Abstract

Pharmaceutical compounds are used for many beneficial purposes in the modern society, but they also contaminate surrounding environment during their exposure. They may enter the environment through numerous routes e.g. treated wastewater discharge, sewage from landfills, sewer lines, runoff from animal wastes and land application of manure fertilizers. The pharmaceutical wastewater consists of high concentration of organic matter, microbial toxicants, high salt concentration and non-biodegradable compounds. Due to limited water resources, it is essential to understand and develop the methodologies for treatment of pharmaceutical wastewater. Trace amounts of suspended solids and dissolved organic matter still persist even after secondary treatment, therefore, advanced treatment is prerequisite in order to improve the quality of pharmaceutical wastewater. In this chapter, the emphasis is mostly on best available technologies to remove and recycle the pharmaceutical wastewater. Effluents arising from different sectors of active pharmaceutical ingredients (API), bulk drugs and related pharmaceutics, consuming a bulk amount of water are evaluated and the strategies are destined to recover valuable compounds upto a larger extent, and finally wastewater treatment is discussed. The complete removal of pharmaceutics from wastewater is not feasible with a single technology. The hybrid wastewater treatment appears to be the best comprising conventional treatment plans in conjunction with biological and advanced post-treatment methods. The recommendations provided in this analysis will be useful for the treatment of wastewater resulting from the pharmaceutical industry.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Pharmaceutical drugs

- Active pharmaceutical ingredients

- Organic pollutants

- Bioremediation

- Phytoremediation

- Hybrid wastewater treatment

9.1 Introduction

Pharmaceuticals are a large and diverse group of synthetic and natural compounds designed to prevent, cure and treat acute and chronic diseases to improve health prospects. A large amount of wastes from pharmaceutical industries are dispensed and consumed annually worldwide. The usage and consumption are increasing constantly due to the discoveries of new drugs. After intake, these active ingredients undergo metabolic processes in organisms. Significant fractions of the parent compound are excreted in unmetabolized form into wastewater treatment systems. Therefore, body metabolization and excretion followed by the wastewater treatment are considered to be the primary route of discharge of pharmaceuticals in the environment.

Pharmaceuticals and their metabolites in the surface water and aquatic sediment is subject of numerous studies concerning pharmaceuticals in the environment (Kadam et al. 2016; Patneedi and Prasadu 2015). Several studies have reported the occurrence and distribution of pharmaceuticals in soil irrigated with reclaimed water (Sui et al. 2015; Ebele et al. 2017) and soil consisting of biosolids from urban sewage treatment plants (Gao et al. 2016). Studies indicated present treatment processes are not sufficient to reduce these micropollutants from the pharmaceutical wastewater, so they find their way into the environment. Once they enter the environment, micropollutants can produce harmful effects on aquatic and terrestrial organisms. Pharmaceutical active compounds are of emerging concern because they are biologically active compound and display toxic effects during exposure on organisms. Various examples of negative effects of pharmaceutical products have been reported in form of development of antibiotic resistance in microbes, reduction in microbial ability of nitric oxidation and methanogenesis, feminization in fish or alligators, migratory behaviour of Salmon and extinction of vulture from India.

9.2 Classification of Pharmaceutical Wastes

Pharmaceutical wastes are classified in three different categories: Hazardous, Non-hazardous and Chemo waste.

9.2.1 Hazardous Waste

Hazardous wastes are of two types: listed and characteristic wastes. Listed wastes appear in one of four lists F, K, P and U. Pharmaceuticals are listed in either P or U category. Characteristic wastes are regulated because they exhibit certain hazardous properties such as ignitability, corrosivity, reactivity and toxicity.

To determining which pharmaceutical waste is hazardous, Resource Conservation and Recovery Act (RCRA) definitions must be considered. Hazardous drugs are categorized as P and U list or chemical characteristic (D-list) by federal Environmental protection Agency (EPA) regulations.

9.2.1.1 P-Listed Pharmaceutical Waste

Acutely hazardous wastes are listed in P category; those are considered harmful even in small quantities. One of the primary criteria for including a drug in the P-list is their lethal dose (LD50). LD50 is the amount of drug which causes the death of 50% of a group of test animals. Eight chemicals in the P-list are used as pharmaceuticals (Table 9.1).

9.2.1.2 U-Listed Pharmaceutical Wastes

This group includes such common compounds e.g. acetone, phenol, lindane, choralhydrate and selected anti-neoplastic waste. There are 21 drugs in the U-list (Table 9.2). These chemicals are listed primarily for their toxicity. Similar to a P-listed waste, when a drug waste containing one of these chemicals is discarded, it must be managed as hazardous waste if two conditions are satisfied: (1) The discarded drug waste contains a sole active ingredient that appears in the U list, and (2) It has not been used for its intended purpose.

9.2.1.3 Chemical Characteristics of Pharmaceutical Wastes

In addition to the P- and U- listed wastes, a waste is considered hazardous under RCRA if it possesses at least one of the four unique and measurable characteristics:

-

1.

Ignitability (D001): Wastes that can easily catch on fire and sustain combustion.

-

2.

Corrosivity (D002): Corrosive wastes corrode metals or other materials or burn the skin.

-

3.

Reactivity (D003): Reactive wastes are unstable under normal conditions. They may cause explosions, toxic fumes, gases, or vapours when heated, compressed, or mixed with water.

-

4.

Toxicity (Multiple D Codes): Toxic wastes are harmful or fatal when ingested or absorbed (e.g., containing mercury, lead, etc.). Toxic D-listed chemicals used in drug formulation are listed in Table 9.3.

Table 9.3 D-listed chemicals used in drug formulations

9.2.2 Nonhazardous Pharmaceutical Waste

It is a general consideration that once the manufacturer’s packaging is opened, any unused or partially used product is nonhazardous pharmaceutical waste e.g. vials, bottles, intravenous (i.v.) therapy bags, tubing containing drugs and expired medicines have been dropped or spit out by a patient. Leftover medications are also considered as pharmaceutical waste those should be disposed of in accordance with EPA and Drug Enforcement Administration (DEA) regulations. When permitted by both state regulations and RCRA, this waste can be solidified and placed in a landfill. However, a better management practice is to have nonhazardous pharmaceutical waste processed by a medical waste incinerator or a properly permitted municipal waste incinerator. Disposal of devices used to administer (such as inhalers) nonhazardous medications, is another consideration. In addition to RCRA requirements, some states have regulations specific to the device and propellant used to deliver drugs, those must be considered in establishing waste streams. For example, in Nebraska, hospitals are required to either segregate inhaler devices from the normal waste stream or puncture and triple rinse the container before disposal in the nonhazardous waste stream (Smith 2002).

9.2.3 Chemo Pharmaceutical Waste

There is some confusion in chemotherapy, antineoplastic and cytotoxic terms. Chemotherapy is a chemical treatment, commonly used for cancer treatment. Antineoplastic refers specifically to inhibiting or preventing the growth or development of cancerous cells. Cytotoxic is referring to any chemical that is toxic to cells. One chemotherapy agent is a P-listed constituent of concern and eight chemotherapy agents are U-listed (Table 9.4).

9.3 Active Pharmaceutical Ingredients (APIs) and Biopharmaceuticals

APIs are complex molecules with different functions including physico-chemical and biological properties. These are polar in nature and their molecular weight typically ranges from 200 to 1000 Dalton (Da). APIs are part of micropollutants because they are often found in the μg/l or ng/l range in the aquatic environment.

Genetically modified pharmaceuticals are known as biopharmaceuticals. The first and best-known example was recombinant human insulin. The environmental relevance of biopharmaceuticals is not yet clear. They are not closely related to natural products and therefore expected to be quickly biodegraded or denatured.

