Abstract

In the past, hysteresis loop and yield stress techniques were rarely used for research in biology and medicine. This article introduces the basic requirements, theoretical classification, and examples of hysteresis loop and yield stress investigations in cell research, biology and medicine (human blood system, human ejaculation system, and plant cells). Experiments are all based on very small forces. In summary, this article points out that hysteresis loop and yield stress techniques may be seen as supplemental tools to show structural change, when biomaterials are subject to mechanical shear action as a result of applied shear field forces.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

If there is a force to act on a system, the system will produce a reaction force. The former belongs to the acting force and the latter to the reacting one. Between both of the forces, which possess dependence and hysteresis of each other, there exist distinct differences in values and in the time they emerge. Through the analysis of these data, structural change of a system can be determined, depending on the history of applied and then withdrawn forces on the system. An example is that, if your hand takes a hammer to hit a rock, you will feel a painful shock in your hand, which tells you the rock is very hard; in the contrary, if you take the hammer to hit cotton material, you won’t feel any pain in your hand, which tells you the cotton material is very soft. This example demonstrates that the analysis of acting and reacting forces on a system will tell us information about the materials’ structure and their possible function. This analysis is called the hysteresis loop technique. It is not only used to observe the quantities of acting and reacting forces, but also to obtain information about the following relationships: (1) the time lag between the acting and reacting forces (generally called ‘mechanical hysteresis’), in case a force field is applied and then withdrawn from a system; and (2) the reaction force development curve, when the system is exposed to an increasing force field from zero to a maximum and vice versa back to zero. Results of above-mentioned measurements can be plotted as mechanical hysteresis loop curves of stress versus time. According to the shape of the hysteresis loop curve, structural changes in the system, energy storage or dissipation, and possibly information about the biological function of the system can be obtained. Yield stress is easily determined in a hysteresis loop when the shear rate falls back to zero. The determination of hysteresis and yield stresses involve multi-dimensional digital record keeping and automation of controlling and sampling action forces, reaction forces, temperature, timing, etc. Today’s high speed computer and information technologies are able to fulfill these functions. However, research in medicine and biology requires dealing with biological samples, which usually provide an additional level of difficulty in comparison to traditional engineering disciplines, due to biological samples being on a very small scale and the reaction forces from tested systems are also very small. Thus, biology experts neglect such techniques. This article will be a review of work done with hysteresis loop and shear stress techniques for cell based research.

2 Requirements for Determining Hysteresis Loops

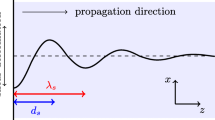

To generate a series of triangular waves of shear rates, including time intervals and the total duration time (Fig. 1), it takes a rheometer, controlled by a servo motor, and suitable computer software. In a tested system, the automation has to generate specified shear rates from zero to a maximum in certain time intervals within a total duration time, and then reverse the shear rates from the maximum back to zero, using the same time intervals and total duration.

During such time courses of applied increasing and decreasing shear rates to a system, the system’s responses in values of shear stress (reaction forces), temperature values, and interval times (in seconds) need to be automatically recorded with real time sampling. Instrumentation used for the experiments described in this article, were a HT Rheometer with an air-bearing design, created by Senior Engineer Jiao S. K., and a commercially available rheometer from USA Brookfield programmable DVII Rheometers.

3 Classification of Hysteresis Loop Types

Results of experimental work in our laboratories showed that hysteresis loops can be divided into 5 classifications as shown in Table 1.

4 Hysteresis Loop Types of Human Whole Blood Samples

Experimental results in our laboratory identified the shape of the hysteresis loop curve found in the human whole blood system to have a shape of the digit “8” type with an intersection point between two loops, therefore being classified as type III (Table 1).

