Abstract

The Tile Calorimeter (TileCal) is a hadronic calorimeter covering the central region of the ATLAS experiment at the LHC. It is a non-compensating sampling calorimeter comprised of steel and scintillating plastic tiles which are read-out by photomultiplier tubes (PMT). The TileCal is regularly monitored and calibrated by several different calibration systems: a Cs radioactive source that illuminates the scintillating tiles directly, a laser light system to directly test the PMT response, and a charge injection system (CIS) for the front-end electronics.

These calibrations systems, in conjunction with data collected during proton-proton collisions, provide extensive monitoring of the instrument and a means for equalizing the calorimeter response at each stage of the signal propagation.

The performance of the calorimeter and its calibration has been established with cosmic ray muons and the large sample of the proton-proton collisions to study the energy response at the electromagnetic scale, probe of the hadronic response and verify the calorimeter time resolution.

This contribution presents a description of the different TileCal calibration systems with the latest results on their performance and the results on the calorimeter operation and performance during the LHC Run 2.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

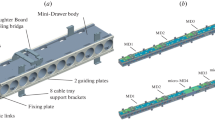

The Tile Calorimeter [1] is a hadronic non-compensating sampling calorimeter of ATLAS experiment [3] at Large Hadron Collider (LHC) [4] at CERN. It uses steel as a radiator and scintillating tiles as an active medium. The 3 mm thick tiles, made of PSM or BASF polystyrene plus dopants, are oriented perpendicular to the beam axis, and are wrapped in Tyvek paper. The light from the tiles is read out via green wavelength shifting fibers (WLS) fibres, of type Y11 made by Kuraray, connected to the both short edges of the tiles. The WLS fibres are bundled and read out by Hamamatsu R7877 photomultiplier tubes, located in a modules girder, as shown in Fig. 1. The calorimeter is divided into 3 cylinders: one Long Barrel (with two readout regions LBA and LBC) and two Extended Barrels (EBA,EBC). Each cylinder is further subdivided azimuthally in 64 modules. The calorimeter is 12 m in overall length with 4.25 m outer radius.

The Long Barrel module covers the pseudo-rapidity region \(|\eta |<1.0\), while the Extended Barrels cover \(0.8<|\eta |<1.7\). Each module have three longitudinal layers (A,BC,D), with the total thickness in radiation lengths of about \(7.4\lambda \). The calorimeter cells are defined by the WLS fiber routing, giving about 5200 cells in all calorimeter with \(0.1\times 0.1~\varDelta \eta \times \varDelta \phi \) granularity for A and BC cells, and \(0.2\times 0.1~\varDelta \eta \times \varDelta \phi \) for outer D cells. Analogue trigger sums from pseudo-projective towers are provided for the first level trigger. The dynamic range of the PMTs and associated electronics from 10 MeV to 750 GeV allows for the measurements of single particles and large jets. The design resolution for jets is \(50\%/\sqrt{E}\oplus 3\%\) and the response is linear within 2% for up to 4 TeV jets [2].

ATLAS Calorimetry and Tile Calorimeter module design [2].

2 Calibration Systems

To provide correct energy and time for data reconstruction, an elaborate chain of calibration systems [5], shown in Fig. 2 is used:

-

Charge injection system (CIS) to calibrate the response of the ADC

-

Laser calibration system to measure the performance of the PMTs

-

Cesium radioactive source system (Cs) to calibrate the full optical path from scintillating tiles and WLS fibres down to integrated current of the PMT

-

Minimum bias monitoring system (MBM) to monitor the response of the calorimeter online via integrated currents of PMTs

About 11% of 192 Tile calorimeter modules were calibrated at the test beams and the electromagnetic (EM) scale (1.05 pC/GeV) was transferred to the final detector with the help of calibration systems [6].

Tile Calorimeter calibration systems chain [2].

For the charge injection system [7], charges of known values, spanning the full range of ADC (0–800 pC) are injected by a 5.2 pF (±2%) or more precise 100 pF capacitor (±1%) into the passive pulse shaper, that produces a pulse with a Gaussian shape (\({\sim }50~\hbox {ns}\)). Then the pulse is split and sent through two different amplifiers with a gain ratio of 1:64 and then digitized by 40 MHz ADCs. The injection timing with respect to the ADC clock can be varied. The charge injection calibration system allows to simulate a physics pulse from PMT and to calibrate both high and low gain ADCs, although the CIS pulse is shorter and has a “leakage” part. The charge of varying amplitude is injected and the slope of the response vs. injected charge gives the CIS constant for that ADC. The calibration is usually performed twice a week (for a few minutes). Typical uncertainty is 0.7% and the average of calibration coefficients was stable within 0.04% overall in year 2016. The system is also used to calibrate the first level calorimeter trigger.