9.4 Characteristics of Pharmaceutical Wastewater

Wastewater characteristics play a key role in the selection of treatment process (Deegan et al. 2011). The wastewater characteristics generated during the manufacturing of pharmaceuticals depending on the raw materials, equipments, manufacturing compounds as well as formulation processes (Mayabhate et al. 1988). Kavitha et al. (2012) studied the physicochemical analysis of pharmaceutical wastes and treatment plant’s efficiency and found the variation in characteristics from the inlet to outlet point of septic tanks. They observed reduction in BOD COD, TSS, TDS, chlorides, sulphates and pH. Das et al. (2012) studied the control of pharmaceutical effluent parameters through bioremediation. They collected the samples from nine different points situated in the industry and observed the range of sulphates (44–1527), TDS (484–1452), TSS (24–84) and COD (1257.9–1542.9) mg/l. Madukasi et al. (2010) characterized the pharmaceutical wastewater and observed the TSS (425), TDS (1600), BOD (146.7), N2 (533.7), Zn (0.056), Fe (2.1), Mn (0.605), Cu (0.022), acetic acid (422.7), propionic acid (201.3) and butyric acid (304.5) mg/l. A suitable range of various parameters of pharmaceutical wastewater has shown in Table 9.5.

9.5 Factors Affecting the Rate of Biodegradation of Pharmaceutical Wastes

The cleaning up of pharmaceutical wastes in the environment is a real world problem. Better understanding of the factors which affect biodegradation is of great ecological significance, since the choice of bioremediation strategy depends on it. Biodegradation of the pharmaceutical wastes depends on a number of factors such as:

-

1.

Stereochemistry of the compound

-

2.

Compound toxicity

-

3.

Compound concentration

-

4.

Microbial strain efficiency

-

5.

Degradation conditions

-

6.

Sludge retention time

-

7.

Environmental factors

-

8.

Contact efficiency between bacterial biomass and organic matter

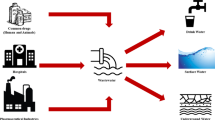

9.6 Sources of Pharmaceutical Wastewater

The introduction of pharmaceuticals products into the environment after use is a typical concern. They are recognized as being an important part of the chemicals those are present in low concentrations in the environment (Schwarzenbach et al. 2006). If the drugs and their transformation products are not eliminated during sewage treatment, they may enter to the aquatic environment and eventually contaminate drinking water. The concentrations of pharmaceuticals in surface water and effluent from sewage treatment plants (STPs) have been shown to lie in range of ng/l to mg/l.

The consumption and application of pharmaceuticals may vary from country to country (Goossens et al. 2007; Schuster et al. 2008). The heavy usage of streptomycin in fruits is reason for the high resistance of pathogenic bacteria against these compounds in USA. In Germany, the use of these antibiotics for this purpose has been banned. If, governmental regulations are imposed on the health system it may happen that some compounds are not used any more or others gain more importance, e.g. for economical reasons. Some antibiotics such as streptomycin are used in the cultivation of fruits (pomology) while others are used in bee-keeping. Pharmaceutical wastes produced by many different sources as follows:

9.6.1 Manufacturers

Because of high cost of pharmaceuticals, the amount of emissions occurring during manufacturing has been thought to be negligible. In Asian countries concentrations of a single compound in water may reach up to mg/l in the effluents (Li et al. 2008).

9.6.2 Hospitals

The effluent of pharmaceuticals in hospital wastewater is higher than other. However, the total substance flow is much lower due to less share of effluent from hospitals in municipal effluent (Schuster et al. 2008).

9.6.3 Private Households

Expired medicines are sometimes disposed of down household drains. In accordance with European Union (EU) prescription, the discarding of unused drugs through household waste has been permitted since 1994.

9.6.4 Landfills

Landfill is a site for the disposal of waste materials. If there is no collection of the effluent, this may be a source for contamination of surface water or groundwater.

9.7 Effects of Pharmaceutical Wastewater

9.7.1 On Human

The extent of human exposure to pharmaceuticals active agents (PAA) from the environment is a complex function of many factors. These factors include the type, distribution, concentrations, pharmacokinetics, structural transformation and the potential bioaccumulation of the diverse pharmaceuticals in the environment. The growing concerns about health risks via environmental exposures, many researchers have speculated about the potential for inducing an antibiotic resistance. Some microbiologists believe that if antibiotic concentrations are higher than the minimum inhibitory concentrations (MICs) of a pathogenic bacterial species, a selective pressure would be exerted and, as a result, antibiotic resistance would be selectively promoted (Segura et al. 2009).

9.7.2 On Environment

Due to high solubility of most PAA, aquatic organisms are exposed to their effects. Researchers have found that a class of antidepressants may be found in frogs and can significantly slow their development. The increased presence of estrogen and other synthetic hormones in wastewater due to birth control and hormonal therapies has been linked to increased feminization of exposed fishes and other aquatic organisms. The chemicals within these PAA could either affect the feminization of different fishes, therefore affecting their reproductive rates (Siegrist et al. 2004). In addition to being found only in waterways, some PAA can also be found in the soil. Since these substances take a long time or cannot be degraded biologically, they make their way up to the food chain. Information pertaining to the transport and fate of these hormones and their metabolites in dairy waste disposal is still being investigated (Zhang et al. 2010). The pollution resulting from PAA not only affects marine ecosystems, but it also affects those habitats depending on this polluted water.

9.8 Biological Methods for Treatment of Pharmaceutical Wastewater

The pharmaceutical industry has adopted different strategies and processes to treat the wastewater and its reuse to control the environmental pollution. The oldest methods employed for wastewater treatment include physical, chemical and thermal treatment methods. But these treatment methods have several disadvantages including huge labour requirement, high maintenance cost, low efficiency, and huge equipments etc. In order to attain maximum efficiency in wastewater treatment and water reuse, an advanced technology has been developed and further research is going on for better results also known as bioremediation and phytoremediation (Chelliapan et al. 2011). Bioremediation (use of microorganisms) and phytoremediation (use of plants) have been adopted to clean up harmful chemicals from the environment.

Biological treatment methods have been widely used in the management of pharmaceutical wastewater treatment due to their low cost and effectiveness. They may be subdivided into aerobic and anaerobic processes (Suman Raj and Anjaneyulu 2005). Aerobic applications include activated sludge, membrane batch reactors and sequence batch reactors (Chang et al. 2008; Chen et al. 2008). Anaerobic methods include anaerobic sludge reactors, anaerobic film reactors and anaerobic filters (Oktem et al. 2007; Sreekanth et al. 2009). Biological methods are also classified as either attached growth or suspended growth according to the living status of the microorganisms. Activated sludge method is effective aerobic process for the treatment of some kinds of low strength pharmaceuticals in wastewater. This process has the disadvantage of slow sludge settling. Activated sludge treatment is also unsuitable for the treatment of wastewater where the COD levels are greater than 4000 mg/l (Suman Raj and Anjaneyulu 2005). The wastewater characteristics such as solvents, APIs intermediates and raw materials play an important role in the selection of biological treatment methods. These characteristics represent recalcitrant substances which affect the efficiency of biological treatment processes (Helmig et al. 2007).

9.8.1 Aerobic Methods

Aerobic condition is speeding up biodegradation process at a faster rate and to a greater extent compared to anaerobic conditions in a given time period (Murphy et al. 1995). Moreover, biological reactors have less construction cost, easy operational and maintenance procedures. An air injection is applied to the biological wastewater treatment plant and access the performance. The treatment process of the bioreactors depends on aeration rate and retention time. The aerobic digestion process consists of two reaction steps (Ros and Zupancic 2002) as follows:

There are various aerobic pharmaceutical wastewater treatment methods which are mentioned below.

9.8.1.1 Conventional Activated Sludge Process (CASP)

CASP is oldest industrial wastewater bio-treatment process. The wastewater after primary treatment (suspended impurities removal) is treated in a CASP that comprises aeration tank followed by secondary clarifier. The aeration tank is completely mixed with air where specific concentration of biomass is maintained along with sufficient concentration of dissolved oxygen (2 mg/l) to affect biodegradation of soluble organic impurities measured as BOD or COD. The aerated mixed liquor from the aeration tank overflows to secondary clarifier unit to separate out the biomass, treated water to the downstream filtration system for finer removal of suspended solids (Fig. 9.1).

