like oxidation and hydrolysis that has occurred because of increased permeability and so on (Duncan and Webster 2009). Flavour scalping in small amount has significant effect on the organoleptic properties of food. However, the nature of flavour absorbed plays a major role in alteration of sensory properties. For instance, d-limonene does not have much effect on the flavour of orange juice. Hence, the absorption of d-limonene to a level of 40% did not significantly affect the orange juice quality. Additionally, d-limonene absorption leads to prevent the formation of off-flavour compounds like α-terpineol (Durr et al. 1981). Another study conducted on absorption of aroma compounds like lemon and orange into LDPE found that sensory panellists were able to identify the significant difference in intensity of aroma (Kwapong and Hotchkiss 1987). To balance the lost favour due to scalping, manufacturers often add additional flavour, so that the end product reaching consumers is acceptable in terms of flavour (Lebossé et al. 1997).

Apart from organoleptic changes, the interaction of food components with packaging material and environment may lead to detrimental effect on the quality of the food. For instance, enhanced permeation may result in oxidation of food, thus reducing the shelf life of the packed food. Mannheim and his team found that citrus juices packed in laminated cartons had limited shelf life than those packed in glass jars (Mannheim et al. 1987).

In cases like packaging material containing antimicrobial or antioxidant agents, interaction can be beneficial. A study on migration of antioxidant (α-tocopherol) from a multilayer packaging material containing high-density polyethylene (HDPE), EVOH, LDPE layers and α-tocopherol into whole milk powder found that antioxidant delivery reduced the rate of lipid oxidation and, hence, extended the shelf life of whole milk powder (Granda-Restrepo et al. 2009).

4.3 Health Effects

Though packaging effectively maintains the safety and nutrition of the food, the use of polymers can lead to negative impact on the health of the consumers. This may be because of migration of undesirable and hazardous components from the polymers into the food material. The effects can be due to exposure for a longer period of time or shorter time period, depending on the component. Hence, the toxicity of the migrating substance is to be considered. Based on the extent of harmfulness, several legislations have set the permissible limit for the migrating substances to be present. Some compounds migrated into food are extremely toxic to consumers. For instance, long-term exposure to BPA (Fig. 1) is dangerous as it mimics female hormone oestrogens (Fig. 2) and it is a potential endocrine disrupter (Thomson and Grounds 2005). Also, fluorinated organic chemicals like perfluorooctanesulfonate (PFOS) and perfluorocarboxylates (PFCs) were found to cause toxicological effect on monkeys and rodents (Kumar 2005).

5 Testing Methods

Testing the quality as well as the quantity of the interacting substance is very important for the manufacturer to ensure that the material meets the standard and also to make sure that packaging material has negligible effect on the final product reaching the consumer and it does not cause any negative impact on health after consumption of the packed food material. To detect and analyse the amount of components present, simulants, mathematical and predictive models and chromatographic techniques are used.

5.1 Simulants

In general, foods are classified into aqueous, acidic, alcoholic, fat-based and dry foods (Castle 2007). Hence, based on the nature of the food material, various simulants are used to mimic the environment. The simulants recommended by US Food and Drug Administration (US FDA) and European Union (EU) for different types of food are illustrated in Table 2 (Castle 2007; Bhunia et al. 2013). These simulants are selected accordingly, and then overall migration or specific migration is calculated by exposing the packaging material to the simulants for the recommended time and temperature (Table 3) (FDA 2007). Overall migration is calculated by evaporating the simulants and then calculating the weight of the remaining residues. This method is limited in case of fatty simulants, because of difficulty in vaporization of simulant. Hence, the loss in weight of the packaging material, followed by subtracting with the amount of fat sorbed gives the overall migration. Specific migration is calculated by mathematical models or analytical techniques. In case, if overall migration value or the total amount of the particular component present in the polymer is less than the maximum permissible limit, then the need for specific migration test is neglectable (Veraart and Coulier 2007).