Significant PMT gain drift affects the detector response and calibration, thus the PMT gain monitoring is vital. Laser calibration system [8] delivers 532 nm green light, similar to the light from WLS fibres, via 400\(\,\times \,\)100 m long clear fibres to all PMTs. For the LHC Run-2, the Laser optics box and control electronics were upgraded [9] to provide a more precise calibration and monitoring of the PMT gains, with the precision of the gain variation measurement better than 0.5%. A new integrated 6U VME control card allowed to reduce the number of system components. The laser runs are taken twice a week (for a few minutes) and some times a special long (1 h) sequence of runs is taken for precise measurements. In addition to the PMT gain monitoring, the Laser calibration system is used to cross-check problematic channels and to set-up and cross-check timing of the ADC channels.

Tile Calorimeter PMT gain variation map during 2016 pp collisions period [11].

To measure the response of the full optical chain from the scintillating tiles down to PMTs, a system with the movable radioactive gamma-source (\(^{137}Cs\), 0.662 MeV, 10 mCi) that floats in a dumb-bell shaped capsule inside stainless steel tubes through all the 436000 scintillating tiles of the calorimeter is provided [10]. The integrated PMT currents are read out during the source movement (30 cm/s). The system has been used during the optical instrumentation to check the quality of the assembly. It provides calibration constants and allows to transfer the EM scale from the test beam measurements of selected Tile Calorimeter modules to all the Tile Calorimeter. It allows to track the calorimeter response in time and to restore the response uniformity by adjusting the PMT gain via high voltage adjustments. The calibration scans are preformed every few months, each scan takes about 8 h during non-collision time. The measurement precision is better than 0.3% (Fig. 3).

Using the same integrated current readout path, the integrated current values are measured during the beam time and stored for later analysis. This data provide additional luminosity measurements and cross-check of other luminometers of ATLAS detector. It provides the transfer of calibration from low to high luminosity conditions, thanks to wide range of measurable currents. The system also allows to follow the evolution of the response of the detector to beam particles between radioactive source scans. The online luminosity is also provided for prompt monitoring.

To allow the monitoring of the calorimeter during beam time, an accelerator abort gap of about 3 us is used to send and register calibration pulses, namely the laser ones. To arbitrate, time and control these pulses with respect to the LHC signals, a 6U VME board called SHAFT is used, that contains a pattern memory with configurable delays. Normally the laser pulses are sent to the Tile Calorimeter at the rate of 3 Hz and recorded for further analysis.

3 Performance

To maintain the smallest possible number of “dead” cells and to ensure the highest quality of the data, the on-detector electronics, normally not accessible during data taking, is maintained yearly during detector openings. During the winter shut down of 2016–2017, 48 out of 256 electronics “drawers” were opened and all high and many low priority problems were fixed, leading to the 0.06% of “dead” cells after the end of the maintenance.

The ever-increasing performance of the LHC led to the increase of the pile-up and hence to the increase of the noise levels, well above the pure electronics noise that stays below 20 MeV for the most of the cells, while the pile-up noise can reach 160 MeV for the inner layer of the calorimeter cells.

The time calibration resolution reaches 1 ns level for energies above 4 GeV in one cell. The timing is initially set with splashes and tuned later with muons and jets. The stability of the time settings during the data taking is monitored with the laser pulses in empty bunches of LHC abort gap, described above.

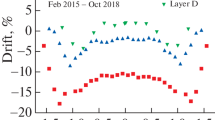

One of the goals of the sophisticated chain of calibration systems is to monitor the response variation of Tile Calorimeter in time, as the cell response is not constant due to PMT gain variation and scintillator degradation. One of the most exposed cells of inner calorimeter layer have shown as much as 2% difference between the Laser (sensitive to PMT gain variation only) and integrated currents (sensitive to PMT gain variation and scintillator degradation) responses. While one can see some recovery during 2015 data taking of LHC Run-2, there was almost no recovery in the following, high luminosity data taking period of 2016, as shown in Fig. 4.