9.8.1.2 Cyclic Activated Sludge System (CASS) or Sequence Batch Reactor (SBR)

SBR is a real time batch process, belongs to the broad category of an unsteady-state activated sludge system (Irvine et al. 1979). The difference between SBR and CASP is that SBR carries out equalization, aeration and sedimentation in time manner rather in a space sequence (Fig. 9.2). In CASP, the relative tank volume is fixed and cannot be redistributed as easily as in SBR. The operational flexibility also allows designers to use the SBR to meet many different treatment objectives at a single time such as BOD reduction along with nitrification/denitrification. The basic configuration and mode of operation permit combined nitrogen and phosphorous removal mechanisms to take place through a simple one shot control of the aeration. SBR utilizes a simple time-based sequence which incorporates: Aeration (for biological reactions), Settle (for solids-liquid separation) and Decant (to remove treated effluent).

The CASS-SBR process maximizes operational simplicity, reliability and flexibility. Important reasons for choosing CASS-SBR over conventional constant volume activated sludge aeration and clarifier process include:

-

1.

Operates under continuous reduced loading through simple cycle adjustment.

-

2.

Operates with feed-starve selectivity, limiting substrate to microorganism ratio, and aeration intensity.

-

3.

Tolerates shock load.

-

4.

Reduced land requirement.

-

5.

Easy plant expansion.

-

6.

No adjustments to the return sludge flow rate are necessary.

9.8.1.3 Integrated Fixed Film Activated Sludge (IFAS) System

It is a latest technology that incorporates an attached growth media within the suspended growth reactor (Fig. 9.3) (U.S. EPA 2010). It provides additional biomass growth within a reactor in order to meet more efficient treatment process. Due to more bacterial population on a fixed surface IFAR system eliminate the need to increase the suspended growth. IFAS configuration is similar to an activated sludge plant, with biomass carriers introduced into carefully selected zones within the activated sludge process. This system allows two different biological populations to act synergistically, with the mixed liquor suspended solids (MLSS) degrading most of the organic load (BOD) and the biofilm creating a strongly nitrifying population for oxidation of the nitrogenous load (NH4 +). The common advantages of all of the above described configurations are as follows:

-

1.

The fixed biomass combines aerobic, anaerobic and anoxic zones and increases the sludge retention time, promoting better nitrification compared to simple suspended growth systems.

-

2.

Fixed film media provides additional surface area for biofilm to grow on it and degrade the organic impurities that are resistant to biodegradation or may even be toxic to some extent.

-

3.

System nitrification is also restored faster since a large mass of nitrifiers is retained on the fixed-film.

-

4.

Reduced sludge production: due to less sludge wastage, the sludge handling and dewatering facility is smaller compared to the activated sludge process.

-

5.

Improved process stability

-

6.

It can be easily incorporated in the existing activated sludge system to meet additional processing capacity requirement and/or stricter discharge regulations without the need of additional concrete tanks

-

7.

For new installations, IFAS systems will generally require less volume and therefore have less capital cost than a CASP system

9.8.1.4 Membrane Bioreactor (MBR)

MBR combines conventional biological treatment (e.g. activated sludge) processes with membrane filtration to provide an advanced level of organic and suspended solids removal. In MBR, the bio-solids are separated by a polymeric membrane based on micro or ultra-filtration unit against gravity in the secondary clarifier as in CASP. When designed accordingly, these systems can also provide an advanced level of nutrient removal (BOD). In an MBR system, the membranes with pore size in a range of 0.035–0.4 μ are submerged in an aerated biological reactor (Fig. 9.4). MBR allows high quality effluent to be drawn and eliminates the sedimentation and filtration processes typically used for pharmaceutical wastewater treatment. Since, sedimentation is not required the biological process operates at a much higher mixed liquor concentration. This reduces the requirement of tanks and allows many existing plants to be upgraded without adding new tanks. To provide optimal aeration and scour around the membranes, the mixed liquor is typically kept in 1.0–1.2% solids range, which is ~4 times that of a conventional plant. Therefore, the advantages of MBR system over CASP system are obvious as listed below:

-

1.

MBR maintained MLSS/MLVSS (mixed liquor suspended solids and mixed liquor volatile suspended solids) ratio 3–4 (~10,000 mg/l) times higher than CASP (~2500 mg/l).

-

2.

MBR requires only 40–60% of the space compared to CASP, therefore significantly reducing the physical workload.

-

3.

Due to micro/ultrafiltration, MBR system has superior effluent quality compared to CASP, so the treated effluent can be directly reused as cooling tower make-up or for gardening

-

4.

High effluent quality

-

5.

High loading rate capability

9.8.1.5 Aquatech Enhanced Membrane Bioreactor (Aqua-EMBR)

It is non-submerged and external type MBR for industrial applications especially in petrochemical and pharmaceutical wastewater applications. The ultrafiltration membrane (UM) is positioned outside the bioreactor tank, rather than submerging in the bioreactor tank or the downstream membrane tank (Fig. 9.5). UM modules are arranged vertically and are aerated continuously at the bottom. Continuous air injection is applied to sustain the design permeate flux and also to drive the mixed liquor recirculating flow back to the aeration tank. Mixed liquor is thus transported via an air lift pump through the module, while the membrane feed/recirculation pump is only used to overcome the hydraulic losses and maintain a relatively constant flow of mixed liquor through the membrane. This innovative design reduces much of the feed pumping energy requirement and enables Aqua-EMBR system to consume lower energy than other MBR systems. The advantages of Aqua-EMBR over submerged MBR systems include:

-

1.

Aqua-EMBR has no membrane tank, it can be built much quicker.

-

2.

Offers friendly working environment.

-

3.

Fifty percent less surface area of membrane needed per unit volume permeate production.

-

4.

Electrical power consumption is 10–15% lower.

-

5.

Contain tightest membrane pore size of 30–40 nm, good turbidity of permeate <0.2 NTU and TSS levels <0.5 mg/l.

-

6.

Highest effluent quality.

9.8.2 Anaerobic Methods

In anaerobic treatment, organic content decomposes into methane and CO2 in the presence of microorganisms. Anaerobic pharmaceutical wastewater treatment process has many advantages such as little sludge production, less energy requirement, high organic loading rate, low nutrient requirement and production of low biogas (Shi et al. 2017). Source of inoculum and feed pre-treatment can affect the treatment efficiency. However, low pH and slow growth rate results into a longer hydraulic retention time (HRT). A high-rate configuration was designed to treat industrial wastewater at relatively shorter HRT to overcome this problem (Patel and Madamwar 2000). Enright et al. (2005) reported anaerobic biological treatment of pharmaceutical wastewater and achieved 60–70% COD removal efficiency.

The biological conversion of organic matter occurs in three steps: hydrolysis, acidogenesis and methanogenesis. (i) Hydrolysis: higher molecular-mass compounds converted into compounds suitable for use as a source of energy (ii) Acidogenesis: bacterial conversion of the compounds into lower-molecular-mass intermediate compounds (iii) Methanogenesis: bacterial conversion of the intermediate compounds into simpler end products, such as CH4 and CO2.

According to trophic requirements, used bacteria can be divided into three groups:

-

1.

Hydrolytic bacteria (acidogens): hydrolyzes the long chain organic compounds into short-chain acids and molecules e.g., carbohydrates are converted into low-chain fatty acids, alcohols, hydrogen and CO2 under anaerobic condition. The generation time of these bacteria is 2–3 h. The distribution of final product depends on the bacterial species and on the environmental factors such as temperature and pH.

-

2.

Obligate hydrogen producing acetogens: This group converts compound formed in the first stage into acetic acid and hydrogen. Low hydrogen pressure favours these reactions (Harper and Pohland 1986).

-

3.

Methanogens (obligate anaerobes): These bacteria produce methane. The doubling time of these bacteria is 2–10 days. These are further divided into two groups as:

-

(a)

Hydrogen utilisers (lithotrophs)

-

(b)

Acetic acid users (acetotrophs)

The methane producing bacteria are strict anaerobes which are extremely sensitive to changes in temperature and pH. These bacteria are active in two different temperature zones, namely, mesophilic (30–35 °C) and thermophilic (50–60 °C). However, anaerobic processes have been operated at 15 °C successfully when sufficient residence time for these bacteria was provided.