Historically, already in the 1970s, Huang et al. performed experiments to determine whole blood hysteresis loops [1]. However, Huang et al. only found a clockwise loop, but did not identify a counter-clockwise loop in his findings. Huang’s research team established a generalized rheological equation to describe the hysteresis loop curve of human whole blood [1]. In 1986, Chen et al. verified the clockwise loop far away from the origination point, but also uncovered a counter-clockwise loop close to the origination point with an intersection location at 1–2 s−1. According to Chen’s findings, he suggested that Huang’s equation should be modified [2]. In the 1990s, investigations on a series of normal and ischemic stroke patients in our laboratories verified the findings as reported earlier by Chen and his team. In 1998, Fang et al. established a new constitutive equation to describe the “8” shape hysteresis loop in whole human blood [3]. In 2016, Shi W. et al. reported a digital solution using a continuous kinetics equation for non-linear hysteresis loop curves in human blood [4]. This article will further review continuous studies in this field performed in our laboratories.

In our recent experimental studies, 86 human blood samples (cases) were tested, of which 44 were normal subjects (30 males and 14 females) and 42 were ischemic stroke patients after a first stroke attack (25 males and 17 females) [5]. The instrument used in our tests was a HT Rheometer (Shanghai Astronaut Bureau), designed by Senior Engineer Jiao S. K. Experimental results are displayed in Fig. 2. Useful information from the “8” shape hysteresis loops were extracted for explanations in biology and clinical medicine as in the following: (A) The intersection point: It divides the “8” into two loop areas. On the one hand, the loop close to the origination point (zero) is a counter-clockwise loop and reflects that the whole blood system absorbs the energy from the servo motor to form red blood cell (RBC) rouleaux under low shear rate conditions. On the other hand, the loop far away from the origination point (at zero) is a clockwise loop and reflects that the whole blood system dissipates the energy from the servo motor to disperse RBC rouleaux into single RBCs or smaller rouleaux under high shear rate conditions. The intersection point of the “8” shape for normal subjects is located at 1 s−1, resembling the velocity gradient in cm/s/cm (Fig. 2, dotted curve). The intersection point of the ischemic stroke patient group, however, is 1.4 s−1 (Fig. 2, solid line), showing an average increase of 40% in comparison to the normal subject group. (B) The enclosed loop area: The area enclosed by the two curves represents the energy density velocity in erg/cm3/s. On the one hand, the counter-clockwise loop close to the origination or zero point encloses an area of 0.17 erg/cm3/s for the male normal subject group, and 0.39 erg/cm3/s for the male ischemic stroke patient group, revealing an increase of 130%. For the female normal subject group, the enclosed area is 0.09 and 0.19 erg/cm3/s for the female ischemic stroke patient group, revealing an increase of 111%. The above results show that the RBC rouleaux formation in the human whole blood system of ischemic patients is stronger in comparison to normal subjects (>100%). On the other hand, the clockwise loop far away from the origination or zero point encloses an area of 0.15 erg/cm3/s for the male normal subject group and 0.40 erg/cm3/s for the male ischemic stroke patient group, revealing an increase of 167%. For the female normal subject group the enclosed are as 0.15 and 0.28 erg/cm3/s for the female ischemic stroke patient group, revealing an increase of 87%.

The results show that the RBC rouleaux formation in the whole blood system of ischemic patients requires more energy to be dispersed into single RBC or smaller rouleaux than those of normal subjects. (C) The yield stress values: When the shear rate decreases from a maximum back to zero, the yield stress values can be identified by the interval point of the vertical axis with the downward loop curve. The yield stress values from both patient groups, either male or female, are higher than those from both normal groups, respectively. The above results can be interpreted that the ischemic stroke patients require a higher energy level in order to maintain their blood in a well-flowing state.