Unlike other components, the interaction of a flavour with polymers cannot be studied by food simulants. In general, diluted aqueous solution of particular flavour is used to simulate the environment. For instance, to mimic the flavour of citrus products, d-limonene is used (Gnanasekharan and Floros 1997). To test the transfer of odour and taste from packaging materials, ASTM (American Society for Testing and Materials) standard test methods are adopted. According to the ASTM standard, 0.9 m2 of test material is placed in a required environment for a minimum of 20 h (Tice 1996).

5.2 Analytical Instruments

The quantification of interacted compounds can be done through mathematical models as well as chromatographic techniques. Application of chromatographic techniques on interaction phenomena directly involving food stuffs is limited than that related to simulants and packaging material. Though some studies have been carried out on the detection of interacted components, there are no standard methods available for analysis of the most of the migrating substances. Also, some migrants like perfluorochemicals cannot be detected by conventional techniques like GC-MS or LC-UV. Begley et al. (2005) adopted LC-MS technique to characterize perfluorochemicals. Table 4 describes some of the commonly found interacting components and the method of detection adopted.

5.3 Mathematical Models

As the experiments are time-consuming and laborious and involve high cost, several mathematical models have been developed to determine diffusion coefficients as well as partition coefficients and also to predict interacting substance concentration (Lau and Wong 1997; Mousavi et al. 1998; Helmroth et al. 2002; Samsudin et al. 2018). A model was developed for the design optimization of the package containing antimicrobial agents. The objective of the model was to make sure the presence of the optimum concentration of the antimicrobial agent on the headspace, so as to prevent the growth of selected microorganisms. The study also claimed that the same model can be used to similar packaging systems also (Cerisuelo et al. 2012). Moreover, Price and Chaudhry (2014) developed a computational model to estimate the toxicity of compounds migrated from the polymer into food material (Price and Chaudhry 2014).

Apart from the testing methods described above, permeation of a particular packaging material can be calculated in terms of gas and moisture transmission rate. The permeability properties of the material depend on film characteristics like thickness, as well as on the surrounding environment. Gas transmission rate is tested by placing the packaging material in between a low-pressure and high-pressure environment, followed by measurement of pressure difference in case of manometric method and volume difference in case of volumetric method. Gas transmission rate is expressed in cc of specific gas permeated per unit area per unit time. Similarly, moisture transmission rate of a packaging material is tested by placing the material in between an environment of two different humidities. Due to vapour pressure difference, permeation of water vapour takes place, and this is calculated in g of moisture permeated m−2 day−1 (Huang and Qian 2008).

6 Regulations

The selection of packaging material for a food should be in such a way that the migration is limited and within the limits set by the legislative bodies. In general, FDA and European Commission (EC) bodies implement threshold policy as well as EC directives, respectively, to set the limits in a way that the compounds on consumption do not create any harm to the consumer (Arvanitoyannis and Kotsanopoulos 2014). The threshold level is set considering the dietary concentration as well as the toxic potency of the harmful component. Regulations are set for labelling as well to mention the possibility of migration of allergens like latex from cold seal adhesives. This is because these allergens may cause serious health hazards in certain individuals (Castle 2007). In case of FDA, the food contact materials should be GRAS (generally recognized as safe) approved. If not, the material and/or the additive migrated from the material should prove to be safe. The level of migration limit varies with the nature of the additive. For instance, according to FDA, carcinogenic compounds if present less than 0.5 μg kg−1a possess a risk of less than one in a million lives (Arvanitoyannis and Kotsanopoulos 2014). Thus, the migration of the compounds from the packaging material at their intended use condition should be less than the maximum permissible limit set by these governing bodies, for the safety of the consumers.