Tile Calorimeter cell response variation in time during 2015 (left) and 2016 (right) pp collisions data taking periods [11].

An important Tile Calorimeter characteristic is the ratio of energy to track momentum (E/p) for isolated, charged hadrons in minimum bias events, and it is used to evaluate calorimeter uniformity and linearity during data taking. The data and simulation agree well, showing linearity and uniformity in detector response, the dE/dx of minimum ionizing muons (near noise threshold) show data and Monte-Carlo (MC) agreement within 3%.

Muons from cosmic rays, beam halo and collisions are used to study in-situ the electromagnetic energy scale. Only 1% response non-uniformity in \(\eta \) is seen in Tile Calorimeter Long Barrel, with a good energy response uniformity in all calorimeter layers and the data and simulation agreement.

One of the main use of the hadronic Tile Calorimeter is the measurement of jet energy and missing transverse energy (MET). The data and MC simulations agree well, the jet energy scale is consistent and the jet energy resolution is below 10% for \(\hbox {p}_\mathrm{T}>100~\hbox {GeV}\). The constant term is within expected 3%.

4 Summary

The hadronic Tile Calorimeter is a key detector to measure jet energy and missing transverse energy in ATLAS experiment at LHC. To calibrate and monitor the calorimeter response a set of calibration systems is used, that allowed to achieve great performance of Tile Calorimeter in LHC Run 2 with better than 1% precision.

References

ATLAS Collaboration: ATLAS Tile Calorimeter: Technical Design report, CERN-LHCC-96-42 (1996). https://cds.cern.ch/record/331062

ATLAS Collaboration: Readiness of the ATLAS Tile Calorimeter for LHC collisions. Eur. Phys. J. C 70, 1193 (2010) https://doi.org/10.1140/epjc/s10052-010-1508-y

ATLAS Collaboration: The ATLAS experiment at the CERN large Hadron Collider. JINST 3, S08003 (2008). https://doi.org/10.1088/1748-0221/3/08/S08003

Evans, L., Bryant, P.: LHC machine. JINST 3, S08001 (2008). https://doi.org/10.1088/1748-0221/3/08/S08001

Boumediene, D., et al.: Calibration of the Tile Hadronic Calorimeter of ATLAS at LHC. J. Phys. Conf. Ser. 587(1), 012009 (2015). https://doi.org/10.1088/1742-6596/587/1/012009

Adragna, P., et al.: Testbeam studies of production modules of the ATLAS tile calorimeter. Nucl. Instrum. Meth. A 606, 362 (2009). https://doi.org/10.1016/j.nima.2009.04.009

Anderson, K., et al.: Design of the front-end analog electronics for the ATLAS tile calorimeter. Nucl. Instrum. Meth. A 551, 469–476 (2005). https://doi.org/10.1016/j.nima.2005.06.048

Abdallah, J., et al.: The Laser calibration of the Atlas Tile Calorimeter during the LHC Run 1. JINST 11, T10005 (2016). https://doi.org/10.1088/1748-0221/11/10/T10005

Scuri, F., at al.: Performance of the ATLAS Tile LaserII calibration system. In: Proceedings, 2015 IEEE Nuclear Science Symposium and Medical Imaging Conference (NSS/MIC 2015) (2015). https://doi.org/10.1109/NSSMIC.2015.7581768

Starchenko, E., et al.: Cesium monitoring system for ATLAS Tile Hadron Calorimeter. Nucl. Instrum. Meth. A 494, 381 (2002). https://doi.org/10.1016/S0168-9002(02)01507-3

ATLAS Tile Calorimeter Subsystem, Approved Plots. https://twiki.cern.ch/twiki/bin/view/AtlasPublic/ApprovedPlotsTile. Accessed 22 May 2017

Author information

Authors and Affiliations

Consortia

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Solovyanov, O., on behalf of the ATLAS Collaboration. (2018). Calibration and Performance of the ATLAS Tile Calorimeter During the Run 2 of the LHC. In: Liu, ZA. (eds) Proceedings of International Conference on Technology and Instrumentation in Particle Physics 2017. TIPP 2017. Springer Proceedings in Physics, vol 213. Springer, Singapore. https://doi.org/10.1007/978-981-13-1316-5_6

Download citation

DOI: https://doi.org/10.1007/978-981-13-1316-5_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-1315-8

Online ISBN: 978-981-13-1316-5

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)