Upflow anaerobic sludge blanket (UASB) reactors and anaerobic fixed film reactor (AFFR) are anaerobic process. Both processes are used for pharmaceutical wastewater treatment (Fang et al. 1995). The success of UASB depends on the formation of active granules. These granules consist of self-immobilized, compact form of aggregate of organisms and lead to an effective retention of organisms in the reactor (Akunna and Clark 2000). UASB reactor is independent from mechanical mixing and recycling of sludge biomass. Researchers have utilized UASB reactor for the treatment of chemical synthesis-based pharmaceutical wastewater (Oktem et al. 2007). In 2009, hybrid UASB reactor was reported to treat bulk drug industrial wastewater utilizing thermophilic strain (Sreekanth et al. 2009). Toth et al. (2011) studied the performance of a laboratory-scale UASB reactor for the treatment of a pharmaceutical wastewater, under different operating conditions.

AFFR has a biofilm support for biomass attachment. This reactor has advantages like construction simplicity, elimination of mechanical mixing, better stability and capability to withstand toxic shock load. This type of reactor can recover very quickly after a period of starvation (Rajeshwari et al. 2000). In this reactor, glass bead, corrugated plastic coconut coir, charcoal and nylon fibre can be used as support media, which enhances the reactor performance (Acharya et al. 2008). Gangagni Rao et al. (2005) studied the treatment of wastewater with high suspended solids from a bulk pharmaceutical industry using AFFR and concluded that the AFFR could be used efficiently for the treatment of bulk pharmaceutical wastewater having high COD (60–70% removal), TDS, TSS and BOD (80–90% removal). It has been recognized that the anaerobic treatment is in many ways ideal for wastewater treatment and has several advantages mentioned as below:

-

1.

A high degree of waste stabilization

-

2.

A low production of excess biological sludge

-

3.

Low nutrient requirements

-

4.

No oxygen requirement

-

5.

Production of valuable by-product e.g. methane gas

-

6.

Organic loading is not limited to oxygen supply

-

7.

Less land required as compared to many aerobic process

-

8.

For few months, non-feed conditions do not affect adversely to the system and this makes it attractive option for seasonal industrial wastewater treatment

9.9 Biological Sources of Pharmaceutical Wastewater Treatment

9.9.1 Bacteria

Some bacterial strains like Pseudomonas, Enterobactor, Streptomonas, Aeromonas, Acinetobactor and Klebsiella showed up to 44% COD reduction of pharmaceutical wastewater (Ghosh et al. 2004). Chaturvedi et al. (2006) isolated 15 rhizosphere bacteria, those show 76% color reduction and 85–86% BOD and COD reduction within 30 days. The bacterial community is required to provide all metabolic capabilities for complete mineralization of toxic organic compounds, which is essential for degradation of pharmaceutical pollutants (Tewari and Malviya 2002). Arthrobacter, Comamonas, Rhodococcus, Pseudomonas and Ralstonia are known to degrade phenolic and complex organic compounds. Some fermenting bacteria such as Clostridium species are able to degrade m-dihydroxybenzene (Kavitha and Beebi 2003). Duffner et al. (2000) proposed phenol/cresol degradation by the thermophilic Bacillus thermoglucosidasius A7.

Kumar et al. (2005) and Agarry and Solomon (2008), reported the biodegradation kinetics of phenol, catechol and chlorophenol using P. putida MTCC 1194 and P. fluorescence. The Rhodobacter sphaeroides was found to be effective in ameliorating hazardous pollutants found in pharmaceutical wastewater with over 80% COD reduction (Madukasi et al. 2010). Researchers also achieved a significant COD removal (62% at 30 °C and 38% at 60 °C) in pharmaceutical wastewater by using mixed bacterial culture (Lapara et al. 2001). Long-term accumulation of persistent antibiotics and their metabolites in agro-ecosystems can result in toxicity to crops and soil ecosystem as well as on the quality of groundwater (Du and Liu 2012). Pharmaceuticals have been shown to affect plant growth and yields (Goss et al. 2013). The most common pharmaceutical wastes and antibiotic degrading bacteria are summarised in Table 9.6.

9.9.2 Fungi

Fungal strains have some limitations due to the presence of a long growth cycle and spore formation for treatment of pharmaceutical wastewater treatment (Table 9.7). Spina et al. (2012) used Bjerkandera adusta MUT 2295, a fungal strain, to compare fungal treatment process with activated sludge treatment process. Through fungal treatment they achieved 91% COD reduction compared to activated sludge, which reduced 78% COD. A group of fungi known as Ascomycetes also play an important role in the treatment of pharmaceutical wastewater, e.g. Penicillium decumbens and Penicillium lignorum have shown significant reduction in COD, phenol and color (Mohammad et al. 2006; Angayarkanni et al. 2003).

9.9.3 Algae

Treatment of pharmaceutical industry wastewater using algae has been studied over 50 years (Nandy et al. 1998; Oswald and Gotaas 1957). Microalgae have a potential to reduce the contaminants such as metals in aquatic systems (Fulke et al. 2010, 2013; Wang et al. 2013; Park et al. 2011). First of all, the metal ions are adsorbed over the algal cell surfaces rapidly, thereafter removed slowly into the cytoplasm (Omar 2002). The biomass of microalgae rises during wastewater treatment and has the potential to remove inorganic pollutants especially nitrogen and phosphorus from wastewater resulting from pharmaceutical industries. However, nutrients are removed from wastewater through a direct uptake by the algal cells (Hoffman 1998). Algal treatment of pharmaceutical wastewater, mediated through a combination of nutrient uptake, elevated pH and high dissolved oxygen concentration, can offer an ecologically secure, cheap and efficient way to remove metals and nutrients compared to conventional treatment procedures (Brennan and Owende 2010; Fulke et al. 2013; Nijhawan et al. 2013). Several researchers have established that metals are sequestered in polyphosphate bodies in green algae. These polyphosphate bodies serve as a storage pool for metals and also act as detoxification agents. Studies have revealed that the alga Scenedesmus obliquus can accumulate Cd and Zn by increasing the amount of phosphorus in the media (Yu and Wang 2004). Physiochemical characteristics like pH, COD, BOD, total solids, sodium, potassium and heavy metals have been analysed for the evaluation of toxicity of pharmaceutical wastewater after its treatment with micro green algae Scenedesmus quadricauda (Vanerkar et al. 2015).

9.9.4 Plants

Phytoremediation of wastewater is an emerging low-cost technique for removal of hazardous metal ions from pharmaceutical wastewater and is still in an experimental stage. Heavy metals such as cadmium and lead are not easily absorbed by microorganisms. In such case, phytoremediation is proved as a better tool for bio-treatment because natural or transgenic plants are able to bioaccumulate these toxins (Amin et al. 2013). Aquatic plants have an excellent capacity to reduce the level of toxic metals, BOD and total solids from the pharmaceutical wastewater (Table 9.8). Typha latipholia and Phragmitis karka used for treatment of pharmaceutical effluent (Billore et al. 2001) by different mechanism such as nitrification and denitrification. Some physicochemical processes such as the fixation of phosphate by iron and aluminium in the soil filter are also used by plant for remediation of wastes. Researchers also reported the phytoremediation of phenol by peroxidases of tomato hairy root cultures in wastewater from pharma industries (González et al. 2006). Moreover, plants are able to tolerate high concentrations of antibiotics, nutrients and heavy metals (Table 9.8) and in some cases even to accumulate them in their tissues. Plant contains various metabolites to degrade pharmaceutical wastes, for example in the case of Lemna gibba, phenyl-beta-D-glucopyranoside was identified as a metabolite resulting from phenol degradation (Barber et al. 1995).

9.10 Water Recycling and Reuse Technologies

Water recycling is a way to reuse treated water for beneficial purposes such as agricultural and landscape irrigation, industrial processes, toilet flushing and replenishing a ground water basin. Water recycling technologies offers resources and financial savings. Wastewater treatment can be tailored to meet the water quality requirements of a planned reuse. Recycled water for landscape irrigation requires less treatment than recycled water for drinking water. Various technologies are using for recycling of pharmaceutical wastewater such as:

-

1.

Membrane filtration system

-

2.

Nanotechnology

-

3.

Microbial fuel cells

-

4.

Natural treatment system

-

5.

