Abstract

Fault diagnosis of power transformer for condition evaluation is being carried out by oil analysis for decades. The most efficient and easy way of condition evaluation of transformer is by evaluating the concentration of gases present in the transformer oil, done using dissolved gas analysis (DGA) over which several techniques are employed to predict the type of fault present in the transformer. Among all the techniques, Duval triangle is the most prominent. However, due to ignorance of the two combustible gases, namely ethane (C2H6) and hydrogen (H2), this technique employs lower accuracy for certain faults type. The paper presents a new DGA interpretation scheme carried out through several case studies using gas ratios and their proportion limit as rules implemented in MATLAB to diagnose the fault. The gases produced during the deterioration of transformer oil and insulation paper have been examined using Duval triangle and the new DGA interpretation scheme, on the DGA samples collected from TIFAC-CORE Laboratory, NIT Hamirpur, and published papers. The result obtained from the new DGA interpretation scheme showed promising results compared to the conventional Duval triangle.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The power transformer is the most valuable equipment in the power generation, transmission, and distribution sector [1]. Nowadays, the demand for electricity in commercial, domestic, industrial, and agricultural sectors is increasing rapidly, the consequence of which is surge in transformer, which increases chances of fault occurrence. So for reliable operation of the transformer, it has become mandatory to continuously monitor and diagnose the insulation condition so that it can detect the incipient fault if any [2,3,4,5,6,7,8]. Dissolved gas analysis (DGA) is the most prominent technique used for detecting the incipient fault occurring in the transformer.

As the temperature in the transformer reaches beyond a particular limit in the presence of oxygen (O2) and moisture, thermal and electrical stresses are introduced degrading the physical, chemical, and electrical properties of oil. This oil degradation is the major cause of transformer failure [9, 10]. Due to these stresses, the carbon chain of oil breaks, thereby introducing hydrocarbon gases in oil as by-products, namely methane (CH4), hydrogen(H2), ethane(C2H6), ethylene(C2H4), acetylene(C2H2), and degradation of insulation paper introduces carbon monoxide(CO) and carbon dioxide (CO2) in oil. These gases introduce further electrical and thermal faults in transformer which are categorized as per IEC 60599 and IEEE C.57.104 standards as shown in Fig. 1. The electrical faults are categorized into partial discharge (PD), discharge of low energy (D1), and discharge of high energy (D2), whereas thermal faults are categorized based on the temperature range as thermal faults of temperature T < 300 °C (T1), 300 < T< 700 °C (T2), and T > 700 °C (T3) [11].

There are several methods for detection of incipient faults in power transformer such as ratio method, key gas method, Duval triangle, artificial intelligence-based methods. [12]. In all these methods, Duval triangle came out to be the most accurate method but the problem with it is, it also does not yield 100% accuracy.

From this point of view, a new technique is required, which can detect faults with better performance than Duval triangle. So a new DGA interpretation scheme has been employed in this paper. The new technique is based on the certain rules programmed in MATLAB which can directly provide the fault present in the transformer. This paper evaluates and compares the results obtained from Duval triangle and the new DGA interpretation scheme.

2 Basic Knowledge

2.1 Graphical Method: Duval Triangle

The Duval triangle fault diagnostic method is a graphical approach first introduced by Michel Duval in 1974 [13]. This method uses a different set of hydrocarbon gases, placed on the three sides of an equilateral triangle representing relative proportion of gases [14]. Till date, a total of seven Duval triangles have been introduced by Duval on the basis of oil used in the equipment. The triangles 1, 2, 3 uses CH4, C2H4, and C2H2 gases, and triangles 4 and 6 use H2, C2H6, and CH4 gases, whereas triangles 5 and 7 uses CH4, C2H6, C2H4 gases [15]. In this paper, we are concerned with triangle 1 of mineral oil to study the type of fault present in the transformer.

The triangle is subdivided into seven zones, each zone signifying a type of fault as mentioned in Fig. 1 with one intermediate fault DT signifying mixture of electrical and thermal fault in the power transformer. The Duval triangle is shown in Fig. 2.