7 Conclusion

In summary, as different kinds of packaging materials have evolved for food applications, interaction of the package and the product is one of the most important properties to be considered. The knowledge on these interaction phenomena is of significant importance in all the stages involving food and the packaging material, as it can lead to unsafe and below standard food product to the consumer. Further, clear understanding on the role of the storage and handling environment as well as the nature of the food and packaging material on the interaction enables to ensure the safety of the product. Besides, the testing of the materials in the intended environment gives the level of interaction, and the manufacturers and handlers should ensure that the level does not exceed the maximum permissible limit set by the legislative bodies. Currently, the legislative bodies like FDA and EC are exploring more on the toxicity and harmfulness of the unintentional additives in the packaging material.

References

Abbes B, Abbes F, Guo Y-Q (2015) Interaction phenomena between packaging and product. In: Alavi S, Thomas S, Sandeep K et al (eds) Polymers for packaging applications, 1st edn. Apple Academic Press, New Jersey, pp 39–70

Alin J, Hakkarainen M (2010) Type of polypropylene material significantly influences the migration of antioxidants from polymer packaging to food simulants during microwave heating. J Appl Polym Sci n/a-n/a. https://doi.org/10.1002/app.32472

Arvanitoyannis IS, Kotsanopoulos KV (2014) Migration phenomenon in food packaging. Food-package interactions, mechanisms, types of migrants, testing and relative legislation-a review. Food Bioprocess Technol 7:21–36. https://doi.org/10.1007/s11947-013-1106-8

Azeredo H, Mattoso L, McHugh T (2011) Nanocomposites in food packaging – a review. In: Reddy B (ed) Advances in diverse industrial applications of nanocomposites. InTech, p 57–78

Barkby CT, Lawson G (1993) Analysis of migrants from nylon 6 packaging films into boiling water. Food Addit Contam 10:541–553. https://doi.org/10.1080/02652039309374177

Begley TH, White K, Honigfort P et al (2005) Perfluorochemicals: potential sources of and migration from food packaging. Food Addit Contam 22:1023–1031. https://doi.org/10.1080/02652030500183474

Bhunia K, Sablani SS, Tang J, Rasco B (2013) Migration of chemical compounds from packaging polymers during microwave , conventional heat treatment, and storage. Compr Rev Food Sci Food Saf 12:523–545. https://doi.org/10.1111/1541-4337.12028

Biran D, Giacin JR, Hayakawa K, Gilbert SG (1979) Vinylchloride sorption by dry casein particles: mechanistic considerations. J Food Sci 44:59–61

Bogdanovičová S, Jarošová A (2015) Phthalate migration from packaging materials into food. Potravin Slovak J Food Sci 9:275–279

Bonifaci L, Frezzotti D, Cavalca G et al (1991) Analysis of epsilon-caprolactam and its cyclic oligomers by high-performance liquid chromatography. J Chromatogr 585:333–336

Bosnir J, Puntaric D, Galic A et al (2007) Migration of phthalates from plastic containers into soft drinks and mineral water. Food Technol Biotechnol 45:91–95

Bott J, Störmer A, Franz R (2014) Migration of nanoparticles from plastic packaging materials containing carbon black into foodstuffs. Food Addit Contam A 31:1769–1782. https://doi.org/10.1080/19440049.2014.952786

Brown H, Williams J (2003) Packaged product quality and shelf life. In: Richard C, McDowell D, Kirwan MJ (eds) Food packaging technology. Blackwell Publishing Ltd, Hoboken, pp 65–94

Caner C (2011) Sorption phenomena in packaged foods: factors affecting sorption processes in package-product systems. Packag Technol Sci 24:259–270. https://doi.org/10.1002/pts

Castle L (2007) Chemical migration into food: an overview. In: Barnes KA, Sinclair CR, Watson DH (eds) Chemical migration and food contact materials, 1st edn. CRC Press, New York, pp 1–13

Castle L, Mayo A, Crews C, Gilbert J (1989) Migration of poly (ethylene terephthalate) (PET) oligomers from PET plastics into foods during microwave and conventional cooking and into bottled beverages. J Food Prot 52:337–342