Dry urine diverting toilets

9.10.1 Membrane Filtration System (MFS)

A membrane is a thin layer of semi-permeable material that separates substances when a driving force is applied across the membrane. MFS is used for removal of microorganisms and natural organic material, which can impart color, tastes, and odors to water and react with disinfectants to form disinfection byproducts. In Pharmaceutical industry MFS is used for cold sterilisation. Cold sterilization is a method of sterilization that requires the reusable semi-critical items to be immersed in EPA-approved liquid chemicals. These chemicals can include glutaraldehydes, peracetic acid, and hydrogen peroxide-based solutions. As advancements are made in membrane production and module design, capital and operating costs continue to decline. The membrane filtration processes includes microfiltration (0.03–10 μ), ultrafiltration (0.002–0.1 μ), nanofiltration (0.001 μ) and reverse osmosis.

9.10.2 Nanotechnology

Nanotechnology encompasses the creation of new materials and devices from nano-sized building blocks (Hu and Shaw 1998). Building blocks that are used to make nano molecules are arranged with dimensions of 1–100 nm. For improving the wastewater treatment and recycling processes, the use of nanomaterials is being researched to construct separation process (Bellona and Drewes 2007). Additionally, the use of nanomaterials for bioremediation and disinfection of wastewater is gaining popularity (Hu et al. 2005; Mohan and Pittman 2007). For instance, nanomaterials metal oxide (TiO2) is tested successfully for their antimicrobial activity. Fullerenes (C60) as pollution tracers are being used to provide contaminant-fate information to assist in developing water remediation strategies. Magnetic nanoparticles are being developed to adsorb metals and organic compounds (Hillie et al. 2006). Various pharmaceutical pollutants such as phthalates, alkylphenols, bisphenol-A and many others could be removed by using nanofiltration membranes. Nanofiltration membranes are used to produce effluent with low concentrations of pharmaceutical pollutants (Bruggen et al. 2008). Table 9.9 summarizes various nanomembranes and their processes.

9.10.3 Microbial Fuel Cells

Microbial fuel cells (MFCs) are promising technology for the treatment of pharmaceutical wastewaters (Mahendra and Mahavarkar 2013). It is a green approach for the utilization of wastewater for the generation of bioelectricity. Its great advantage is the direct conversion of organic waste into electricity. They have capability to recover bioenergy out of the wastewater, while limiting both the energy input and the excess sludge production (Rabaey and Verstraete 2005). MFC is just like a unique kind of battery or electrochemical cell, which contains two electrodes anode and cathode, separated by an ion exchange membrane (Fig. 9.6). On the anode side, bacteria grow and proliferate, forming biofilm (a dense cell aggregate) that adheres to the MFC’s anode. During their microbial metabolism the bacteria act as catalysts for converting the organic substrate into CO2 and H+/e−. Normally many bacteria use oxygen as a final electron acceptor, but in the anaerobic environment of the MFC, specialized bacteria that send the electrons to an insoluble electron acceptor means to MFC’s anode. The anode-respiring bacteria are able to oxidize organic pollutants found in pharmaceutical wastewater and transfer the electrons to the anode. The scavenged electrons then flow through an electrical circuit and terminate at cathode of MFC, thus generating electricity. Ions are transported through the fuel cell’s ion membrane, to maintain electroneutrality, although the membrane is often excluded. Therefore, MFC may perform double duty, targeting electrons from waste streams and converting them into useful energy. The performance of MFCs decreased with a decrease in the wastewater concentration. If electricity generation in these systems can be increased, MFC technology may provide a new method to counteract wastewater treatment plant operating cost, making wastewater treatment more affordable for both developing and developed nations. Thus, wastewater treatment along with production of electricity may help in saving money.

9.10.4 Natural Wastewater Treatment System

Natural treatment systems (NTS) are engineered system that has a minimal dependence on mechanical elements to support the wastewater treatment and recycling processes, instead using microorganism, plants, soil and other natural processes to degrade pharmaceutical wastewater pollutants. NTS cleans pharmaceutical wastewater in a sustainable form at low cost, low input manner and can be designed to have a long life. NTS are intended to treat wastewater that has already gone through primary or secondary treatment for providing further treatment, polishing and recycling. Some important processes that play a role in the NTS include bacterial decomposition, natural aeration, natural cooling (especially in night), nutrient uptake by plants, metal reduction through sedimentation, adsorption of metals to soils and filtration through gravel or other media. Five major types of NTS are commonly used:

-

1.

Wetland treatment

-

2.

Phytotreatment

-

3.

Water quality trading

-

4.

Indirect discharge

-

5.

Wastewater pond systems

9.10.4.1 Wetland Treatment

Wetland treatment involves utilizing existing wetlands or constructing engineered wetlands to treat pharmaceutical wastewater. Many natural processes such as water uptake, microbial breakdown, passive cooling, sedimentation etc occur in wetlands can help to reduce common pollutants (TSS, BOD, COD, metals and temperature). Wetland used for wastewater treatment typically has a capacity to control flow direction, detention time, water level and rely totally on natural processes. There are two basic types of wetland treatment systems: free water surface (FWS) (Fig. 9.7) and vegetated submerged bed (VSB) wetlands (Fig. 9.8).

FWS visually resemble wetland that contains aquatic plants that grow in soil layer on bottom of wetland and water flow through the stems and leaves of plants. VSB do not resemble natural wetlands because they have no visible water instead they consist of a bed of media (crushed rock, small stones, sand or soil) which has been planted with aquatic plants. Wetland treatment may also provide additional community benefits including the creation and preservation of wildlife habitat, environmental education and recreation opportunities for hiking and bird watching.

9.10.4.2 Phytotreatment

Treatment of wastewater by using plants (rooted plants, floating aquatic plants and algae) is known as phytoremediation. In this treatment system effluent passes through a vegetated medium, allowing for further recycling of effluent. N and P in the wastewater are utilised as nutrients by plants. The plants uptake the treated wastewater and absorb the nutrients along with other pollutants such as metals. Further polishing occurs as the effluent filters through the soil medium in which the plants grow before flowing to ground or surface water. There are two major phototreatment systems: water recycling and tree farms.

Recycled treated wastewater can be used for:

-

Irrigation on animal pasture, parks and playgrounds.

-

Irrigation on orchards and vineyards.

-

Industrial uses such as cooling, rock crushing, street sweeping, commercial car washing and dust control.

Tree farms treatment systems can be used to grow trees, such as poplars to absorb nutrients, reuse biosolids and grow woods.

9.10.4.3 Water Quality Trading (WQT)

WQT is a flexible approach to achieve water quality goals in cost effective manner with great environmental benefits. It can be used to balance a variety of pharmaceutical wastewater pollutants parameters such as temperature, nutrients etc. Sponsored committee can obtain pollution reduction credits by taking action to create or restore wetlands, streamside riparian areas, floodplains, aquatic habitat or other stream related areas. Thus, WQT can provide supplementary environmental benefits such as flood retention, riparian improvement and habitat.

9.10.4.4 Indirect Discharge (ID)

ID involve physical, chemical and biological treatment processes for further treatment of groundwater through the soil matrix before it reaches to the surface water. The soil matrix may be saturated all the time by infiltration, and the soil and associated microbial and chemical/physical activity further treats the wastewater. Systems that could be used for ID of treated pharmaceutical wastewater include:

-

Rapid and moderate rate infiltration systems

-

Constructed wetlands for evaporation/transpiration and minimal seepage

-

Surface spray irrigation applied at greater than agronomic rates

-

Exfiltration galleries, drainfields, mounds and bottomless sand filters

-

Evaporation ponds with infiltration components

-

Injection wells discharging above the water table

9.10.4.5 Wastewater Pond Systems (WPS)

Wastewater ponds are large ponds where wastewater is held for days or months. These ponds are designed to reproduce a natural pond, encouraging the growth of aerobic and anaerobic bacteria those may reduce BOD, TSS and pathogens levels. There are two main types of WPS:

-

1.

Facultative wastewater ponds: This is used to treat raw industrial wastewater at primary or secondary treatment level (Fig. 9.9). They contain an aerobic layer of water overlaying an anaerobic layer. Aerobic bacteria provide odor control along with nutrient and BOD removal, while anaerobic bacteria aid in sludge digestion, denitrification and some BOD removal. The system relies on oxygen production by photosynthetic algae and/or reaeration at the surface to maintain the aerobic processes.