In some individual cases, the above mentioned parameter can be found to be several times higher than the normal group’s measurements. In such cases, the patients should be treated urgently, since either an ischemic stroke has already taken place, or will happen with very high probability as a serious indication of the onset of an (micro-) vascular disease. In addition, if longitudinal comparisons of blood hysteresis loops continuously increase to a higher level with a trend to the left area in the coordinate system, this change may indicate the need of the blood circulatory system to dissipate in vivo a substantial higher amount of energy than normal subjects. The quantity of the necessary energy can be divided into two parts: one part serves the blood to stay in a liquid state, and the other part serves to overcome the forces of inner friction to keep the blood flowing. Differences in whole blood hysteresis loop morphology between males and females can be explained by females in reproductive age having a 10% lower hematocrit value than males of the same age group. This leads to localizations of hysteresis curves slightly lower in the coordinate system in females. However, the differences between males and females are not considered significant after females’ loss of productive ability at a higher age, or no difference in whole blood hysteresis loop morphology can be seen in comparison to the male counter group. Additional detailed information about blood yield stress methodologies and its applications in medicine, especially in geriatrics, can be found in other publications from our laboratories [6, 7], but would go beyond the scope of this article.

5 Hysteresis Loop Type of Human Sperm

In recent reports, it had been discussed that the quality of human semen is declining [8]. The reasons for this development may be connected to two factors: changes in cellular development and environmental influences. Changes in cellular development of the human ejaculate may include biochemical, biophysical, and cytological in vivo conditions during the course of maturation and transportation of spermatozoa and seminal plasma. Examples of such conditions that influence the quality of human semen are sperm density and distribution, protein modification and rearrangement of the sperm surface, changes in the sperm surface charges, scavenging of reactive oxygen species, levels of hepatocyte growth factors, zinc, and other molecules, and the functional processing of fertility in epididymis. The mentioned biochemical factors may lead to abnormal gene expression and/or altered gene regulation. Environmental factors, such as different levels of electromagnetic radiation due to geographical regions and latitudes, seasonal changes, occupational risk factors, and other conditions may also lead to changes in the quality of the human ejaculation system.

The quality of human semen is routinely assessed by the ejaculate volume, sperm density, and observations of sperm morphology and motility. The sperm motility test is a very popular parameter used in the diagnosis of medical infertility conditions. From a bio-mechanical perspective, sperm motility should be determined on spermatozoa themselves, using the seminal plasma as medium. The bulk fluidity of human semen should also be considered. Some other reports mentioned ejaculate viscosity. However, viscosity values are inconstant and depending on the extent of the thinning process and the time passed since ejaculation. Preliminary thinning of the ejaculate takes about 5–10 min after ejaculation and the completion to total ejaculate thinning may take up to 20–40 min. The viscosity of the thinning semen can be estimated by the length (2–3 cm) of the spinning filaments, using a syringe or a glass rod, and the semen thinning time can be recorded using a simple timer on a viscometer filled with 0.5 ml of thinning semen. The accuracy of these methods, used in clinics, seems to be not very satisfactory or standardized. Therefore, it is necessary to study the relationship of fluid behavior and ejaculation time, in order to describe sperm motility more accurately and to characterize the mechanical properties of semen. This article is focused on the characteristics of yield stress and hysteresis loops for human semen during liquefaction, based on the results from experiments in our laboratories [8].

Immediately after ejaculation ejaculates were transferred into the test cup of the Brook Field Programmable DV-II Rheometer to determine the hysteresis loops and yield stresses on fresh human ejaculates. Data were measured every minute for a time period of 20 min [8]. Results suggested the following conclusions: (A) Yield stress values dropped from more than 3000 mPa to 60 mPa in about 5 min after ejaculation; (B) The shape of hysteresis loops of shear stress versus shear rates changed from a counter-clockwise loop, enclosing a large area, to a loop, enclosing a very small area after about 4–5 min. This can be interpreted that the ejaculated semen initially exhibited a semi-solid or viscoelastic body behavior in the first 5 min after ejaculation, and thereafter changed into a thinning fluid with very low viscosity.