Cerisuelo JP, Muriel-galet V, Bermúdez JM et al (2012) Mathematical model to describe the release of an antimicrobial agent from an active package constituted by carvacrol in a hydrophilic EVOH coating on a PP film. J Food Eng 110:26–37. https://doi.org/10.1016/j.jfoodeng.2011.12.013

Charara ZN, Williams JW, Schmidt RH, Marshall MR (1992) Orange flavor absorption into various polymeric packaging materials. J Food Sci 57:963–968. https://doi.org/10.1111/j.1365-2621.1992.tb14334.x

Coles R (2003) Introduction. In: Richard C, McDowell D, Kirwan MJ (eds) Food packaging technology. Blackwell Publishing Ltd, Hoboken, pp 1–31

Colín-Chávez C, Soto-Valdez H, Peralta E et al (2013) Diffusion of natural astaxanthin from polyethylene active packaging films into a fatty food simulant. Food Res Int 54:873–880. https://doi.org/10.1016/j.foodres.2013.08.021

Del-Valle V, Almenar E, Lagarón JM et al (2003) Modelling permeation through porous polymeric films for modified atmosphere packaging. Food Addit Contam 20:170–179. https://doi.org/10.1080/0265203021000042869

Dong Z, Lu L, Liu Z et al (2014) Migration of toxic metals from ceramic food contact materials into acid food. Math Probl Eng:1–7. https://doi.org/10.1002/pts.2122

Duncan SE, Webster JB (2009) Sensory impacts of food-packaging interactions. In: Taylor SL (ed) Advances in Food and Nutrition Research, Volume 56. Elsevier, Amsterdam, pp 17–64

Duran M, Aday MS, Zorba NND et al (2016) Potential of antimicrobial active packaging “containing natamycin, nisin, pomegranate and grape seed extract in chitosan coating” to extend shelf life of fresh strawberry. Food Bioprod Process 98:354–363. https://doi.org/10.1016/j.fbp.2016.01.007

Durr P, Schobinger U, Waldvogel R (1981) Aroma quality of orange juice after filling and storage in soft packages and glass bottles. Alimenta 20:91

Ehret-Henry J, Bouquant J, Scholler D et al (1992) 1H-NMR for the safety control of food packaging materials: analysis of extracts from polyolefin samples. Food Addit Contam 9:303–314. https://doi.org/10.1080/02652039209374076

Fantoni L, Simoneau C (2003) European survey of contamination of homogenized baby food by epoxidized soybean oil migration from plasticised PVC gaskets. Food Addit Contam 20(11):1087–1096. https://doi.org/10.1080/02652030310001615186

FDA (2007) U.S. food and drug administration. https://www.fda.gov/Food/GuidanceRegulation/ucm081818.htm. Accessed 13 Dec 2017

Ferrara G, Bertoldo M, Scoponi M, Ciardelli F (2001) Diffusion coefficient and activation energy of Irganox 1010 in poly(propylene-co-ethylene) copolymers. Polym Degrad Stab 73:411–416. https://doi.org/10.1016/S0141-3910(01)00121-5

Franz R, Welle F (2008) Migration measurement and modelling from poly (ethylene terephthalate) (PET) into soft drinks and fruit juices in comparison with food simulants. Food Addit Contam Part A 25:1033–1046. https://doi.org/10.1080/02652030701837381

Galić K, Ciković N (2001) Permeability characterisation of solvent treated polymer materials. Polym Test 20:599–606. https://doi.org/10.1016/S0142-9418(00)00081-7

Gilbert SG, Miltz J, Giacin JR (1980) Transport considerations of potential migrants from food packaging materials. J Food Process Preserv 4:27–49. https://doi.org/10.1111/j.1745-4549.1980.tb00594.x