-

2.

Aerobic pond systems: These are shallower ponds that maximize aerobic processes. Aerobic ponds are often adopted to improve effluent treatment High light penetration and good aeration at the surface allow aerobic bacteria to biochemically stabilize the wastewater (Fig. 9.10). Advantage of this system includes short detention time with low land and energy requirements. The disadvantage of this pond system is more complexity and the effluent may contain high levels of TSS if the algae are not removed prior to discharge.

9.10.5 Dry Urine-Diverting Toilets

Dry urine-diverting toilets neither pollute nor waste the water. The human waste is diverted, sanitised and recycled in a safer way. This approach is also called ecological sanitation or ecosan. For an adequate functioning of these kinds of toilets, system does not require a constant source of water. The design of a toilet makes it easily adaptable to different types of communities and can be assembled with cheap and locally produced materials.

Special toilets don’t mix the urine and faeces (Fig. 9.11). Dry urine diverting toilets separate, collect, store and treat these two flows. Well-constructed and well-maintained urine-diverting toilets don’t develop bad odors, nor attract flies. After sanitising the urine and faeces, these nutrients rich products are reused in agriculture or garden.

For better activity of dry urine diverting toilet, four things must be keep in mind that will assure that there will be no smell and the products can be adequate sanitised:

-

The design of the toilet-slap assures urine does not touch the faeces.

-

The faeces are led into a faeces chamber and are covered with prepared soil, ashes, lime and/or wood-flints.

-

The chambers must be kept completely dry.

-

Urine and faeces are always treated separately.

9.11 Environmental Benefits of Water Recycling

Water recycling decreases the diversion of water from responsive ecosystems. Other advantages of waste recycling include decreasing wastewater discharges and reducing pollution. Recycled water can also be used to create or enhance wetlands and riparian habitats. Some most important benefits of wastewater recycling are as:

9.11.1 Decrease Diversion of Freshwater from Sensitive Ecosystems

Plants, wildlife and fish depend on sufficient water flow to their habitats to live and reproduce. The lack of adequate flow, as a result of diversion for agricultural, urban, and industrial purposes, may cause drop of water quality and ecosystem health. People who reuse water have demand of using recycled water for the environment and ecosystems health.

9.11.2 Decrease Wastewater Discharge to Active Water Bodies

In some cases, a driving force for water recycling does not come from water supply requirement but from a need to eliminate or decrease wastewater discharge to the ocean or a stream. By avoiding such conversion of salt water marsh to brackish marsh, the habitat for two endangered species can be protected.

9.11.3 Used to Create or Enhance Wetlands and Riparian Habitats

Wetlands provide many benefits including wildlife habitat, water quality improvement, flood diminishment and fisheries breeding grounds.

9.11.4 Reduce and Prevent Pollution

When pollutant discharge to water bodies is reduced, the pollutant loadings to these bodies are decreased. Application of recycled water for agricultural and landscape irrigation can provide an additional source of nutrients and natural sources of fertilizers.

9.11.5 Save Energy

As the demand for water increases, more water is treated and transported over large distances which can require a lot of energy. Recycling water reduces the energy need to move water longer distances or pump water from deep within an aquifer.

9.12 Future of Water Recycling

Water recycling has proven to be effective, essential and successful process in creating a reliable water supply without compromising public health. Nonpotable reuse is a widely acceptable practice that will continue to grow. However, in many parts of the developed countries, the usage of recycled water is increasing to accommodate environmental need and water supply demand. Recycling of wastewater requires far less energy than treating salt water using a desalination system.

While water recycling is vary cost effective and environmental sustainable approach, the wastewater treatment for reuse and the installation of distribution systems at centralized facilities can be initially expensive compared to such water supply alternatives as imported water, ground water or the use of gray water. Institutional barriers, as well as varying agency priorities and public misperception, can make it difficult to implement water recycling projects. Finally, early in the planning process, agencies must reach out to the public to address any concerns and to keep the public informed and involved in the planning processes. As water energy demand and environmental need grow, water recycling will play a big role to insure proper water supply. By working together to overcome problems, water recycling with its conservation can help us to sustainably manage our vital water resources. Communities and businesses are working together to meet the need of water supply locally in a way to expand the resources, support the environment and strengthen the economy.

References

Acharya BK, Mohana S, Madamwar D (2008) Anaerobic treatment of distillery spent wash: a study on up flow anaerobic fixed film bioreactor. Bioresour Technol 99:4621–4626

Agarry SE, Solomon BO (2008) Kinetics of batch microbial degradation of phenols by indigenous Pseudomonas fluorescence. Int J Environ Sci Technol 5:223–232

Aissaoui S, Ouled-Haddar H, Sifour M et al (2017) Biological removal of the mixed pharmaceuticals: diclofenac, ibuprofen, and sulfamethoxazole using a bacterial consortium. Iranian J Biotech 15:136–142

Akunna JC, Clark M (2000) Performance of granular bed anaerobic baffled reactor treating whiskey distillery wastewater. Bioresour Technol 74:257–261

Allam A, Tawfik A, El-Saadi A et al (2016) Potentials of using duckweed (Lemna gibba) for treatment of drainage water for reuse in irrigation purposes. Desalin Water Treat 57:459–467

Amin A, Naik ATR, Azhar M et al (2013) Bioremediation of different waste waters – a review. Cont J Fish Aquat Sci 7:7–17

Angayarkanni J, Palaniswamy M, Swaminathan K (2003) Biotreatment of distillery effluent using Aspergillus niveus. Bull Environ Contam Toxicol 70:268–277

Barber JT, Sharma HA, Ensley HE et al (1995) Detoxification of phenol by the aquatic angiosperm, Lemna gibba. Chemosphere 31:3567–3574

Bellona C, Drewes JE (2007) Viability of a low-pressure nanofilter in treating recycled water for water reuse applications: a pilot-scale study. Water Res 41:3948–3958

Billore SK, Singh N, Ram HK et al (2001) Treatment of a molasses based distillery effluent in a constructed wetland in central India. Water Sci Technol 44:441–448

Brain RA, Ramirez AJ, Fulton BA et al (2008) Herbicidal effects of sulfamethoxazole in Lemna gibba: using paminobenzoic acid as a biomarker of effect. Environ Sci Technol 42:8965–8970

Brennan L, Owende P (2010) Biofuels from microalgae – a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sust Energ Rev 14:557–577

Bruggen BVD, Mänttäri M, Nyström M (2008) Drawbacks of applying nanofiltration and how to avoid them: A review. Sep Purif Technol 63:251–263

Chang C, Chang J, Vigneswaran S et al (2008) Pharmaceutical wastewater treatment by membrane bioreactor process – a case study in southern Taiwan. Desalination 234:386–392

Chaturvedi S, Chandra R, Rai V (2006) Isolation and characterization of Phragmitis australis (L) rhizosphere bacteria from contaminated site for bioremediation of colored distillery effluent. Ecol Eng 27:202–207

Chelliapan S, Yuzir A, Md Din MF et al (2011) Anaerobic pre-treatment of pharmaceutical wastewater using packed bed reactor. Int J Chem Eng Appl 2:32–37

Chen Z, Nanqi R, Wang A et al (2008) A novel application of TPAD-MBR system to the pilot treatment of chemical synthesis based wastewater. Water Res 42:3385–3392

Cortes-Esquivel JA, Giácoman-Vallejos G, Barceló-Quintal ID et al (2012) Heavy metals removal from swine wastewater using constructed wetlands with horizontal sub-surface flow. J Environ Prot 3:871–877

D’Abrosca B, Fiorentino A, Izzo A et al (2008) Phytotoxicity evaluation of five pharmaceutical pollutants detected in surface water on germination and growth of cultivated and spontaneous plants. J Environ Sci Health A 43:285–294

Das MP, Bashwant M, Kumar K et al (2012) Control of pharmaceutical effluent parameters through bioremediation. J Chem Pharm Res 4:1061–1065

Deegan AM, Shaik B, Nolan K et al (2011) Treatment options for wastewater effluents from pharmaceutical companies. Int J Environ Sci Tech 8:649–666