Figure 3 shows 20 hysteresis loop curves, each obtained in 1-min intervals at 1–20 min time points after ejaculation. The first curve, obtained 1 min after ejaculation (series 1), shows a marching direction to become a counter-clockwise loop and to enclose a very large area, which cannot fully be displayed in Fig. 3 due to limits of the testing range of the instrument used. The rheometer’s maximum value is 3000 mPa, however, the estimated intersection point with the vertical axis or the yield stress value is over 5000 mPa. The second hysteresis curve, obtained 2 min after ejaculation, also shows a large enclosed area (1389 erg/cm3/s) and indicates the yield stress value being at 1900 mPa. The third minute curve continues to show a counter-clockwise directional loop with an enclosed area of 411.8 erg/cm3/s and a yield stress value of 900 mPa. The fourth minute curve shows an enclosed area of 36.75 erg/cm3/s and a yield stress value of 200 mPa. In the fifth minute hysteresis curve, the enclosed area has decreased to 8.5 erg/cm3/s and the yield stress value dropped to 60 mPa. This trend continued in all curves obtained between the 6th and the 20th minute. At above sixth minute hysteresis curves appear crowded and overlapping (Fig. 3). Integral calculations showed that the enclosed areas in the hysteresis loops of the 6th to the 20th minute ranges from 60 erg/cm3/s to near zero, and the yield stress ranges from 60 to 30 mPa.

Hysteresis loops of a human ejaculate: a hysteresis curve was obtained every minute for a 20 min time period. The measurement times are indicated in the figure. After the 5th minute, the hysteresis loops are overlapping, indicating that the human ejaculate changed from a viscoelastic body to a liquid state about 5 min past ejaculation [8]

Functional human ejaculation is expected to have a yield stress of more than 5000 mPa and is considered a specialized semi-solid or viscoelastic body. The stress value of a healthy human ejaculate is expected to be about 40,000 Pa. Before ejaculation, spermatozoa are stored and protected in the epididymal fluid in the epididymis. The semen ejaculated is composed of spermatozoa and seminal plasma. The latter includes secretions from the epididymis, ductus deferens, ampulla, seminal vesicles, and the prostate gland, among others. Seminal plasma is a chemical mixture, and from a physio-mechanical perspective to a complex viscoelastic body. In the epididymal fluid the sperm is quiescent, receiving nutrition during maturation, but with limited motility. At the event of ejaculation, motility is initiated for capacitation. Shortly after ejaculation, the semen changes its physical properties from semi-solid or viscoelastic into a thinning fluid, loosing its high yield stress and its viscoelastic counter-clockwise hysteresis loop. After ejaculation this change is necessary for the sperm, in order to secure active motility and to penetrate the cervical mucus to reach the ovum for fertilization. From a bio-mechanical point of view, the parameter of the semen changes after ejaculation can be precisely established, such as standardized yield stress and enclosed area values of a counter-clockwise hysteresis loop. These standardized parameters reflect the semen thinning course from viscoelastic to semi-solid over a specified time period and can serve as a more precise, medical semen quality test in the future. Furthermore, according to above shown experimental results, human semen’s yield stresses drop down from a high value of 5000 mPa to a low value of about 60–30 mPa in about 4.45 min. At the same time the counter-clockwise hysteresis loop is lost, indicating that the ejaculate has changed from a viscoelastic or semi-solid state into a fluid state. Since these two events take place at a natural coincidental time line, a logical explanation could be a possible configuration change of effected molecules of the semen. A model of this transformation may be incorporating a change of the tri-dimensional network structure of seminal plasma before its liquefaction into dissociation into mono-molecules after its liquefaction. This model is matching the findings of our experiments, relating a tri-dimensional structure with high yield stresses and counter-clockwise hysteresis loops, and mono-molecules in a liquid revealing very low yield stresses and loss of the counter-clockwise hysteresis loop [8].