The relative percentage of each gas is given by

where CH4, C2H4, C2H2 concentrations all are in ppm.

Plotting the relative percentage of each gas in the triangle provides only one point in the triangle. The location of point at a particular zone decides the type of fault present in the transformer.

2.2 New DGA Interpretation Technique

The techniques use relative proportion of four combustible gases (%H2, %C2H2, %CH4, %C2H4) out of seven gases present in the oil sample to detect the fault type [16]. For this, certain rules are employed derived from several case studies. Table 1 shows the rules employed in the technique, and Table 2 shows the ratios associated with the rules. The percentage relative proportion of CH4, C2H2, C2H4 is as shown in Eqs. (1)–(3), respectively, and the percentage relative proportion of H2 gas is given by

where H2, C2H6, CO, CO2 concentrations all are in ppm.

The faults in this technique are categorized mainly into five types usually found in transformers in service as partial discharge (PD), discharge of low energy (D1), discharge of high energy (D2), thermal faults of T < 700 °C (T1/T2), and thermal faults of T > 700 °C (T3) [17].

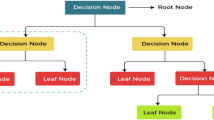

Initially, step 1 is used to detect the PD fault type. If rule 1 is true, the fault is PD. If not, step 2 is employed in which rule 2 is checked for identifying whether fault is electrical fault (D1 or D2) or thermal fault ((T1/T2), T3). If rule 2 is true implies the fault is electrical fault type; further in step 3, rule 3 is checked. If rule 3 is true, the fault is D1 else D2. Also, if rule 2 is false, the fault lies in the thermal fault category; further in step 4, rule 4 is checked. If rule 4 is true, the fault is T3 else T1 or T2. Figure 3 shows the flowchart associated with the technique [16].

Flowchart for fault diagnosis [16]

The fault diagnosis using the proposed technique is carried out by developing and running a MATLAB program based on the rules and the flowchart as shown in Table 1 and Fig. 3, respectively.

3 Results and Discussion

The proposed new technique is compared with the conventional Duval triangle, the most efficient technique till date. A total of 109 DGA samples have been analyzed to predict and compare the percentage accuracy of the two techniques. Out of 109 DGA samples, 29 samples and 10 samples are collected from reference [4] and reference [18], respectively. Remaining 70 samples has been collected from TIFAC-Core Laboratory, NIT Hamirpur.

The 29 DGA samples from reference [4] include several different types of oil-filled electrical equipment such as power transformers with or without on load tap changers, instrument transformer, bushing, reactor, and cable. The other 70 DGA samples are of various oil-filled working transformers currently operating in Himachal Pradesh, India.

For the new technique, a total of 7 DGA samples became a challenging task due to unavailability of one or more gases introducing (0/0) or (a/0) condition. For this, the ratio (0/0) is set to 0 and ratio (a/0) where ‘a’ is not zero is set to 25 in the MATLAB programming.

Table 3 shows some of the DGA samples and the fault obtained by the two techniques. Table 4 shows the number of correct diagnoses, wrong diagnosis, and the percentage accuracy of the two techniques for all the DGA samples collected.

From Table 4, it is clear that the proposed new technique has better performance than the conventional Duval triangle with 88.99% accuracy and the method can be universally accepted as a new technique for fault diagnosis.

4 Conclusion

The new proposed method uses gas ratios and proportion as their main tool to detect the type of fault in the oil-filled transformers. The method is simple and easy to use. Several steps and the rules associated with the method can easily be programmed in MATLAB for fault diagnosis. The method calculates higher accuracy compared to conventional Duval triangle which is considered as the most accurate method till date. The reason for higher accuracy is that the proposed method uses all the seven gases concentration for fault diagnosis whereas the Duval triangle uses only three gases.