Di Luca GA, Hadad HR, Mufarrege MM et al (2014) Improvement of Cr phytoremediation by Pistia stratiotes in presence of nutrients. Int J Phytoremediation 16:167–178

Du, Liu (2012) Occurrence, fate and ecotoxicity of antibiotics in agro-ecosystems: a review. Agron Sustain Dev 32:309–327

Duffner FM, Kirchner U, Bauer MP et al (2000) Phenol/cresol degradation by the thermophillic Bacillus thermoglucosidasius A7: cloning and sequence analysis of five genes involved in the pathway. Gene 256:215–221

Ebele AJ, Abdallah MAE, Harrad S (2017) Pharmaceuticals and personal care products (PPCPs) in the freshwater aquatic environment. Emerg Contam 3:1–16

Enright AM, McHugh S, Collins G et al (2005) Low-temperature anaerobic biological treatment of solvent containing pharmaceutical wastewater. Water Res 39:4587–4596

Fang HHP, Chui HK, Li YY (1995) Anaerobic degradation of butryate in UASB reactor. Bioresour Technol 51:75–81

Fulke AB, Mudliar SN, Yadav R et al (2010) Bio-mitigation of CO2, calcite formation and simultaneous biodiesel precursors production using Chlorella sp. Bioresour Technol 101:8473–8476

Fulke AB, Chambhare KY, Sangolkar LN et al (2013) Potential of wastewater grown algae for biodiesel production and CO2 sequestration. Afr J Biotechnol 20:2939–2948

Furtula V, Stephenson GL, Olaveson KM et al (2012) Effects of the veterinary pharmaceutical salinomycin and its formulation on the plant Brassica rapa. Arch Environ Contam Toxicol 63:513–522

Gangagni Rao A, Venkata Naidu G, Krishna Prasad K et al (2005) Anaerobic treatment of wastewater with high suspended solids from a bulk drug industry using fixed film reactor (AFFR). Bioresour Technol 96:87–93

Gao J, Huang J, Chen W et al (2016) Fate and removal of typical pharmaceutical and personal care products in a wastewater treatment plant from Beijing: a mass balance study. Front Env Sci Eng 10:491–501

Ghosh M, Verma SC, Mengoni A et al (2004) Enrichment and identification of bacteria capable of reducing chemical oxygen demand of anaerobically treated spent wash. J Appl Microbiol 6:241–278

González PS, Capozucca CE, Tigier HA et al (2006) Phytoremediation of phenol from wastewater, by peroxidises of tomato hairy root cultures. Enzym Microbial Technol 39:647–653

Goossens H, Ferech M, Coenen S et al (2007) European surveillance of antimicrobial consumption project group: comparison of outpatient systemic antibacterial use in 2004 in the United States and 27 European countries. Clin Infect Dis 44:1091–1095

Goss MJ, Tubeileh A, Goorahoo D (2013) Chapter 5 – A review of the use of organic amendments and the risk to human health. In: Donald LS (ed). Adv Agron 120:275–379

Harper SR, Pohland FG (1986) Recent developments in hydrogen management during anaerobic biological wastewater treatment. Biotechnol Bioeng 28:585–602

Helmig E, Fettig J, Cordone L (2007) API removal from pharmaceutical manufacturing wastewater – results of process development, pilot-testing, and scale-up WEF session, Rhode Island 10:207–226

Hill GA, Milne BJ, Nawrocki PA (1996) Cometabolic degradation of 4-chlorophenol by Alcaligenes eutrophus. Appl Microbiol Biotechnol 46:163–168

Hillie T, Munasinghe M, Hlobe M et al (2006) Nanotechnology, water, development. Background paper for International Workshop on. Nanotechnology, Water and Development, Chennai, India, 10–12 October, Meridian Institute, P44

Hillis D, Fletcher J, Solomon K et al (2011) Effects of ten antibiotics on seed germination and root elongation in three plant species. Arch Environ Contam Toxicol 60:220–232

Hirth N, Topp E, Dörfler U et al (2016) An effective bioremediation approach for enhanced microbial degradation of the veterinary antibiotic sulfamethazine in an agricultural soil. Chem Biol Tech Agric 29:2–11

Hoffman JP (1998) Wastewater treatment with suspended and non suspended algae. J Phycol 34:757–763

Hu EL, Shaw DT (1998) Synthesis and assembly. In: Siegel RW, Hu E, Roco MC (eds) Nanostructure science and technology. Kluwer academic publishers, Dordrecht

Hu J, Chen G, Lo IMC (2005) Removal and recovery of Cr(VI) from wastewater by maghemite nanoparticles. Water Res 39:4528–4536

Husnain A, Ali SS, Zaheeruddin et al (2013) Phytoremediation of heavy metals contamination in industrial waste water by Euphorbia Prostrata. Curr Res J Biol Sci 5:36–41

Irvine RL, Miller G, Bhamrah AS (1979) Sequencing batch treatment of wastewater in rural areas. J Water Pollut Control Fed 51:244–254

Jones-Lepp TL, Sanchez CA, Moy T et al (2010) Method development and application to determine potential plant uptake of antibiotics and other drugs in irrigated crop production systems. J Agric Food Chem 58:11568–11573

Kadam A, Patil S, Tumkur A (2016) Pharmaceutical waste management an overview. Ind J Pharm Pract 9:1–3

Kavitha GV, Beebi SK (2003) Biodegradation of phenol in a packed bed reactor using peat media. Asian J Microbiol Biotechnol Environ Sci 5(2):157–159

Kavitha RV, Murthy VK, Makam R et al (2012) Physico-chemical analysis of effluents from pharmaceutical industry and its efficiency study. Int J Eng Res Appl 2:103–110

Kong WD, Zhu YG, Liang YC et al (2007) Uptake of oxytetracycline and its phytotoxicity to alfalfa (Medicago sativa L.). Environ Pollut 147:187–193

Kotyza J, Soudek P, Kafka Z et al (2010) Phytoremediation of pharmaceuticals-preliminary study. Int J Phytoremediation 12:306–316

Kristiansen R, Nguyen HT, Saunders AM et al (2013) A metabolic model for members of the genus Tetrasphaera involved in enhanced biological phosphorus removal. Multidiscip J Microb Ecol 7:543–554

Kumar A, Kumar S, Kumar S (2005) Biodegradation kinetics of phenol and catechol using Pseudomonas putida MTCC 1194. Biochem Eng J 22:151–159

Lapara TM, Nakatsu CH, Pantea LM et al (2001) Aerobic biological treatment of a pharmaceutical wastewater: effect of temperature on COD removal and bacterial community development. Water Res 35:4417–4425

Levine R (2016) Microbial degradation of sulfonamide antibiotics: A Thesis, vol 5. Springer, pp 1–46

Li D, Yang M, Hu J et al (2008) Determination and fate of oxytetracycline and related compounds in oxytetracycline production wastewater and the receiving river. Environ Toxicol Chem 27:80–86

Liu F, Ying G-G, Tao R et al (2009) Effects of six selected antibiotics on plant growth and soil microbial and enzymatic activities. Environ Pollut 157:1636–1642

Liu L, Liu YH, Liu CX et al (2013) Potential effect and accumulation of veterinary antibiotics in Phragmites australis under hydroponic conditions. Ecol Eng 53:138–143

Llaneza J, Villar CJ, Salas JA et al (1985) Plasmid-mediated fosfomycin resistance is due to enzymatic modification of the antibiotic. Antimicrob Agents Chemother 28:163–164

Madukasi EI, Dai X, He C et al (2010) Potentials of phototrophic bacteria in treating pharmaceutical wastewater. Int J Environ Sci Technol 7:165–174

Mahendra BG, Mahavarkar S (2013) Treatment of wastewater and electricity generation using microbial fuel cell technology. Int J Res EngTechnol 1:2321–7308

Mayabhate, Gupta SK, Joshi SG (1988) Biological treatment of pharmaceutical wastewater. Water Air Soil Pollut 38:189–197

Migliore L, Brambilla G, Cozzolino S et al (1995) Effect on plants of sulphadimethoxine used in intensive farming (Panicum miliaceum, Pisum sativum and Zea mays). Agric Ecosyst Environ 52:103–110