Gnanasekharan V, Floros JD (1997) Migration and sorption phenomena in packaged foods migration and sorption phenomena in packaged foods. Crit Rev Food Sci Nutr 37:519–559

Goodson A, Robin H, Summerfield W, Cooper I (2004) Migration of bisphenol a from can coatings – effects of damage, storage conditions and heating. Food Addit Contam 21:1015–1026. https://doi.org/10.1080/02652030400011387

Goulas AE, Anifantaki KI, Kolioulis DG, Kontominas MG (2000) Migration of di- ( 2-ethylhexylexyl ) Adipate plasticizer from food-grade polyvinyl chloride film into hard and soft cheeses. J Dairy Sci 83:1712–1718. https://doi.org/10.3168/jds.S0022-0302(00)75040-5

Granda-Restrepo DM, Soto-Valdez H, Peralta E et al (2009) Migration of α-tocopherol from an active multilayer film into whole milk powder. Food Res Int 42:1396–1402. https://doi.org/10.1016/j.foodres.2009.07.007

Guart A, Bono-Blay F, Borrell A, Lacorte S (2011) Migration of plasticizers, phthalates, bisphenol A and alkylphenols from plastic containers and evaluation of risk. Food Addit Contam A 28:676–685. https://doi.org/10.1080/19440049.2011.555845

Halek GW, Luttmann JP (1991) Sorption behaviour of citrus-flavor compounds in polyethylenes and polypropylenes. In: Risch SJ, Hotchkiss JH (eds) Food and packaging interactions II. American Chemical Society, Washington, DC, pp 212–226

Hammarling L, Gustavsson H, Svensson K et al (1998) Migration of epoxidized soya bean oil from plasticized pvc gaskets into baby food. Food Addit Contam 15:203–208. https://doi.org/10.1080/02652039809374631

Helmroth E, Rijk R, Dekker M, Jongen W (2002) Predictive modelling of migration from packaging materials into food products for regulatory purposes. Trends Food Sci Technol 13:102–109

Hernandez RJ, Giacin JR (1998) Factors affecting permeation, sorption, and migration processes in package-product systems. In: Taub IA, Singh RP (eds) Food storage stability, 1st edn. CRC Press, New York

Huang J, Qian X (2008) Comparison of test methods for measuring water vapor permeability of fabrics. Text Res J 78:342–352. https://doi.org/10.1177/0040517508090494

Huang Y, Chen S, Bing X et al (2011) Nanosilver migrated into food – simulating solutions from commercially available food fresh containers. Packag Technol Sci 24:291–297. https://doi.org/10.1002/pts

Kumar KS (2005) Fluorinated organic chemicals: a review. Res J Chem Environ 9:50–79

Kwapong OY, Hotchkiss JH (1987) Comparative sorption of aroma compounds by polyethylene and lonomer food-contact plastics sensory evaluation. J Food Sci 52:761–763

Lamberti M, Escher F (2007) Aluminium foil as a food packaging material in comparison with other materials. Food Rev Int 23:407–433. https://doi.org/10.1080/87559120701593830

Lau O-W, Wong S-K (1997) Mathematical model for the migration of plasticisers from food contact materials into solid food. Anal Chim Acta 347:249–256. https://doi.org/10.1016/S0003-2670(97)00175-X

Lebossé R, Ducruet V, Feigenbaum A (1997) Interactions between reactive aroma compounds from model citrus juice with polypropylene packaging film. J Agric Food Chem 45:2836–2842. https://doi.org/10.1021/jf960957e

Linssen JP, van Willige RW, Dekker M (2003) Packaging-flavour interactions. In: Ahvenainen R (ed) Novel food packaging techniques, 1st edn. CRC Press, New York, pp 144–171

Mannheim CH, Miltz J, Letzter A (1987) Interaction between polyethylene laminated cartons and aseptically packed citrus juices. J Food Sci 52:737–740