6 Hysteresis Loop Comparison of Plant and Animal Cells

Already in a very popular children’s book series in China, named the ‘100 thousand WHYs’, the question of how a leave of a plant of Mimosa pudica can move is addressed. However, the children’s book uses an explanation for plant movement based on increasing turgor pressure provided by osmosis on the pulvinus of the leave in comparison to a decreasing turgor pressure on the other side of the leave. Can this be applied to the movement of the plant Mimosa pudica L. as a reaction to very small forces applied to the petioles of the leaves? Taking a closer look at the mechanism why Mimosa pudica L. will move by a small force appears not that simple and is not clear.

On the other hand, in lectures for medical students in the Department of Biophysics, Shanghai Medical College, Fudan University, where the author was an instructor from 1960–1998, the movement of the plant Mimosa pudica L. leaves was used to explain the term ‘thixotropy’. Adding the example of how Mimosa pudica moves it leaves as a reaction to a very small force initiated by touch and slowly recovers its original shape after the force of touch is removed, helped the students to understand the process of thixotropy more clearly. Biomaterials, such as the Mimosa pudica leaves, can change their flow properties when they are exposed to a force action, and can recover their original state when the force is withdrawn. This phenomenon is called thixotropy.

Following the question about how the plant Mimosa pudica L. can move its leaves in reaction to a very small force, our laboratories used hysteresis loops to possibly shed light on the underlying mechanisms. Following the idea from the children’s book ‘100 thousand WHYs’, petioles and leaves of the Mimosa pudica L. plant were used to make a homogenous suspension in water. Hysteresis loops on the plant suspensions were tested and recorded using the rheological instrument and computer software from BROOKFIELD ENGINEERING LABORATORIES, INC, USA [9]. The shear rates were adjusted to triangular waves of 0-1-0, 0-2-0, 0-4-0, 0-6-0, and 0-10-0 s−1. Figure 4 shows the results of triangular wave measurements of the first experiment, using 0-1-0 s−1. Follow-up experiments with above listed triangular wave ranges are not displayed in this article, since they were revealing similar results as established in the first experiment (see [9] for more details). Figure 4 shows the comparison of experimental results from three homogenate suspension samples of (a) plant Mimosa pudica, (b) pig skeleton muscles, and (c) another plant called Thyllanthus urinaria, which has nearly the same shape as Mimosa pudica, but lacks the movement ability. As visible in Fig. 4a, only the suspension from the Mimosa pudica plant revealed a significant counter-clockwise hysteresis loop and a certain yield stress value. The other two suspension samples (Fig. 4b, c) do not show such loops or yield stress values. These results indicate that only in the Mimosa pudica homogenate suspension, protein or cytoskeletal substances may be present that can change their structural state from granules into networks, from disorder into order, and from fluidity into viscoelasticity, when exposed to a very small shear stress field. The related protein or cytoskeletal substances had to have the ability to re-form their structures, while suspended in the Mimosa pudica solution. Such remolding behavior involves the generation of a certain energy level, in order to be able to couple molecules forming a structural change. Therefore, such changes would need energy in the suspension itself. In the contrary, the other two suspension samples (B- from pig skeleton muscles and C- from the plant Thyllanthus urinaria) do not exhibit such significant phenomena.

Figure 5 exhibits the results of experiments with varying yield stress values in the Mimosa pudica L. suspension only. The system reveals that applied triangular waves of increasing shear rates (horizontal axis) linearly increases the wave’s peaks of shear rates (vertical axis). Figure 6 shows the comparison between the 3 suspension systems of Mimosa pudica, pig skeleton muscle, and the plant Thyllanthus urinaria under an applied shear rate triangular wave of 0-1-0 s−1. As discussed before, only the Mimosa pudica suspension system (first column) shows a significant yield stress value.