Mishra S, Mohanty M, Pradhan C et al (2013) Physico-chemical assessment of paper mill effluent and its heavy metal remediation using aquatic macrophytes-a case study at JK Paper mill, Rayagada. India. Environ Monit Assess 185:4347–4359

Mohammad P, Azarmidokht H, Fatollah M et al (2006) Application of response surface methodology for optimization of important parameters in decolorizing treated distillery wastewater using Aspergillus fumigatus UB2.60. Int Biodeterior Biodegrad 57:195–199

Mohan D, Pittman CU Jr (2007) Arsenic removal from water/wastewater using adsorbents-a critical review. J Hazard Mater 142:1–53

Morisaki N, Iwasaki S, Yazawa K et al (1993) Inactivated products of rifampicin by pathogenic Nocardia spp.: structures of glycosylated and phosphorylated metabolites of rifampicin and 3-formylrifamycin SV. J Antibiot 46:1605–1610

Murphy RJ, Jones DE, Stessel RI (1995) Relationship of microbial mass and activity in biodegradation of solid waste. Waste Manag Res 13:485–497

Nandy T, Kaul SN, Szpyrcowicz L (1998) Treatment of herbal pharmaceutical wastewater with energy recovery. Int J Environ Stud 54:83–105

Nijhawan A, Labhasetwar P, Jain P et al (2013) Public consultation on artificial aquifer recharge using treated municipal wastewater. Resour Conserv Recycl 70:20–24

Oktem Y, Ince O, Sallis P et al (2007) Anaerobic treatment of a chemical synthesis-based pharmaceutical wastewater in a hybrid upflow anaerobic sludge blanket reactor. Bioresour Technol 99:1089–1096

Omar HH (2002) Bioremoval of zinc ions by Scenedesmus obliquus and Scenedesmus quadricauda and its effect on growth and metabolism. Int Biodeter Biodegr 50:95–100

Oswald WJ, Gotaas HB (1957) Photosynthesis in sewage treatment. Trans Am Soc Civ Eng 122:73–105

Park BH, Levy SB (1988) The cryptic tetacycline resistance determinant on Tn4400 mediates tetracycline Park, S.B. Levy degradation as well as tetracycline efflux. Antimicrob Agents Chemother 32:1797–1800

Park JBK, Craggs RJ, Shilton AN (2011) Wastewater treatment high rate algal ponds for biofuel production. Bioresour Technol 102:35–42

Patel HD, Madamwar (2000) Biomethanation of low pH petrochemical wastewater using up-flow fixed film anaerobic bioreactors. World J Microbiol Biotechnol 16:69–75

Patneedi CB, Prasadu KD (2015) Impact of pharmaceutical wastes on human life and environment. Rasayan J Chem 8:67–70

Piotrowicz-Cieślak AI, Adomas B, Nałęcz-Jawecki G et al (2010) Phytotoxicity of sulfamethazine soil pollutant to six legume plant species. J Toxic Environ Health 73:1220–1229

Rabaey K, Verstraete W (2005) Microbial fuel cells: novel biotechnology for energy generation. Trends Biotechnol 23:291–298

Rajeshwari KV, Balakrishnan M, Kansal A et al (2000) State-of art of anaerobic digestion technology for industrial wastewater treatment. Renew Sustain Energy Rev 4:135–156

Ros M, Zupancic GD (2002) Thermophilic aerobic digestion of waste activated sludge. Acta Chim Slov 49:931–943

Rozitis DZ, Strade E (2015) COD reduction ability of microorganisms isolated from highly loaded pharmaceutical wastewater pre-treatment process. J Mater Environ Sci 6:507–512

Šabić M, Čižmek L, Vuković Domanovac M et al (2015) Biodegradation of erythromycin with environmental microorganism Pseudomonas aeruginosa 3011. Chem Biochem Eng 29:367–373

Saha P, Banerjee A, Sarkar S (2015) Phytoremediation potential of Duckweed (Lemna minor L.) on steel wastewater. Int J Phytoremediation 6:589–596

Saha P, Shinde O, Sarkar S (2017) Phytoremediation of industrial mines wastewater using water hyacinth. Int J Phytoremediation 19:87–96

Schuster A, Hädrich C, Kümmerer K (2008) Flows of active pharmaceutical ingredients originating from health care practices on a local, regional, and nationwide level in Germany-is hospital effluent treatment an effective approach for risk reduction? Water Air Soil Pollut 8:457–471

Schwarzenbach RP, Escher BI, Fenner K et al (2006) The Challenge of micropollutants in aquatic systems. Science 313:1072–1077

Segura PA, Francois M, Gagnon C et al (2009) Review of the occurrence of anti-infectives in contaminated wastewaters and natural and drinking waters. Environ Health Perspect 117:675–684

Shi X, Leong KY, Ng HY (2017) Anaerobic treatment of pharmaceutical wastewater: a critical review. Bioresour Technol 245:1238–1244

Siegrist H, Ternes TA, Joss A (2004) Scrutinizing pharmaceuticals and personal care products in wastewater treatment. J Env Sci Tech 38:392–399

Smith CA (2002) Managing pharmaceutical waste. J Pharm Soc Wisc 6:17–22

Spina F, Anastasi A, Prigione V et al (2012) Biological treatment of industrial wastewaters: a fungal approach. Chem Eng Trans 27:175–180

Sreekanth D, Sivaramakrishna D, Himabindu V et al (2009) Thermophilic treatment of bulk drug pharmaceutical industrial wastewaters by using hybrid up flow anaerobic sludge blanket reactor. Bioresour Technol 100:2534–2539

Sui Q, Cao X, Lu S et al (2015) Occurrence, sources and fate of pharmaceuticals and personal care products in the groundwater: a review. Emerg Contam 1:14–24

Suman Raj D, Anjaneyulu Y (2005) Evaluation of biokinetic parameters for pharmaceutical wastewaters using aerobic oxidation integrated with chemical treatment. Process Biochem 40:165–175

Tanaka Y, Yazawa K, Dabbs ER et al (1996) Different rifampicin inactivation mechanisms in Nocardia and related taxa. Microbiol Immunol 40:1–4

Tewari L, Malviya P (2002) Biodegradation of catechol by fluorescent Psuedomonas for sustainable environment. J Sci Ind Res 61:70–74

Tóth AJ, Gergely F, Mizsey P (2011) Physicochemical treatment of pharmaceutical process wastewater: distillation and membrane processes. Chem Eng 55:59–67

United States EPA (2010) Nutrient control design manual. United States Environmental Protection Agency, Washington, DC

Vanerkar AP, Fulke AB, Lokhande SK et al (2015) Recycling and treatment of herbal pharmaceutical wastewater using Scenedesmus quadricuada. Curr Sci 108:979–983

Wang H, Zhang W, Chen L et al (2013) The contamination and control of biological pollutants in mass cultivation of microalgae. Bioresour Technol 128:745–750

Wolverton BC, McKown MM (1976) Water hyacinths for removal of phenols from polluted waters. Aquat Bot 2:191–202

Wright GD (2005) Bacterial resistance to antibiotics: enzymatic degradation and modification. Adv Drug Deliv Rev 57:1451–1470

Yu RQ, Wang WX (2004) Biokinetics of cadmium, selenium and zinc in freshwater alga Scenedesmus obliquus under different phosphorus and nitrogen conditions and metal. Environ Pollut 129:443–456

Zhang J, Jiang Y, Zhou J et al (2010) Elevated body burdens of PBDEs, dioxins, and PCBs on thyroid hormone homeostasis at an electronic waste recycling site in China. Environ Sci Technol 44:3956–3962

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Gupta, R., Sati, B., Gupta, A. (2019). Treatment and Recycling of Wastewater from Pharmaceutical Industry. In: Singh, R., Singh, R. (eds) Advances in Biological Treatment of Industrial Waste Water and their Recycling for a Sustainable Future. Applied Environmental Science and Engineering for a Sustainable Future. Springer, Singapore. https://doi.org/10.1007/978-981-13-1468-1_9

Download citation

DOI: https://doi.org/10.1007/978-981-13-1468-1_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-1467-4

Online ISBN: 978-981-13-1468-1

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)