References

N.A.B. Muhamad, N. Bashir, A.A.S. Alghamdi, A.A. Suleiman, Asset management through effective transformer diagnostics & condition monitoring, in IEEE International Conference on Power and Energy (PECon) (Kota Kinabalu Sabah, Malaysia, Dec 2012), pp. 212–216

IEEE guide for the interpretation of gases generated in oil-immersed transformers. IEEE std. C57.104-2008 (New York, USA, 2009)

IEC guide to the interpretation of dissolved and free gases analysis-mineral oil-impregnated electrical equipment in service. IEC60599 (Geneva, Switzerland, 1999)

M. Duval, A. de Pablo, Interpretation of gas-in-oil analysis using new IEC publication 60599 and IEC TC10 data bases. IEEE Electr. Insul. Mag. 17(2), 31–41 (March/April 2001)

I.A.R. Gray, A guide to transformer oil analysis. Transformer Chem. Serv. http://www.satcs.co.za

G.K. Irungu, A.O. Akumu, J.L. Munda, Transformer condition assessment using dissolved gas analysis, oil testing and evidential reasoning approach, in Proceedings of 33rd EIC 2015 (Seattle, USA, June 2015), pp. 145–149

Z. Mao, J. Wen, Detection of dissolved gas in oil-insulated electrical apparatus by photoacoustic spectroscopy. IEEE Electr. Insul. Mag. 31(4), 7–14 (2015)

W.H. Tang, Q.H. Wu, Condition monitoring and assessment of power transformers using computational intelligence (Springer-Verlag limited, London, UK, 2011)

M. Wang et al, Review of condition assessment of power transformers in service. IEEE Electr. Insul. Mag. (2002)

P. Gill, Electrical Power Equipment Maintenance and Testing, 2nd ed. (CRC Press, 2009)

G.K. Irungu, A.O. Akumu, J.L. Munda, Fault diagnosticsin oil filled electrical equipment: review of duval triangle and possibility of alternatives, in 2016 Electrical Insulation Conference (EIC) (Montréal, Qc, Canada, 19–22 June 2016), pp. 174–177

D.-E.A. Mansour, Development of a new graphical technique for dissolved gas analysis in power transformers based on the five combustible gases. IEEE Trans. Dielectr. Electr. Insul. 22(5), 2507–2512 (October 2015)

M. Duval, Fault gases formed in oil-filled breathing EHV power transformers—the interpretation of gas analysis data, in IEEE PAS Conference, Paper no C 74 476-8 (1974)

M. Duval, A review of faults detectable by gas-in-oil analysis in transformers. IEEE Electr. Insul. Mag. 18(3), 8–17 (2002)

M. Duval, The duval triangle for load tap changers, non-mineral oils and low temperature faults in transformers. IEEE Electr. InsuI. Mag. 24(6), 22–29 (2008)

X. Li, H. Wu, D. Wu, DGA interpretation scheme derived from case study. IEEE Trans. Power Delivery, 1292–1293

A.-X. Zhao, X.-J. Tang, Z.-H. Zhang, J.-H. Liu, The DGA interpretation method using relative content of characteristic gases and gas-ratio combinations for fault diagnosis of oil-immersed power transformers, in Conference Proceedings of ISEIM 2014, pp.124–127

A. Abu-Siada, S. Islam, A new approach to identify power transformer criticality and asset management decision based on dissolved gas-in-oil analysis. IEEE Trans. Dielectr. Electr. Insul. 19(3), 1007–1012 (June 2012)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gupta, A., Jain, K., Sood, Y.R., Sharma, N.K. (2019). Comparative Study of Duval Triangle with the New DGA Interpretation Scheme. In: Singh, S., Wen, F., Jain, M. (eds) Advances in System Optimization and Control. Lecture Notes in Electrical Engineering, vol 509. Springer, Singapore. https://doi.org/10.1007/978-981-13-0665-5_24

Download citation

DOI: https://doi.org/10.1007/978-981-13-0665-5_24

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-0664-8

Online ISBN: 978-981-13-0665-5

eBook Packages: EngineeringEngineering (R0)