Moreta C, Tena M (2015) Determination of plastic additives in packaging by liquid chromatography coupled to high resolution mass spectrometry. J Chromatogr A 1414:77–87. https://doi.org/10.1016/j.chroma.2015.08.030

Mousavi SM, Desobry S, Hardy J (1998) Mathematical modelling of migration of volatile compounds into packaged food via package free space. Part I: cylindrical shaped food. J Food Eng 36:453–472. https://doi.org/10.1016/S0260-8774(98)00059-4

Munguia-Lopez EM, Gerardo-Lugo S, Peralta E et al (2005) Migration of bisphenol A (BPA) from can coatings into a fatty-food simulant and tuna fish. Food Addit Contam 22:892–898. https://doi.org/10.1080/02652030500163674

Nerín C, Fernández C, Domeño C, Salafranca J (2003) Determination of potential migrants in polycarbonate containers used for microwave ovens by high-performance liquid chromatography with ultraviolet and fluorescence detection. J Agric Food Chem 51:5647–5653. https://doi.org/10.1021/jf034330p

Othman SH (2014) Bio-nanocomposite materials for food packaging applications: types of biopolymer and nano-sized filler. Agric Agric Sci Proc 2:296–303. https://doi.org/10.1016/j.aaspro.2014.11.042

Pieper G, Borgudd L, Ackermann P, Fellers P (1992) Absorption of aroma volatiles of orange juice into laminated carton packages did not affect sensory quality. J Food Sci 57:1408–1411. https://doi.org/10.1111/j.1365-2621.1992.tb06870.x

Piringer O (2007) Mathematical modelling of chemical migration from food contact materials. In: Barnes KA, Sinclair CR, Watson DH (eds) Chemical engineering journal, 1st edn. CRC Press, New York, pp 180–202

Pouech C, Lafay F, Wiest L et al (2014) Monitoring the extraction of additives and additive degradation products from polymer packaging into solutions by multi-residue method including solid phase extraction and ultra-high performance liquid chromatography-tandem mass spectrometry analysis. Anal Bioanal Chem 406:1493–1507. https://doi.org/10.1007/s00216-013-7551-4

Price N, Chaudhry Q (2014) Application of in silico modelling to estimate toxicity of migrating substances from food packaging. Food Chem Toxicol 71:136–141. https://doi.org/10.1016/j.fct.2014.05.022

Quinto-Fernández EJ, Pérez-Lamela C, Simal-Gándara J (2003) Analytical methods for food-contact materials additives in olive oil simulant at sub-mg kg-1 level. Food Addit Contam 20:678–683. https://doi.org/10.1080/0265203031000114219

Ramos M, Beltrán A, Peltzer M et al (2014) Release and antioxidant activity of carvacrol and thymol from polypropylene active packaging films. LWT – Food Sci Technol 58:470–477. https://doi.org/10.1016/j.lwt.2014.04.019

Rhim J, Park H, Ha C (2013) Bio-nanocomposites for food packaging applications. Prog Polym Sci 38:1629–1652. https://doi.org/10.1016/j.progpolymsci.2013.05.008

Risch SJ, Hotchkiss JH (eds) (1991) Food and packaging interactions II, ACS symposium. American Chemical Society, Washington, DC

Robertson GL (2013) Food packaging: principles and practice, 3rd edn. CRC Press, New York

Sadler GD, Braddock RJ (1990) Oxygen permeability of low density polyethylene as a function of limonene absorption: an approach to modeling flavor “Scalping”. J Food Sci 55:587–588. https://doi.org/10.1111/j.1365-2621.1990.tb06826.x

Sajilata MG, Savitha K, Singhal RS, Kanetkar VR (2007) Scalping of flavors in packaged foods. Compr Rev Food Sci Food Saf 6:17

Samsudin H, Auras R, Mishra D et al (2018) Migration of antioxidants from polylactic acid films: a parameter estimation approach and an overview of the current mass transfer models. Food Res Int 103:515–528