Comparison of the yield stress values among 3 suspension systems of (1) Mimosa pudica, (2) Pig skeleton muscle, and (3) Thyllanthus urinaria plant. Suspensions are prepared in the same concentration of 15% fresh tissue precipitation. Triangular shear rate waves of 0-1-0 s−1 were applied to all three systems. Only the Mimosa pudica suspension shows a significant yield stress value

7 Summary

Hysteresis loop and yield stress techniques belong to the supplemental tools to show structural change, when biomaterials are exposed to a shear rate field and react with a mechanical shear action. Information gained from hysteresis loop analysis about the molecular and structural changes in biological systems can be coupled with measurement from molecular biology and biochemistry methods, in order to enhance techniques like isolation, purification, crystallization, and X-ray diffraction of proteins and cytoskeletons.

References

Huang, C. R., & Fabisiak, W. (1978). A rheological equation characterizing both time dependent and the steady state viscosity of whole human blood. AIChE Symposium Series, 74(182), 19–21.

Chen S. Q., & Liang Z. J. (1986). The study of Hysteresis loop of whole human blood and Huang’s equation characterizating thixotropy of blood system. In W. F. Chen L. W. Yuan & Y. Z. Xu (Eds.), Advances in rheology (pp. 492–499). Beijing, China: Academic Press. (in Chinese).

Fang, B., & Jiang, T. Q. (1998). A novel constitutive equation for viscoelastic-thixotropic fluids and its application in characterization of blood hysteresis loop. Chinese Journal of Chemical Engineering, 6(3), 264–270. (in Chinese).

Shi, W., Jiao, S. K., Yang, J. W., Le, Z. Q., & Shi, Y. D. (2016). Digital solution of continuous kinetics for blood non-linear hysteresis loop curves. Chinese Journal of Hemorheology, 26(4), 389–396. (in Chinese).

Shi Y. D. (1990). Thixotropy, viscoelasticity and hysteresis in blood system. In Y. D. Shi (Ed.), Horizons in hemorheology, Part I (pp. 67–81). Shanghai: Shanghai Scientific and Technological Literature Publishing House.

Shi, Y. D. (2013). Yield stress of blood. Chinese Journal of Hemorheology, 23(2), 199–202. (in Chinese).

Shi, Y. D. (2016). Blood yield stress and aging. Chinese Journal of Hemorheology, 26(2), 135–142. (in Chinese).

Shi, Y. D., Pan, L. F., Yang, F. K., & Wang, S. Q. (2004). A preliminary study on the rheological properties of human ejaculate and changes during liquefaction. Asian Journal of Andrology, 6(4), 299–304.

Shi, Y. D., Pan, L. F., Yang, F. K., & Artmann, G. M. (2003). Stress-shear hysteresis loops of homogenate suspension from leaves and petioles of Mimosa pudica. Journal of Plant Physiology and Molecular Biology, 29(4), 275–280. (in Chinese).

Acknowledgements

We thank Prof. Zhi-jiu Qin, Prof. Zhen-sheng Tang, and Prof. Chuan-zhen Lv for their co-investigation on the research grant entitled “Studies on hemorheology of cerebral vascular diseases”, received from the Central Health Ministry in 1990. For work on the instrument, we thank Senior Engineer Prof. Shu-kui Jiao, who designed the HT Rheometer for us to test the samples. The instrument belongs to the Shanghai 9th Hospital, administrated by Prof. Jing-wen Yang and Prof. Zhong-qing Le, who both helped us to execute the measurements. Blood samples were obtained of patients of the emergency Departments of the Huashan and Zhongshan Hospitals.

We thank Dr. Luan-feng Pan (Fudan University), Dr. Fei-kun Yang, and Dr. Si-qi Wang.

Last not least we thank Dr. Luan-feng Pan (Fudan University), and Dr. Fei-kun Yang for their cooperation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Shi, Yd. (2018). Histeresis Loops and Yield Stress in Cell Research. In: Artmann, G., Artmann, A., Zhubanova, A., Digel, I. (eds) Biological, Physical and Technical Basics of Cell Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-7904-7_6

Download citation

DOI: https://doi.org/10.1007/978-981-10-7904-7_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-7903-0

Online ISBN: 978-981-10-7904-7

eBook Packages: EngineeringEngineering (R0)