Silvestre C, Duraccio D, Cimmino S (2011) Food packaging based on polymer nanomaterials. Prog Polym Sci 36:1766–1782. https://doi.org/10.1016/j.progpolymsci.2011.02.003

Simoneau C, Van den Eede L, Valzacchi S (2012) Identification and quantification of the migration of chemicals from plastic baby bottles used as substitutes for polycarbonate. Food Addit Contam – Part A Chem Anal Control Expo Risk Assess 29:469–480. https://doi.org/10.1080/19440049.2011.644588

Siracusa V (2012) Food packaging permeability behaviour: a report. Int J Polym Sci. https://doi.org/10.1155/2012/302029

Song YS, Begley T, Paquette K, Komolprasert V (2003) Effectiveness of polypropylene film as a barrier to migration from recycled paperboard packaging to fatty and high-moisture food. Food Addit Contam 20:875–883. https://doi.org/10.1080/02652030310001597592

Song H, Li B, Lin QB et al (2011) Migration of silver from nanosilver-polyethylene composite packaging into food simulants. Food Addit Contam – Part A 28:1758–1762. https://doi.org/10.1080/19440049.2011.603705

Thomson BM, Grounds PR (2005) Bisphenol A in canned foods in New Zealand: an exposure assessment. Food Addit Contam 22:65–72. https://doi.org/10.1080/02652030400027920

Tice P (1996) Packaging materials as a source of taints. In: Saxby MJ (ed) Food taints and off-flavours. Springer Science and Businees Media, Berlin, pp 226–263

van Willige RW, Linssen JP, Voragen AG (2000) Influence of food matrix on absorption of flavour compounds by linear low-density polyethylene: proteins and carbohydrates. J Sci Food Agric 80:1779–1789. https://doi.org/10.1002/1097-0010(20000915)80:12<1779::AID-JSFA726>3.0.CO;2-F

Van Willige RWG, Linssen JPH, Meinders MBJ et al (2002) Influence of flavour absorption on oxygen permeation through LDPE, PP, PC and PET plastics food packaging. Food Addit Contam 19:303–313. https://doi.org/10.1080/02652030110081146

Vera P, Canellas E, Nerín C (2014) Migration of odorous compounds from adhesives used in market samples of food packaging materials by chromatography olfactometry and mass spectrometry ( GC – O – MS). Food Chem 145:237–244

Veraart R, Coulier L (2007) Compliance testing of chemical migration from food contact materials. In: Barnes KA, Sinclair CR, Watson DH (eds) Chemical migration and food contact materials. CRC Press, New York, pp 87–121

Vieira MGA, Da Silva MA, Dos Santos LO, Beppu MM (2011) Natural-based plasticizers and biopolymer films: a review. Eur Polym J 47:254–263. https://doi.org/10.1016/j.eurpolymj.2010.12.011

Youssef AM (2013) Polymer nanocomposites as a new trend for packaging applications. Polym Plast Technol Eng 52:635–660. https://doi.org/10.1080/03602559.2012.762673

Zafeiraki E, Costopoulou D, Vassiliadou I et al (2014) Determination of perfluorinated compounds (PFCs) in various foodstuff packaging materials used in the Greek market. Chemosphere 94:169–176

Zhang Z, Britt IJ, Tung MA (2001) Permeation of oxygen and water vapor through EVOH films as influenced by relative humidity. J Appl Polym Sci 82:1866–1872. https://doi.org/10.1002/app.2030

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Vimala Bharathi, S.K., Moses, J.A., Anandharamakrishnan, C. (2018). Interaction Phenomena Between Packaging and Product. In: Ahmed, S. (eds) Bio-based Materials for Food Packaging. Springer, Singapore. https://doi.org/10.1007/978-981-13-1909-9_2

Download citation

DOI: https://doi.org/10.1007/978-981-13-1909-9_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-1908-2

Online ISBN: 978-981-13-1909-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)